Inflated and deflated control system of patterning cross-country vehicle tyre center and thereof method

A technology for inflation and deflation control and automobile tires, which is applied in tire measurement, tire parts, vehicle parts, etc., and can solve problems such as the structure and method of patterned control that have not been found, the inability to shut off tire airflow, and the inconvenience of operation. , to achieve the effect of simple structure, convenient installation and maintenance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

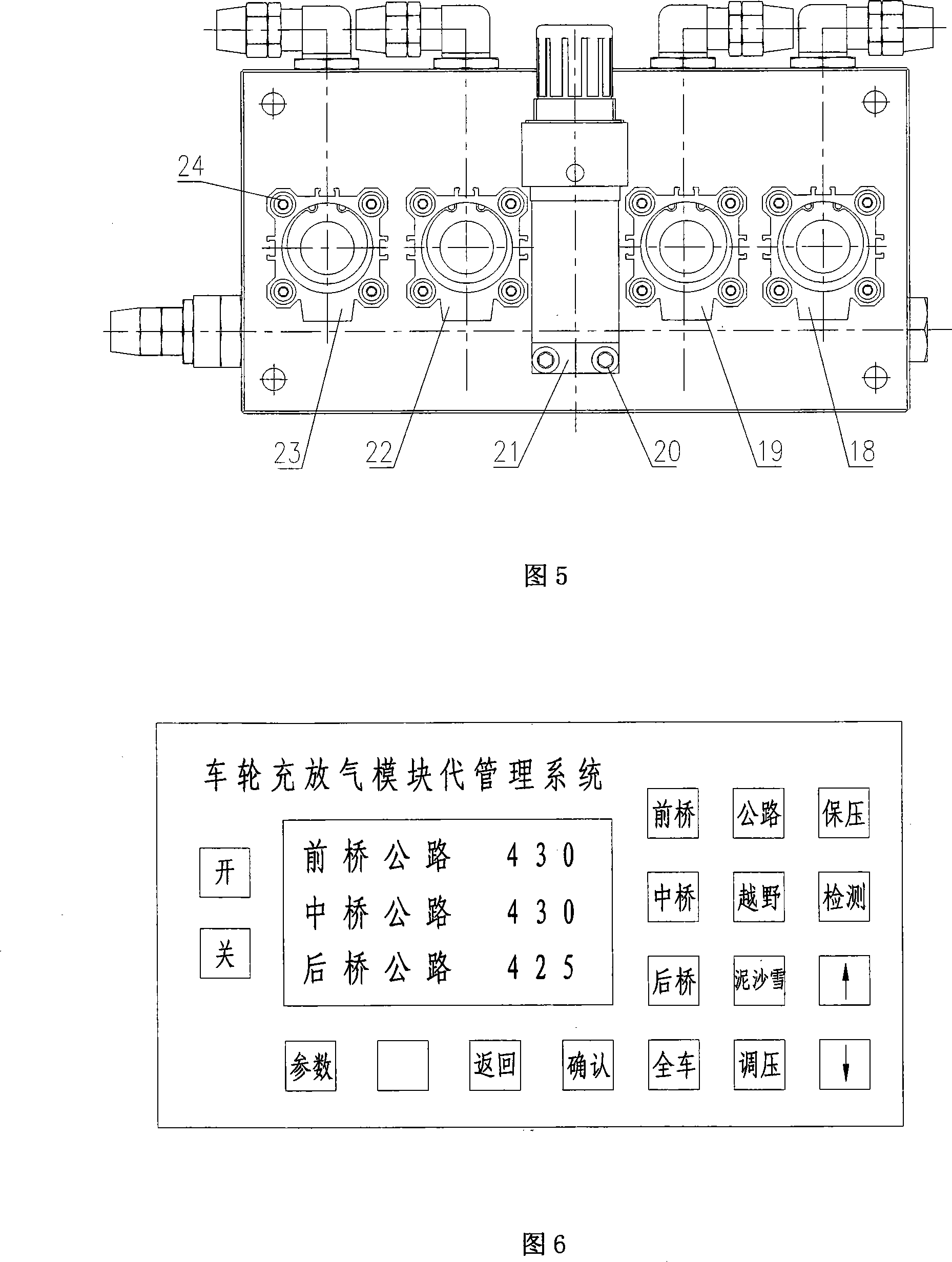

[0082] Below in conjunction with accompanying drawing and embodiment describe in detail:

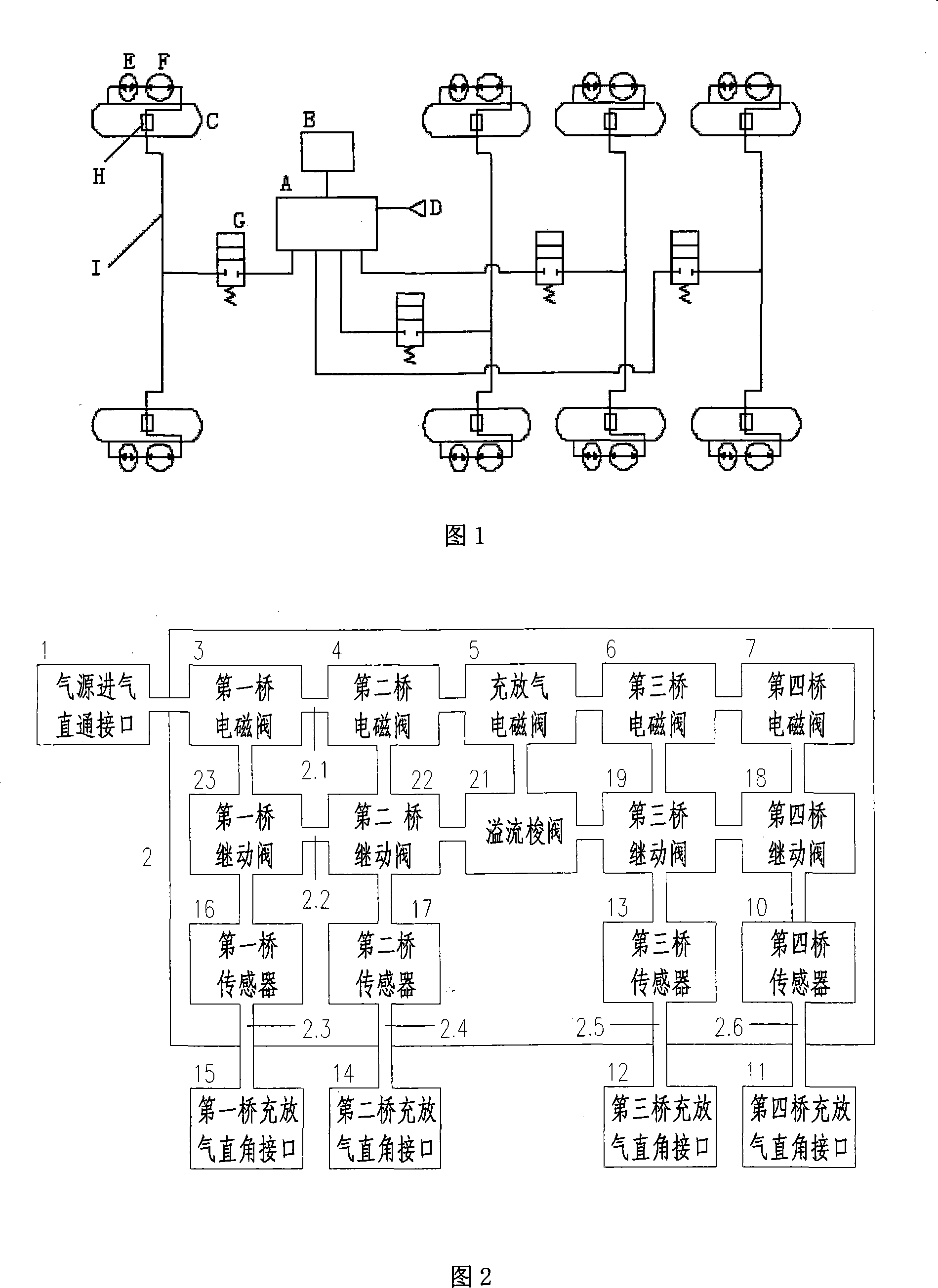

[0083] 1. Overall

[0084] The number of axles of the off-road vehicle involved in the present invention comprises 2 axles, 3 axles and 4 axles, and the module structure and principle of its central inflation and deflation control valve assembly (A) are the same; in view of the difference in the number of axles, by increasing or decreasing The channel and its valves on the module can be designed as 2-axle central filling and deflation control valve assembly, 3-axle central filling and deflation control valve assembly and 4-axle central filling and deflation control valve assembly. The above-mentioned assembly is the 4-axle central inflation and deflation control valve assembly.

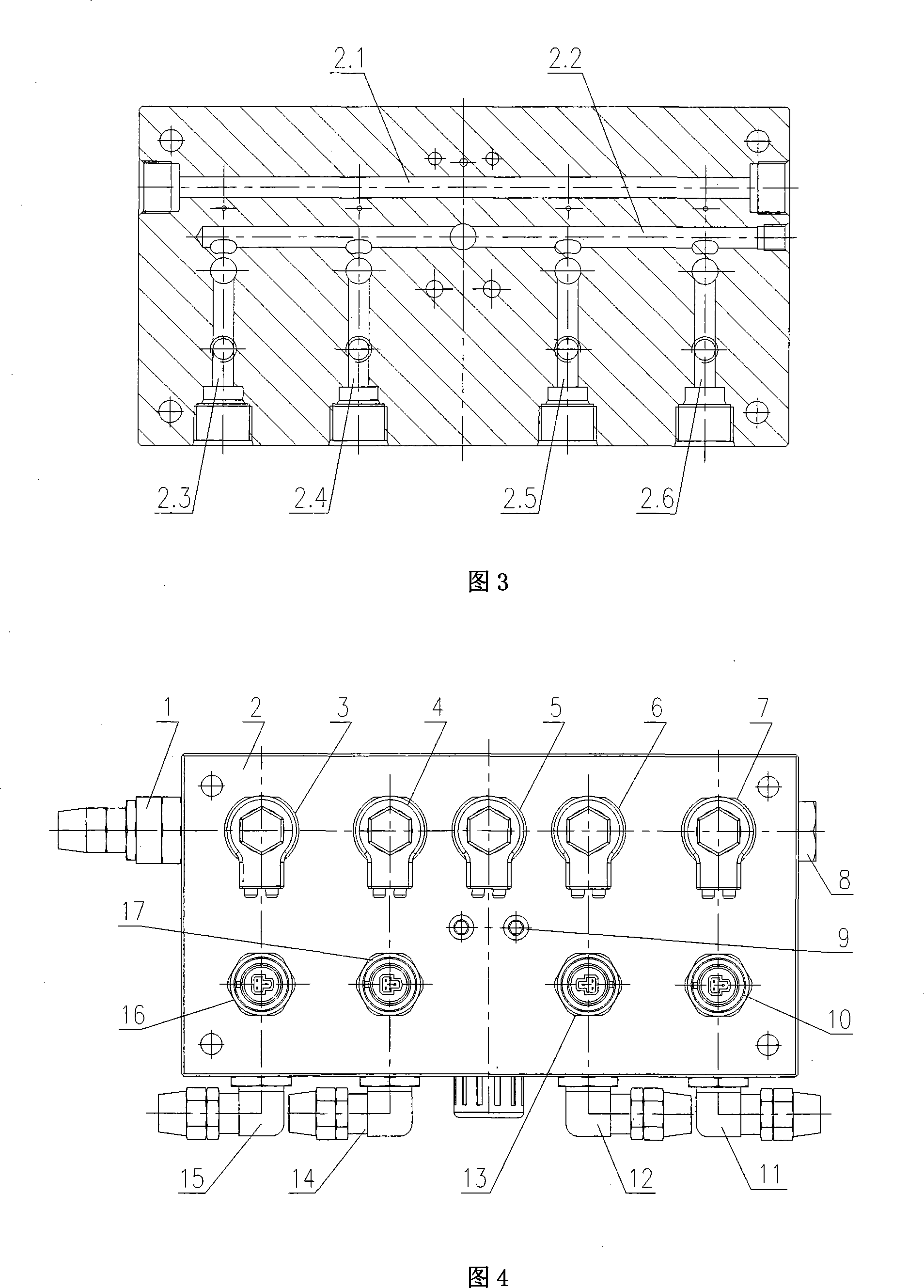

[0085] 2. Central inflation and deflation control valve assembly (A)

[0086] As shown in Figures 2, 3, 4, and 5, the central inflation and deflation control valve assembly (A) has applied for an invention pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com