Automatic fire extinguishing device with leakage stopping structure

A technology of automatic fire extinguishing and fire extinguishing agent, which is applied in the fields of automatic fire extinguishing devices, fire prevention, suppression or extinguishing equipment, can solve the problems affecting the effect, and achieve the effect of simple structure, simple and convenient assembly, and strong safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with each accompanying drawing.

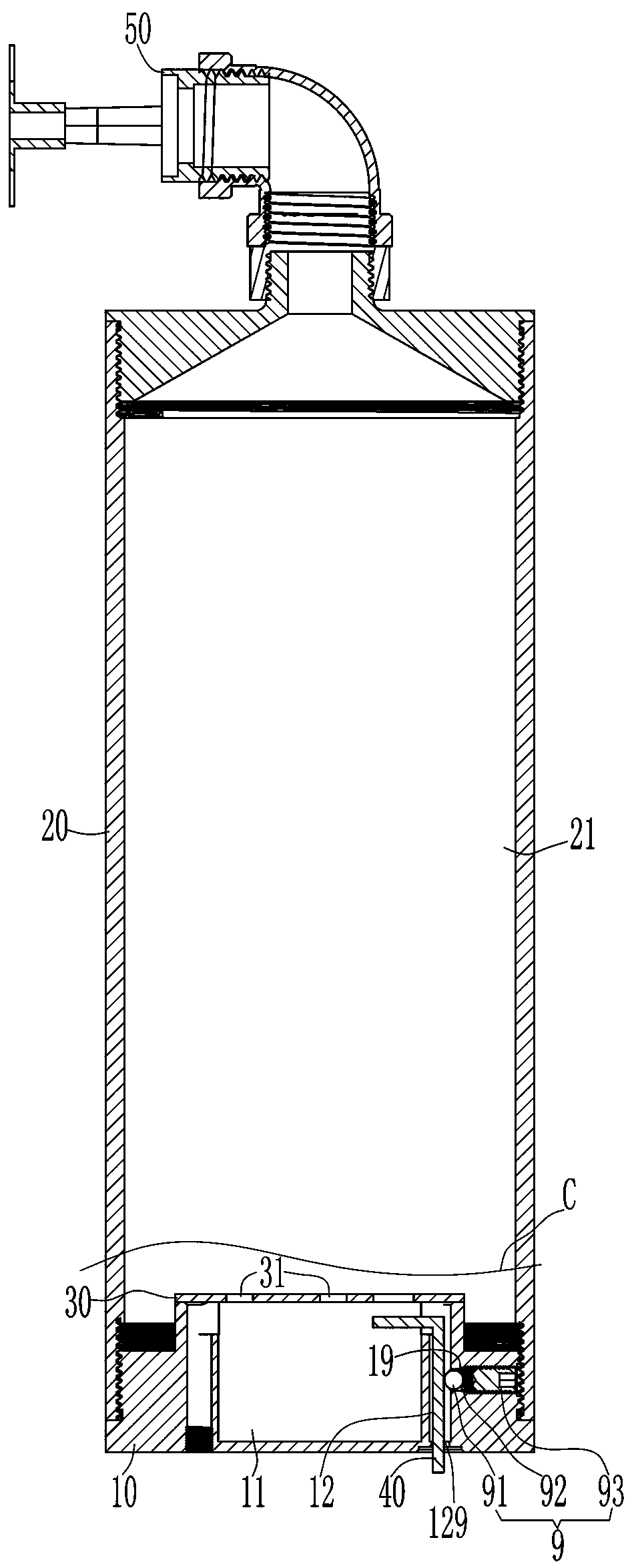

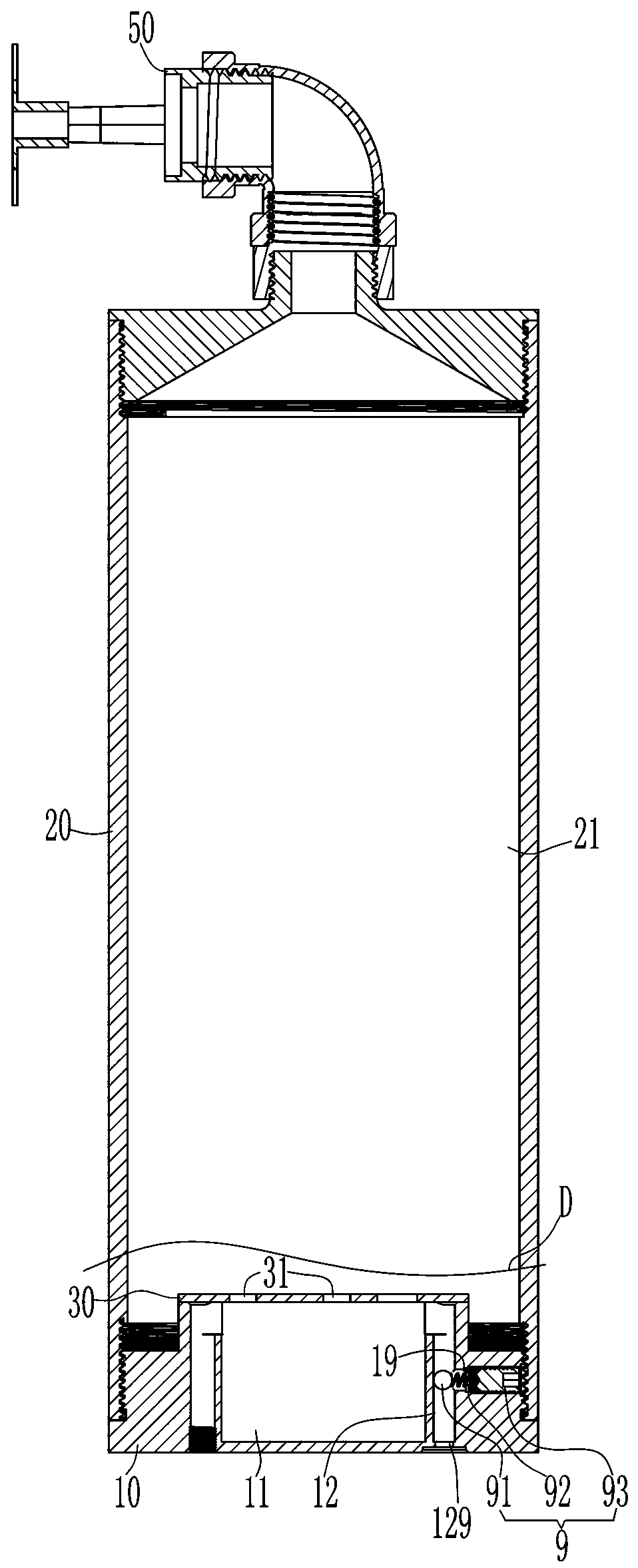

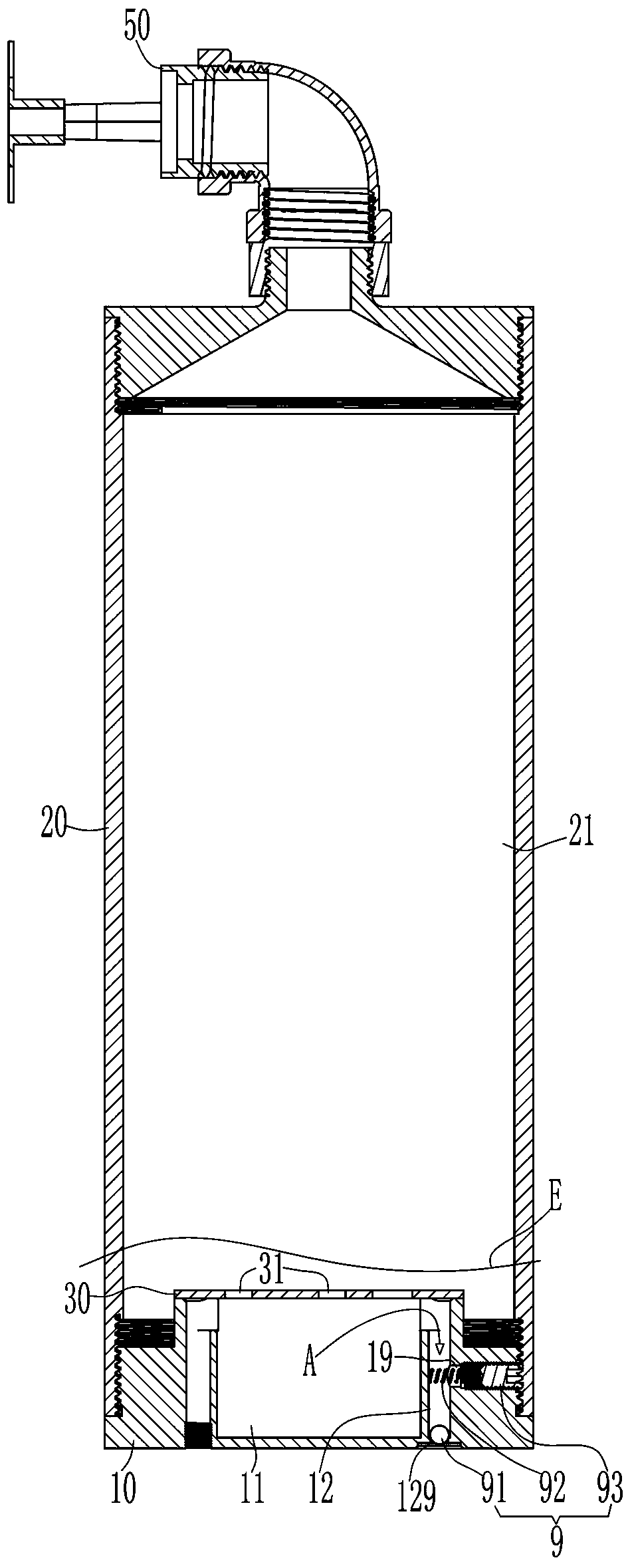

[0025] see Figure 1 to Figure 7, an automatic fire extinguishing device provided with an anti-leakage structure, comprising a base 10, a bottle body 20, a gas diffuser cover 30 and a thermal activation wire 40; the base 10 is provided with a first cavity 11 for accommodating a gas generating agent and a The first cavity 11 communicates with the first through hole 12, and the first through hole 12 also communicates with the outer space of the base 10, the first through hole 12 is actually set upward from the bottom of the base 10 A vertical through hole, after the thermal starting line 40 passes through the first through hole 12 of the base 10, one end is located in the first cavity 11 of the base 10, and the other end is exposed behind the bottom surface of the base 10 Located at the outer space of the base 10; the diffuser cover 30 is provided with at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com