Camouflage spraying zoning operation method

A technology of spraying areas and sub-areas, which is applied in the direction of coatings, spraying devices, and devices for coating liquid on the surface, etc., can solve the problems of back and forth empty running, and achieve the effects of improving efficiency, avoiding singular points of spray guns, and reducing invalid paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

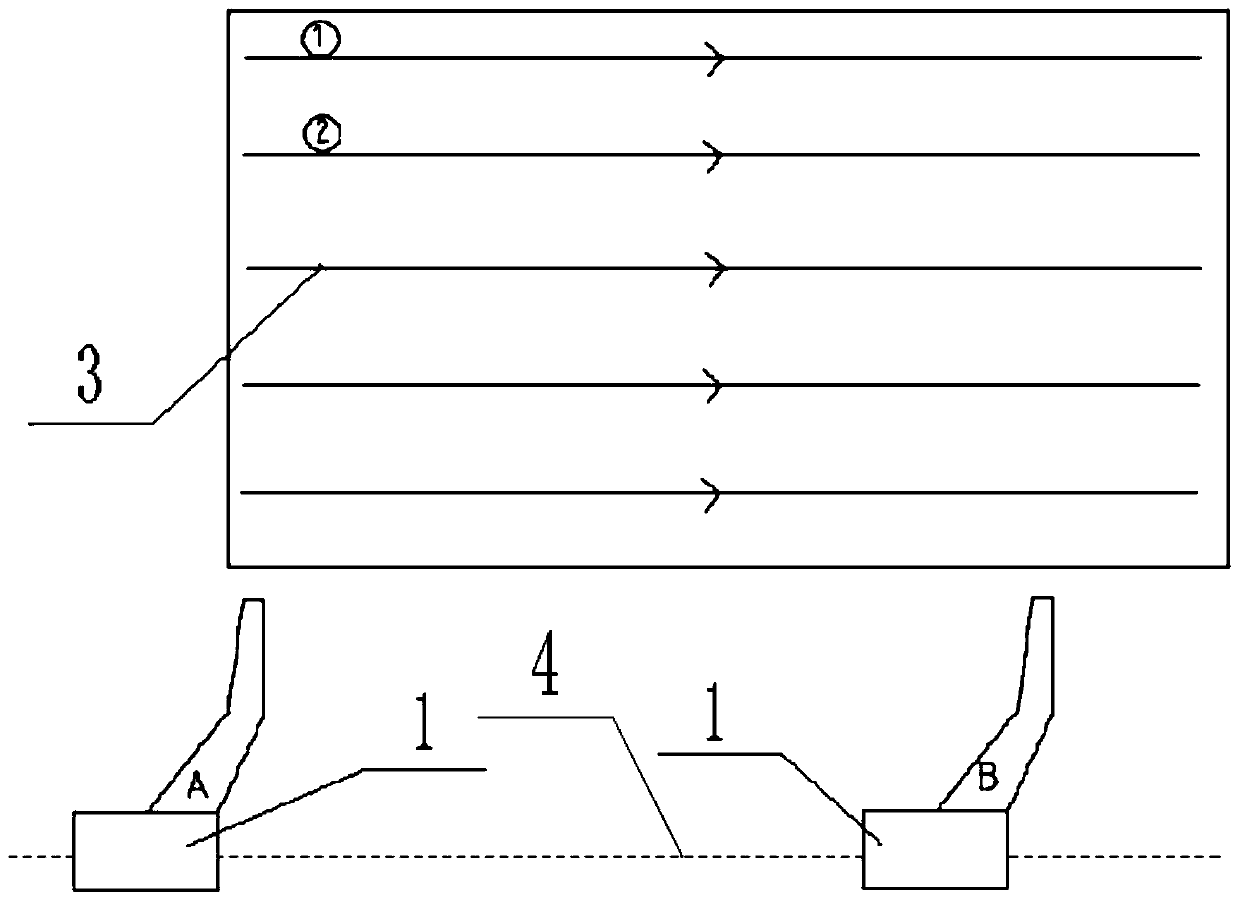

[0043] A typical embodiment of the present disclosure, such as figure 1 , figure 2 As shown, a kind of camouflage spraying sub-area operation method is provided, including the following steps:

[0044] Scan the spraying area, scan the area to be sprayed 2 of the workpiece, and obtain the length of the area to be sprayed according to the scan; during the scanning process, the obtained length is the length of the area to be sprayed parallel to the seventh axis of the spraying robot;

[0045] Set the division parameters, and determine the one-way path length of the spraying robot according to the range of motion of the spraying robot and the length of the area to be sprayed; the said one-way path length is the length that the spray gun moves on the same spraying path when the seventh axis of the spraying robot is fixed ;

[0046] Spraying area division, according to the determined one-way path length and the length of the area to be sprayed, the area to be sprayed is divided t...

Embodiment 2

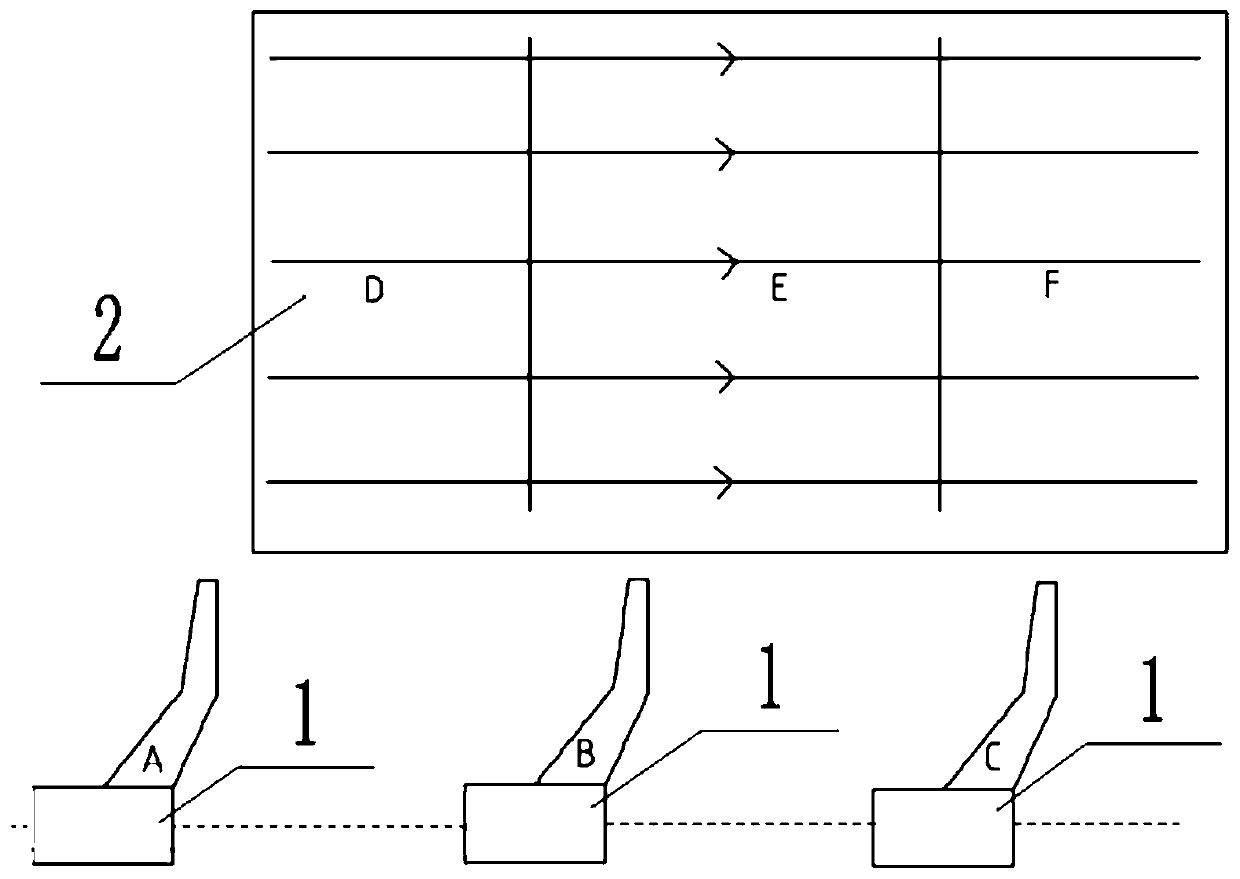

[0058] The present invention also provides another embodiment, which is different from Embodiment 1 in the division process of the spraying area.

[0059] According to the length of the area to be sprayed, the area to be sprayed is divided into several small areas along the length direction;

[0060] Calculate the idling length of the spraying robot along the seventh axis during the entire spraying process;

[0061] Re-divide the area to be sprayed according to the dry run length along the seventh axis;

[0062] Recalculate the length of the empty run;

[0063] Repeat the above process until the length of the empty run is 0, and several unit spraying areas are obtained, and the division of the area to be sprayed is completed.

[0064] Further, the length of the small area is less than the maximum working length of the spraying robot when the seventh axis is fixed; the length threshold for dividing the area to be sprayed is 0.6-2m.

[0065] Preferably, all the unit spray are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com