Crane, and method and device for controlling super-lifting derricking oil cylinder thereof

A technology of luffing oil cylinder and control device, which is used in cranes, transportation and packaging, fluid pressure actuating devices, etc., can solve problems such as the reduction of the lifting capacity of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

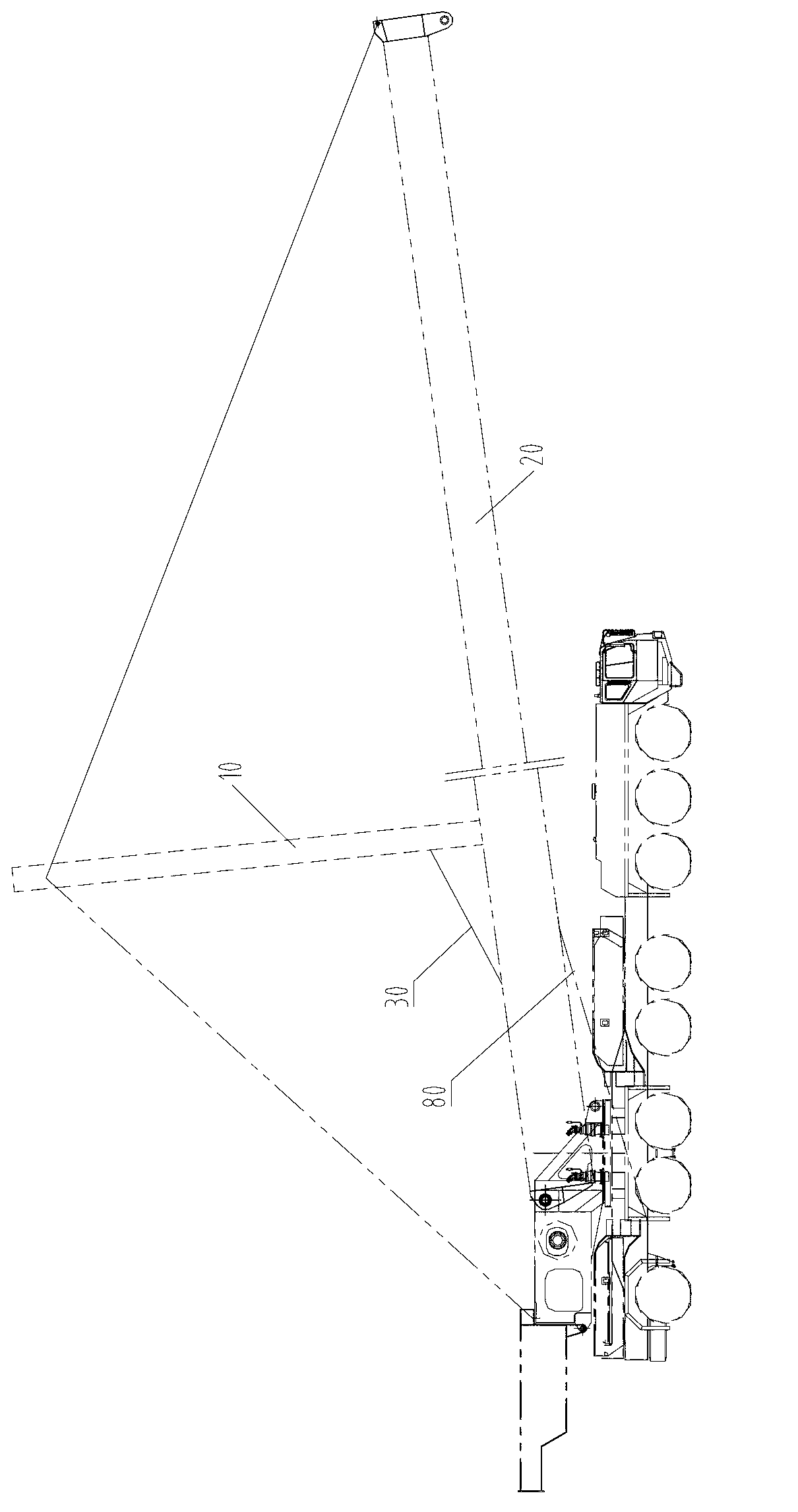

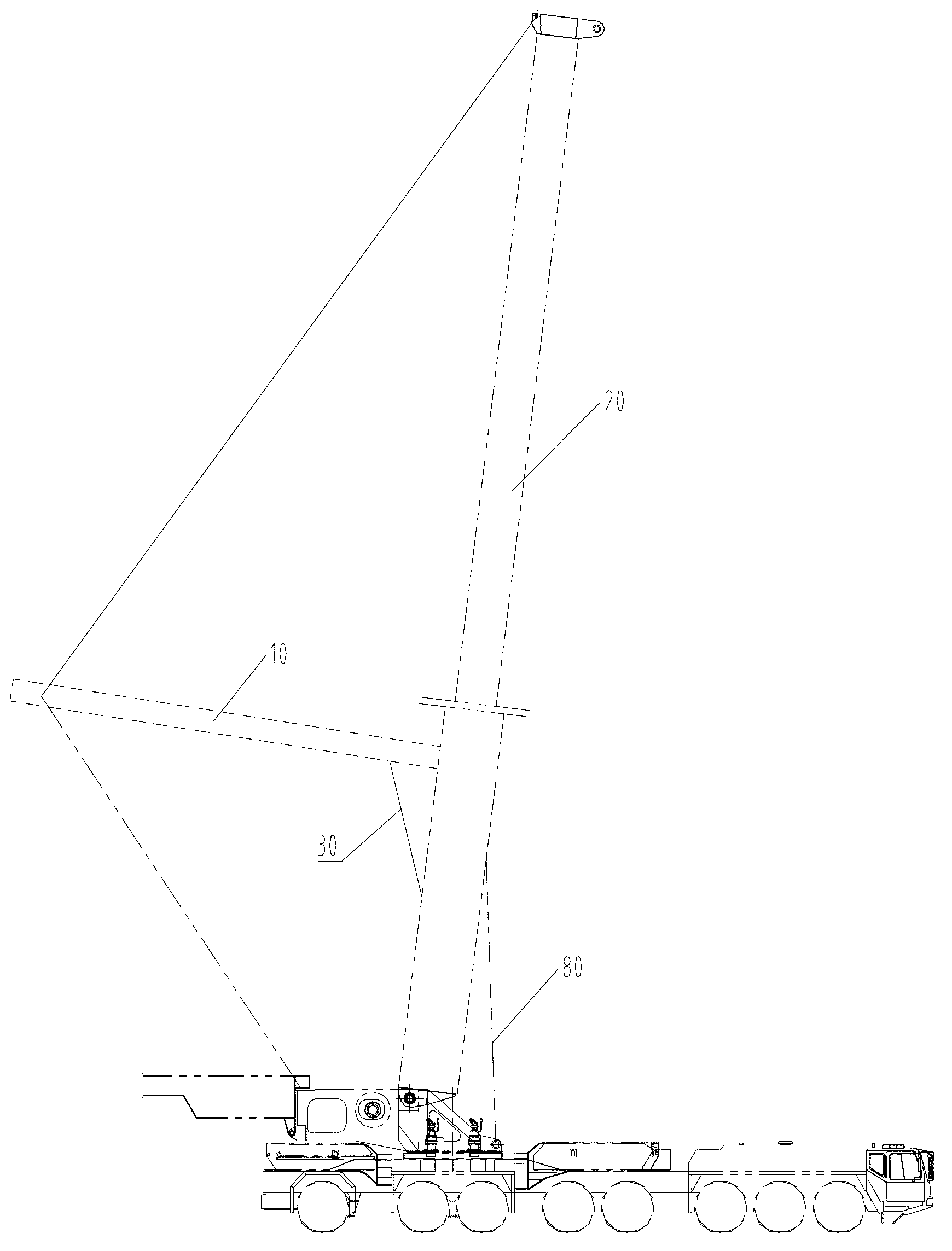

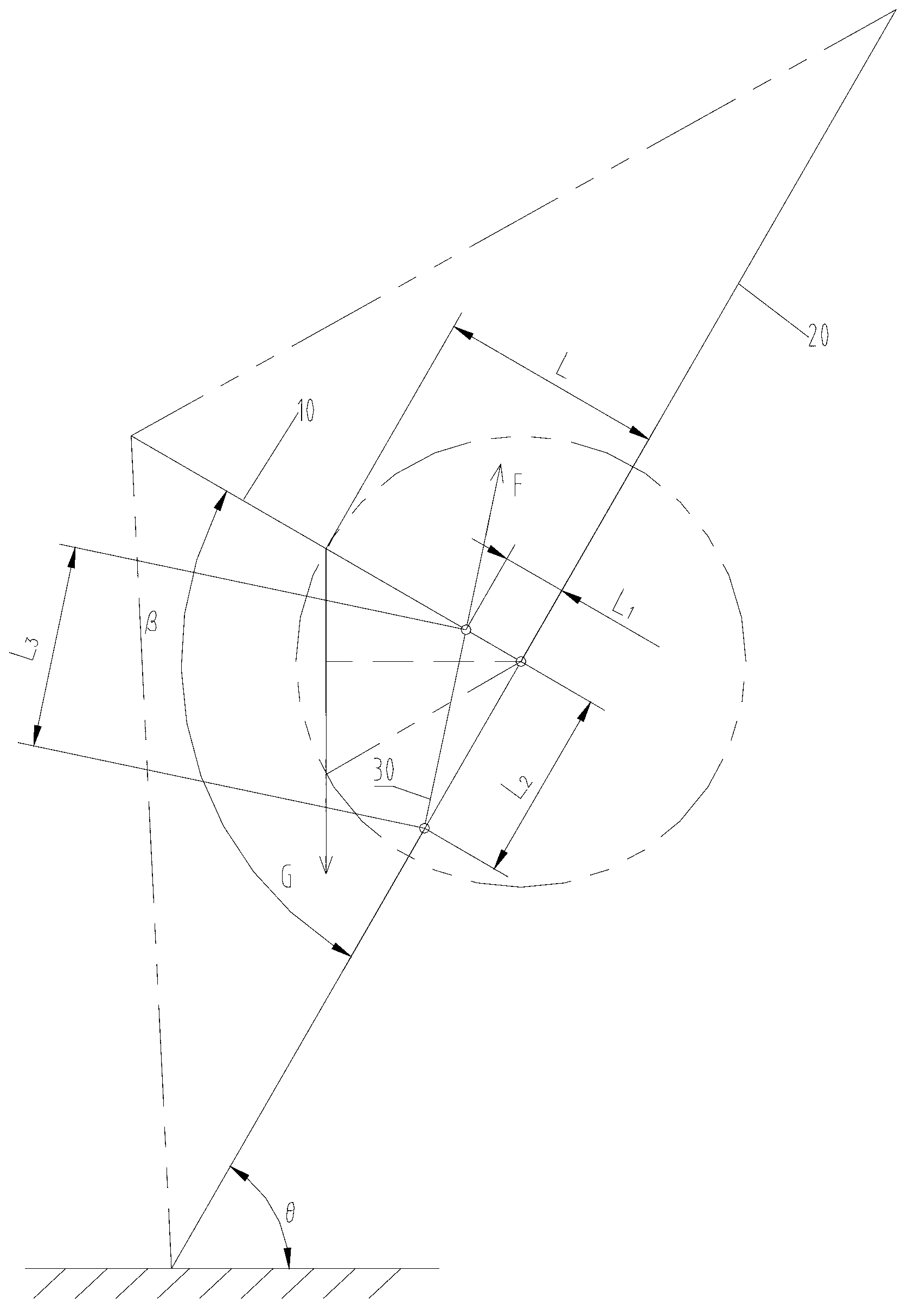

[0039] As a first aspect of the present invention, a method for controlling a superlift luffing cylinder is provided. Please refer to Figure 1 to Figure 3, the control method specifically includes: obtaining in real time the first included angle between the superlift mast 10 and the boom 20 of the crane, and the second included angle between the boom 20 and the horizontal plane; calculating when the boom 20 is in the second clipped angle angle and when the super-lifting luffing cylinder 30 is at the first included angle, the real-time oil pressure needed to overcome the self-weight of the super-lifting mast 10; according to the real-time oil pressure, the safe working pressure (or maximum Working pressure) until the amplitude of the super-lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com