Quick beverage mixing equipment based on rotary jetting principle

A technology of rotary spraying and mixing equipment, which is applied in the direction of mixers, fluid mixers, chemical/physical processes, etc., to achieve the effect of improving service life and reducing wear efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

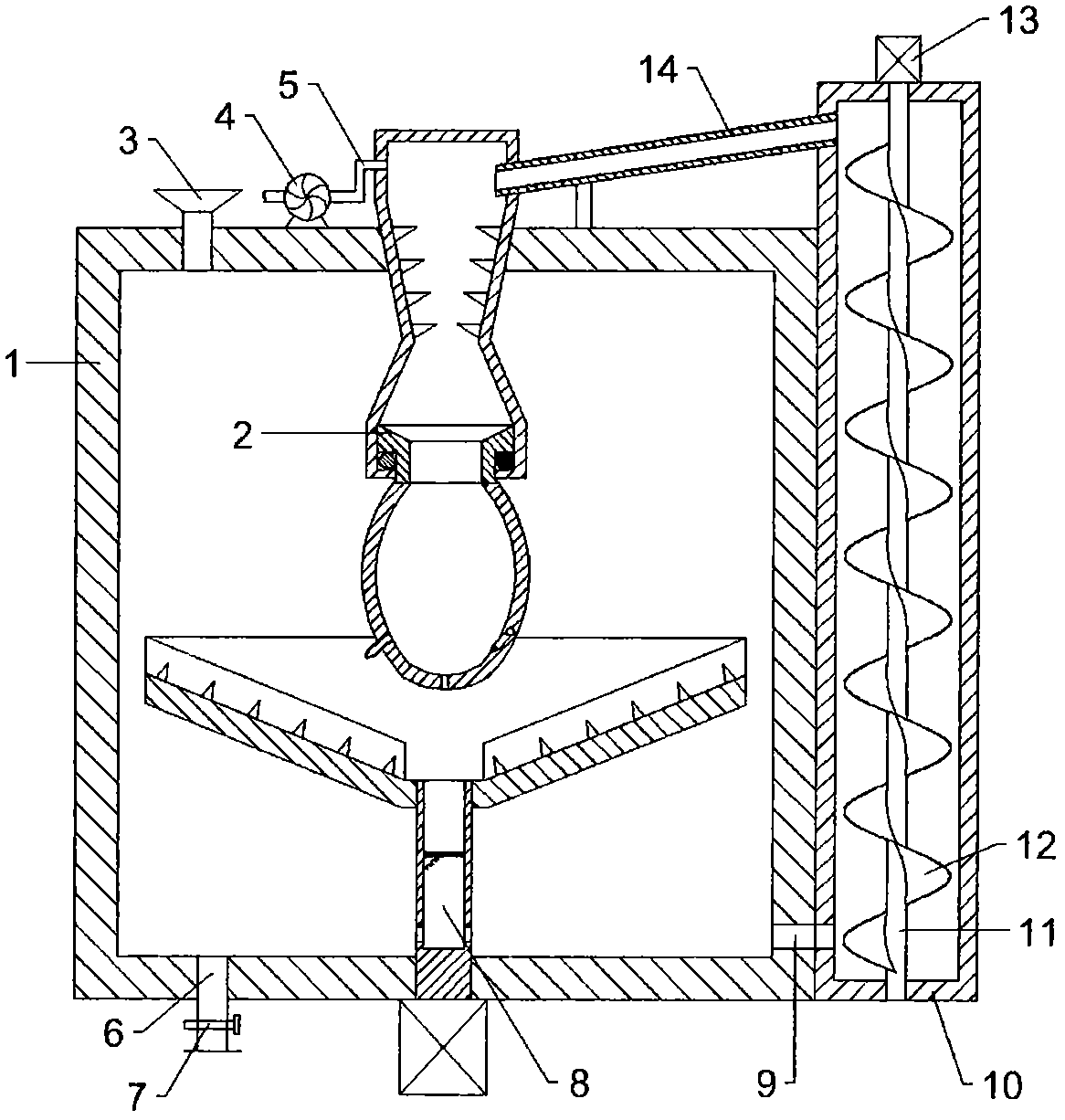

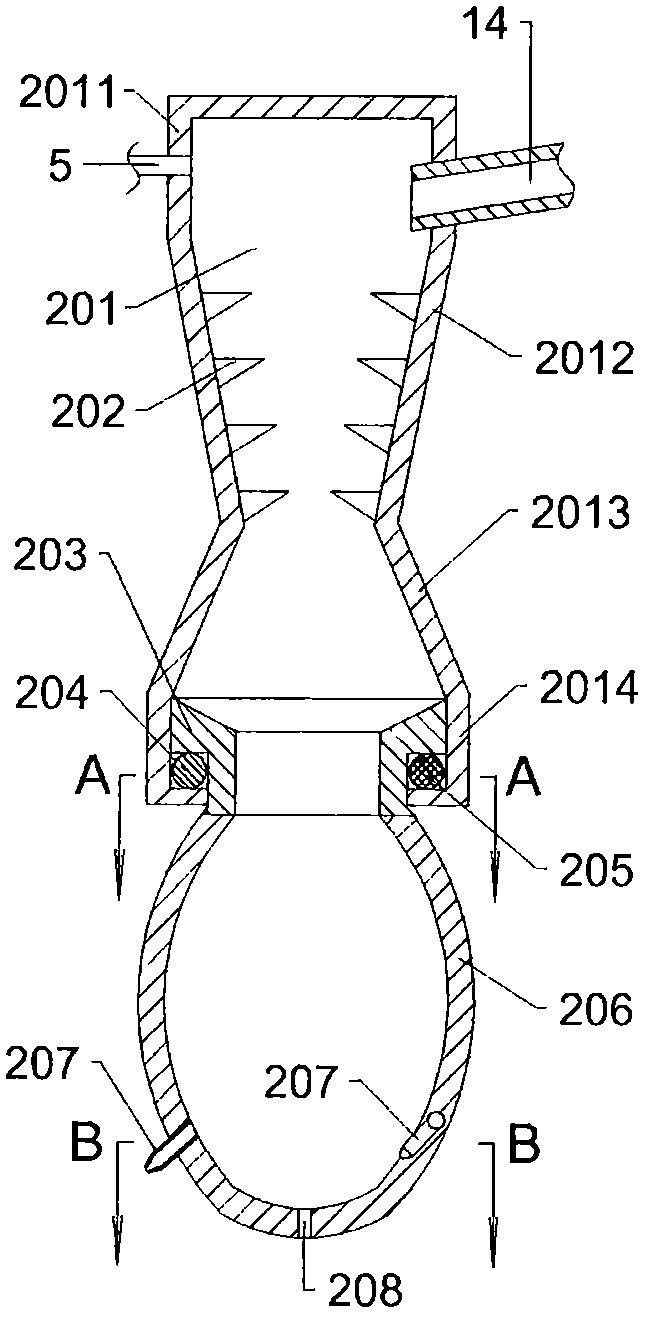

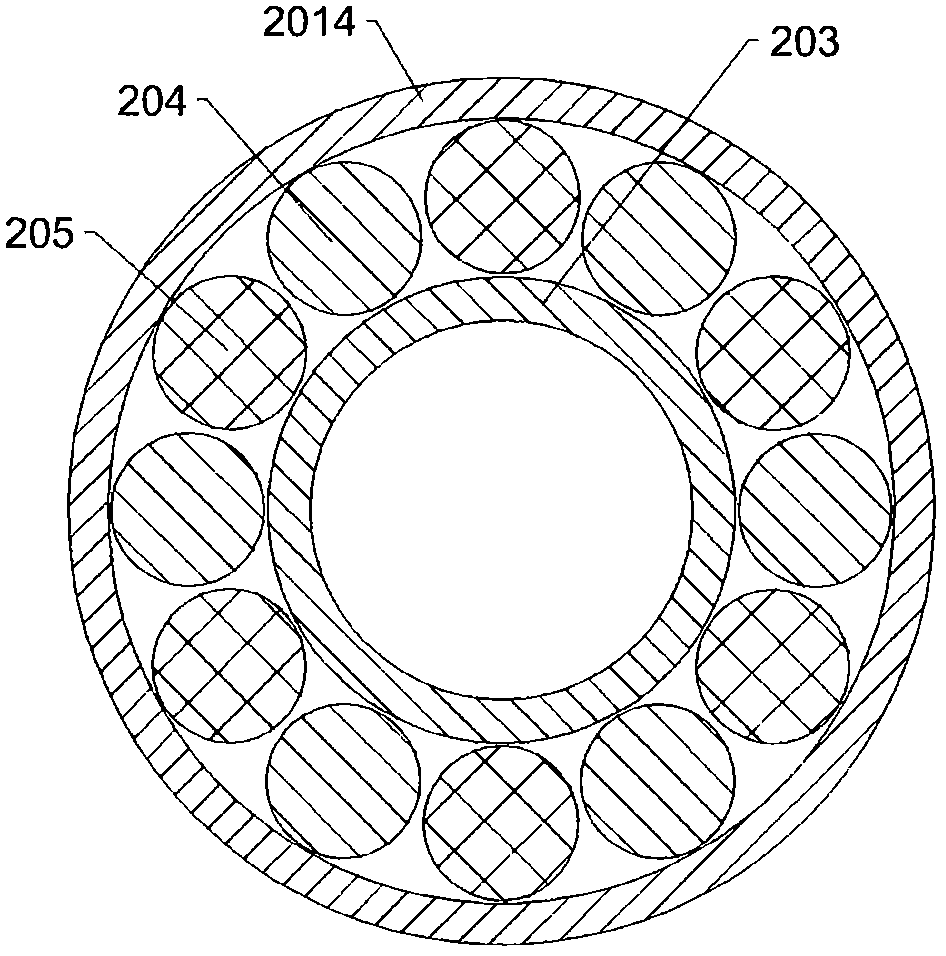

[0032] see figure 1 , figure 2 and image 3 , in this embodiment, a beverage rapid mixing device based on the principle of rotary jetting, including a tank body 1, the upper part of the tank body 1 is fixedly connected with a rotary jetting device 2, and the rotary jetting device 2 includes a jetting housing 201, The injection shell 201 includes a first cylindrical section 2011, a first circular truncated section 2012, a second circular truncated section 2013 and a second cylindrical section 2014 from top to bottom, and the first circular truncated section 2012 is in the shape of a large top and a small bottom, and the second circular truncated section Section 2013 is in the shape of small up and down, the first cylindrical section 2011, the first circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com