Electrical control device for crawler-type counter weight trolley and control method thereof

An electrical control device, counterweight trolley technology, applied in cranes, transportation and packaging, load hanging components, etc., to achieve the effect of increasing automation strength, avoiding asynchronous problems, and being convenient to move.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

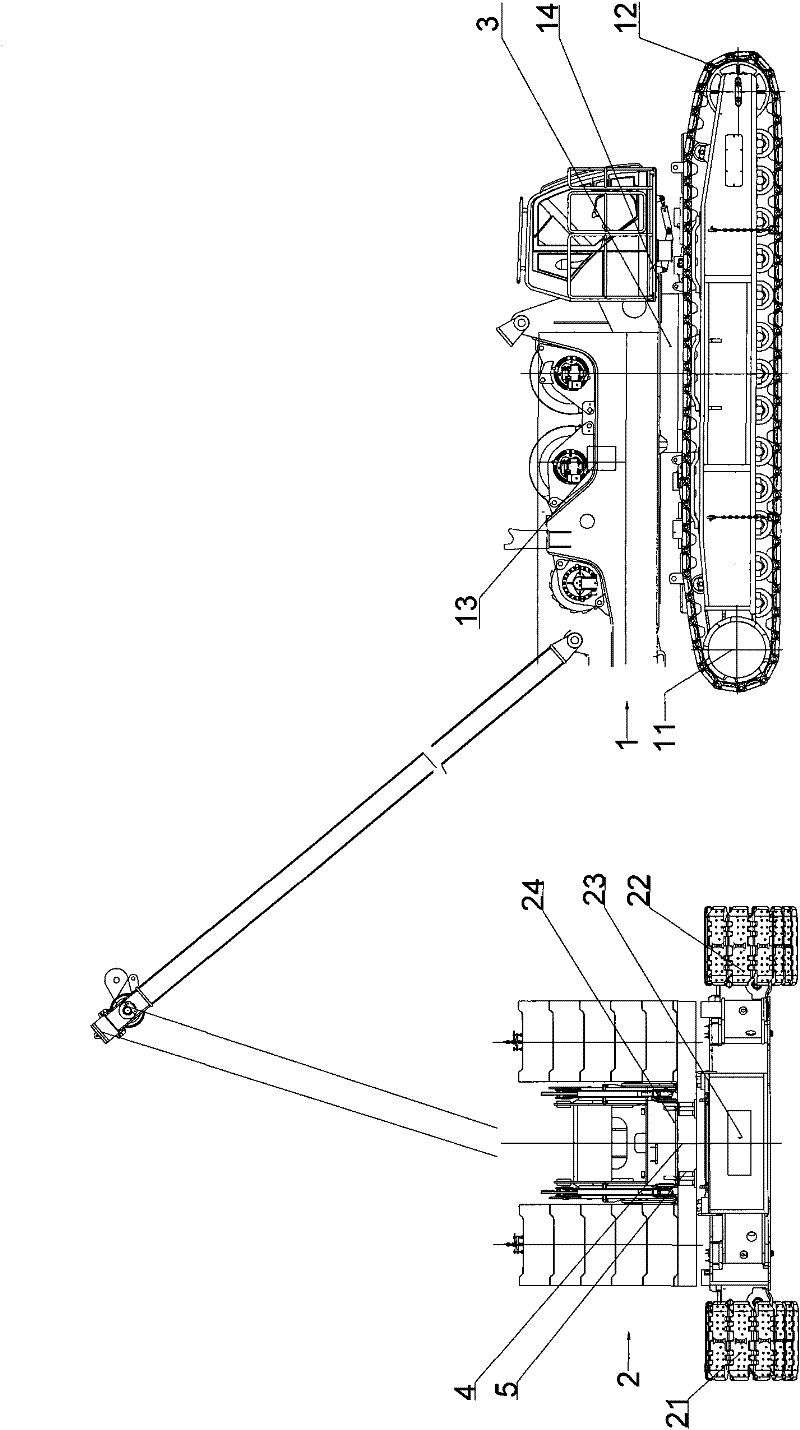

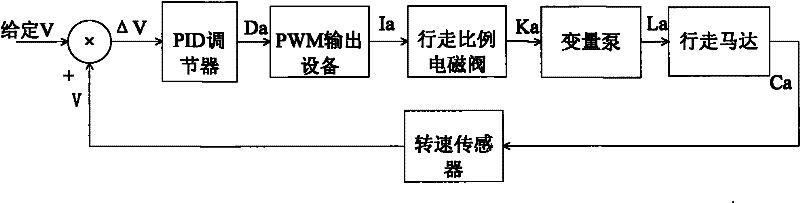

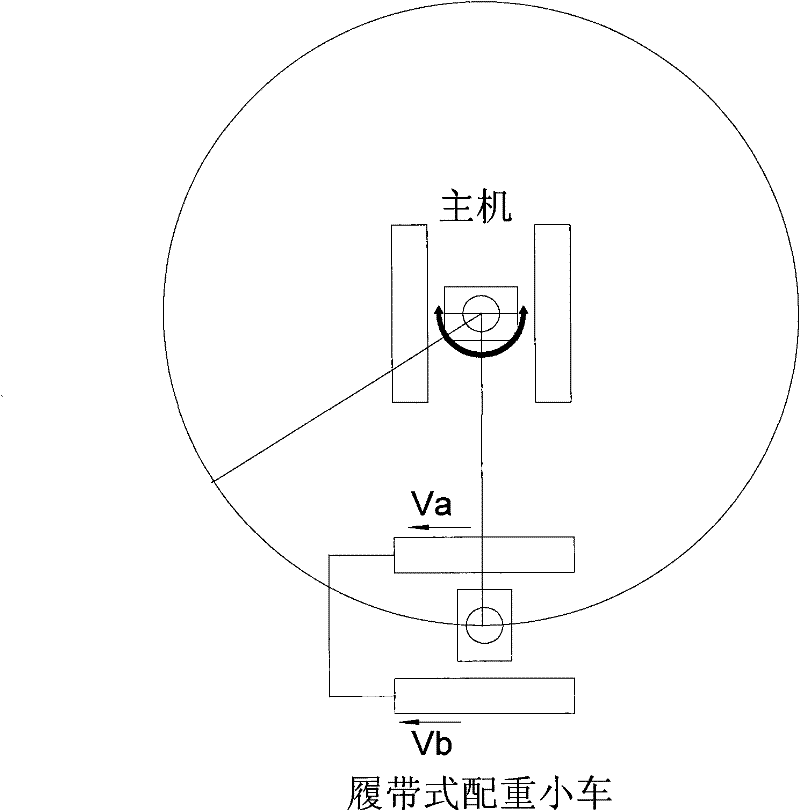

[0063] See figure 1 As shown, an electrical control device for a crawler-type counterweight trolley includes a main engine control part 1 arranged on the crane main engine and a counterweight trolley control part 2 arranged on the crane counterweight trolley; the main engine control part 1 includes the right crawler belt of the main engine Travel motor speed sensor 11, main engine left crawler walking motor speed sensor 12, main engine controller 13 and main engine rotation angle displacement sensor 14; counterweight trolley control part 2 includes counterweight trolley right crawler walking motor speed sensor 21, counterweight trolley left crawler The travel motor speed sensor 22, the counterweight trolley controller 23 and the counterweight trolley rotation angle displacement sensor 24; the host controller 13 and the counterweight trolley controller 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com