Device for automatically measuring and inkjet-marking steel tube

An automatic measurement and steel pipe technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, unsightly printing effect, low efficiency, etc., to reduce labor intensity, good spraying effect, detection high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

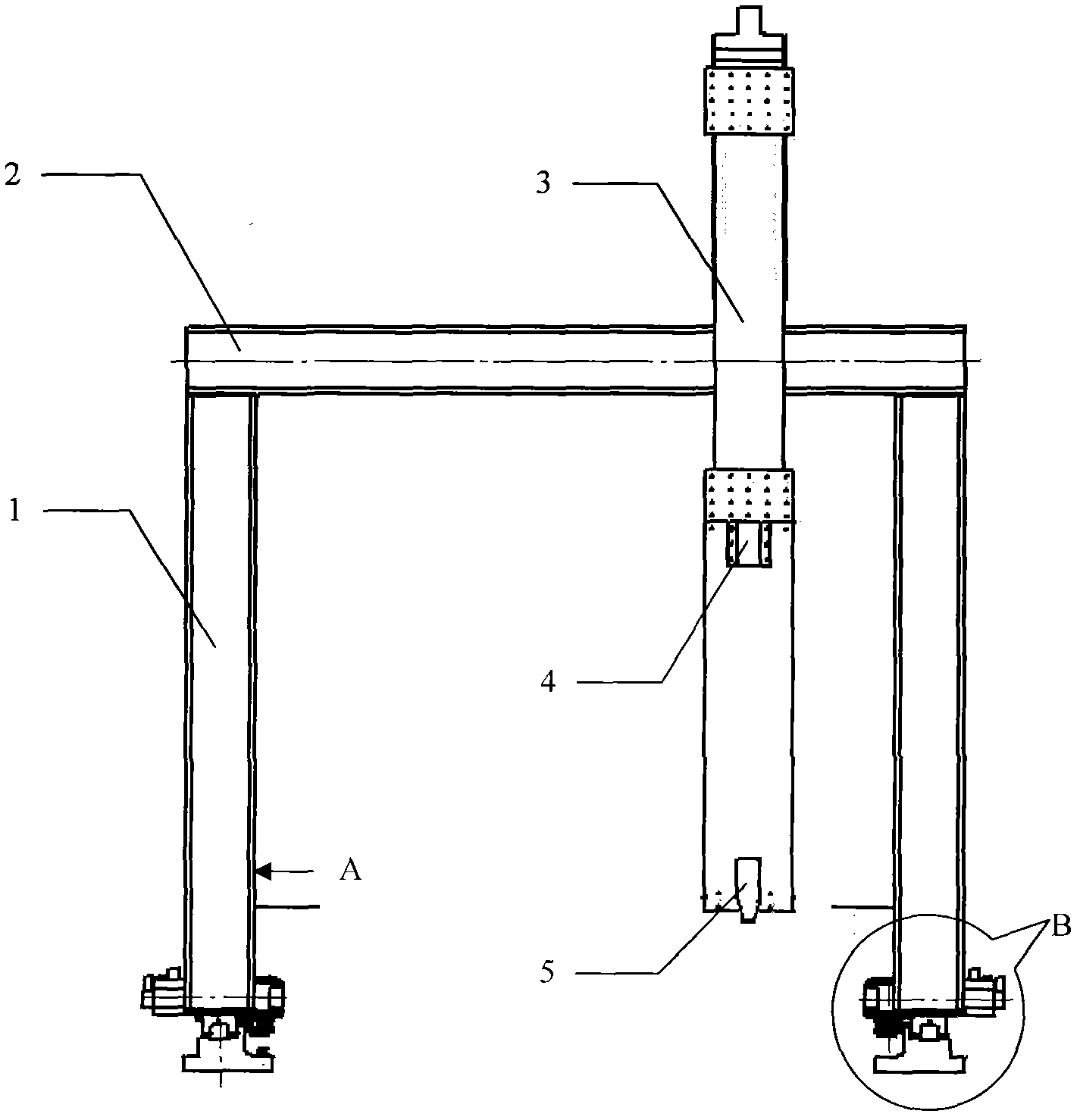

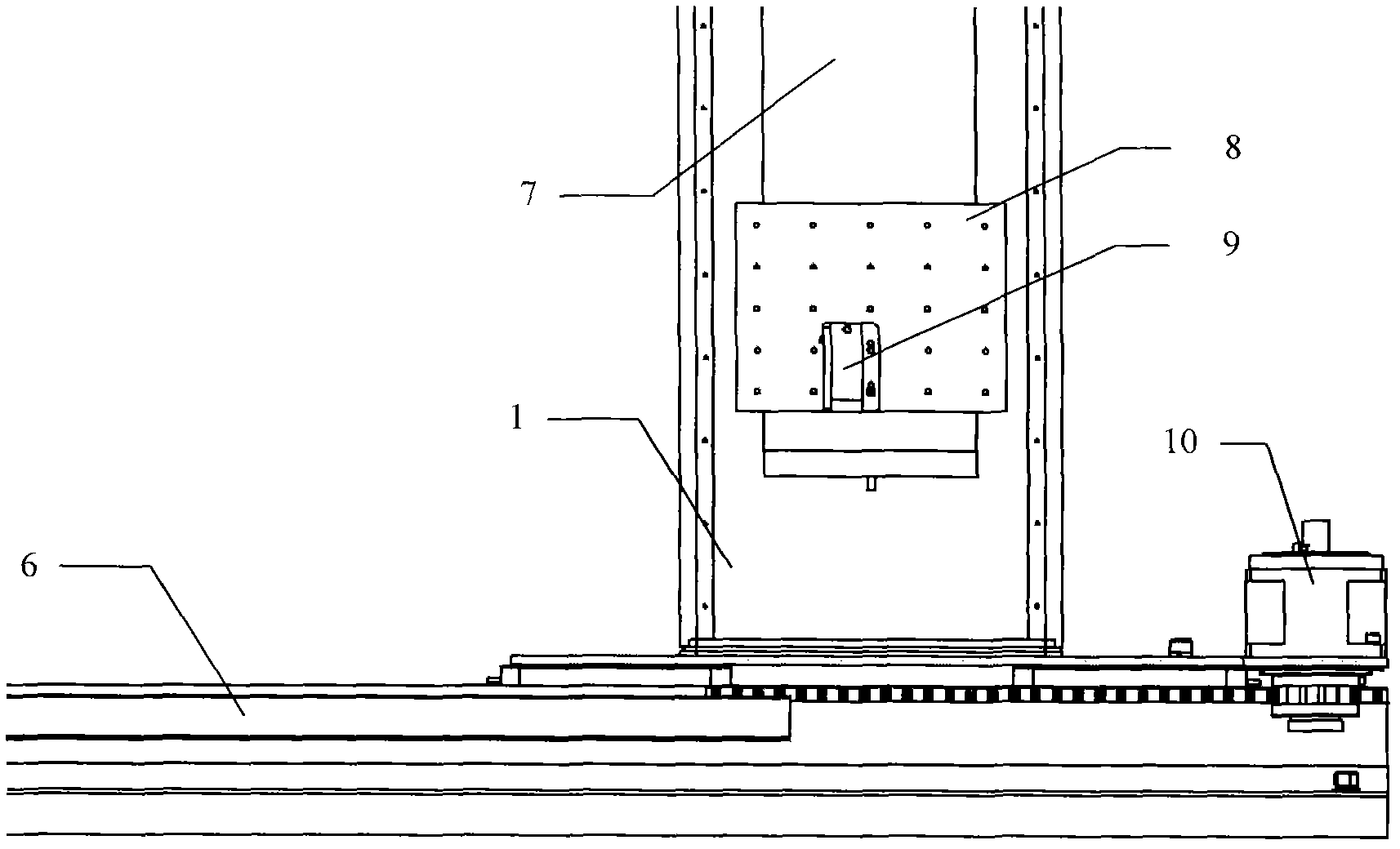

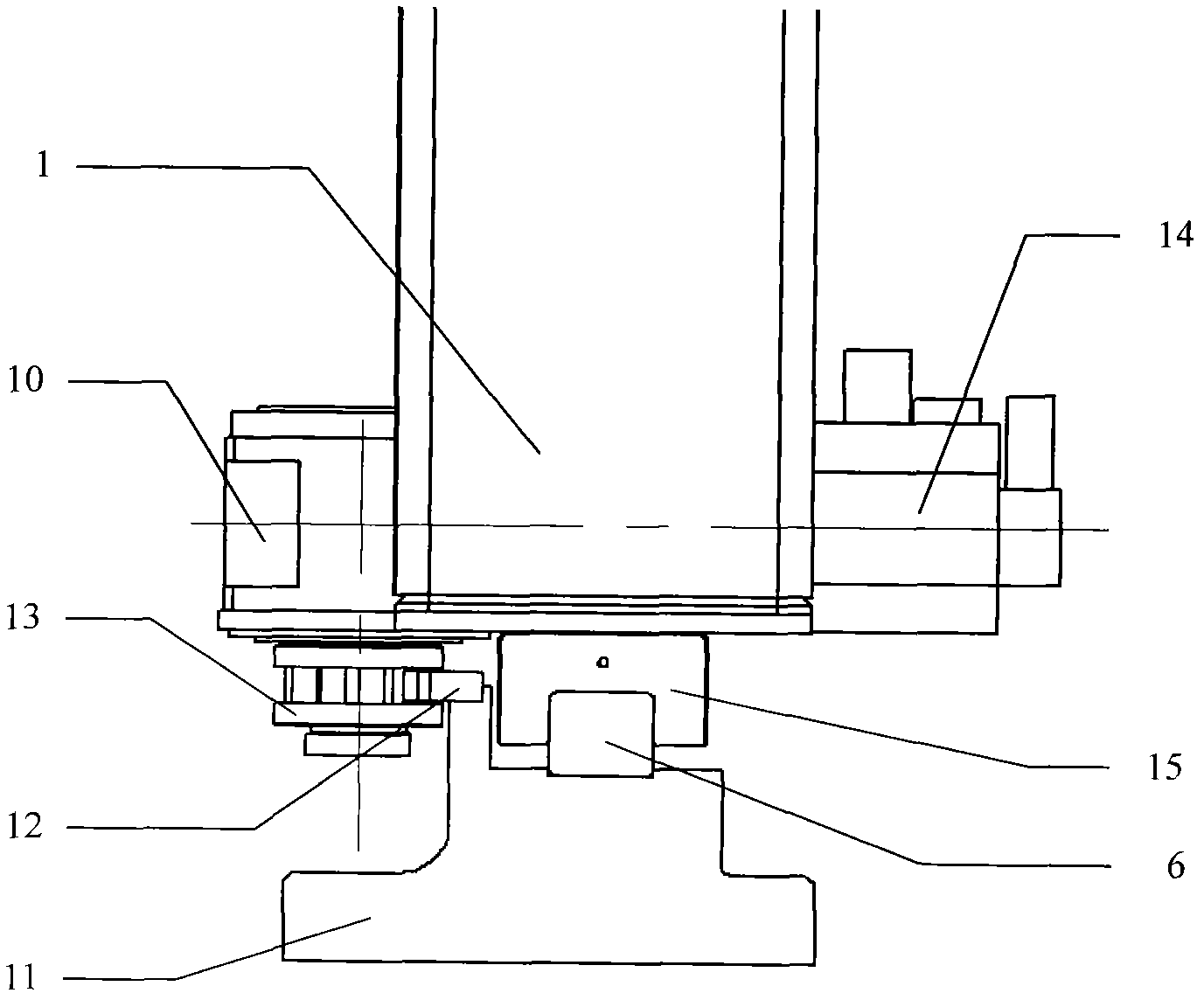

[0014] The present invention includes: a base 11, a gantry, and an electrical control system. The gantry includes: two columns 1, a beam 2, two guide rails 6 installed in parallel on the base 11 on the ground, and one side of the guide rail 6 is provided with teeth Bar 12, a guide rail slider 15 is installed on the guide rail, a drive motor 14 and a reducer 10 are installed on the guide rail slider 15, a gear 13 is installed on the shaft of the reducer 10, and the gear 13 meshes with the rack 12; the column 1 is respectively installed on the guide rail slide On the block 15, the column 1 is respectively installed on the first slide block 8, the first slide block 8 is equipped with a sensor mobile platform 7, the sensor mobile platform 7 is provided with a sensor 9, and the sensor 9 is driven by the first slide block 8 Move up and down along the column 1, the sensor 9 is a laser displacement sensor, the second slider 3 is vertically installed on the gantry beam 2, the second sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com