Evaluation method of anti-slide performance of rigid connection structure of simulated micropile

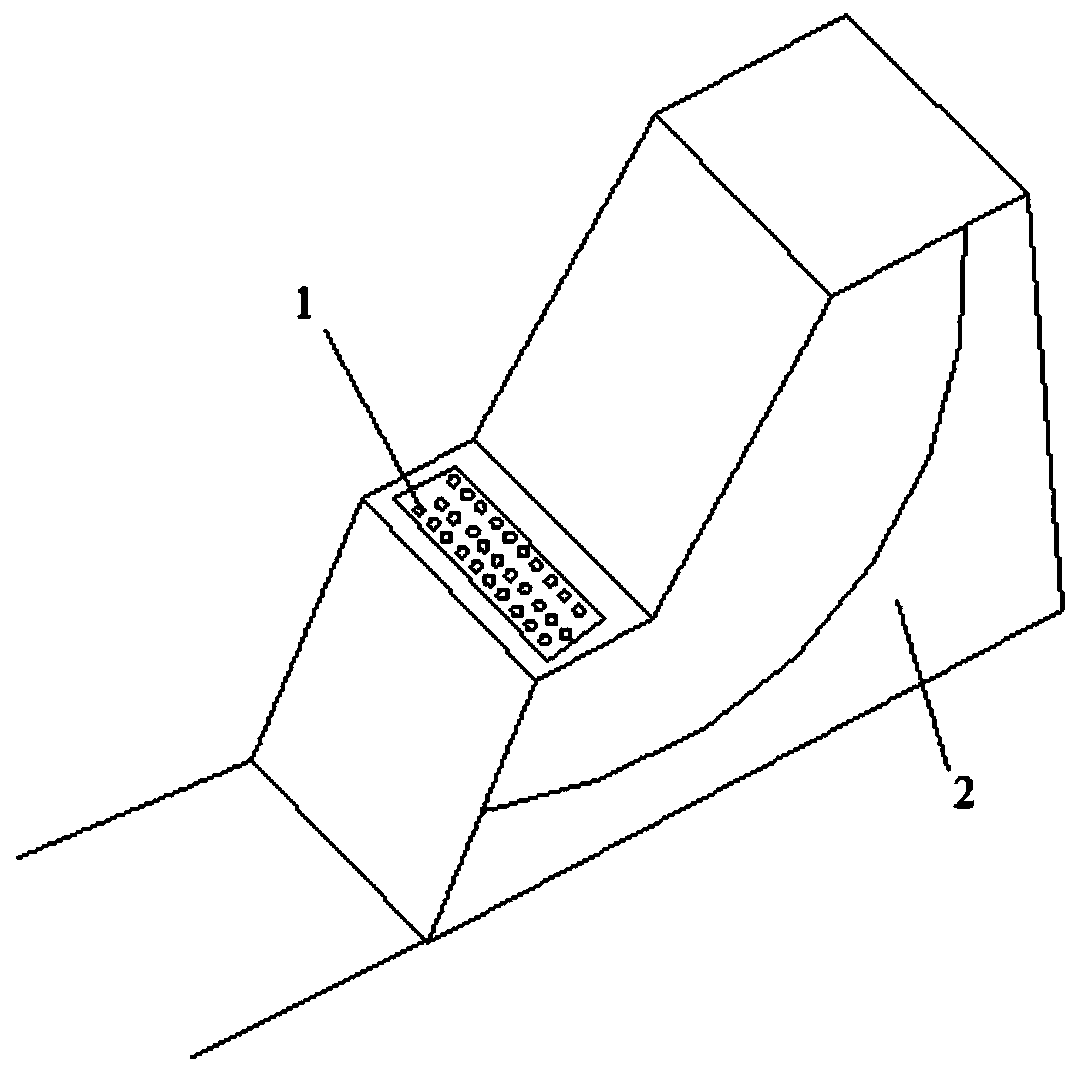

A technology of rigid connection and anti-skid performance, applied in the field of landslide prevention and control, to achieve the effect of increasing the utilization area, fast construction speed and small construction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

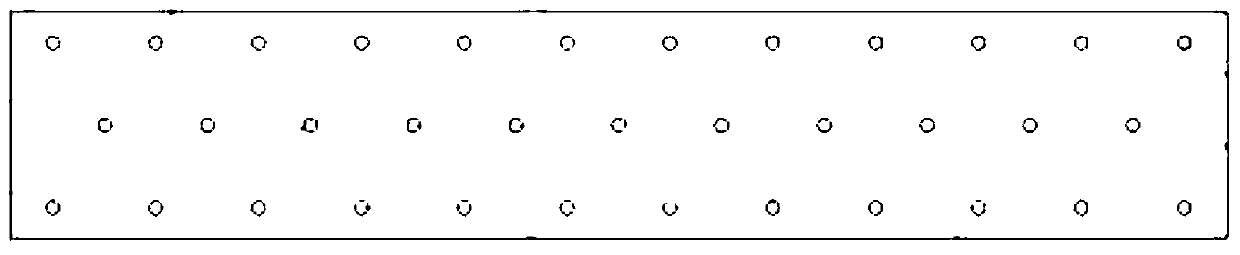

Embodiment 1

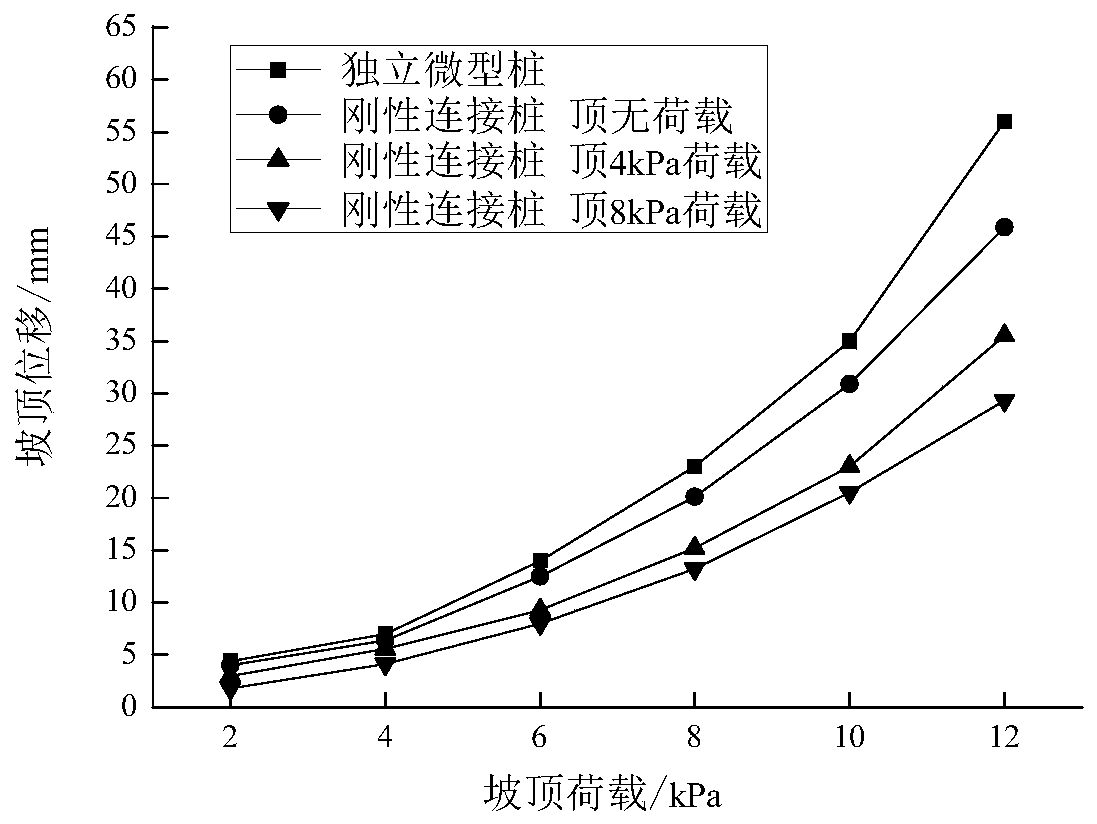

[0050] The present invention has carried out simulation test to the anti-sliding ability of the present invention by arranging contrast test, and contrast test is the micro-pile pile group that the gap between each micro-pile does not have concrete filling, promptly the micro-pile pile group of independent arrangement, also to the present invention in addition After the 4kPa load and 8kPa load are applied to the top, the displacement, pile body strain and landslide thrust produced by the micro-pile are monitored, and the monitoring data is used to analyze the force status of the pile top against the landslide thrust of the micro-pile under different loads. By adding loading equipment on the structure of the present invention, sticking strain gauges on the pile body, placing an earth pressure cell in the soil body, and arranging displacement gauges at the top of the landslide, at the top of the micro-pile and at the foot of the slope, the earth pressure cell, the strain gauge Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com