Spraying device used for automobile part machining

A technology for auto parts and spraying devices, applied in the direction of spraying devices, etc., can solve problems such as manual spraying, and achieve the effects of improving quality, facilitating cleaning, and reducing spraying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

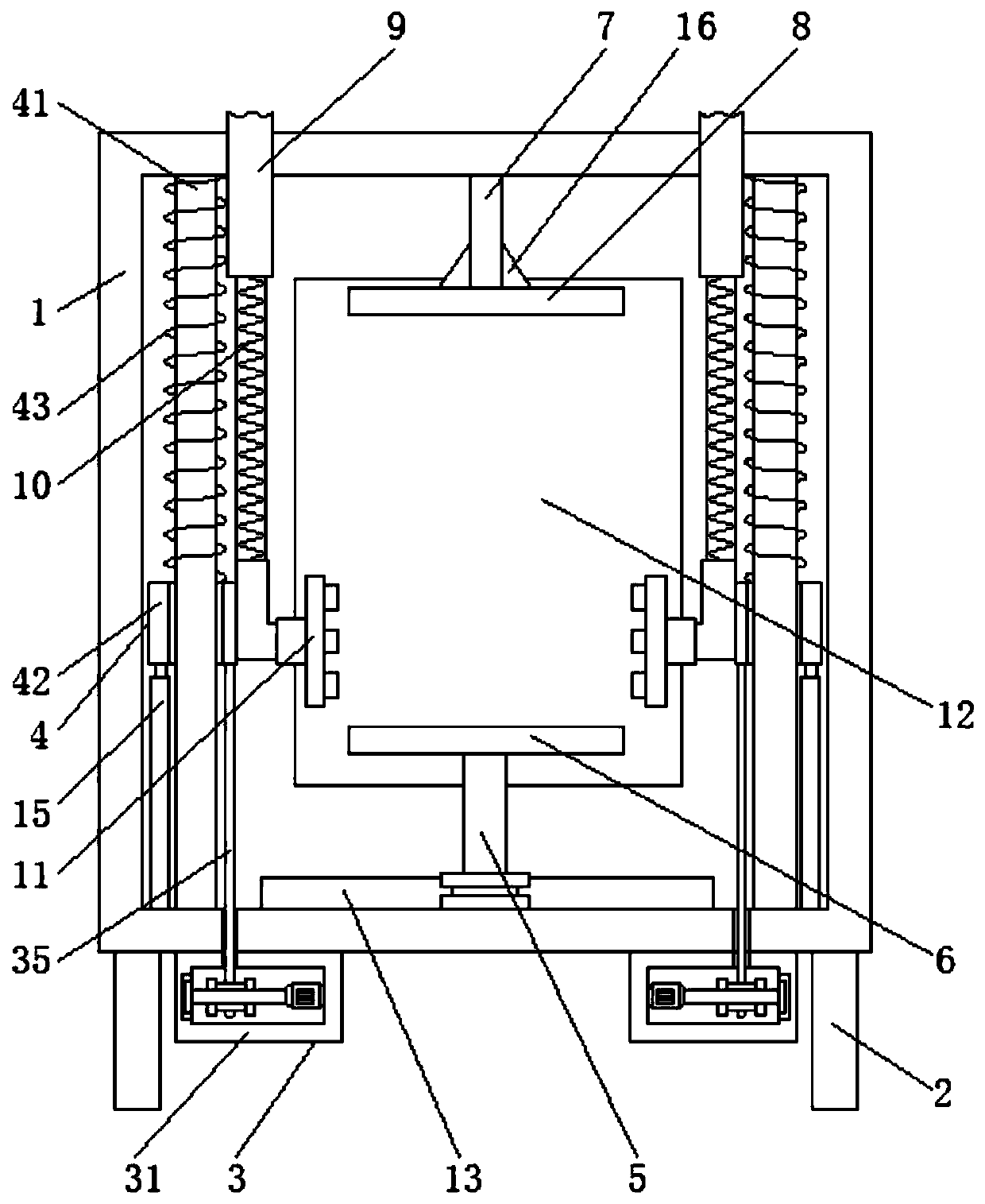

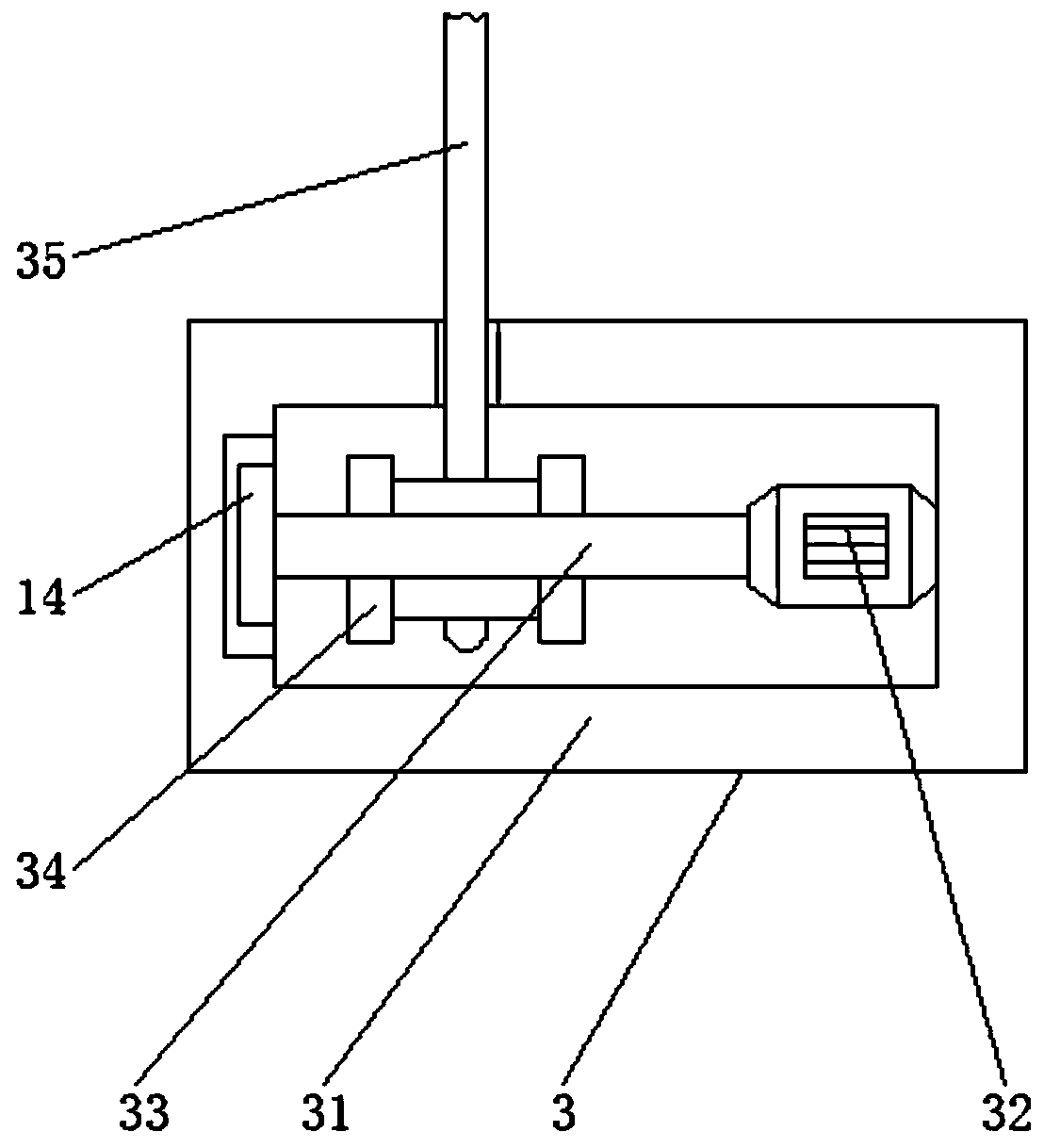

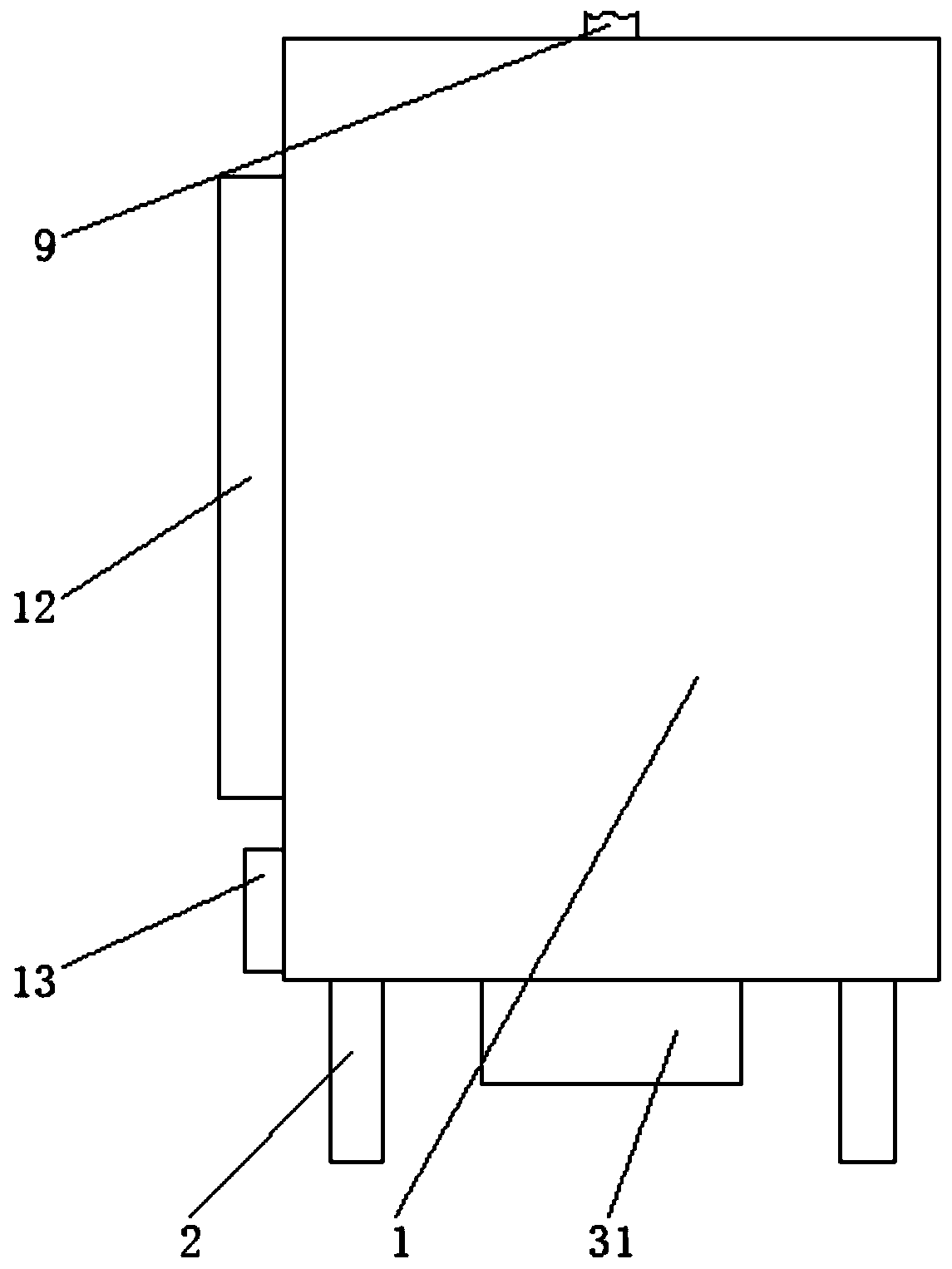

[0022] Example 1: See figure 1 or image 3 , a kind of spraying device for auto parts processing, comprising a fixed shell 1, the four corners of the bottom of the fixed shell 1 are fixedly connected with a support plate 2, by setting the support plate 2, it plays a role of supporting the fixed shell 1, and the bottom of the fixed shell 1 The left and right sides of the fixed shell 1 are fixedly connected with adjusting devices 3, the left and right sides of the inner wall of the fixed shell 1 are equipped with movable devices 4, the midpoint of the bottom of the fixed shell 1 inner wall is fixedly connected with a cylinder 5, and the top of the cylinder 5 is fixedly connected with a fixed Plate 6, the top of the inner wall of the fixed shell 1 and the position corresponding to the fixed plate 6 are fixedly connected with a connecting plate 7, the bottom of the connecting plate 7 is fixedly connected with a stable plate 8 that is compatible with the fixed plate 6, and the left...

Embodiment 2

[0027] Embodiment 2: On the basis of the first embodiment, a T-shaped thin bar with a scale is added inside each nozzle 11, so that the verticality of the workpiece when it is clamped and the centering or spacing of the workpiece on the fixed plate 6 Placement, the specific design is that each nozzle 11 is provided with a T-shaped thin strip inside, and the T-shaped thin strip includes a straight section and two transverse sections perpendicular to the straight section, and one end of the straight section is connected to the intersection point of the two transverse sections. Scale and all can be stretched and stretched on section and two transverse sections, and the end of these two transverse sections and the front end on the intersection point of two transverse sections are provided with magnetite, and the specific working process of this embodiment is as follows: use When first pulling out the T-shaped thin strips on the inner sides of the two nozzles 11 to make the straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com