Construction Method of Vertical Laying and Bricking of Blast Furnace Cooling Wall

A construction method and stave cooling technology, which can be applied to cooling devices and other directions, can solve problems such as increasing construction costs, and achieve the effects of saving cranes, being easy to use, and having fewer construction tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

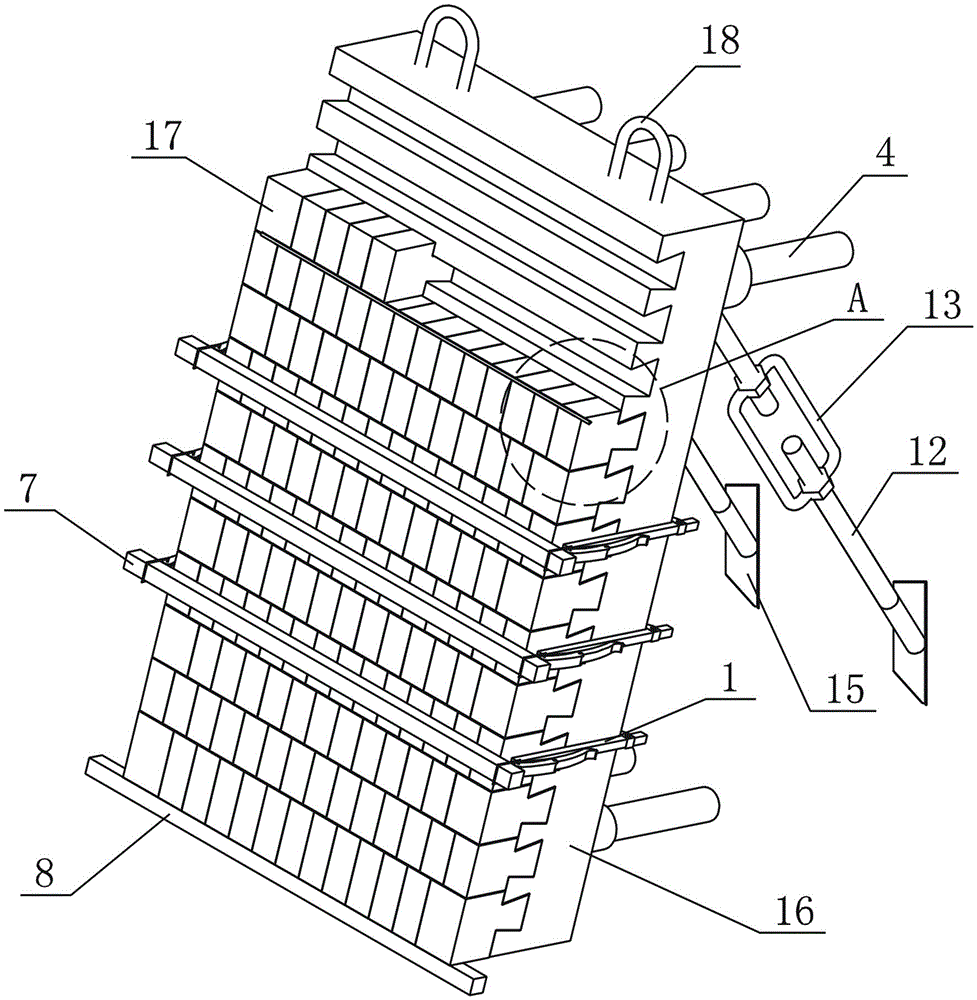

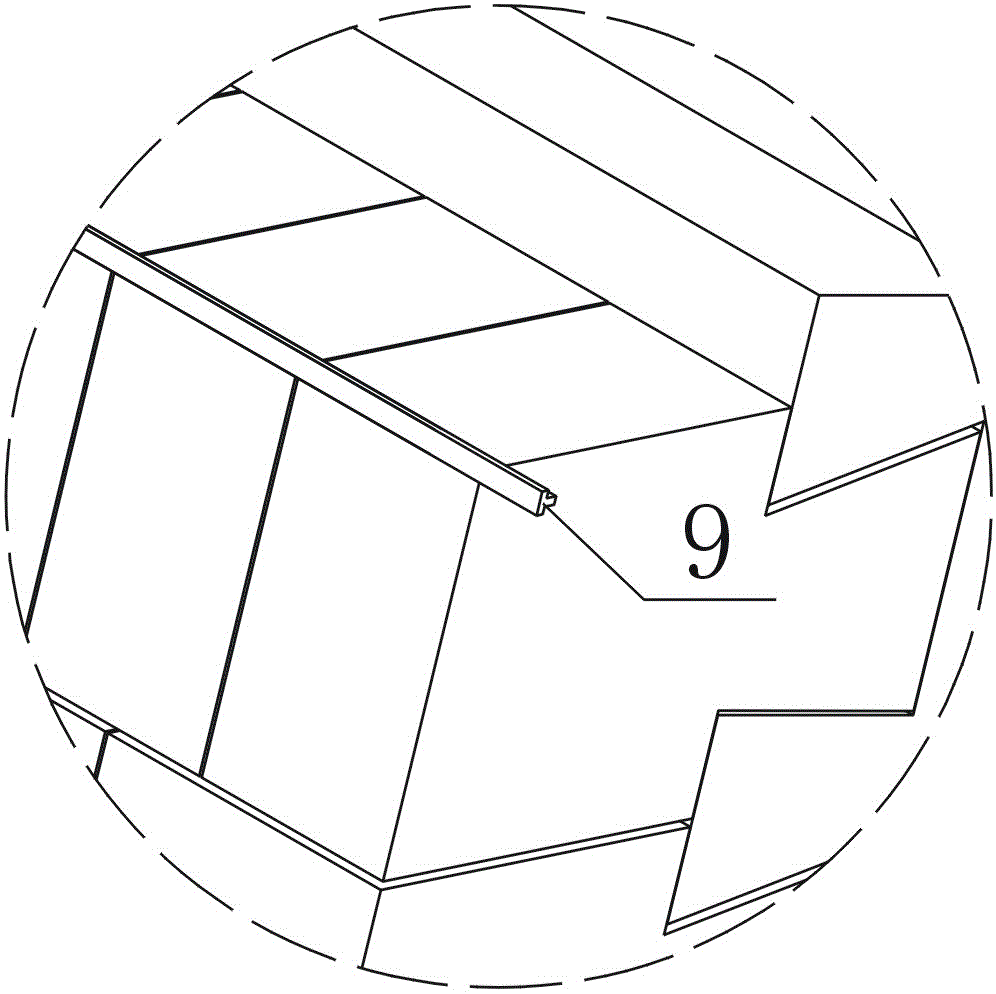

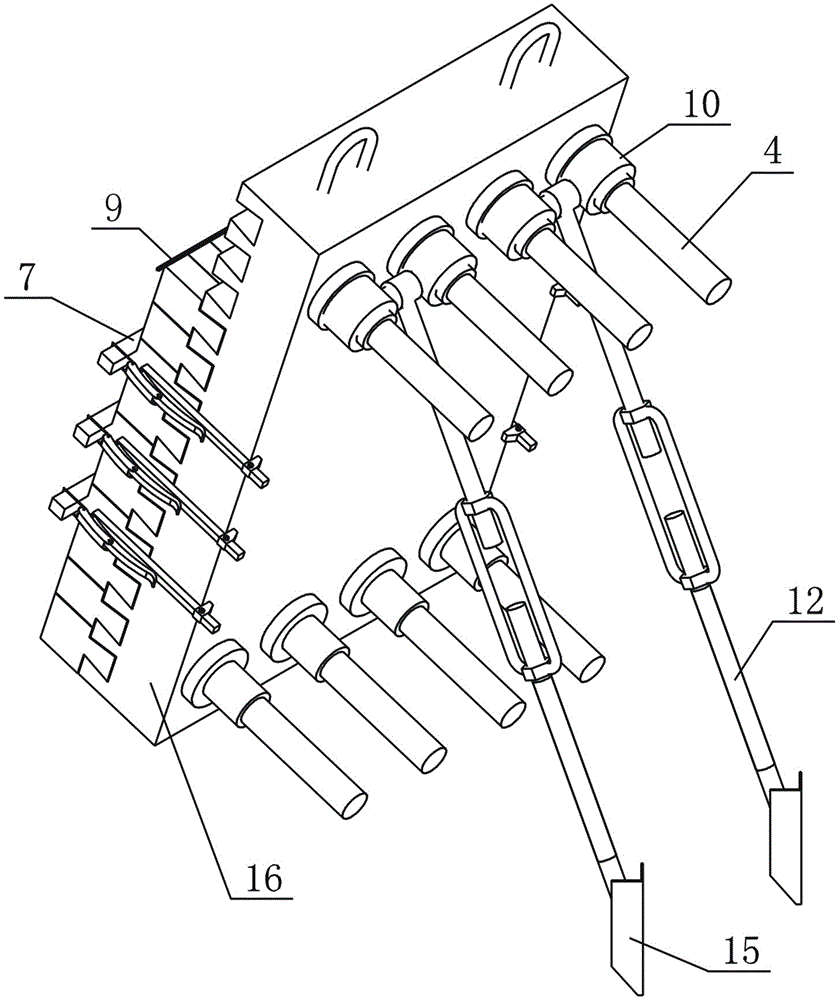

[0032] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0033] A construction method for vertically laying and inlaying bricks on a cooling wall of a blast furnace, comprising the following steps:

[0034] Step 1: After leaving the factory, the stave water-cooled pipes are transported to the construction site after the pressure test. The construction site is within the working radius of the large-scale crane for blast furnace shell installation (the construction site is flat and firm, and it can achieve the vertical placement of the stave 16 without collapsing) ;

[0035] Step 2: Turn the stave 16 over on site and place it upright (with the lifting lug 18 facing upwards), and use the anti-tilt support frame to support and fix the stave 16 (the stave 16 is placed in a centralized manner according to the principle of placing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com