Device for realizing operation of mobile tower crane on structural floor and construction method

A mobile tower crane and operating device technology, applied in the directions of transportation and packaging, load hanging components, rail systems, etc., can solve the problems of restrictions on the popularization and use of mobile tower cranes, and achieve reduced construction cost requirements, high safety performance, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

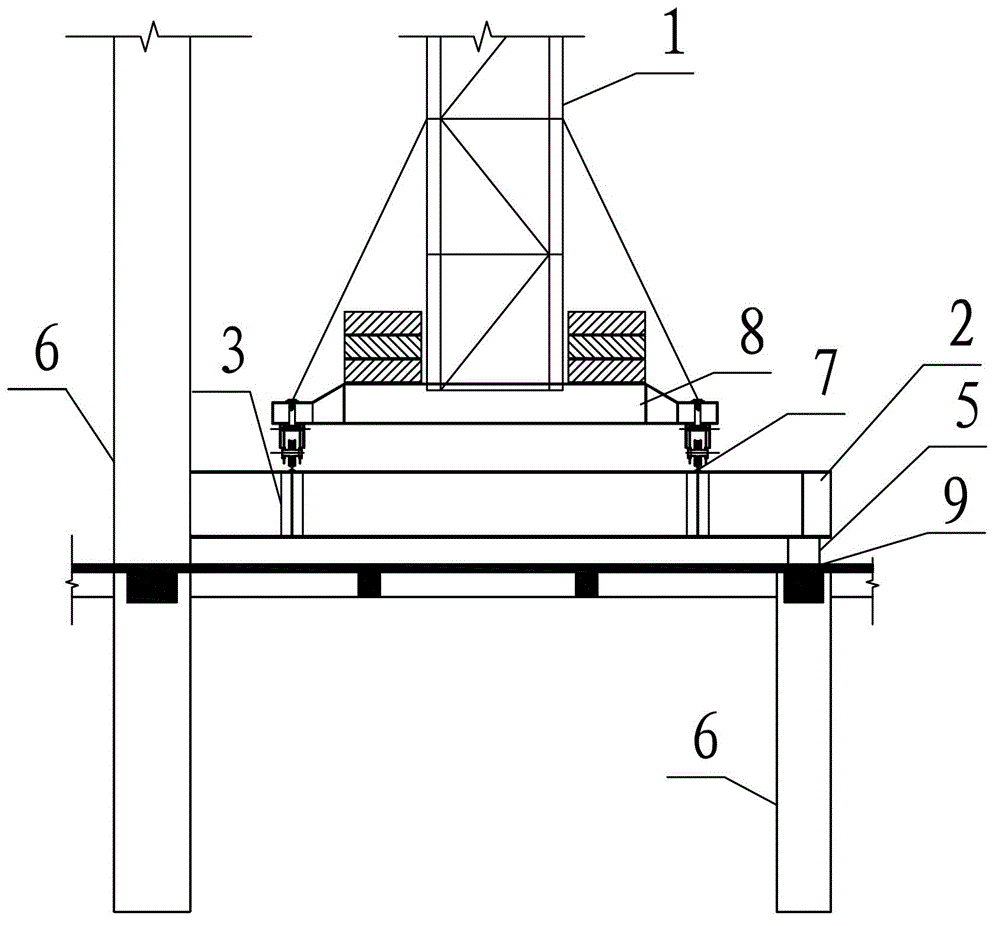

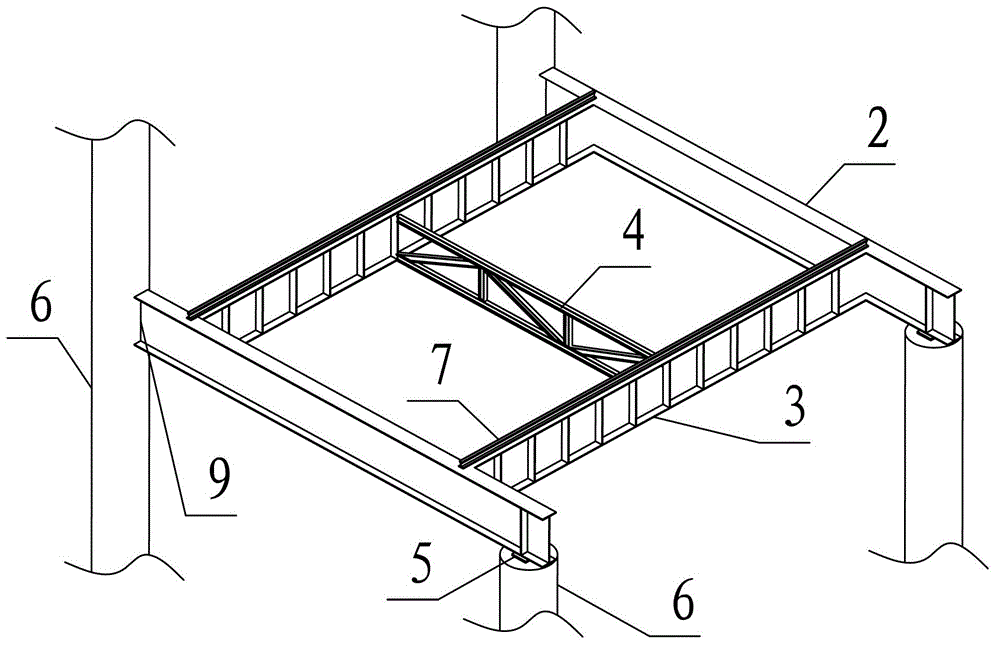

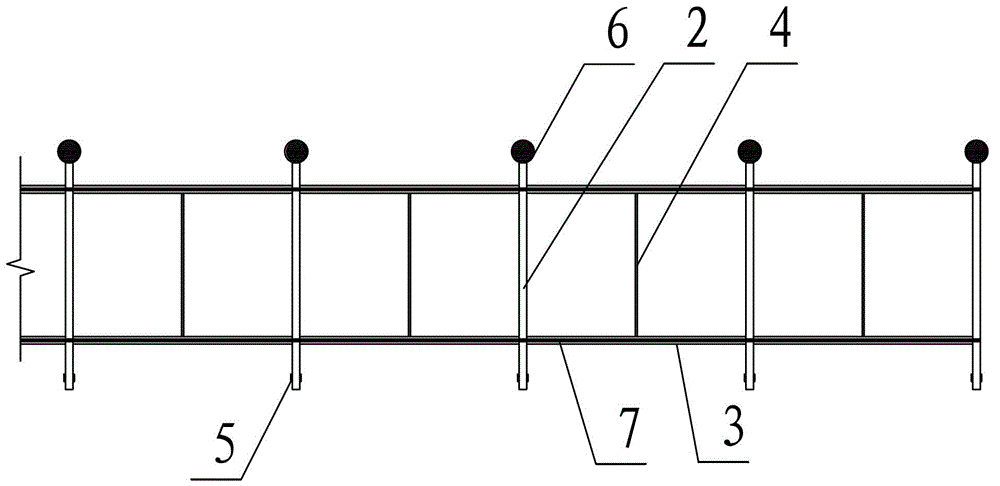

[0033] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

[0034] The main function of the present invention is to realize the safe operation and construction of the mobile tower crane 1 on the floor.

[0035] Take an airport terminal building project as an example. The terminal building is 110 meters wide and 330 meters long. The cover is a long-span steel truss structure. This project is a typical project where the lower single-story area is large, and the roof adopts a large-span steel structure to realize a large building space. If a conventional construction plan is adopted, large crawler cranes or mobile tower cranes are used on the ground on both sides of the structure for construction. As a result, the lifting radius is large, and due to the heavy weight of the truss, the performance requirements for the crane will be very high, resulting in extremely high construction costs. Therefor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com