Spraying device and spraying method for bottle bodies

A spraying equipment and bottle body technology, which is applied in the bottle body spraying equipment and spraying field, can solve the problems of uneven spraying and waste of paint, and achieve the effect of accurate speed and shortened spraying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

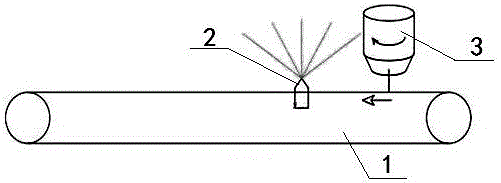

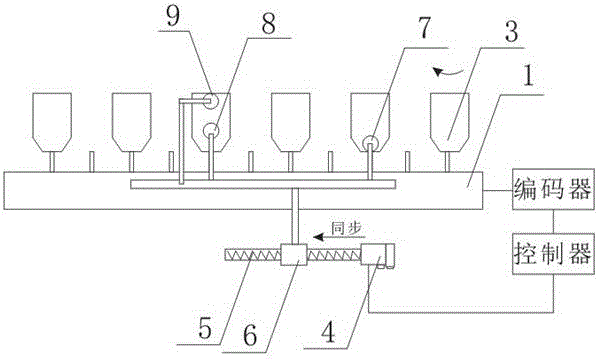

[0035] Embodiment 1: see figure 1 , figure 2 , a kind of bottle body spraying equipment, comprises assembly line 1, is provided with several rotating shafts vertically on assembly line 1, and described rotating shaft can rotate horizontally around the vertical line of itself, is provided with the tooling that installs bottle body 3 on the rotating shaft, and described bottle body 3 The tooling is inserted upside down and evenly distributed. A spray gun assembly 2 is provided on one side of the assembly line 1, and the spray gun assembly 2 is connected to an automatic controller; a linear guide rail 5 is provided on the lower side of the assembly line 1. Moving slider 6, the driver 4 is connected with the controller, and its work is controlled by the controller. A bracket is provided on the slider 6, and the spray gun assembly 2 is fixed on the bracket and is located on the side of the assembly line 1. The spray gun assembly 2 includes several spray guns, and is aimed at the ...

Embodiment 2

[0046] Embodiment 2: The spray gun assembly 2 includes a first spray gun 7, a second spray gun 8 and a third spray gun 9, the first spray gun 7 is aimed at the lower part of a bottle body 3 at the front of the assembly line 1, and the second and third spray guns 9 are aimed at the assembly line 1 the middle and the top of a bottle body 3 at the rear, then the step (4) is specifically:

[0047] When the first bottle 3 approaches the first spray gun 7 and the first spray gun 7 first detects that the bottle 3 is in front of it, the controller starts the first spray gun 7 to spray paint, and at the same time controls the slider 6 to drive the bracket and the bottle 3 synchronous movement;

[0048]When the first bottle body 3 approaches the second and third spray guns 9 and the two spray guns detect that the bottle body 3 is located directly in front of them, the controller starts the second and third spray guns 9 to spray paint.

[0049] All the other are identical with embodimen...

Embodiment 3

[0050] Embodiment 3: For better spraying, we set the first spray booth and the second spray booth along the flow direction on the assembly line 1, and a bottle spraying equipment is set in the first spray booth and the second spray booth, the bottle body 3 Pass through the first spray booth and the second spray booth in turn through the assembly line 1;

[0051] In the first spray booth, complete the first spraying through steps (1)-(6);

[0052] In the second spray booth, complete the second spraying through steps (1)-(6).

[0053] All the other are identical with embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com