Cable rope coating spraying device and method

A technology of spraying device and cable, applied in the direction of spraying device, etc., can solve the problems of low spraying efficiency, waste of spraying materials, inconsistent distance, etc., and achieve the effect of high spraying efficiency, good spraying effect and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

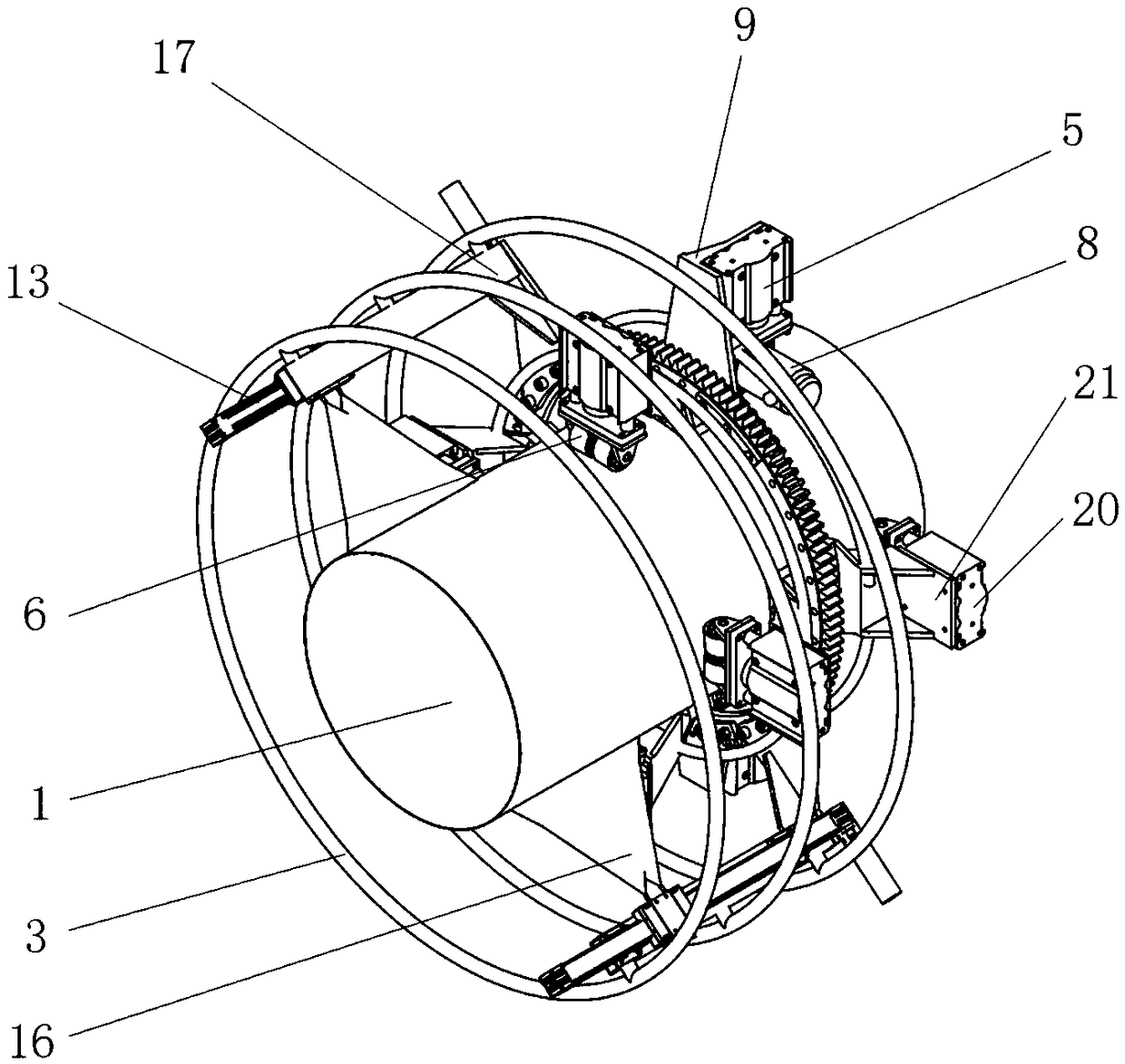

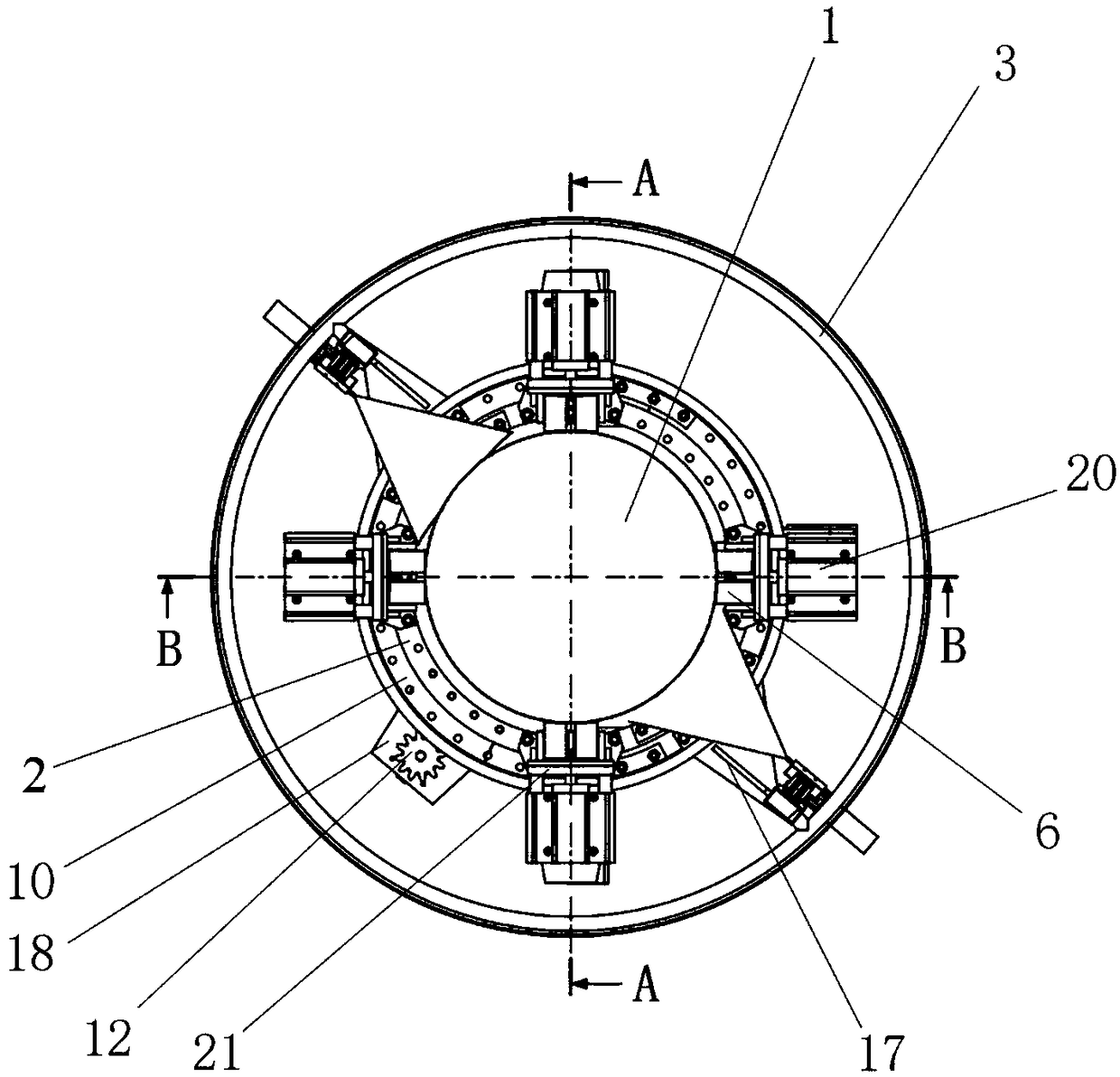

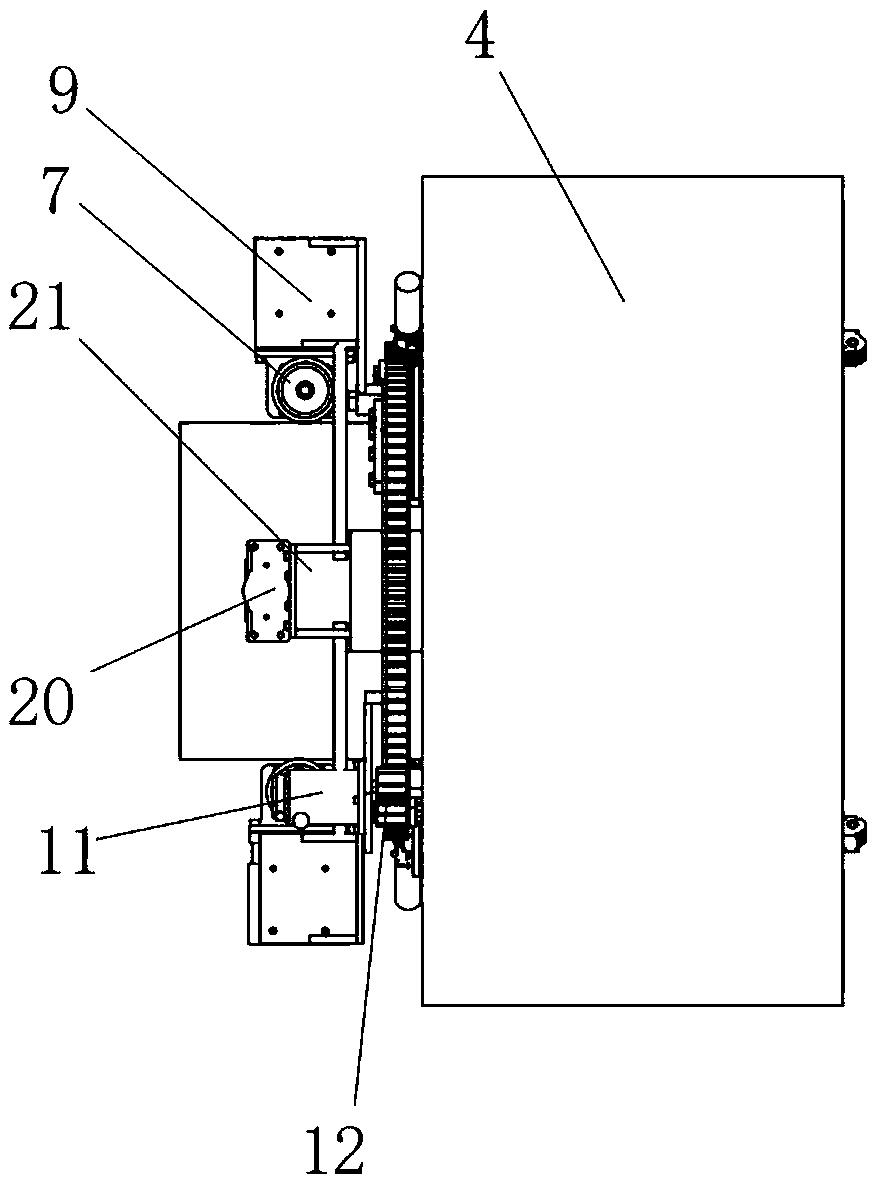

[0031] A cable paint spraying device, including an air pump, a supporting and rotating mechanism, a spraying mechanism, a traveling mechanism and a wireless receiving controller, is characterized in that: the inner ring formed by overlapping two identical semicircular rings is the surrounding of the cable 1 Supporting mechanism, the outer diameter of the inner ring is provided with grooves matching the balls, the inner diameter of the outer gear ring 10 is also provided with grooves matching the balls, and the rotation mechanism is formed by combining the balls with the outer diameter of the inner ring; two track brackets 17 along the The radial direction of the center of the outer gear ring 10 is set, and the connecting end of the track bracket 17 is fixed with the outer gear ring 10 by bolts. The cantilever side of the track bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com