System for spraying stamping part

A technology for sheet metal parts and pendants, applied in the field of sheet metal spraying systems, can solve the problems of affecting the spraying effect, insufficient dust removal of sheet metal parts, a large number of dust spots, etc., and achieve better spraying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

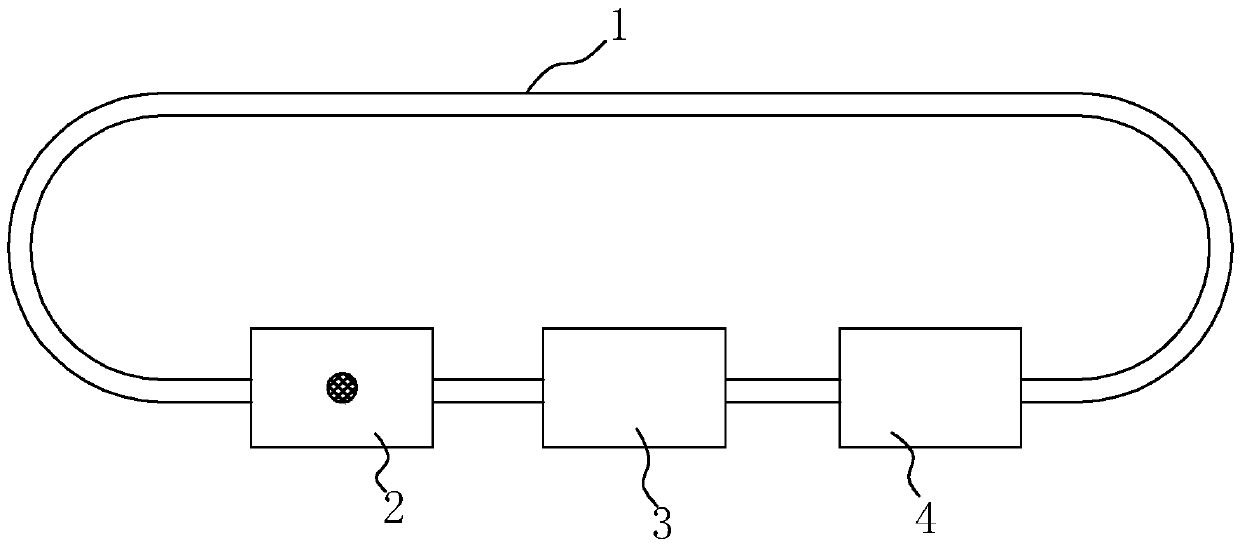

[0033] A sheet metal spraying system, such as figure 1 As shown, it includes a conveying chain 1 and a blowing chamber 2, a spraying chamber 3 and a drying chamber 4 arranged in sequence, wherein the conveying chain 1 is connected end to end to form a closed loop, and the sheet metal parts 24 are sequentially transported to the blowing chamber 2, spraying chamber 2 through the conveying chain 1 The chamber 3 and the drying chamber 4 perform dust removal, spraying and drying operations to complete the painting treatment on the surface of the sheet metal, wherein the conveyor chain 1 can be driven by a motor and a sprocket (not shown in the figure).

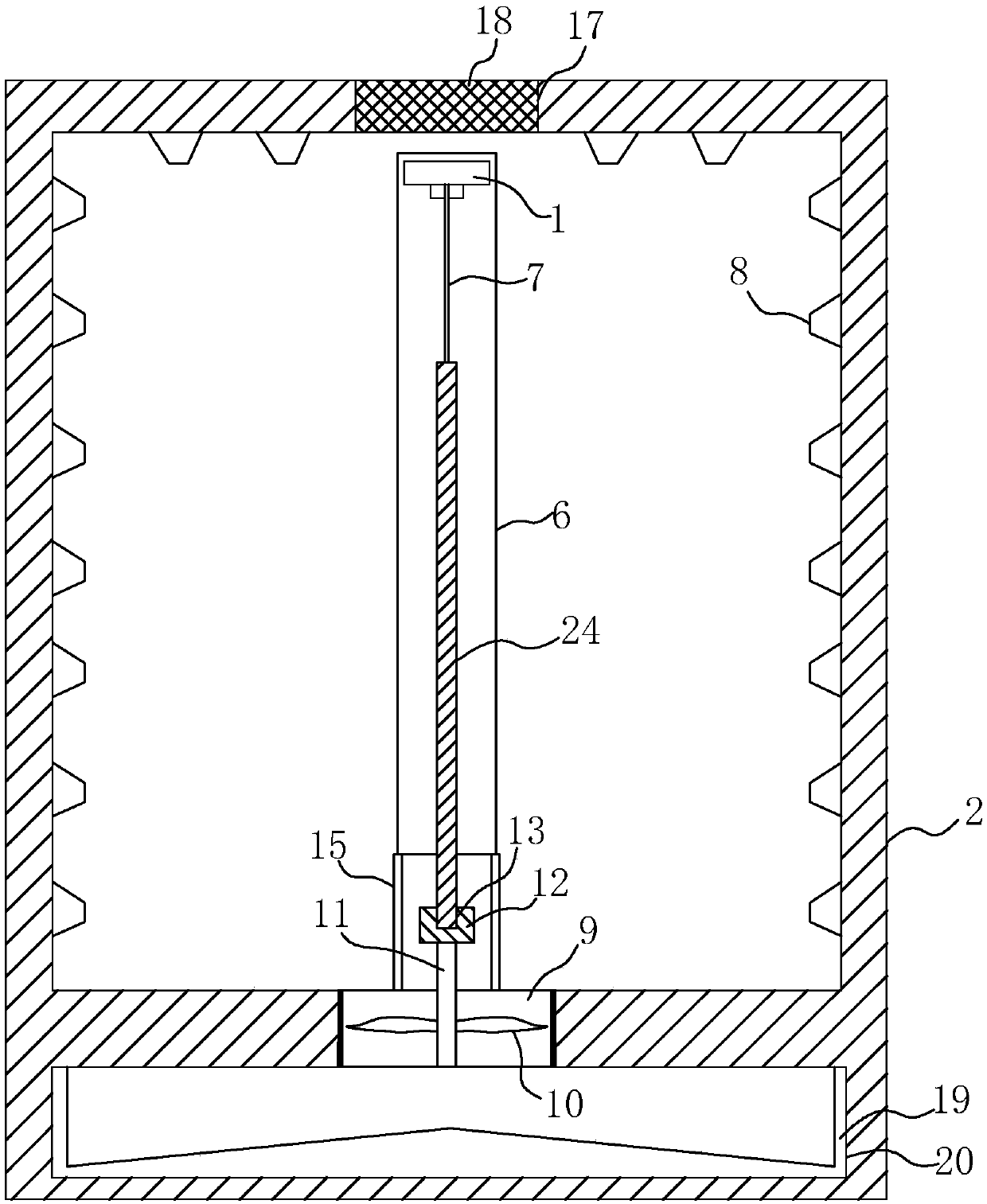

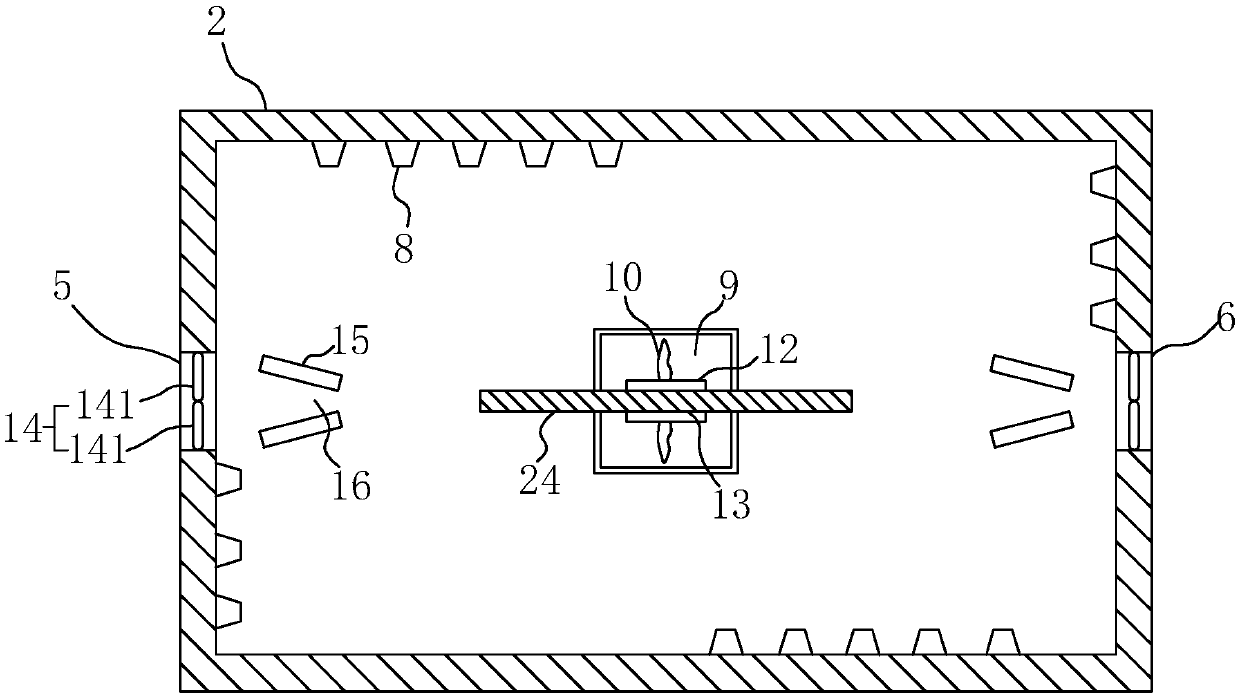

[0034] Such as figure 2 and image 3 , the two sides of the blowing chamber 2 are respectively provided with an inlet 5 and an outlet 6 for the sheet metal parts 24 to enter and exit, and a hanger 7 for the she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com