Liquefied foundation treatment method based on building garbage

A technology of construction waste and liquefied foundation, which is applied in the direction of construction, foundation structure test, soil protection, etc. It can solve the problems of insignificant soil squeezing effect and easy collapse of pile holes, achieve obvious reinforcement effect, reduce mud discharge, avoid The effect of complex construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention are described below to facilitate those skilled in the art to understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments. For those of ordinary skill in the art, as long as various changes Such changes are obvious within the spirit and scope of the present invention as defined and determined by the appended claims, and all inventions and creations utilizing the inventive concept are within the scope of protection.

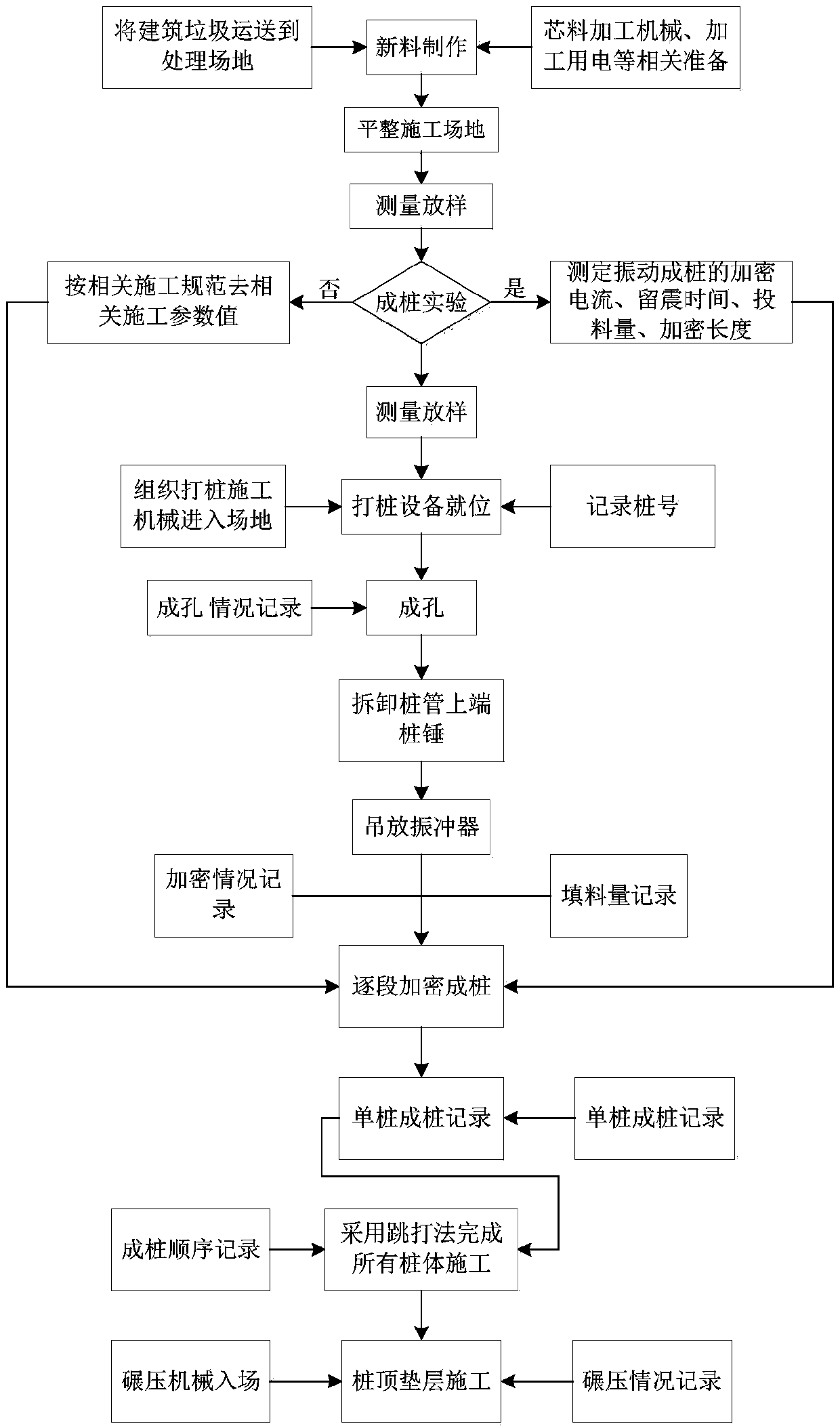

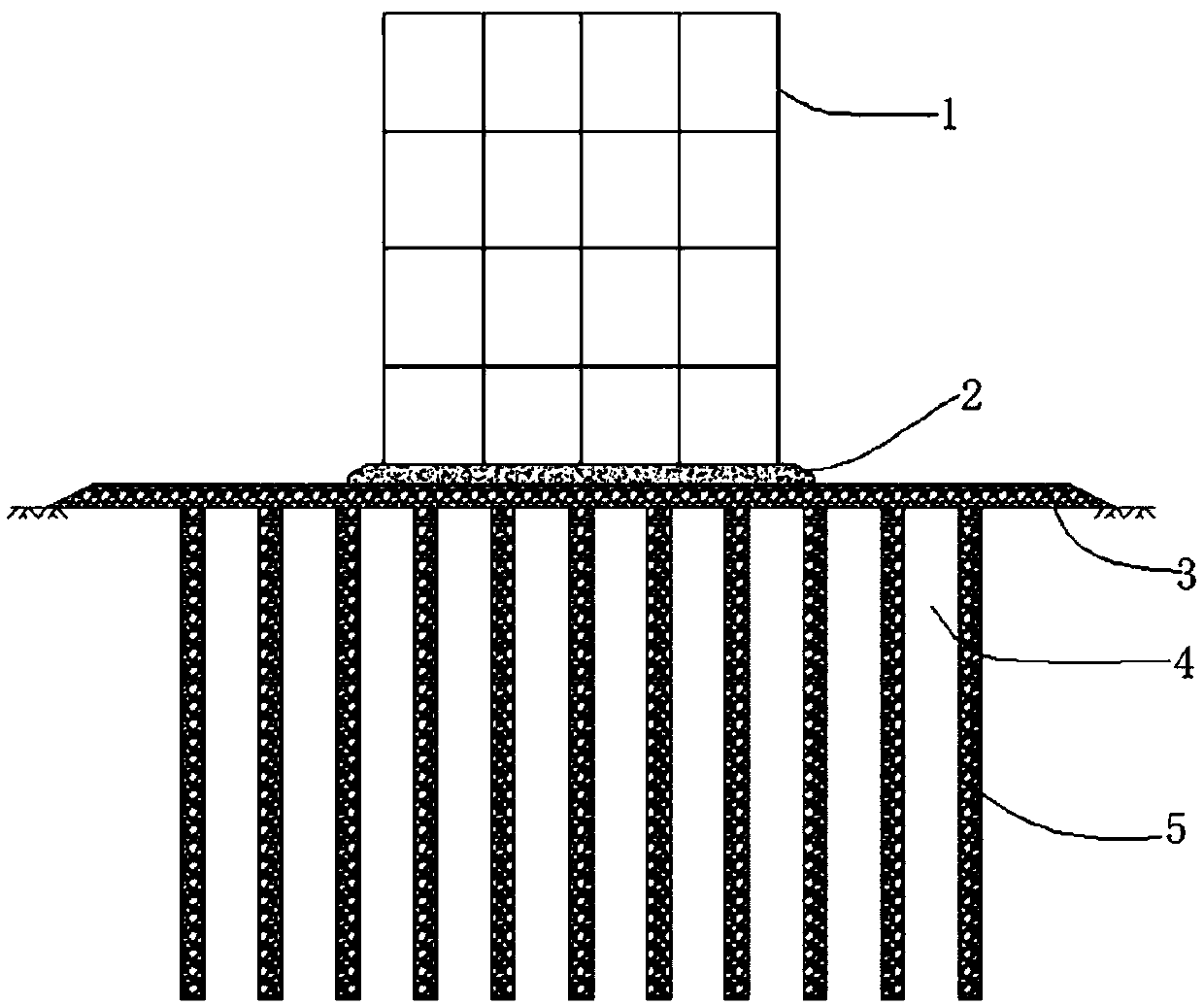

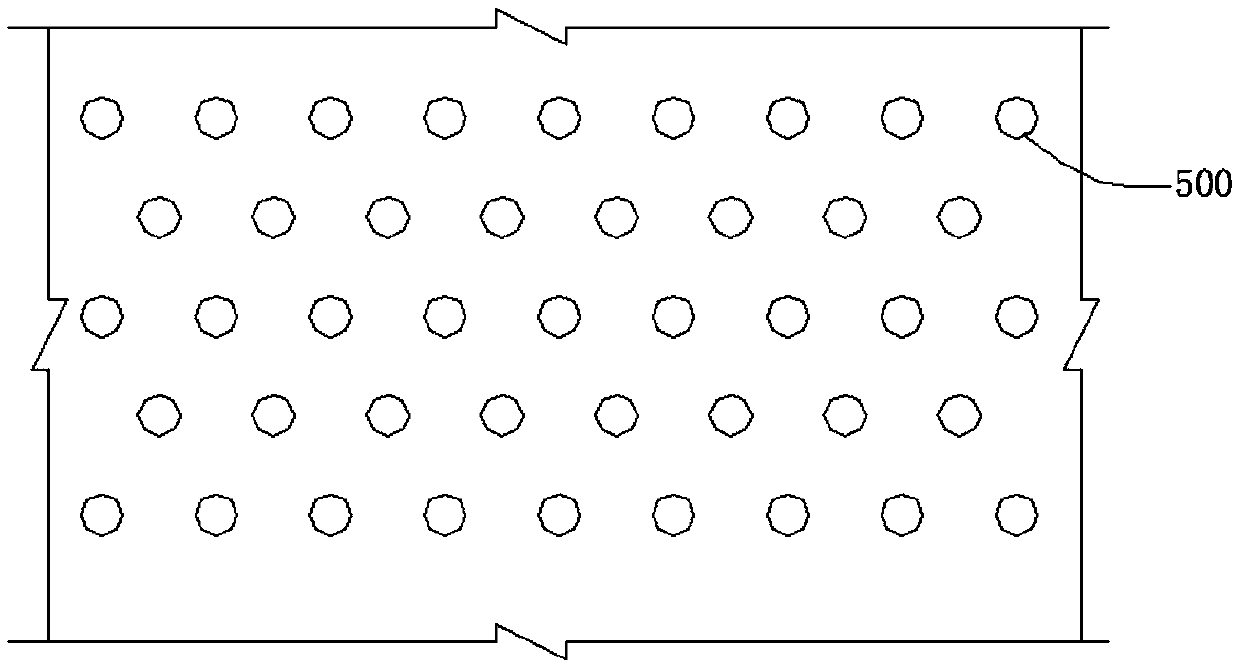

[0034] According to one embodiment of the present application, reference is made to Figure 1-Figure 7 , the construction waste-based liquefaction foundation treatment method of this scheme includes:

[0035] S1. Remove the white garbage in the construction waste, crush the construction waste and transport it to the construction site;

[0036]The specific methods include: transporting construction waste generated from demolition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com