Sprinkling equipment for built bridge

A technology for sprinkler equipment and bridges, applied in bridge construction, bridges, erection/assembly of bridges, etc., can solve the problems of slow sprinkler speed and uneven sprinkler, and achieve the effect of convenient sprinkler position and good sprinkler effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

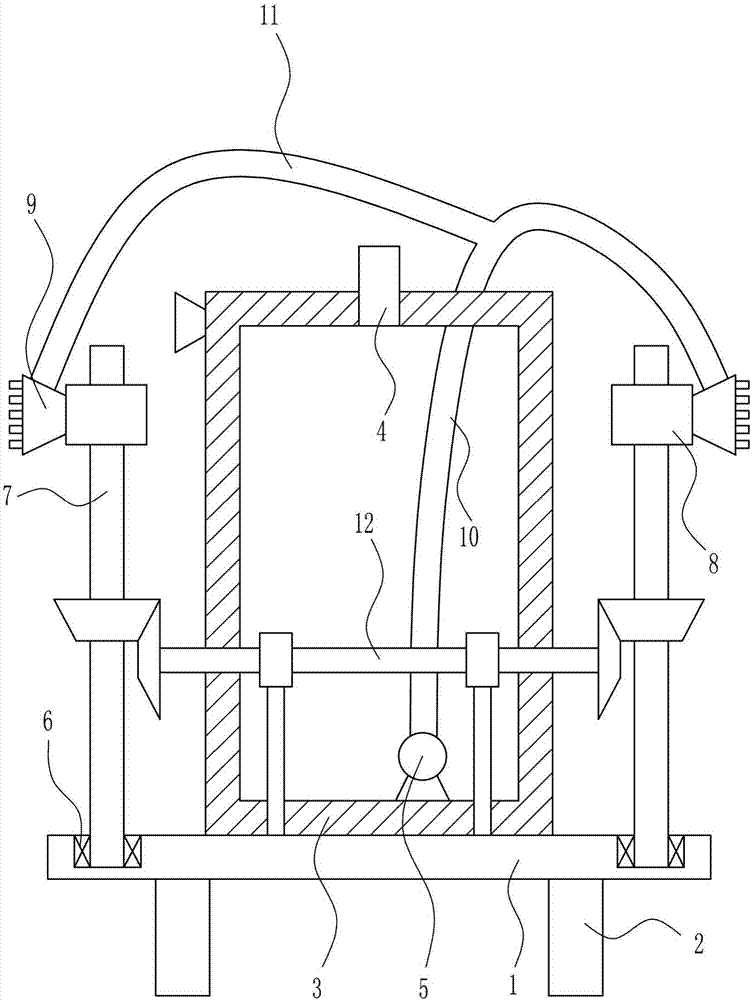

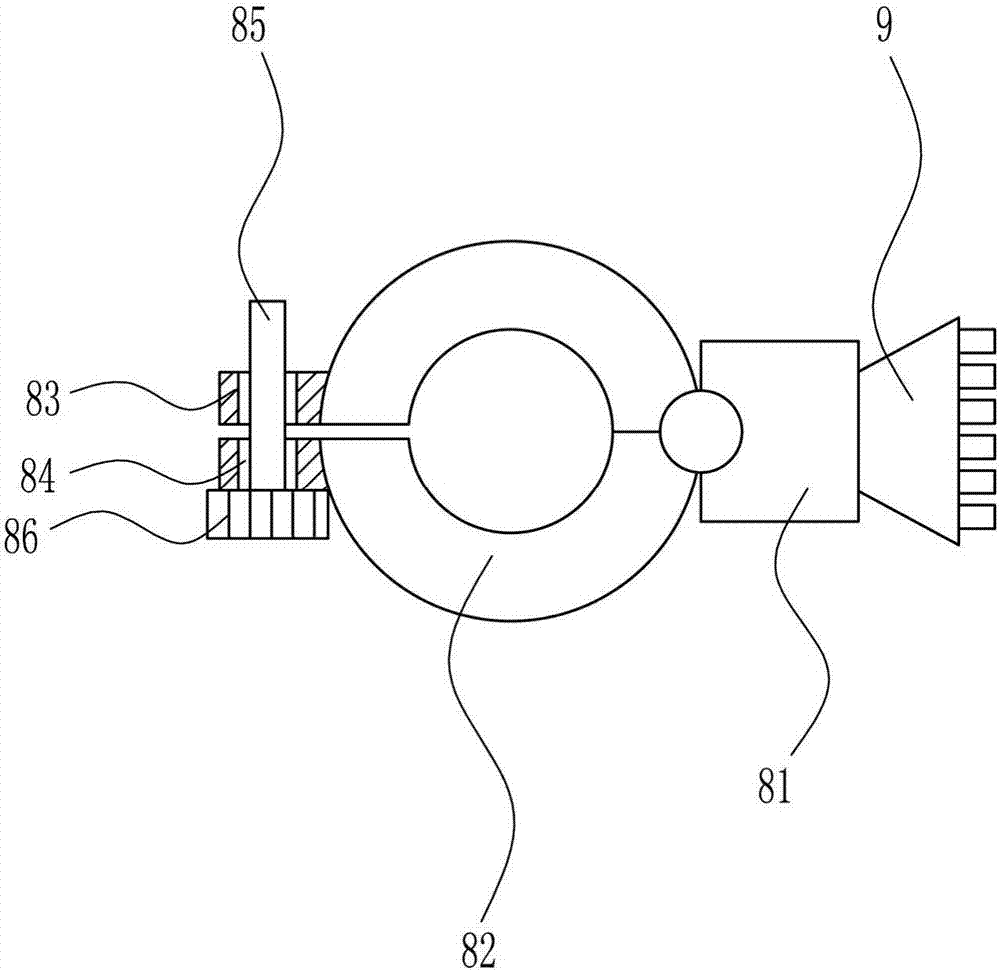

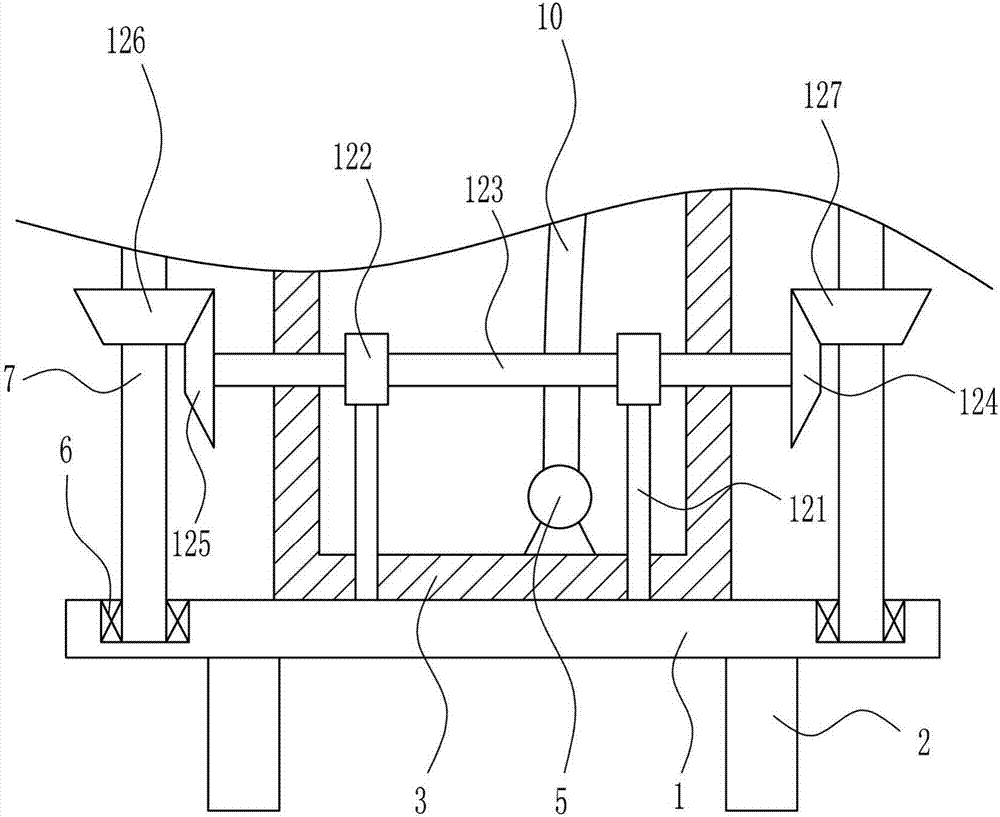

[0029] A kind of sprinkling equipment used after the bridge is built, such as Figure 1-5 As shown, it includes a mounting plate 1, a wheel 2, a box body 3, a water inlet pipe 4, a water pump 5, a first bearing 6, a first rotating shaft 7, a fixing device 8, a nozzle 9, a first pipeline 10, a second pipeline 11 and Rotating device 12, the left and right sides of mounting plate 1 are symmetrically provided with wheels 2, the center of mounting plate 1 top is provided with box body 3, the center of box body 3 top is provided with water inlet pipe 4, and the right side of box body 3 inner bottom is provided with water pump 5, installs The top of the board 1 is left and right symmetrically provided with first bearings 6, and first rotating shafts 7 are arranged inside the first bearings 6, and fixing devices 8 are arranged on the upper parts of the first rotating shafts 7, and nozzles 9 are arranged on the outside of the fixing devices 8, and the water pump 5 is connected to There...

Embodiment 2

[0031] A kind of sprinkling equipment used after the bridge is built, such as Figure 1-5 As shown, it includes a mounting plate 1, a wheel 2, a box body 3, a water inlet pipe 4, a water pump 5, a first bearing 6, a first rotating shaft 7, a fixing device 8, a nozzle 9, a first pipeline 10, a second pipeline 11 and Rotating device 12, the left and right sides of mounting plate 1 are symmetrically provided with wheels 2, the center of mounting plate 1 top is provided with box body 3, the center of box body 3 top is provided with water inlet pipe 4, and the right side of box body 3 inner bottom is provided with water pump 5, installs The top of the board 1 is left and right symmetrically provided with first bearings 6, and first rotating shafts 7 are arranged inside the first bearings 6, and fixing devices 8 are arranged on the upper parts of the first rotating shafts 7, and nozzles 9 are arranged on the outside of the fixing devices 8, and the water pump 5 is connected to There...

Embodiment 3

[0034] A kind of sprinkling equipment used after the bridge is built, such as Figure 1-5 As shown, it includes a mounting plate 1, a wheel 2, a box body 3, a water inlet pipe 4, a water pump 5, a first bearing 6, a first rotating shaft 7, a fixing device 8, a nozzle 9, a first pipeline 10, a second pipeline 11 and Rotating device 12, the left and right sides of mounting plate 1 are symmetrically provided with wheels 2, the center of mounting plate 1 top is provided with box body 3, the center of box body 3 top is provided with water inlet pipe 4, and the right side of box body 3 inner bottom is provided with water pump 5, installs The top of the board 1 is left and right symmetrically provided with first bearings 6, and first rotating shafts 7 are arranged inside the first bearings 6, and fixing devices 8 are arranged on the upper parts of the first rotating shafts 7, and nozzles 9 are arranged on the outside of the fixing devices 8, and the water pump 5 is connected to There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com