Three-barrel self-elevating gantry type wind power generator foundation structure and construction method thereof

A wind power foundation and gantry-type technology, which is applied in infrastructure engineering, construction, etc., can solve the problems of difficulty in construction and optimization of economic benefits, and can not meet the needs of engineering, so as to achieve fast construction speed, less construction equipment, and smooth construction process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

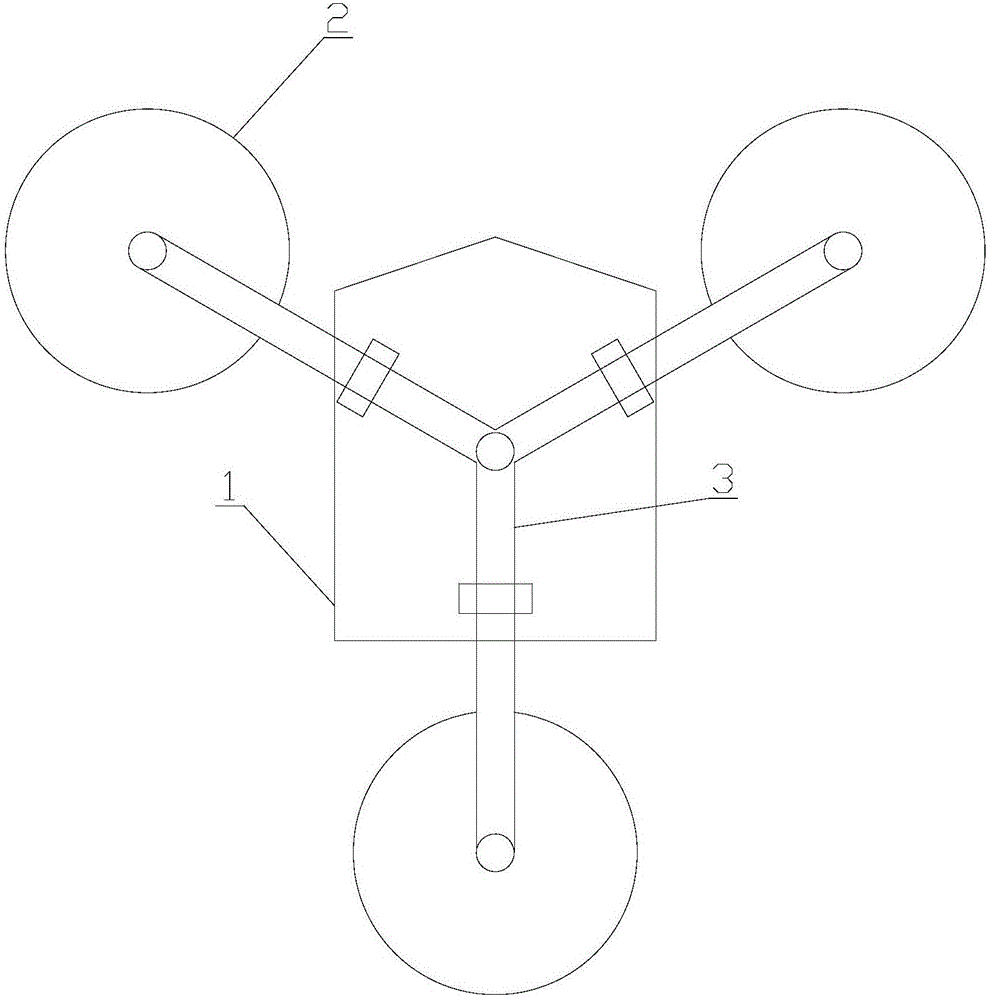

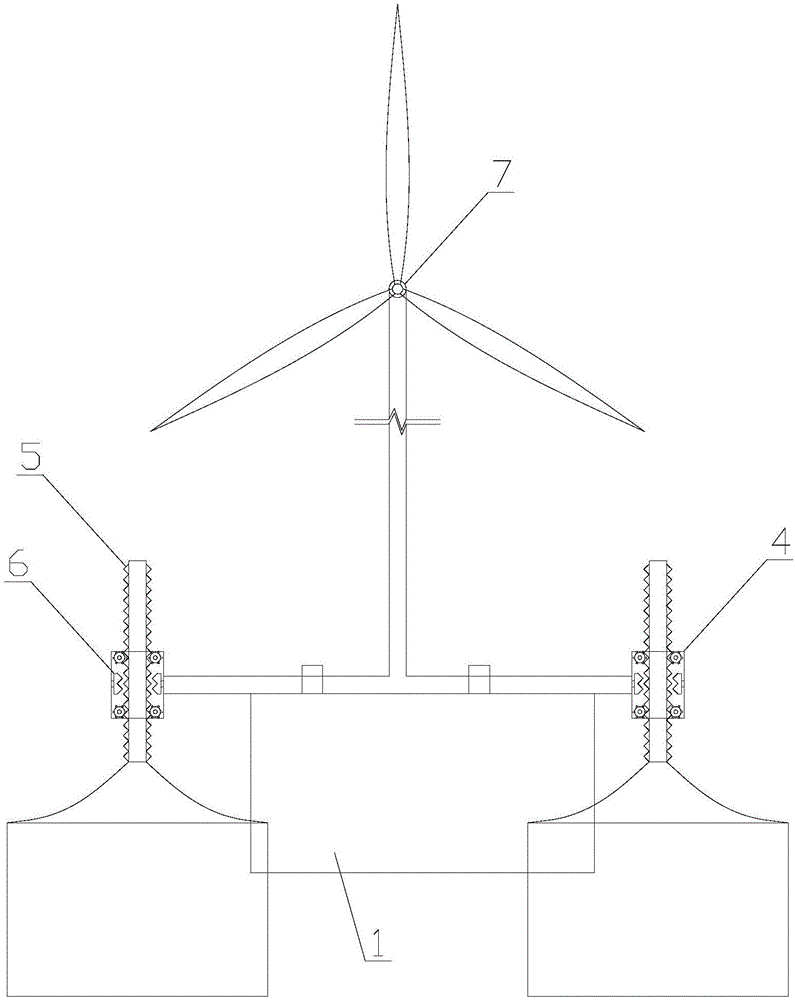

[0024] like figure 1 and figure 2 As shown, this embodiment discloses a three-tube self-elevating gantry type wind power foundation structure, which includes three identical cylindrical foundations 2, a group of portal towers 3, gears 4, racks 5, and locking devices 6.

[0025] The cylindrical foundation 2 is a cylindrical steel structure foundation with a closed top and an open bottom. Three identical cylindrical foundations 2 are arranged at the three vertices of a triangle, and the gap between every two cylindrical foundations 2 The distance can be set according to the actual project, and each cylindrical foundation 2 is provided with an independent negative pressure and loading device. Dividing panels can be arranged inside the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com