A consumable impeller with long service life

A technology with wearing parts and long service life, which is applied to parts of pumping devices for elastic fluids, pump elements, liquid fuel engines, etc., and can solve the problems of reduced service life of impellers, poor torque resistance of shaft holes, and wear of shaft holes High efficiency and other issues, to achieve the effect of enhancing service life, improving performance, and increasing anti-torque ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

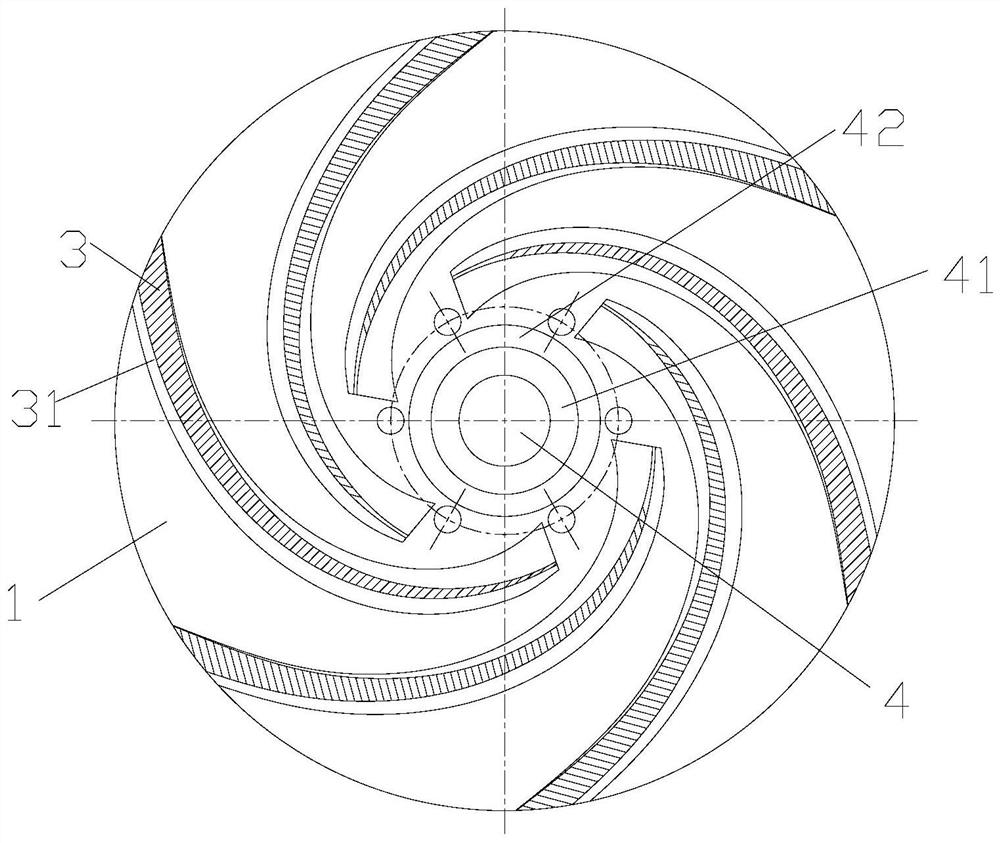

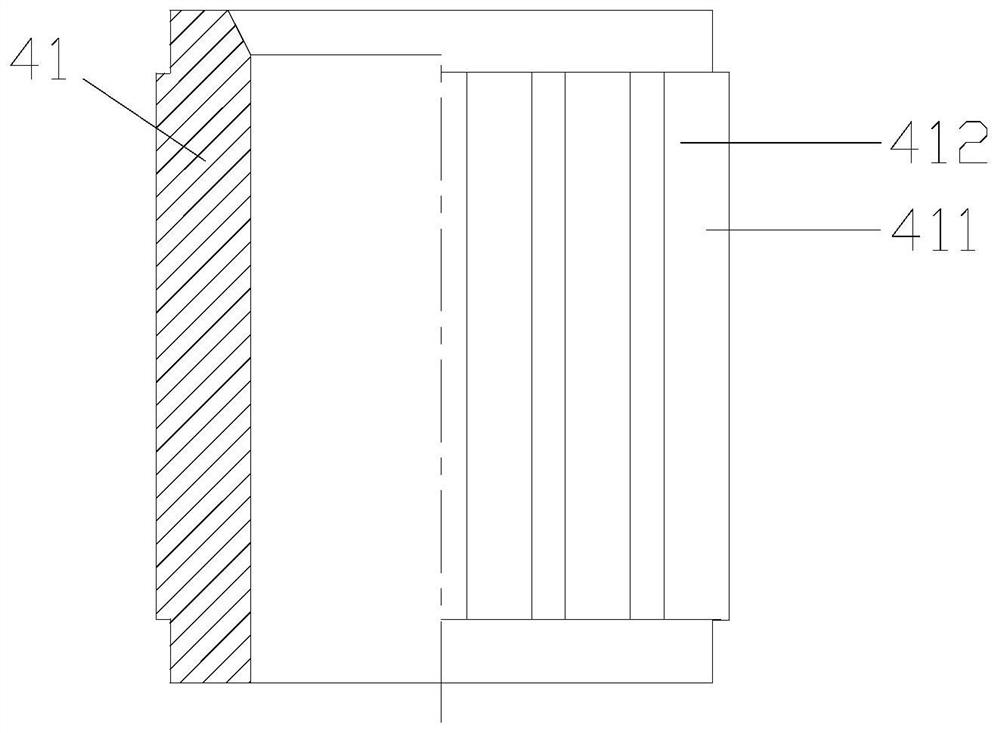

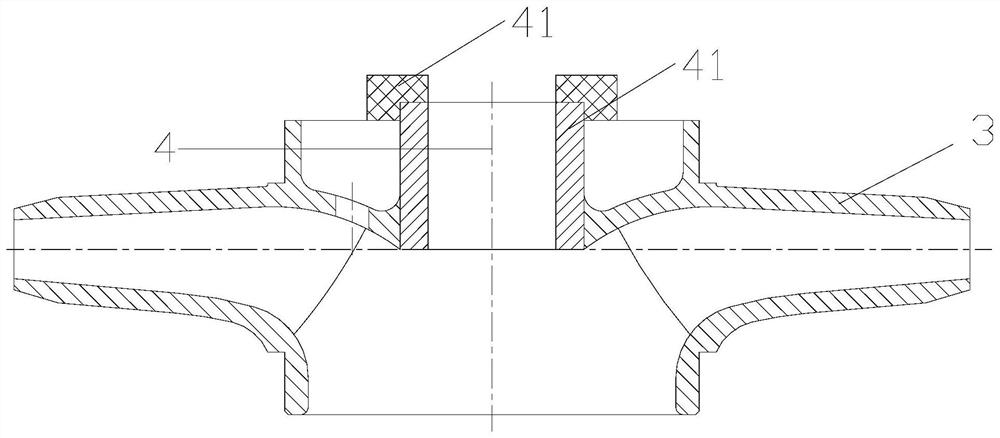

[0029] See attached Figure 1-4 As shown, a consumable impeller with long service life includes a wheel disc 1, a wheel hub 2 which is arranged on the wheel disc 1 and integrally formed with the wheel disc, and a wheel hub 2 which is arranged on the outside of the wheel hub 2 and is connected to the wheel hub. The blade 3 integrally formed on the disk 1, the blade 3 is provided with more than one piece, and is evenly distributed on the upper surface of the wheel disk 1, and one end of the blade 3 is provided with a reinforcement integrally formed with the blade 3 to enhance the strength of the blade 3 Rib 31, the center of the wheel disc 1 is provided with a shaft hole 4 for placing the connecting shaft, the upper end of the shaft hole 4 is provided with a mouth ring sleeve 42 connected with the shaft hole 4 screws, and the shaft hole 4 is provided with a shaft hole 4. 4. The bushing 41 connected by screws. The outer side of the bushing 41 is provided with a rack 411 integrall...

Embodiment 2

[0038] See attached Figure 1-4As shown, a consumable impeller with long service life includes a wheel disc 1, a wheel hub 2 which is arranged on the wheel disc 1 and integrally formed with the wheel disc, and a wheel hub 2 which is arranged on the outside of the wheel hub 2 and is connected to the wheel hub. The blade 3 integrally formed on the disk 1, the blade 3 is provided with more than one piece, and is evenly distributed on the upper surface of the wheel disk 1, and one end of the blade 3 is provided with a reinforcement integrally formed with the blade 3 to enhance the strength of the blade 3 Rib 31, the center of the wheel disc 1 is provided with a shaft hole 4 for placing the connecting shaft, the upper end of the shaft hole 4 is provided with a mouth ring sleeve 42 connected with the shaft hole 4 screws, and the shaft hole 4 is provided with a shaft hole 4. 4. The bushing 41 connected by screws. The outer side of the bushing 41 is provided with a rack 411 integrally...

Embodiment 3

[0047] See attached Figure 1-4 As shown, a consumable impeller with long service life includes a wheel disc 1, a wheel hub 2 which is arranged on the wheel disc 1 and integrally formed with the wheel disc, and a wheel hub 2 which is arranged on the outside of the wheel hub 2 and is connected to the wheel hub. The blade 3 integrally formed on the disk 1, the blade 3 is provided with more than one piece, and is evenly distributed on the upper surface of the wheel disk 1, and one end of the blade 3 is provided with a reinforcement integrally formed with the blade 3 to enhance the strength of the blade 3 Rib 31, the center of the wheel disc 1 is provided with a shaft hole 4 for placing the connecting shaft, the upper end of the shaft hole 4 is provided with a mouth ring sleeve 42 connected with the shaft hole 4 screws, and the shaft hole 4 is provided with a shaft hole 4. 4. The bushing 41 connected by screws. The outer side of the bushing 41 is provided with a rack 411 integrall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com