Patents

Literature

31results about How to "Realize automatic unpacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

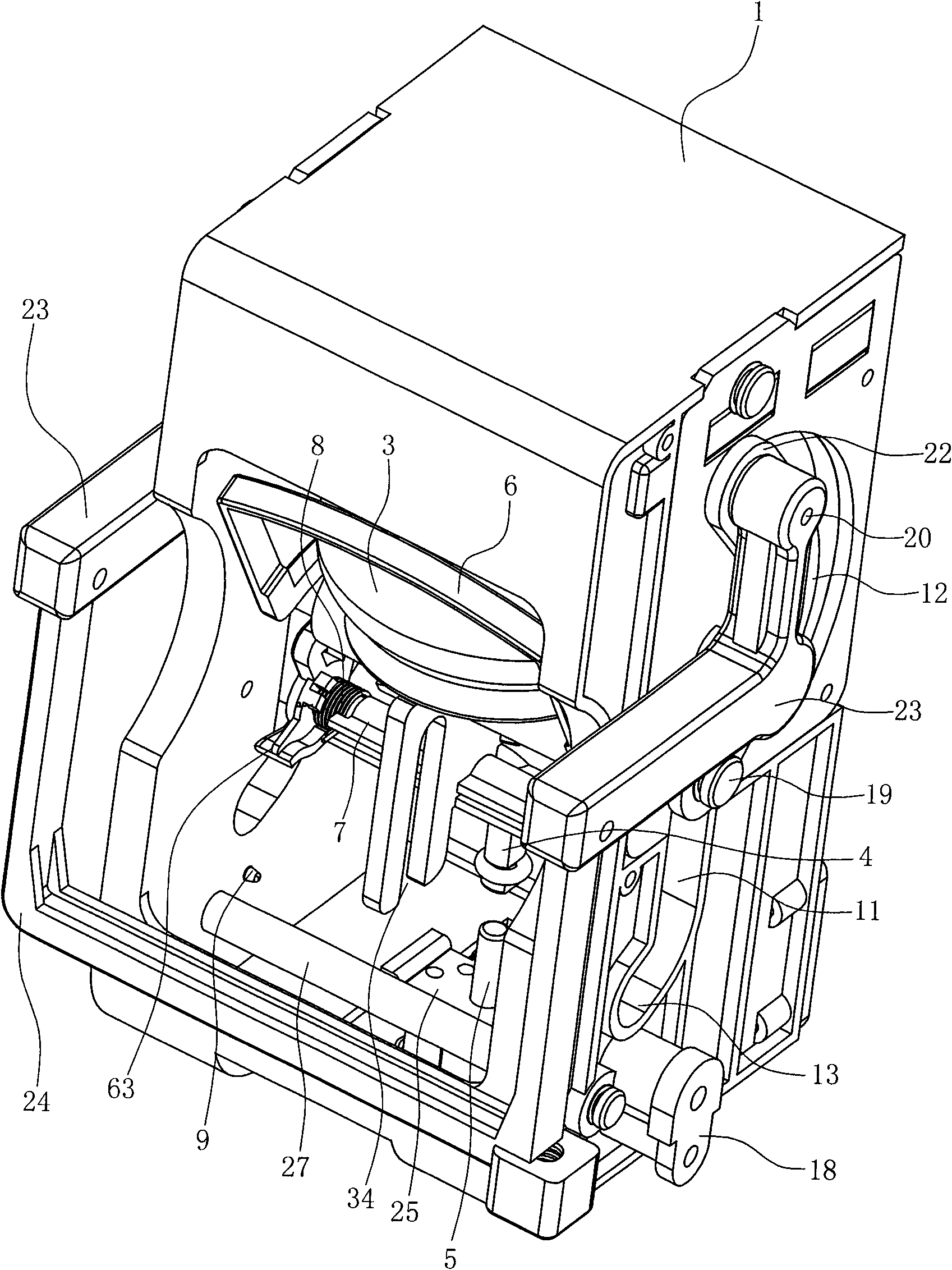

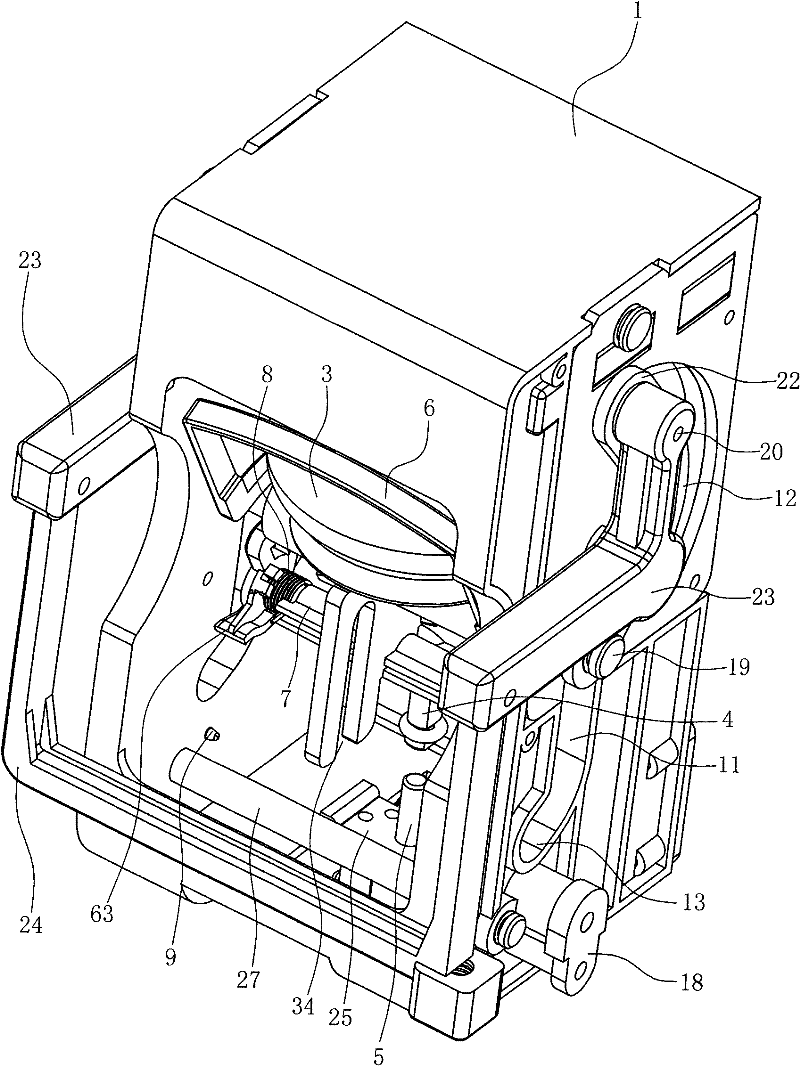

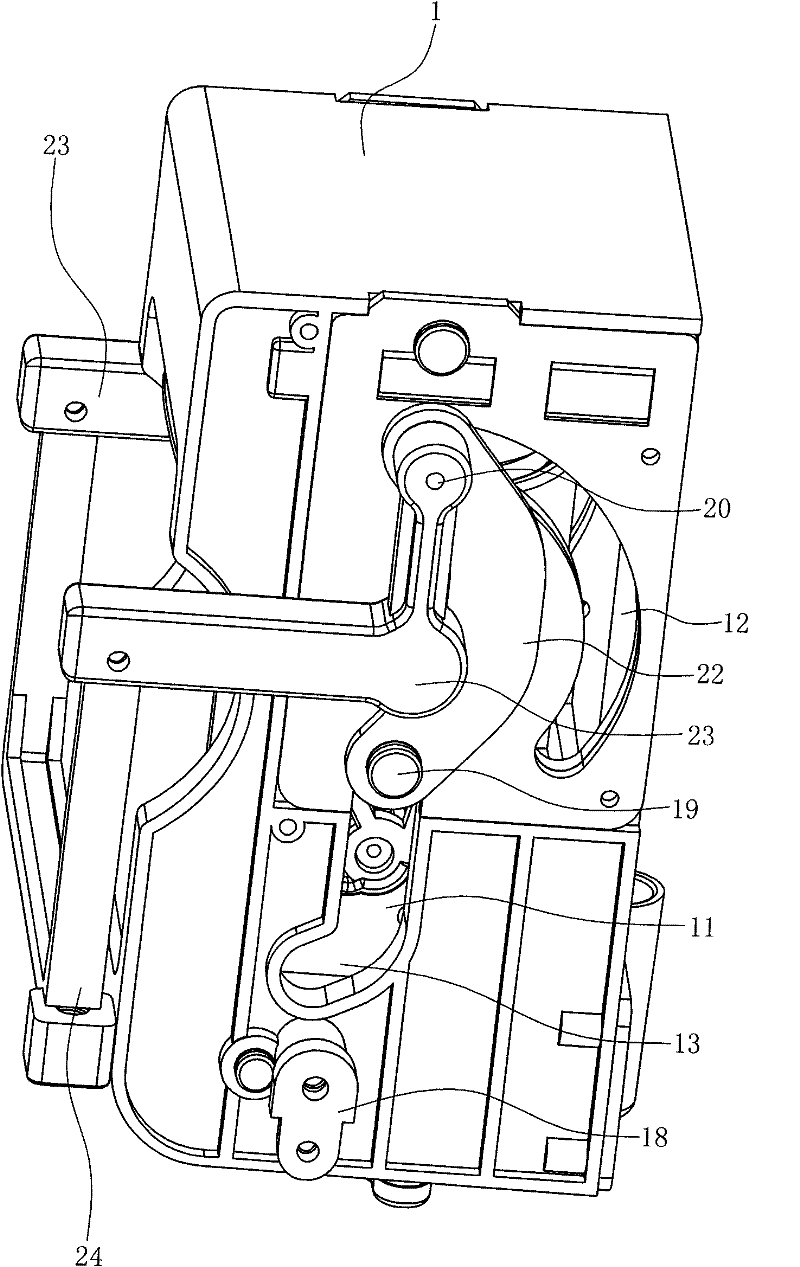

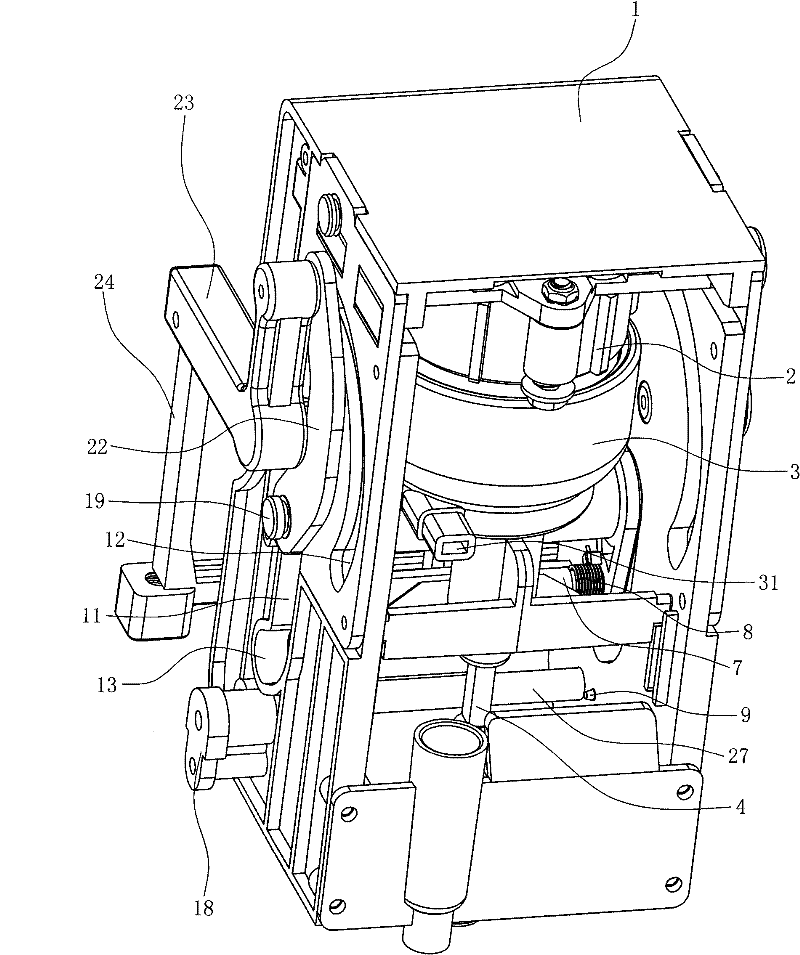

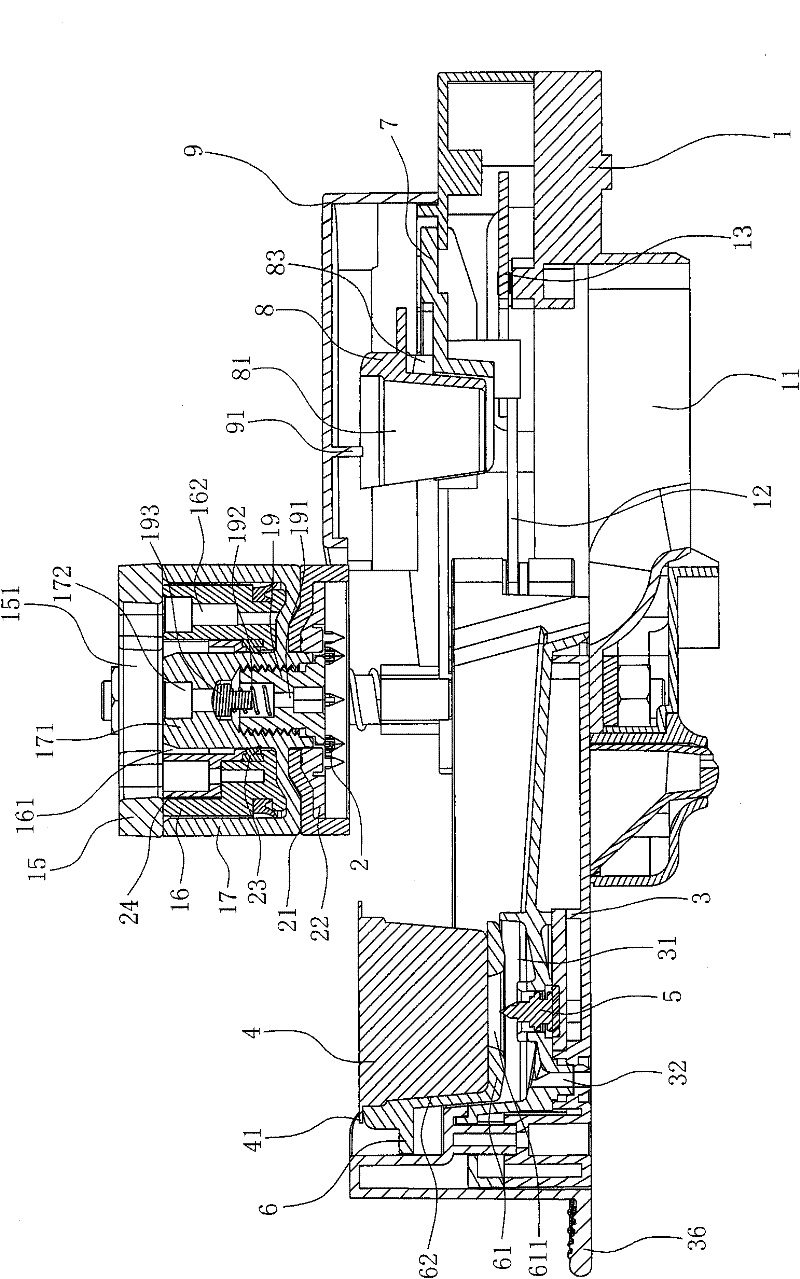

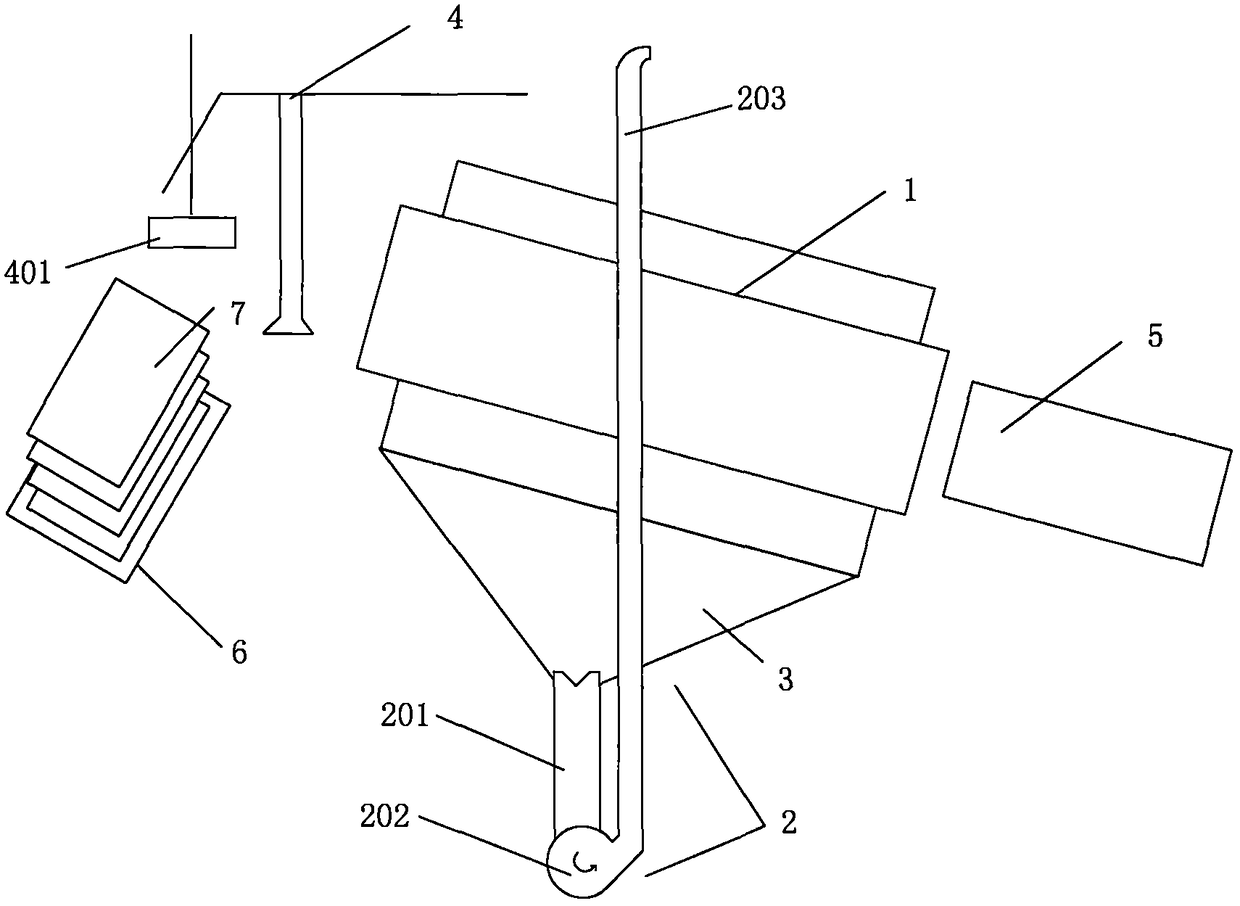

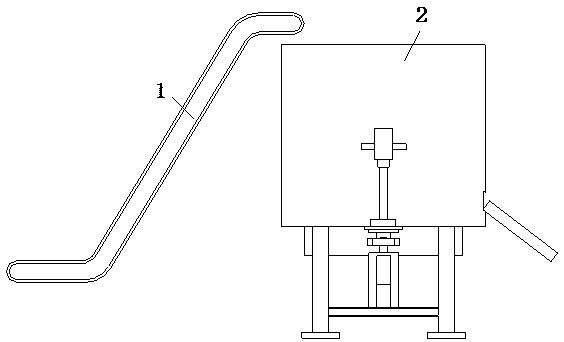

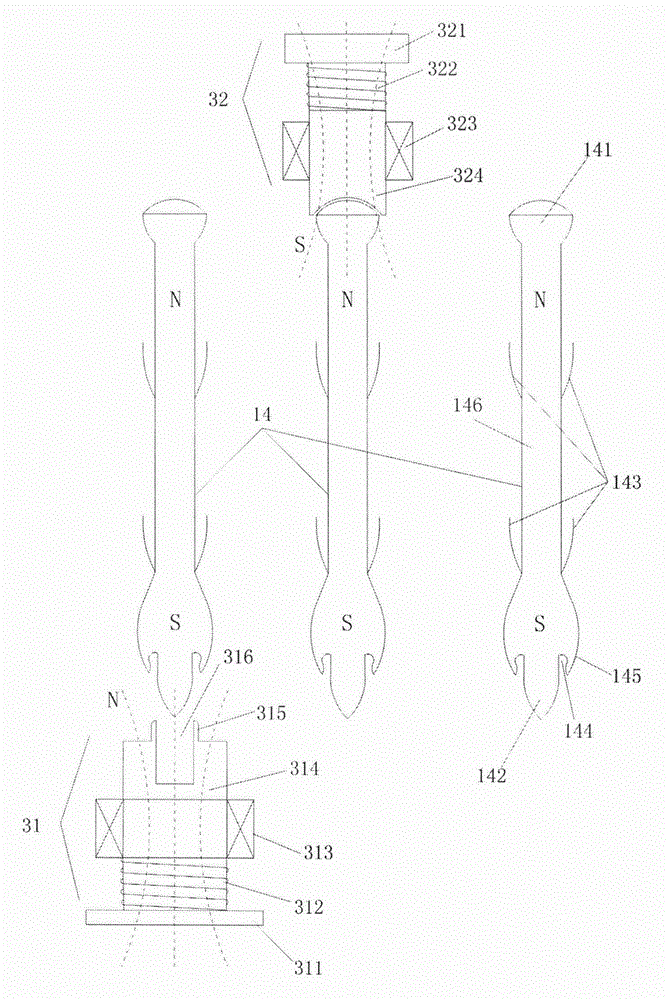

Beverage extraction plant extracting vertically

The invention relates to a beverage extraction plant extracting vertically, comprising a stand, a first machine element and a second machine element, wherein, the second machine element is arranged at the lower part in the stand and can glide relative to the first machine element up and down. The beverage extracting device is characterized by also comprising a push rod, a blocking rod, a scraping piece, a connection shaft, a torsional spring and two blocking pieces, wherein, the push rod is movably arranged on the second machine element passing through the bottom wall of a concave cavity; the blocking rod is arranged at the bottom of the stand and is supported by a spring and keeps moving upwards; the scraping piece is provided with a horizontal driving lever and a connection rod positioned at two ends of the driving lever and extending downwards, and the bottom of the connection rod is provided with an elastic blocking part; the connection shaft is arranged at the lower part of the second machine element, and the lower end of the connection rod is sheathed at the two ends of the connection shaft in a rotating manner; the torsional spring is sheathed on the connection shaft and acts on the scraping piece; and the two blocking elements are respectively inserted on the inner end faces at the left side wall and the right side wall of the stand, and are matched with the elastic blocking part. The beverage extracting device can realize automatically packaging and has convenient use.

Owner:NINGBO AAA GROUP ELECTRIC APPLIANCE

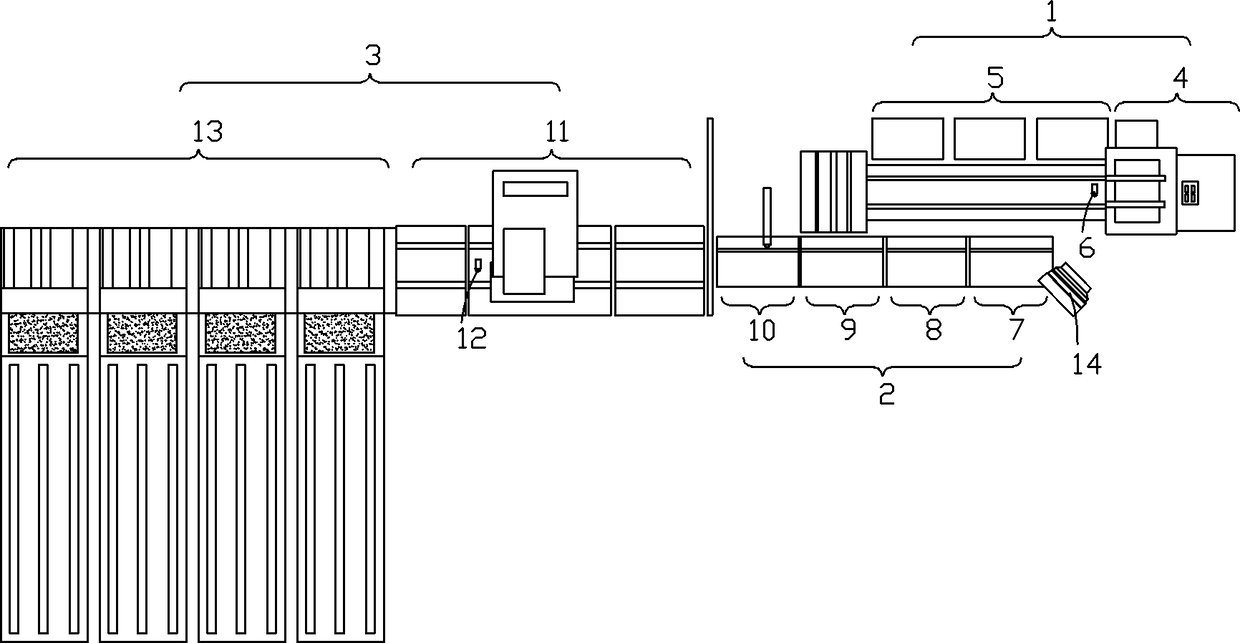

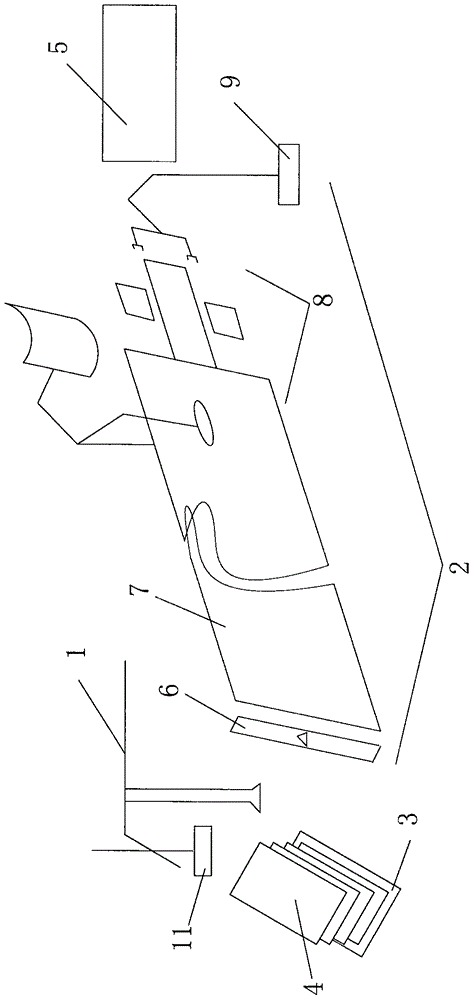

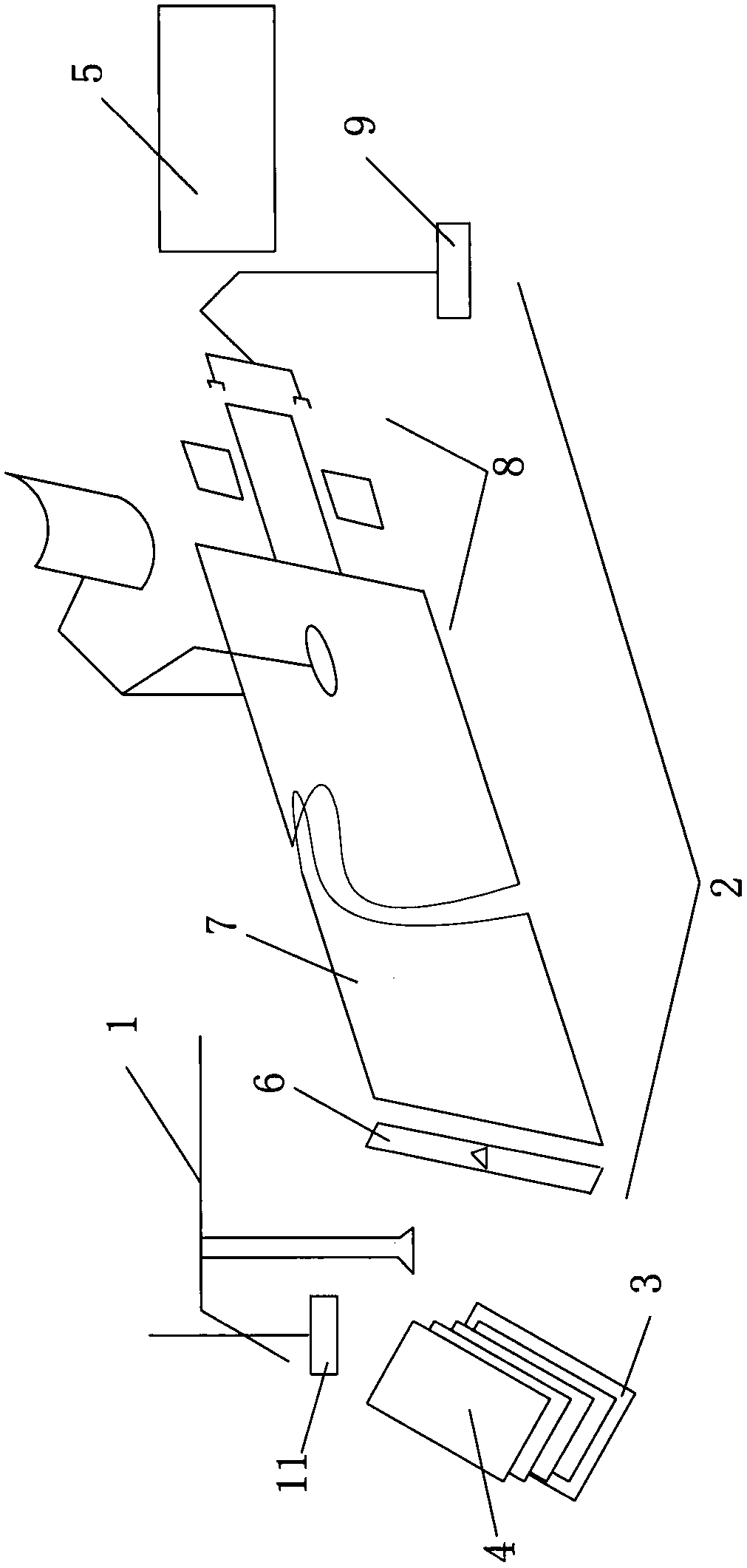

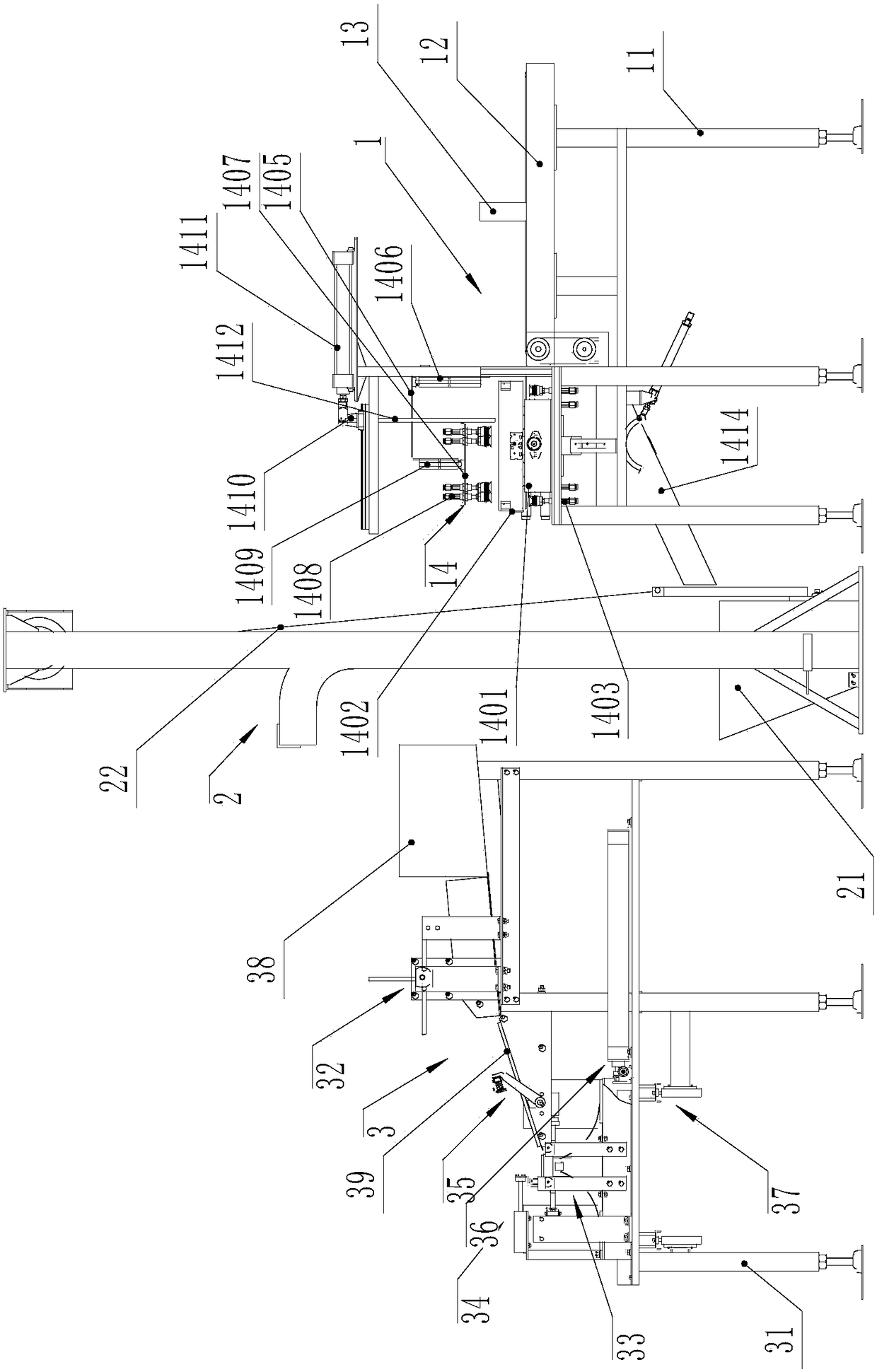

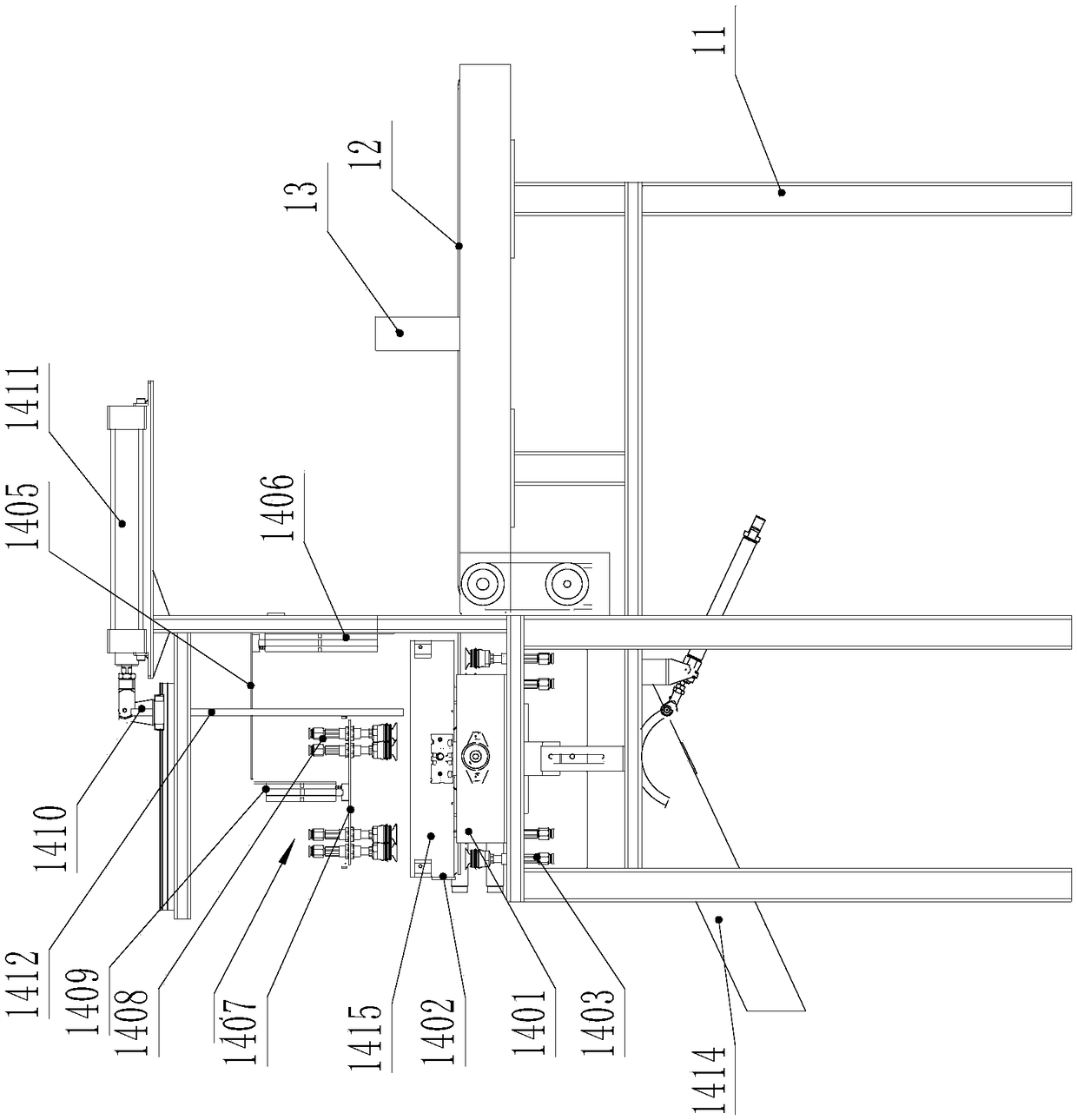

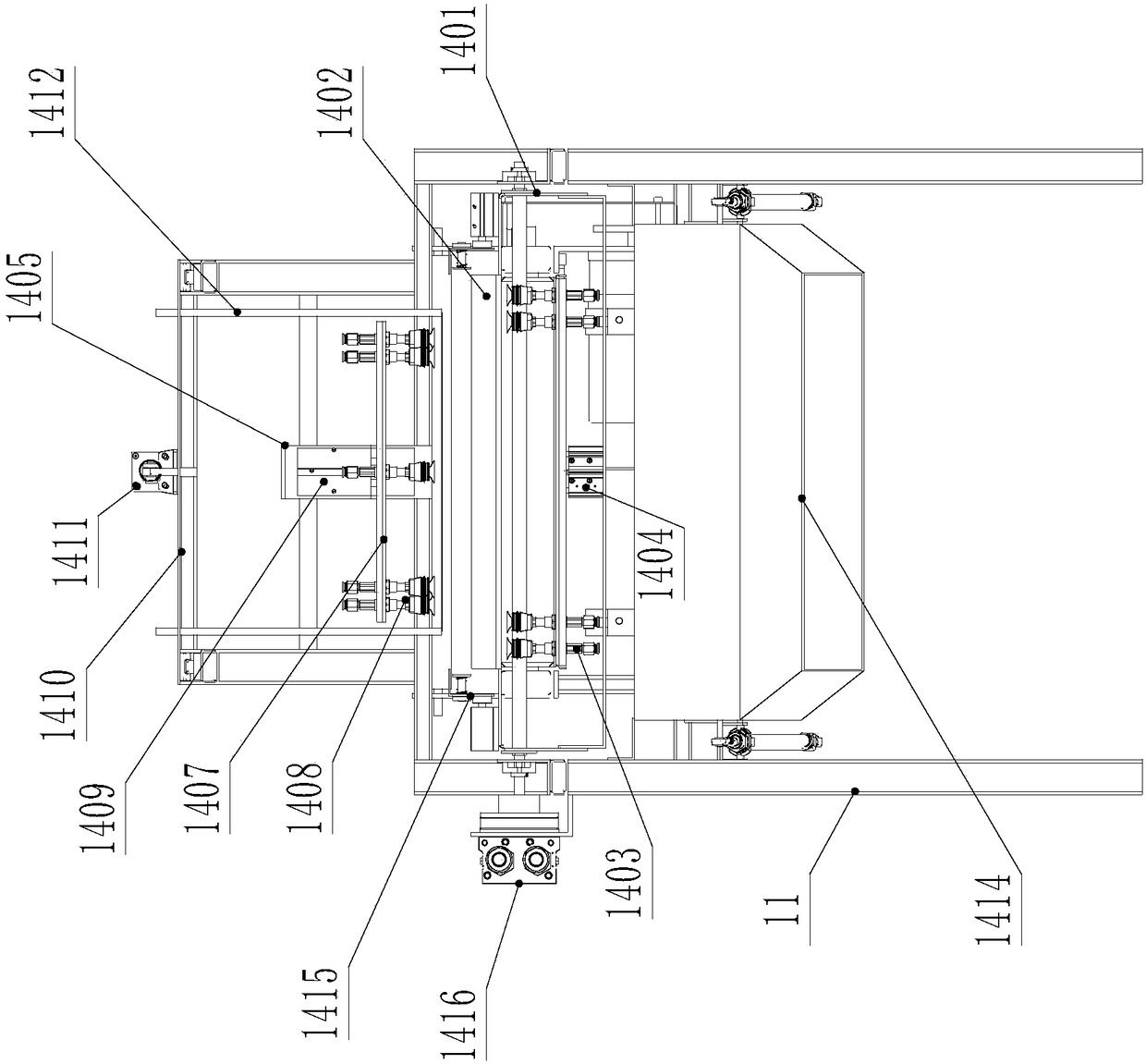

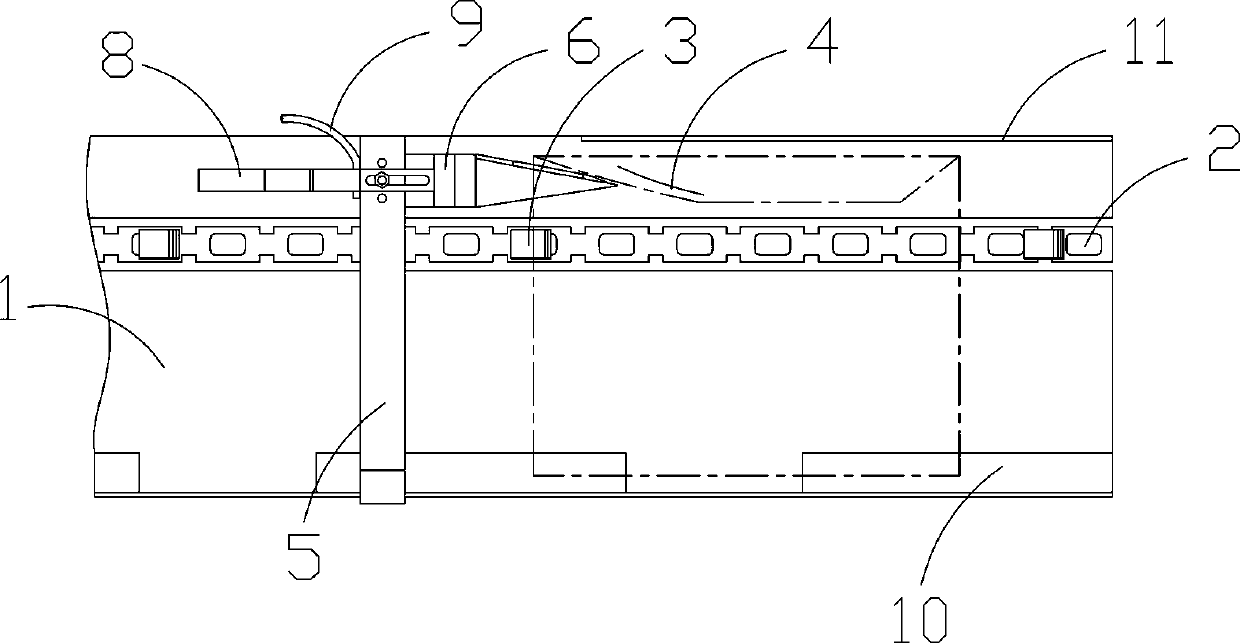

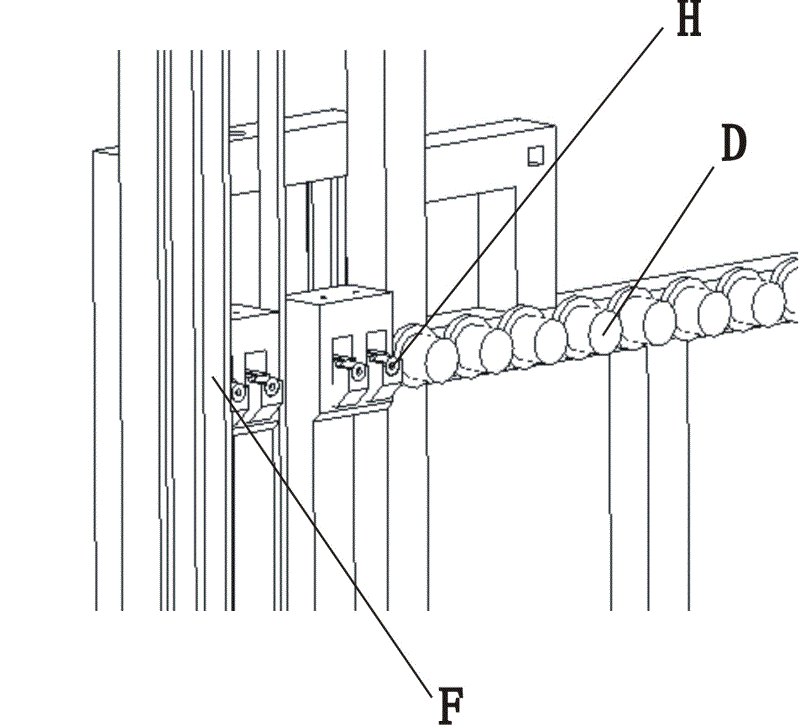

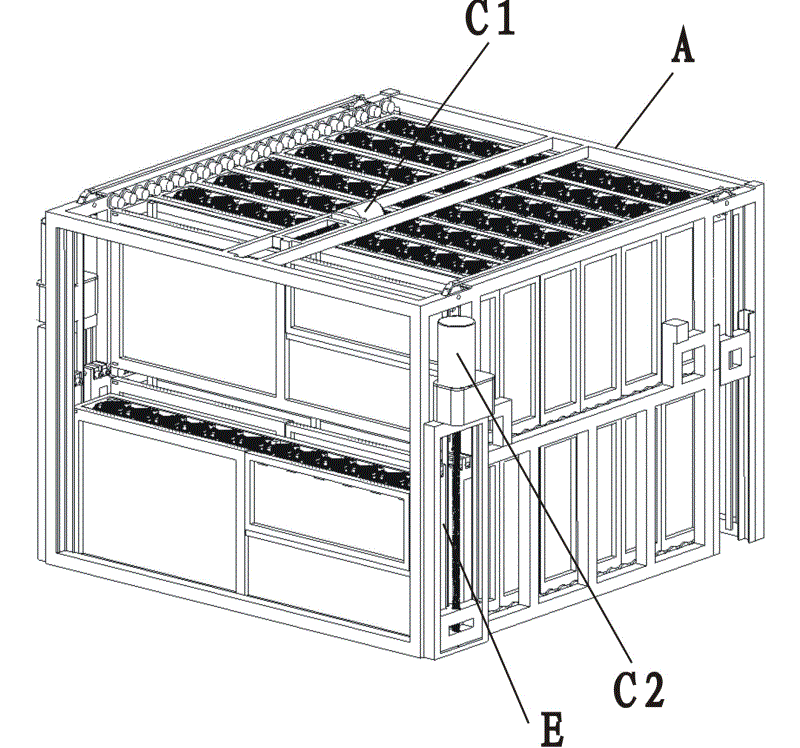

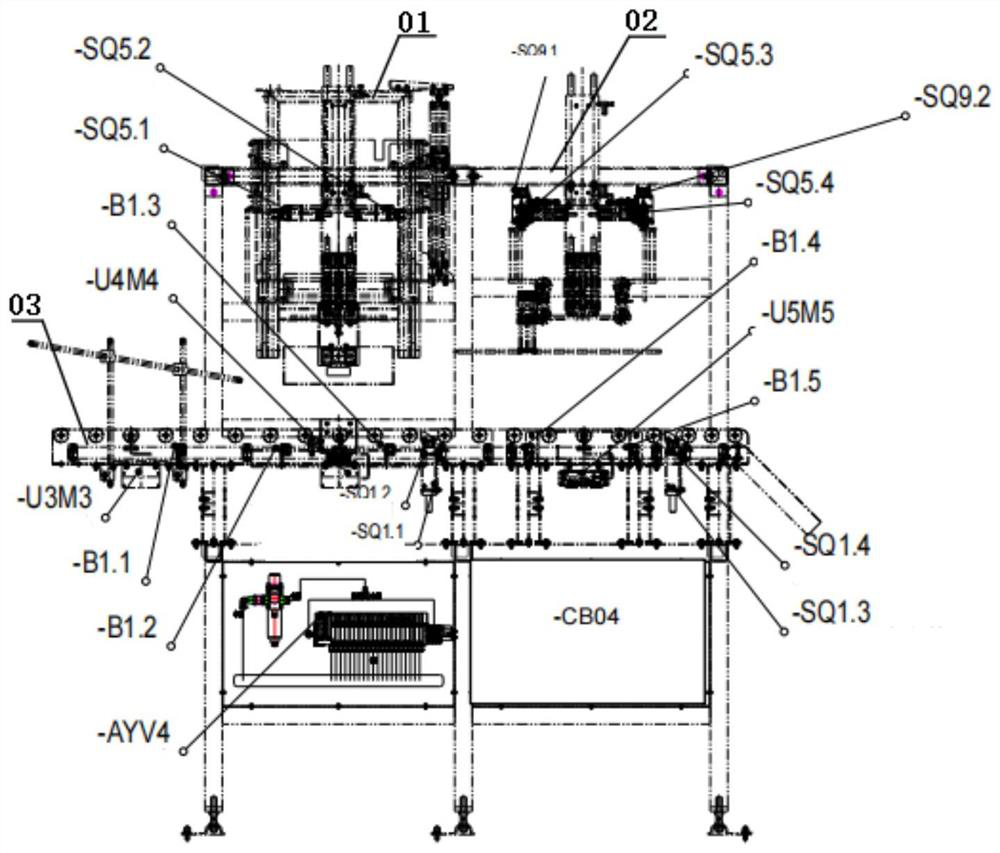

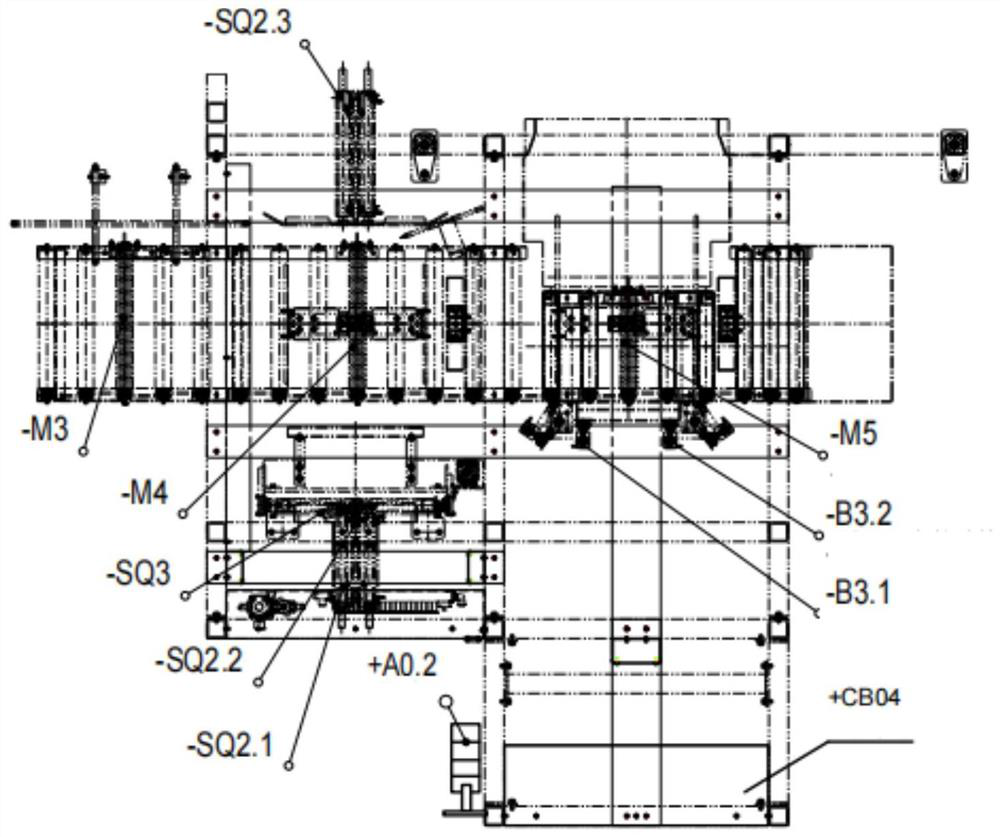

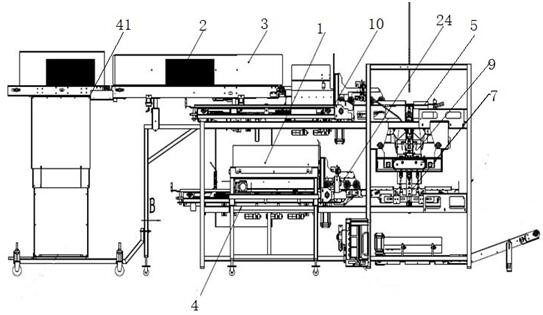

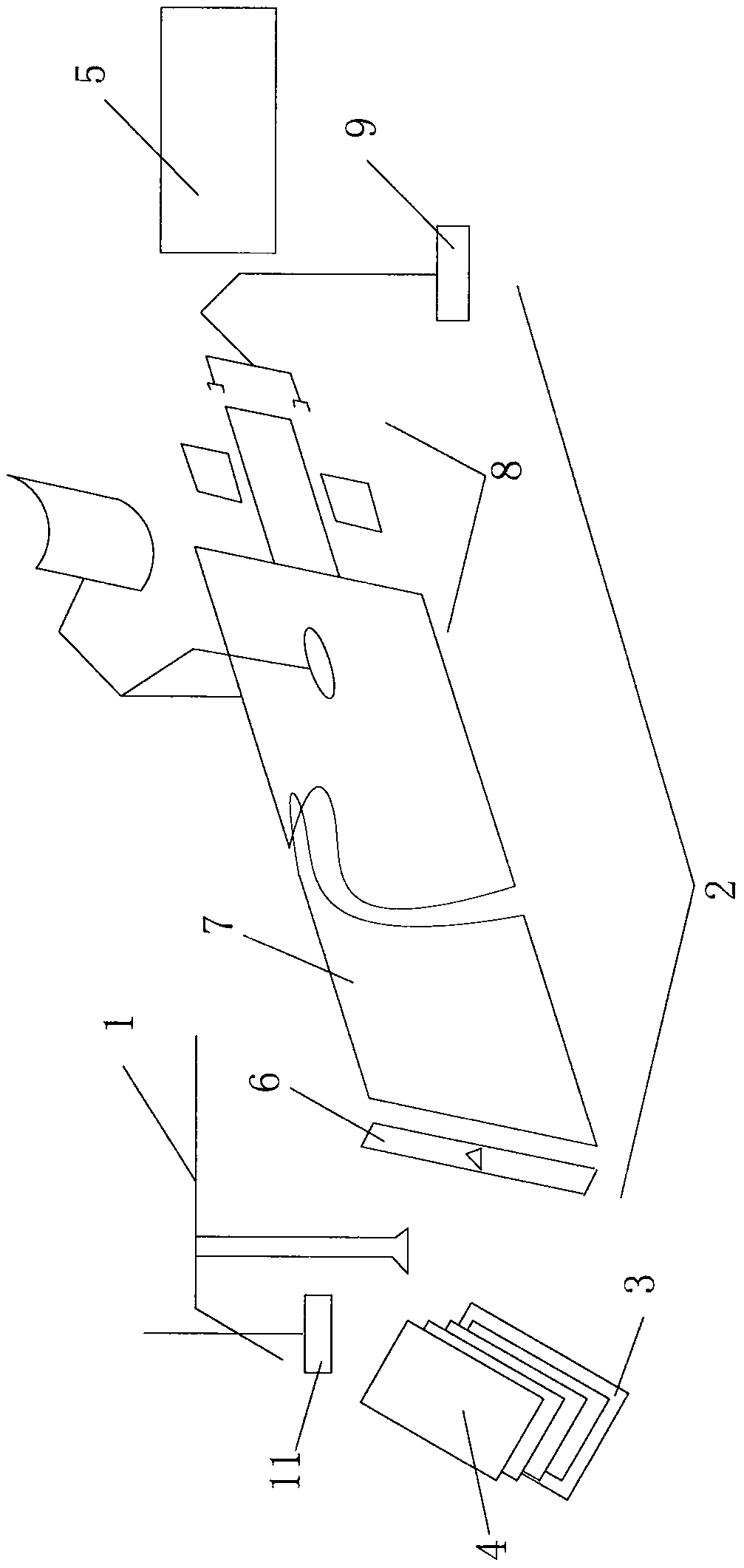

Automatic mail packaging and sorting production line

PendingCN108906640AImprove packaging efficiencyImprove sorting efficiencySortingIndividual articlesProduction linePersonal computer

The invention discloses an automatic mail packaging and sorting production line. The automatic mail packaging and sorting production line comprises a conveying line A, a conveying line B and a conveying line C. A letter conveying device and an insert feeding device are sequentially arranged on the conveying line A, and a bar code scanner A is arranged. An envelope feeding device, an envelope sealing cover unsealing device, a letter bagging device and an envelope sealing device are sequentially arranged on the conveying line B. A mail address tag pasting device is arranged on the conveying lineC, and a bar code scanner B is arranged. A mail sorting device is arranged at the tail end of the conveying line C. The bar code scanner A and the bar code scanner B are in communication connection with an industrial personal computer, and the industrial personal computer controls the mail address tag pasting device and the mail sorting device in real time. According to the automatic mail packaging and sorting production line, the links of letter and envelope feeding, mail bagging operation and subsequent mail sorting on a mail packaging production line are updated and optimized, the efficiency of mail packaging and sorting is greatly improved, the workload of workers is greatly reduced, and the work intensity of the workers is reduced.

Owner:中国邮政速递物流股份有限公司黄石市分公司

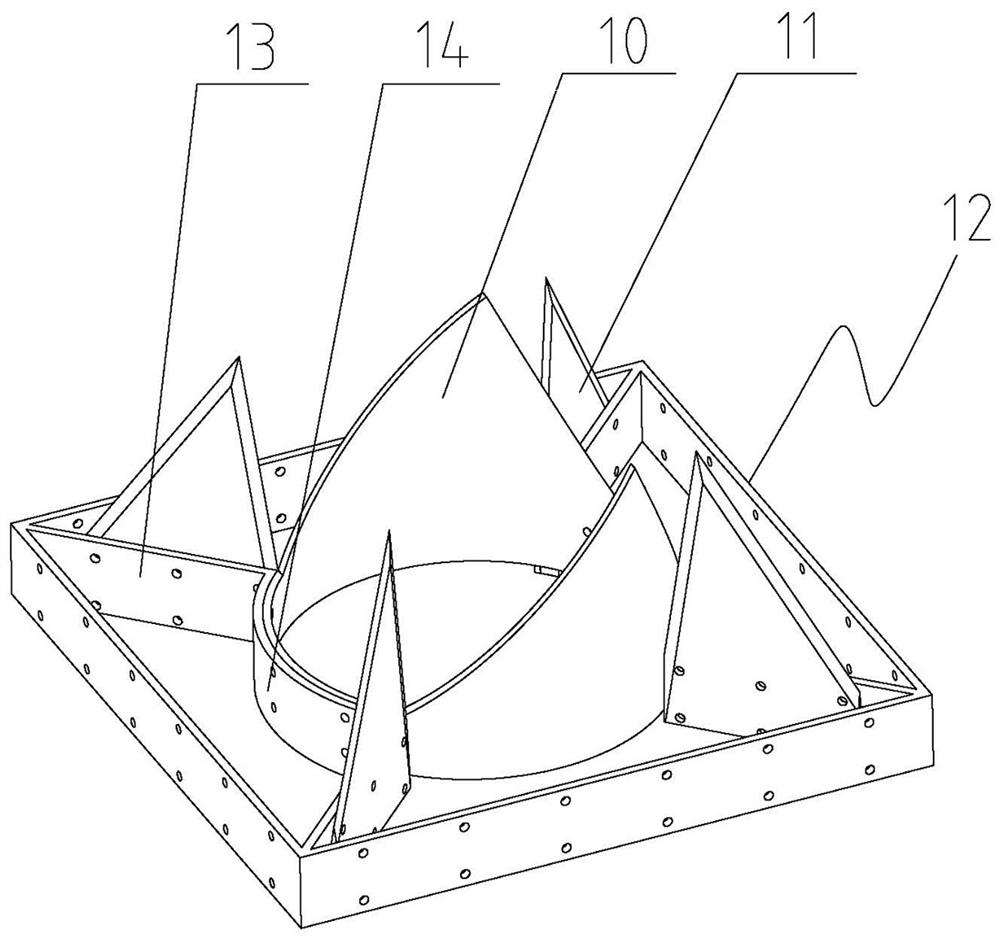

Washing type automatic unpacking system

PendingCN108146754APrevent spillageQuick changeCleaning using liquidsUnpacking by cuttingAutomatic controlEngineering

The invention relates to a washing type automatic unpacking system. The washing type automatic unpacking system comprises an integrated box. The integrated box comprises a feeding chute, a sieving cylinder box, a waste bag outlet and a discharging hopper. The front end of the sieving cylinder box is provided with the feeding chute. The rear end of the sieving cylinder box is provided with the waste bag outlet. A waste bag outlet automatic control opening and closing door is arranged at the position of the waste bag outlet. A rear drive sieving mechanism is arranged above the waste bag outlet.The bottom end of the sieving cylinder box is connected with the discharging hopper. The top end of the sieving cylinder box is provided with a dedusting opening. A bag breaking box is installed abovethe feeding chute. A rapid cutter changing mechanism and a bag breaking mechanism with a lip-shaped seal are arranged at the position where the feeding chute is located on the bag breaking box. An inlet sealing mechanism is arranged above a packaging bag inlet. The front face of the sieving cylinder box is provided with a quick-opening observation access door. The bag breaking box and the sievingcylinder box are internally provided with 360-degree automatic washing systems. Compared with the prior art, the washing type automatic unpacking system can achieve automatic unpacking and can be rapidly mounted, demounted and overhauled, and sealed type rapid washing is achieved.

Owner:HANRUI PUZER BULK HANDLING TECH SHANGHAI

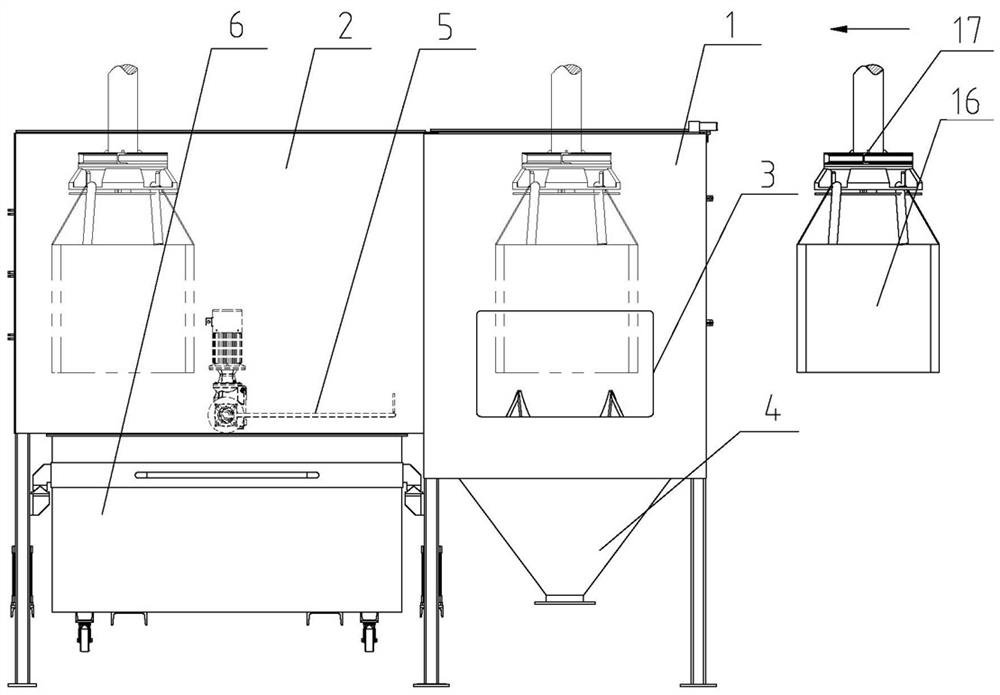

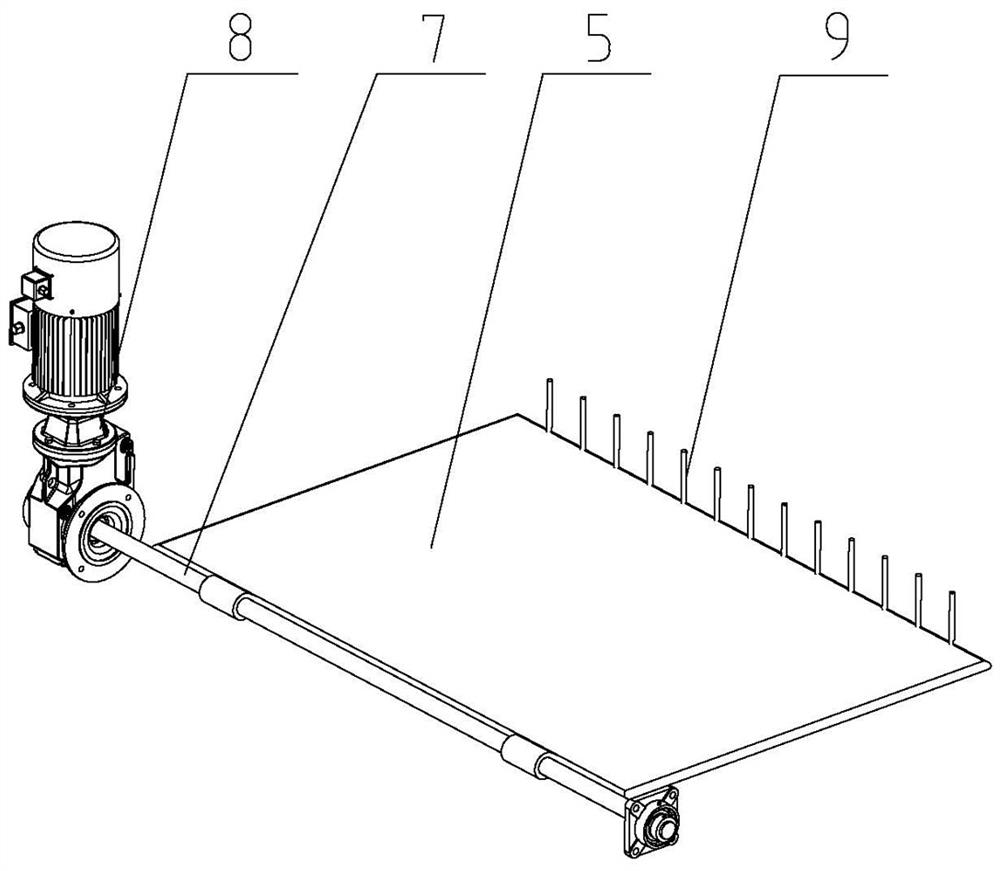

Automatic ton bag opening machine

PendingCN113955259ASmooth entryEnter the discharge bin, the spreader hangs the waste bag and enters smoothlyLoading/unloadingUnpacking by cuttingElectric machineryEngineering

The invention relates to the technical field of ton bag opening and blanking, in particular to an automatic ton bag opening machine which can achieve automatic ton bag opening and collecting, reduce labor intensity and improve efficiency and safety. The machine comprises a bag breaking cutter and a lifting appliance used for hanging ton bags, and is characterized by further comprising a bag opening bin and a bag collecting bin which are arranged side by side and integrated into a whole. The bag breaking cutter is installed in the bag opening bin, the bottom of the bag opening bin is connected with a discharging bin, a turnover pressing plate is installed in the bag collecting bin, one end of the pressing plate is connected with a driving motor through a rotating shaft, a row of teeth is installed at the other end of the pressing plate, and a waste bag collecting mechanism is arranged at the bottom of the bag collecting bin.

Owner:WUXI RICH INTELLIGENT EQUIP CO LTD

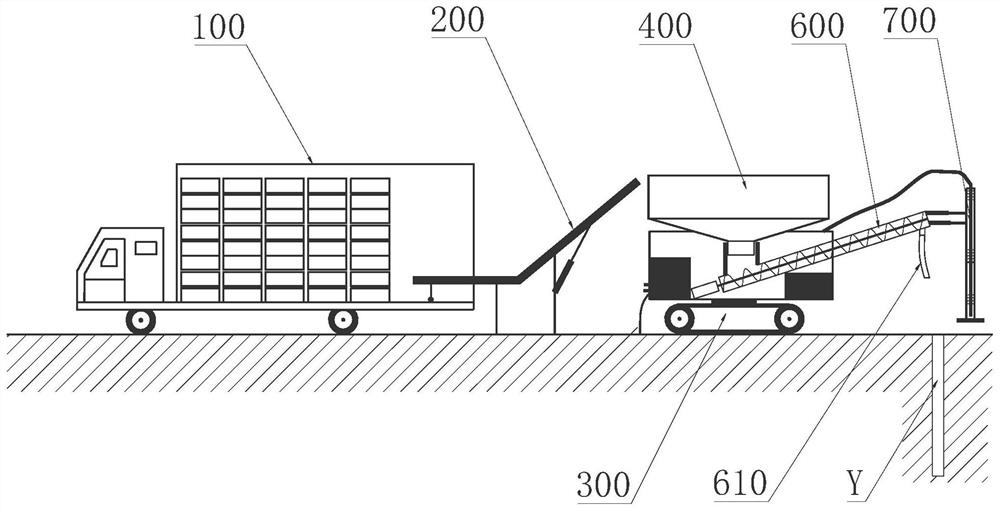

Vibrating and residue removing manner based automatic unpacking and charging method

ActiveCN106628460ARealize automatic unpackingWill not polluteBags openingEngineeringMechanical engineering

The invention discloses a vibrating and residue removing manner based automatic unpacking and charging method. The method comprises the following steps: material packs are carried onto a conveyor belt; the surface of the conveyor belt is obliquely upward, and a first pack sensor for detecting the material packs is arranged on the conveyor belt; a collector is arranged below the conveyor belt, and the materials are collected and then charged; the material packs enter the front end position of the conveyor belt, and the middle part of the lower side edge of each material pack is cut through a cutting mechanism which is mounted close to the front end of the conveyor belt; each cut material pack is continuously conveyed; after that each material pack arrives at a preset position at the rear end of the conveyor belt is detected, a pack vibrating mechanism at the rear end of the conveyor belt works in a manner of vibrating and flapping each material pack to accelerate the discharging of residues; when the pack vibrating mechanism vibrates and flaps the material packs, a pack dragging mechanism grips the material packs and drags the material packs to move forwards, and the material packs are dragged away from the conveyor belt while the residues are completely discharged. With the adoption of the method, the unpacking is automatically carried out, and particles can be prevented from being polluted by broken packing bags. Therefore, the residues can be avoided, and as a result, the waste on the raw materials can be prevented.

Owner:CHINA JILIANG UNIV

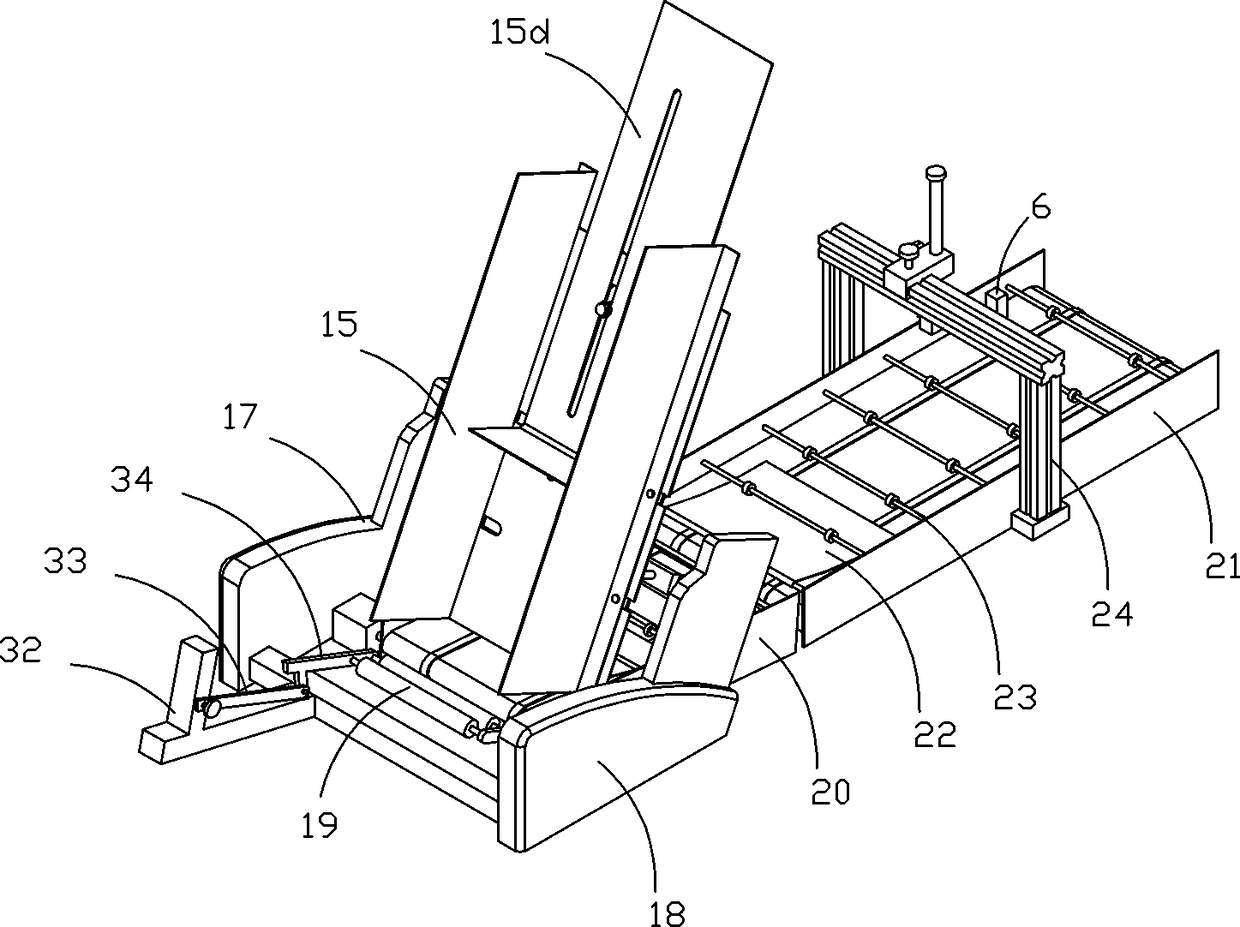

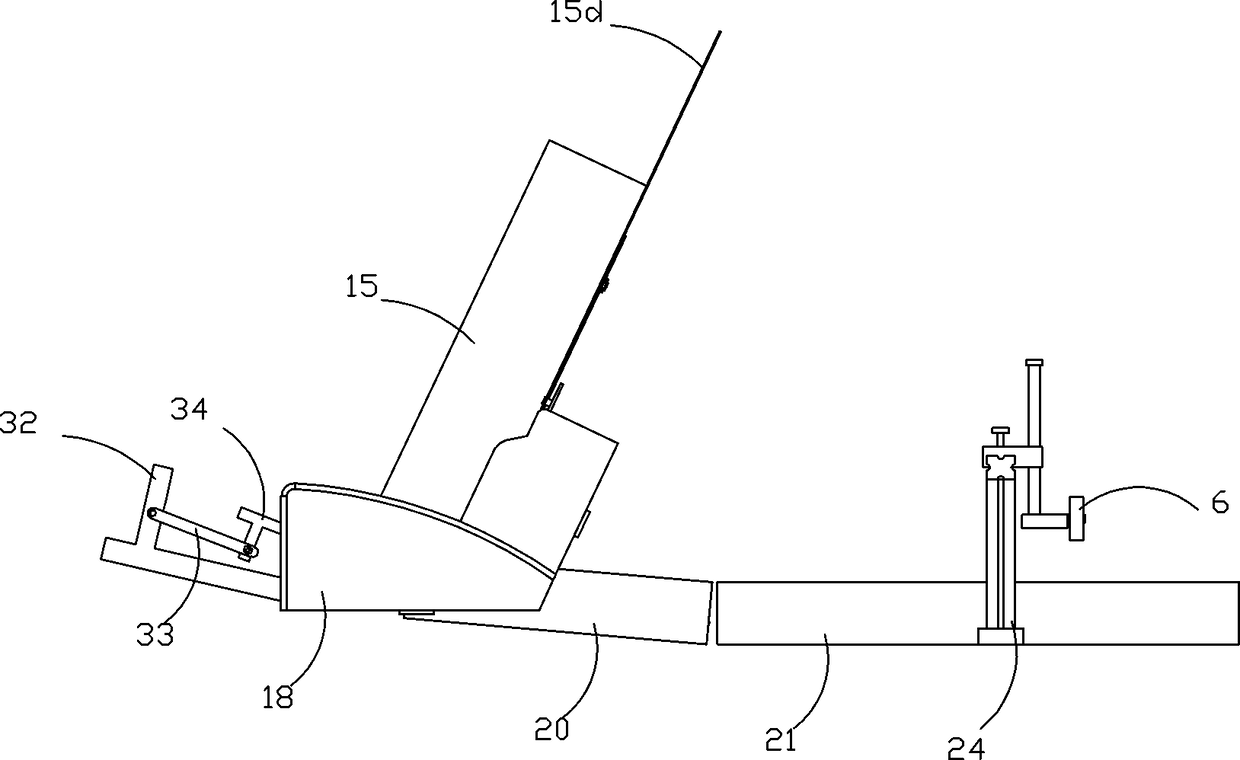

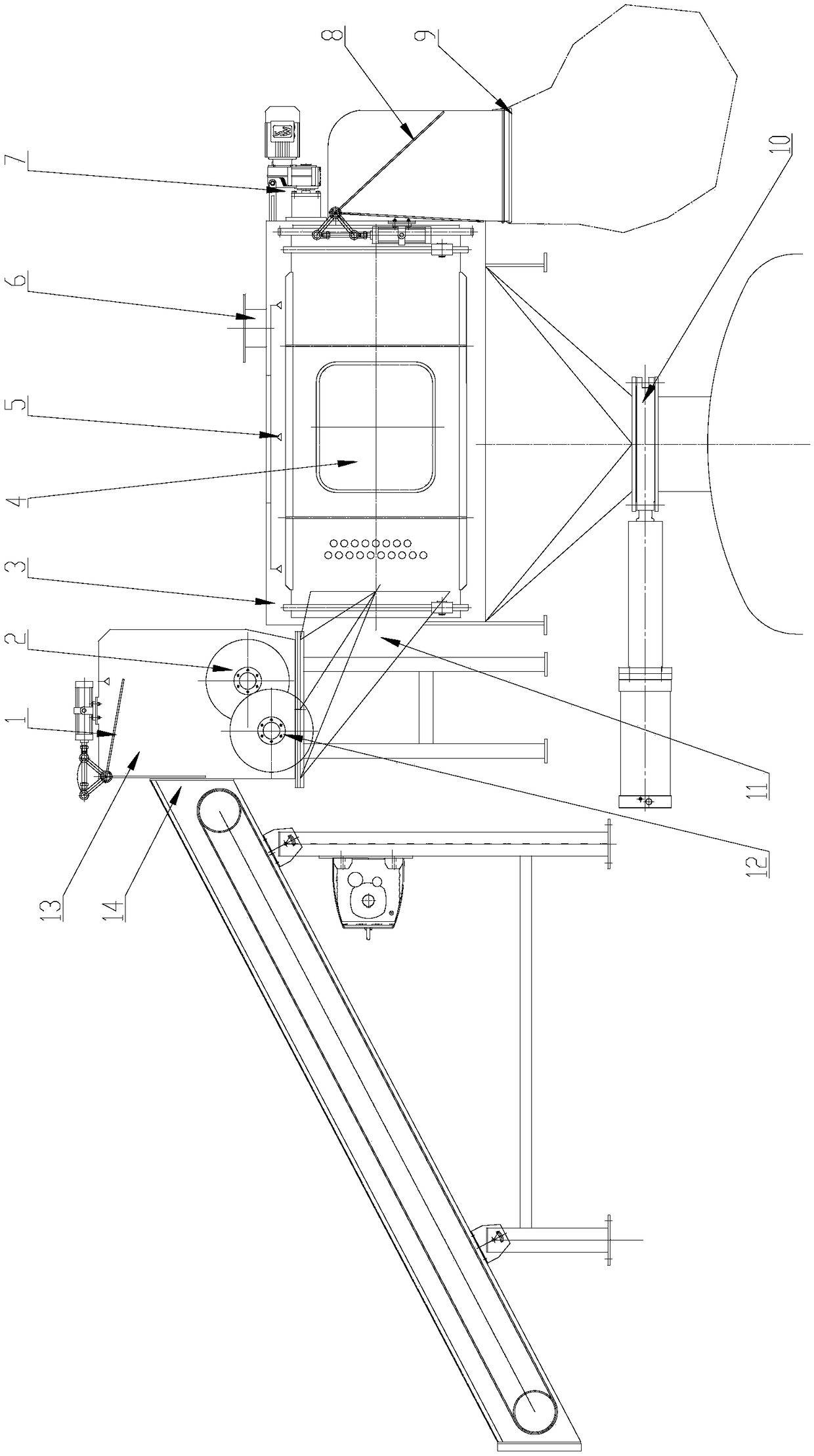

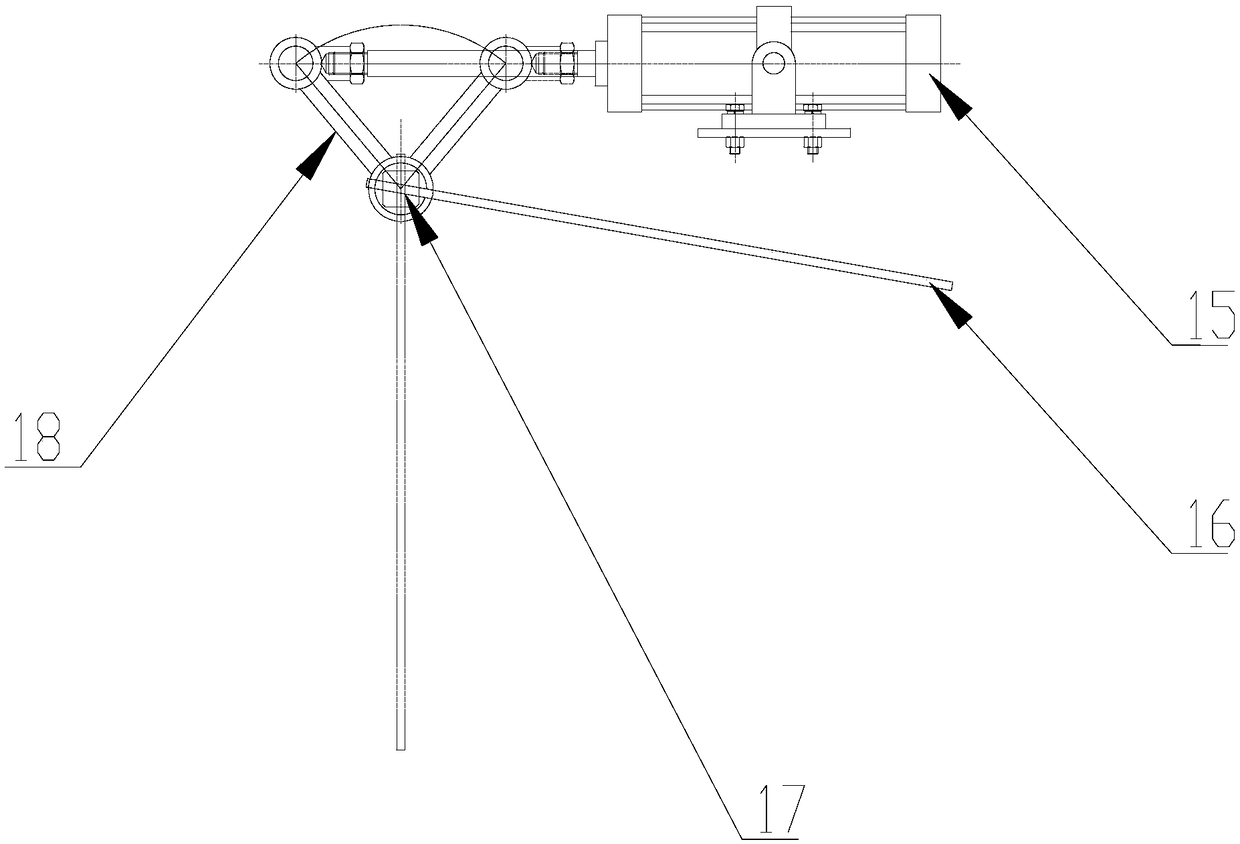

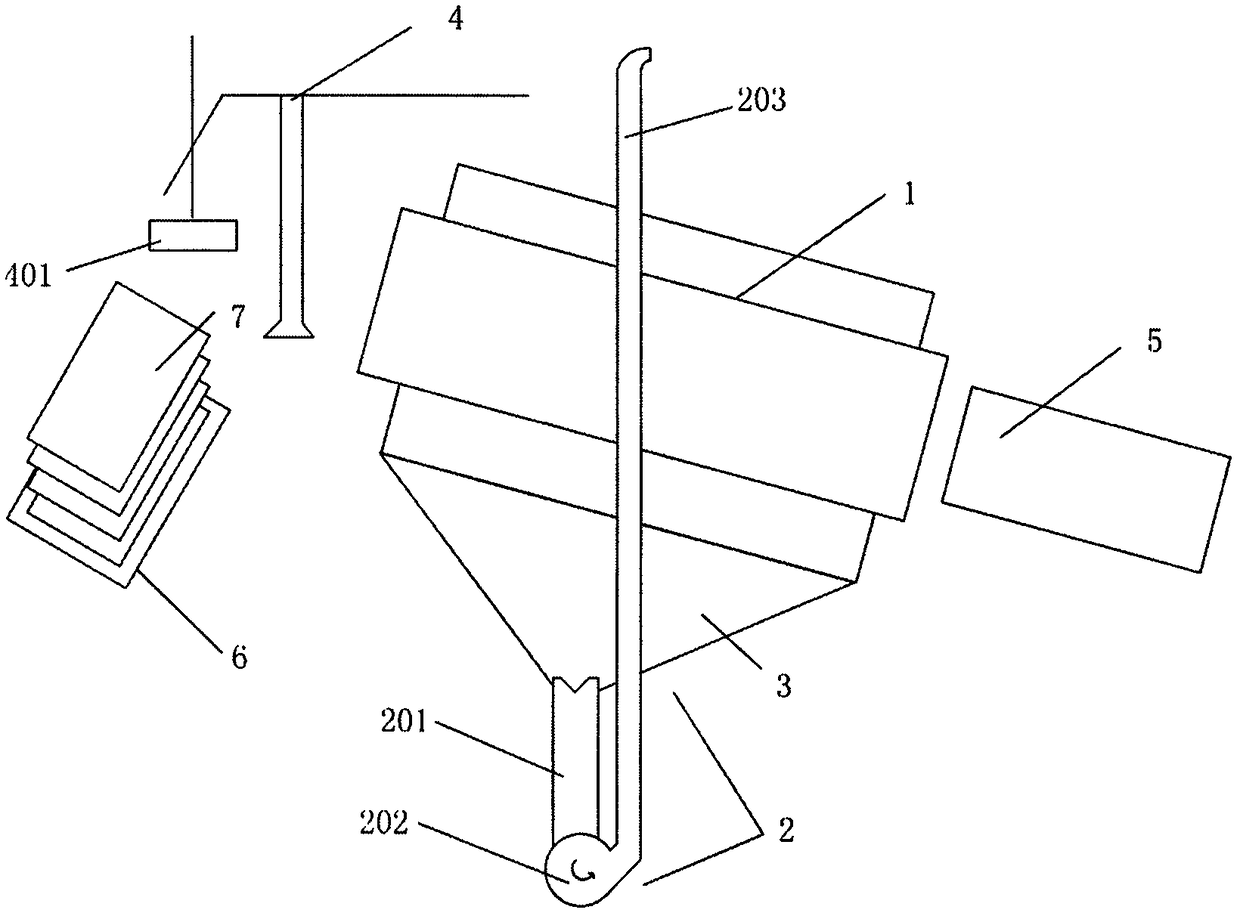

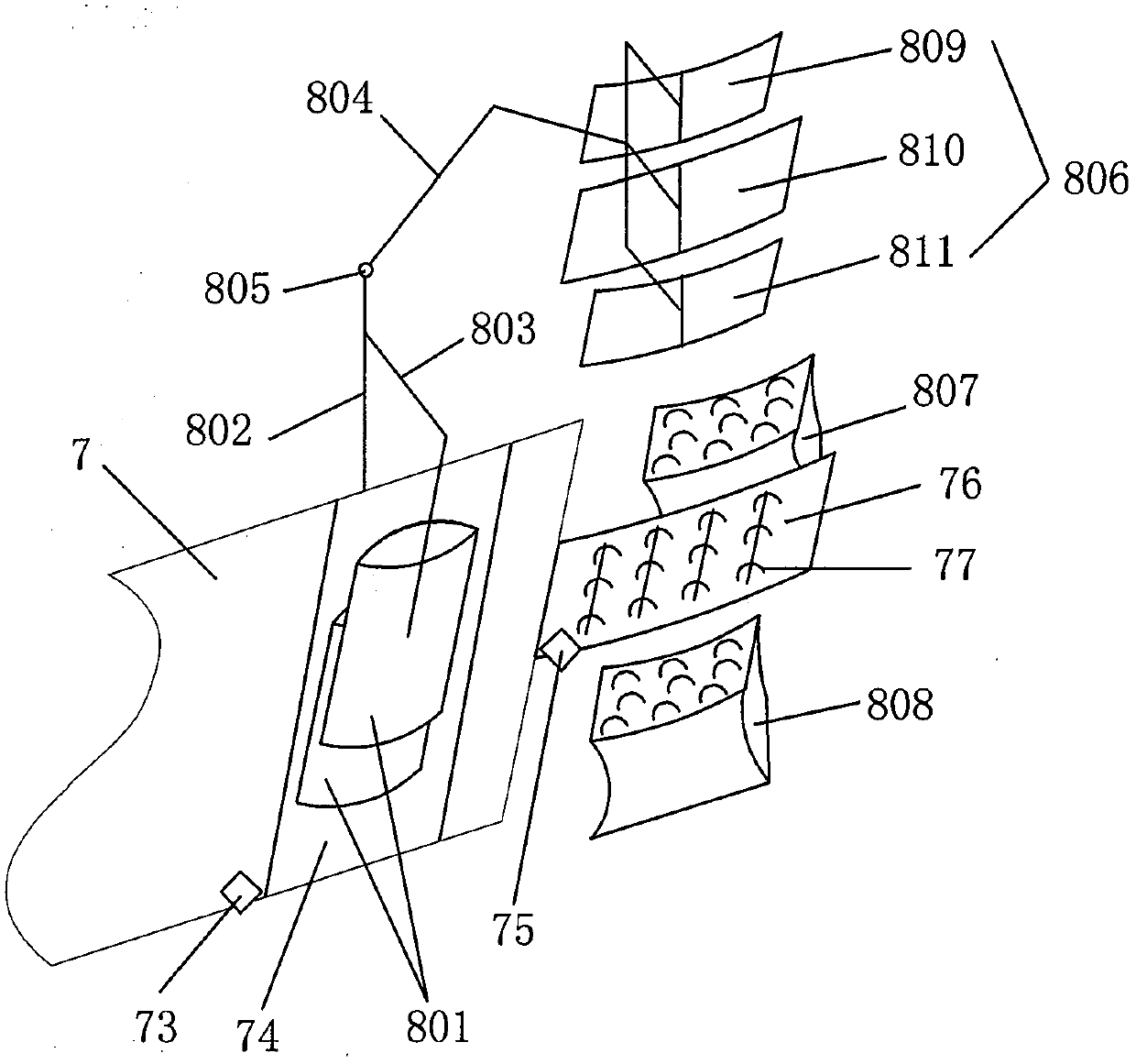

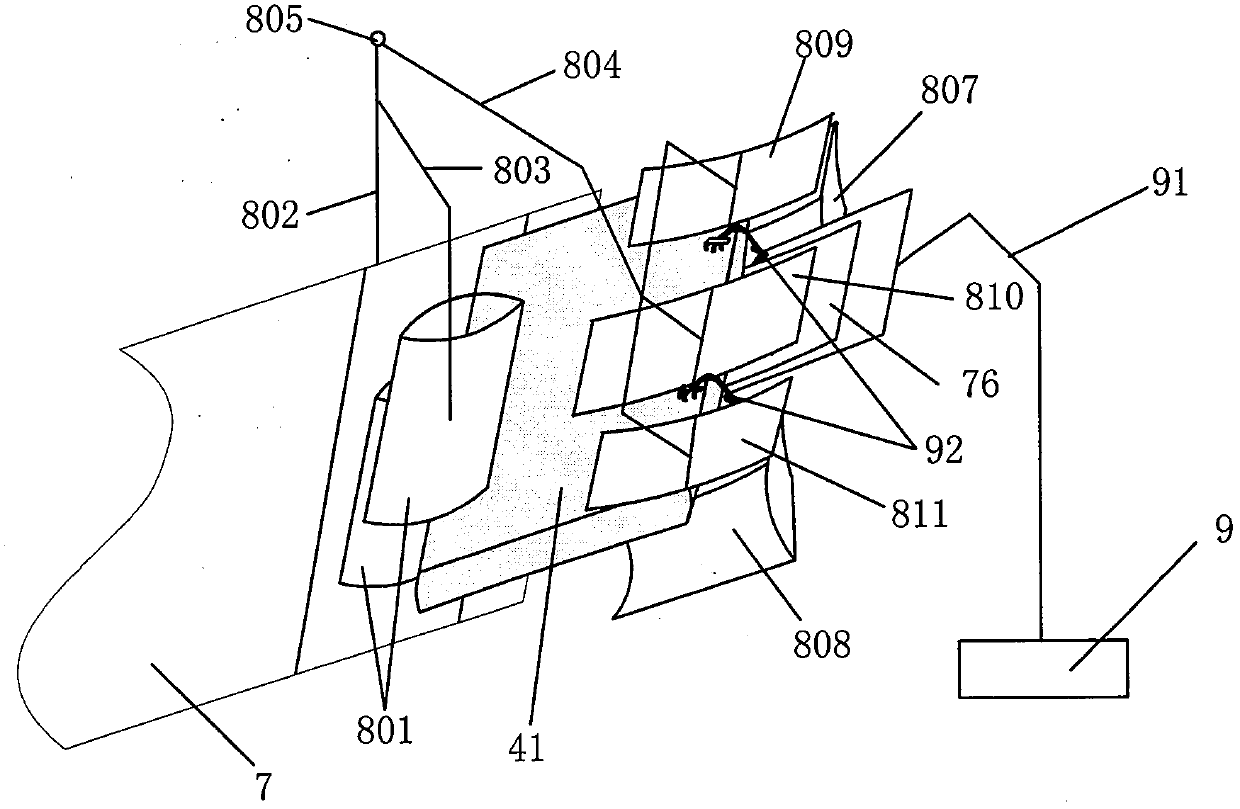

Residual material removing vibration type automatic unpacking and unloading device

ActiveCN108860868ARealize automatic unpackingWill not pollutePlastic recyclingBags openingConveyor beltPollution

The invention discloses a residual material removing vibration type automatic unpacking and unloading device. The device comprises the following parts: a conveyor belt, the surface of which slopes downward, the conveyor belt is used for conveying a material package and conveying the material package to a package cutting warehouse located at the rear of the material package; the package cutting warehouse, which is arranged vertically, and an opening is arranged at the bottom of the package cutting warehouse; a cutting mechanism, which is mounted near the rear of the conveyor belt, and is located at the lower part of the package cutting warehouse, the material package enters into the package cutting warehouse, and the cutting mechanism penetrates through the opening at the bottom of the package cutting mechanism to cut the material package; a package vibration mechanism, which is located on the outer side of the package cutting warehouse, when the cutting is completed, the package vibration mechanism works to vibrate and flap the material package to facilitate the unloading of residual materials; and a package dragging mechanism, when the package vibration mechanism vibrates and flaps the material package, the material package is grabbed and dragged to move upward, when the residual materials are discharged fully, the material package is dragged away from the conveyor belt. According to the invention, the residual material removing vibration type automatic unpacking and unloading device achieves automatic unpacking, and will not produce packaging bag debris pollution to granular materials; the device achieves no residual materials, and prevents the waste of raw materials.

Owner:CHINA JILIANG UNIV

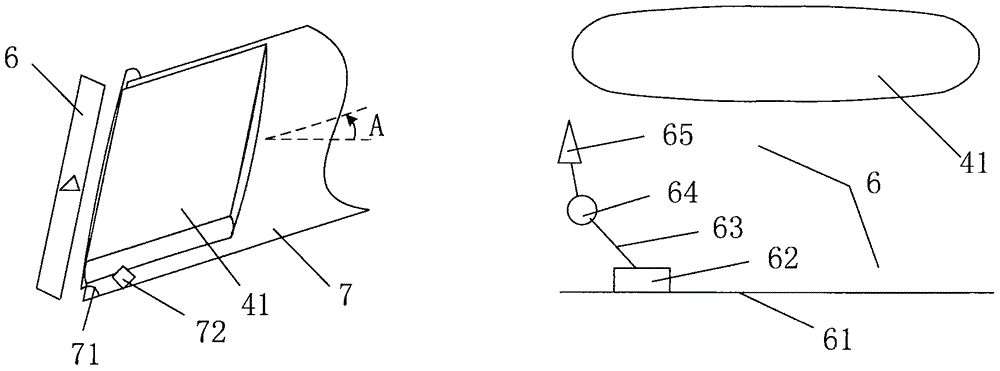

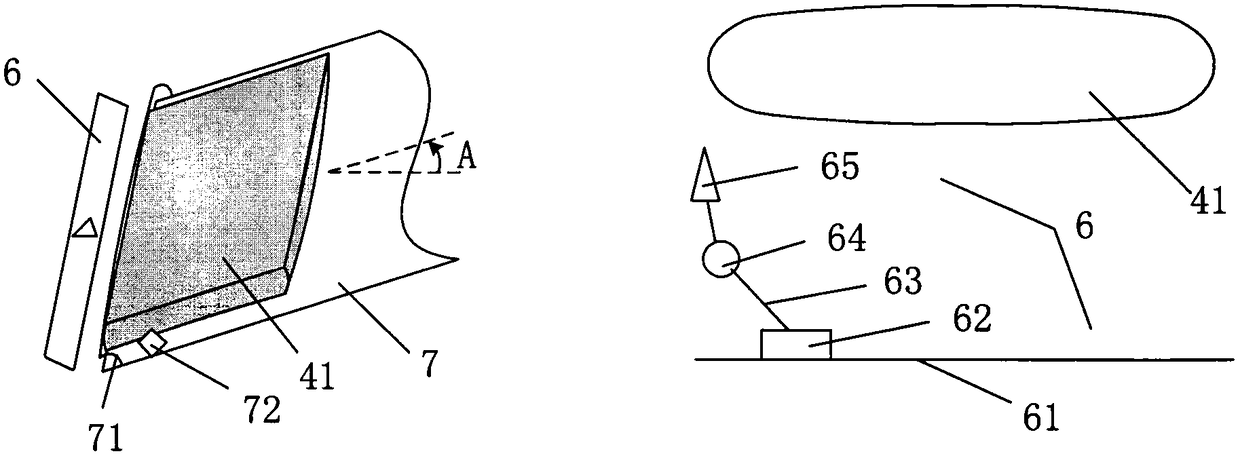

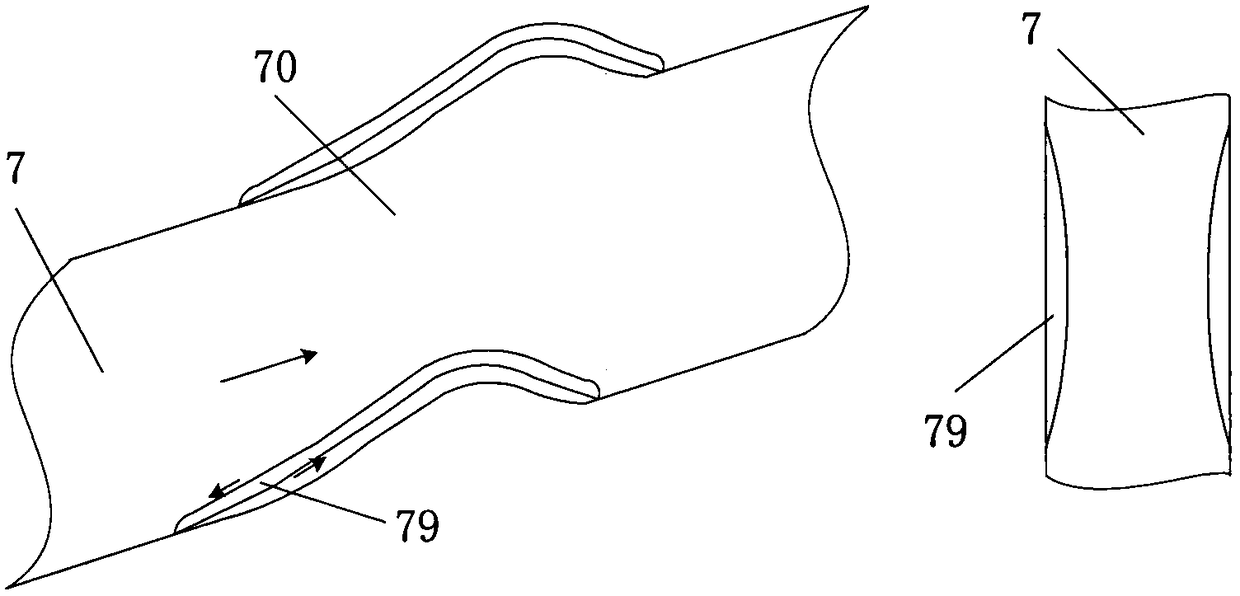

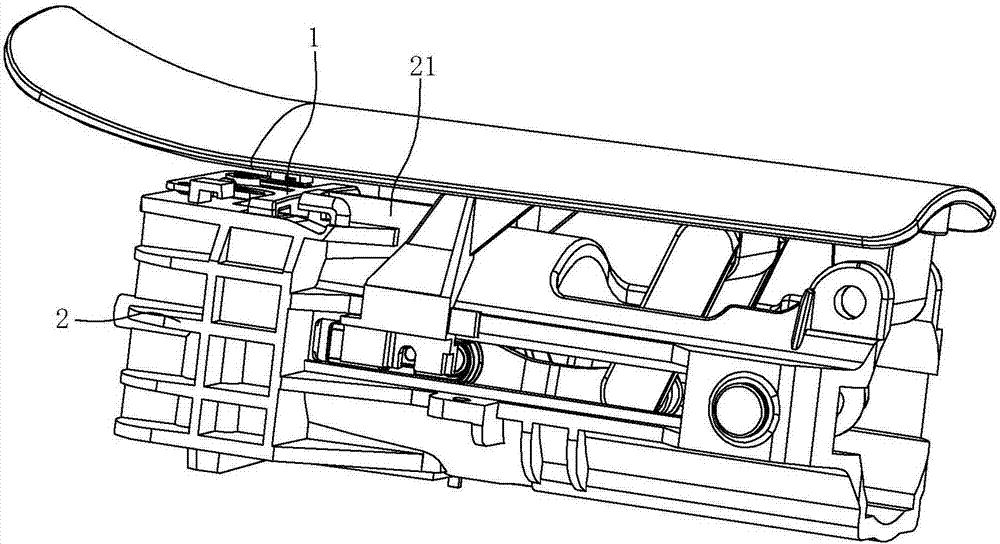

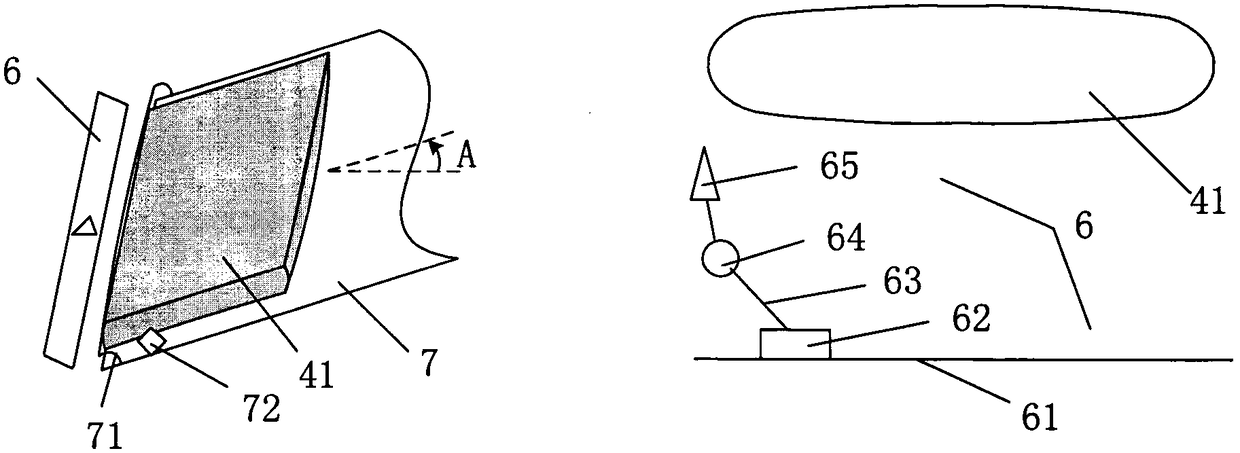

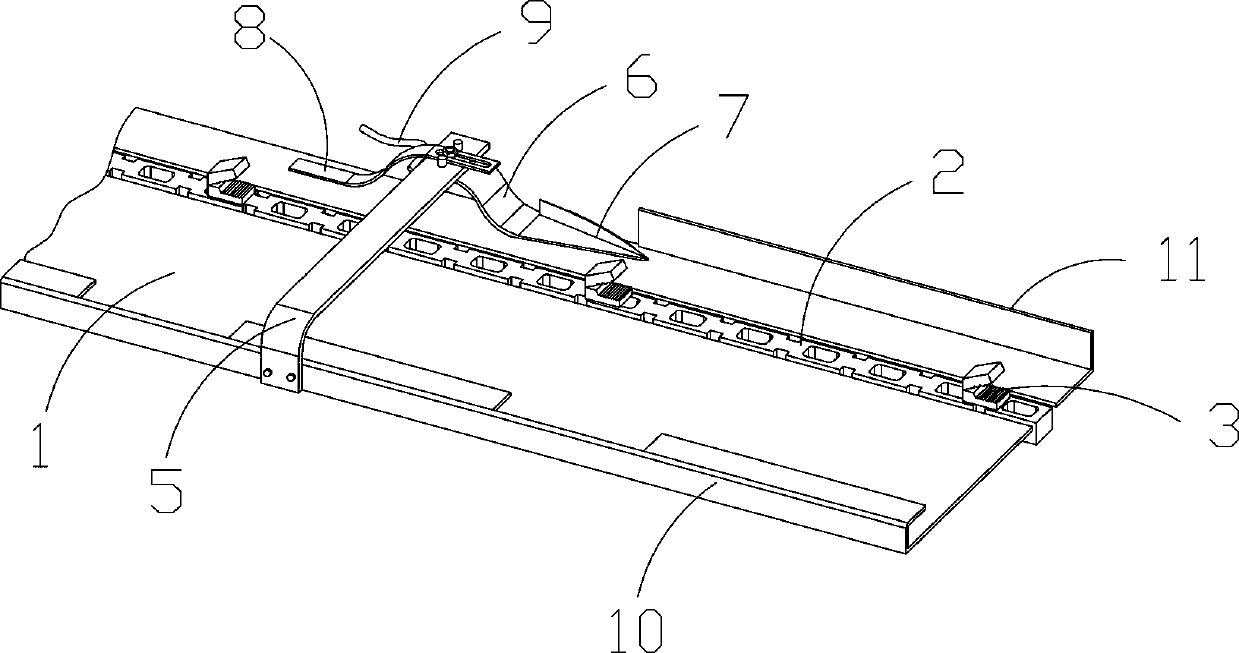

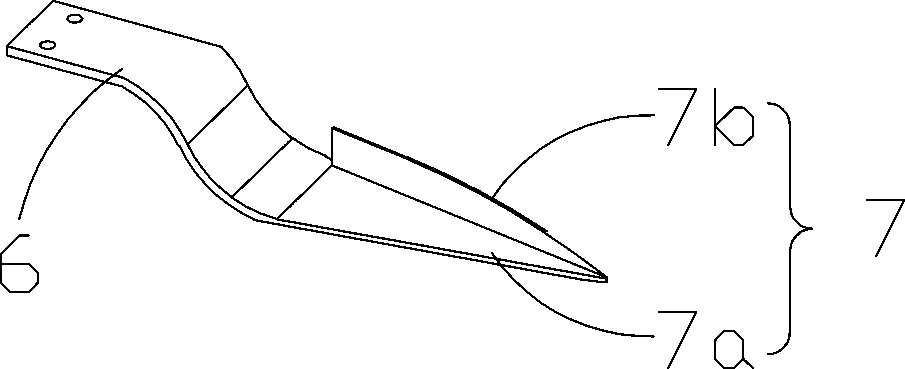

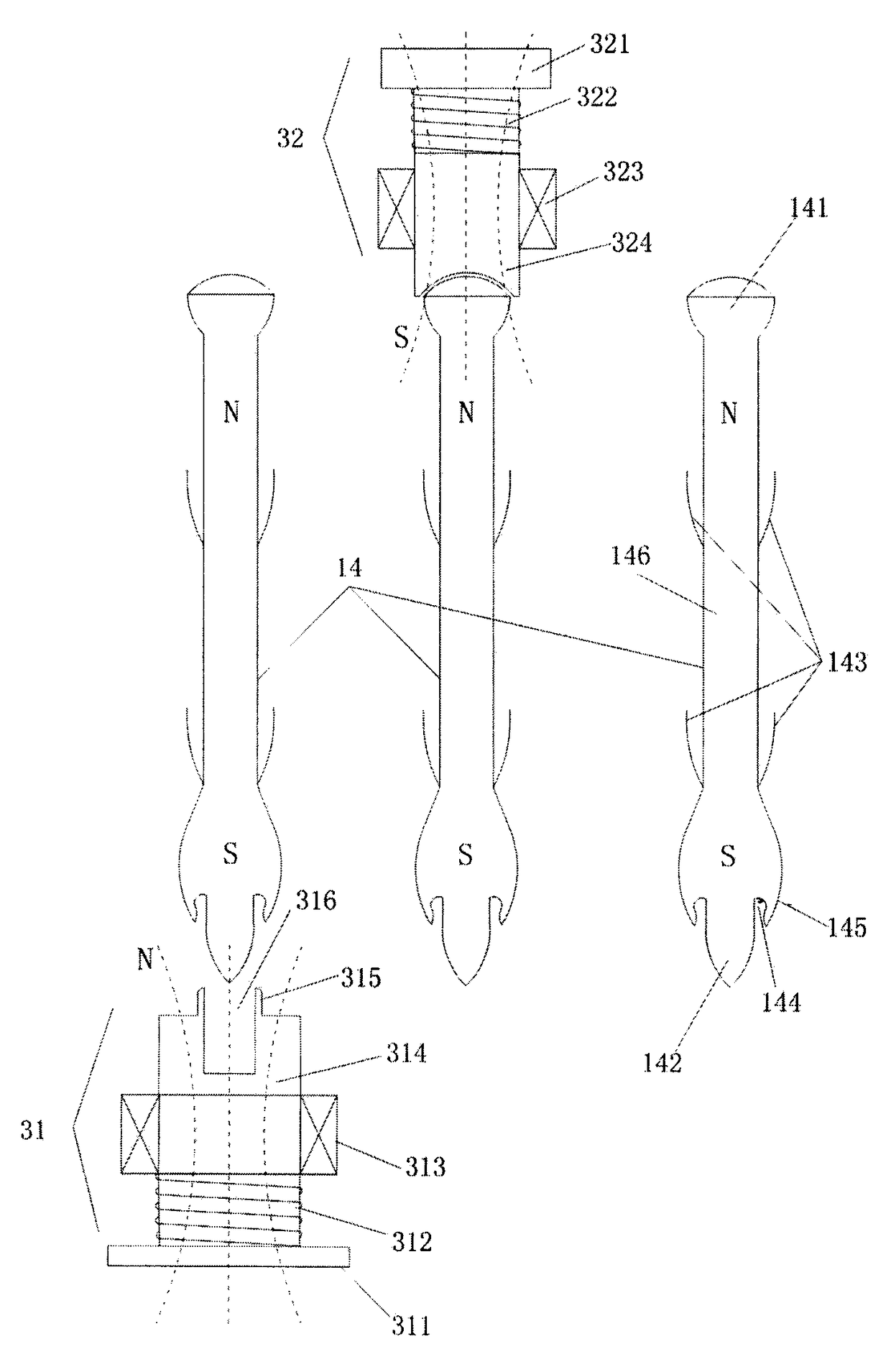

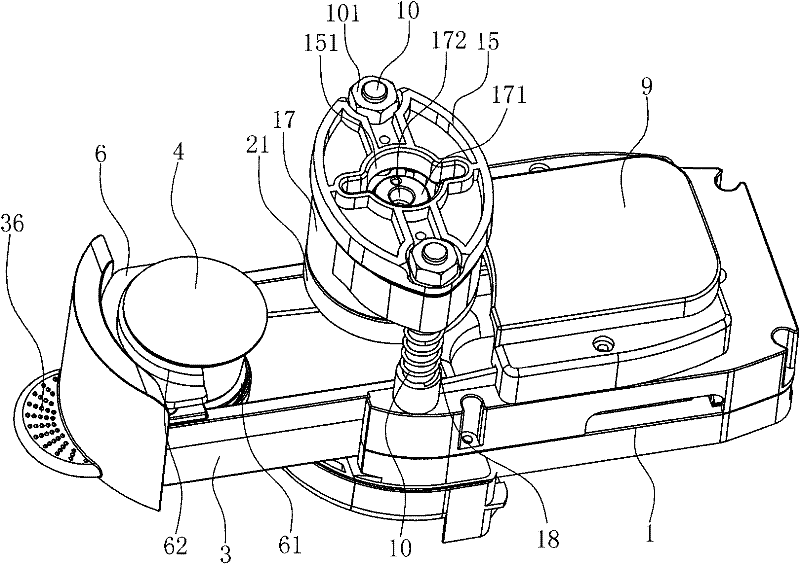

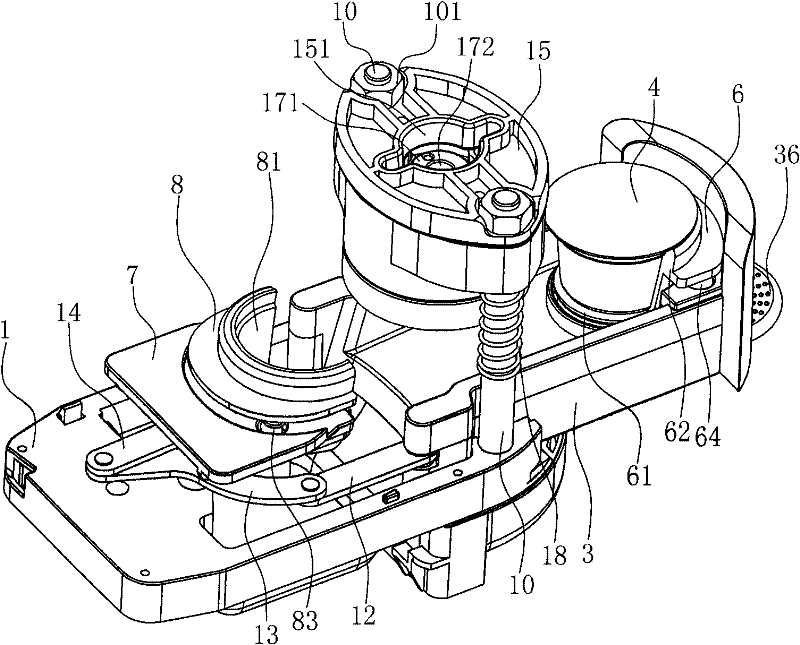

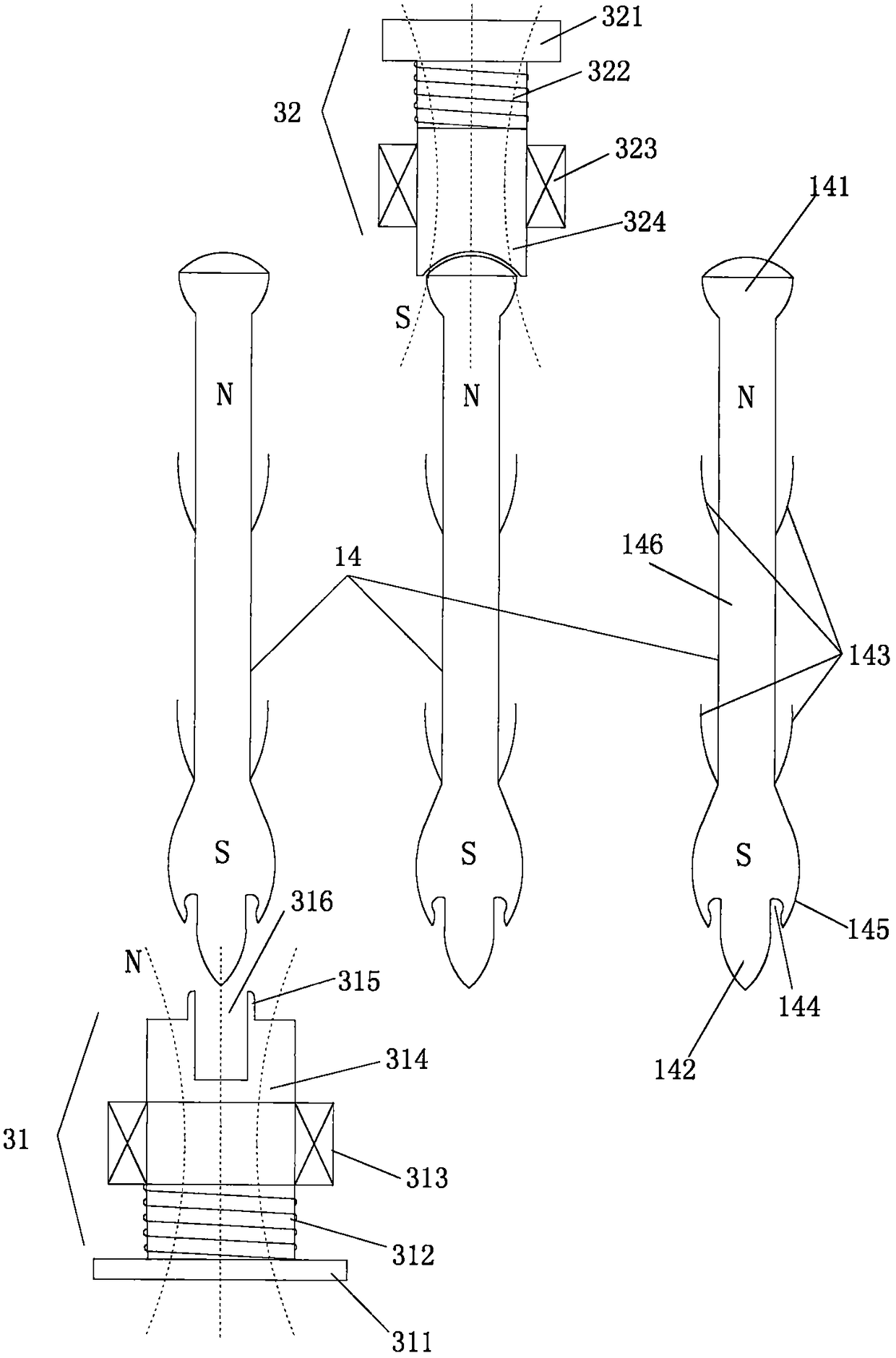

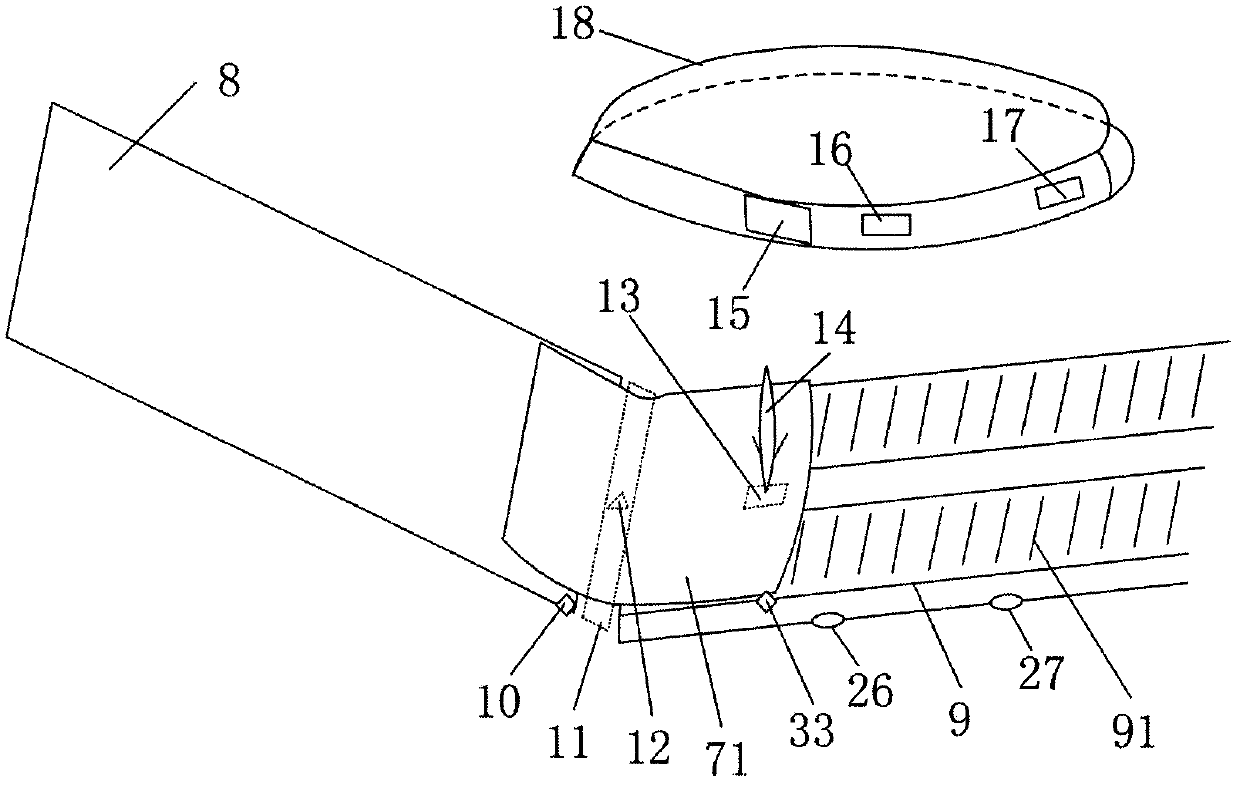

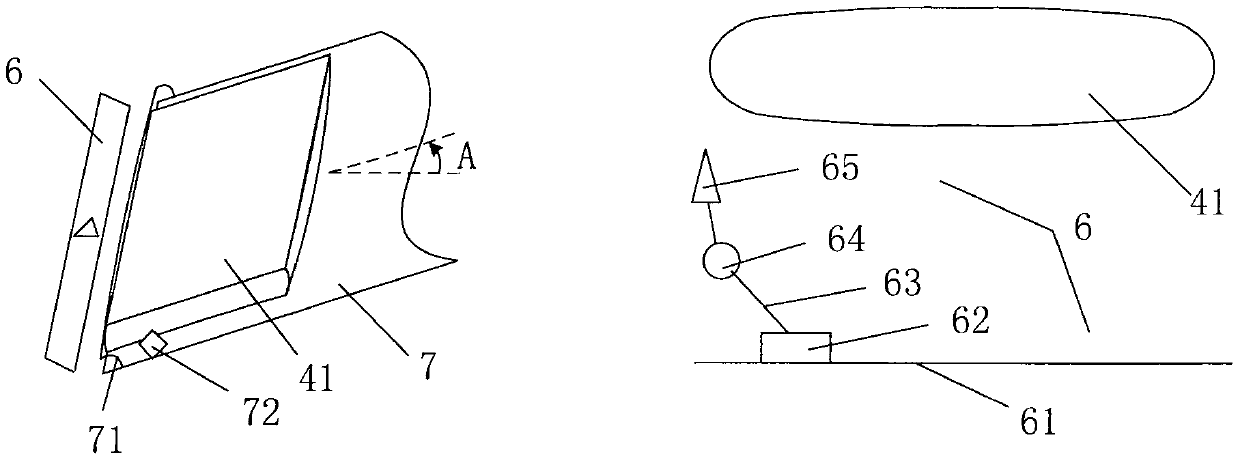

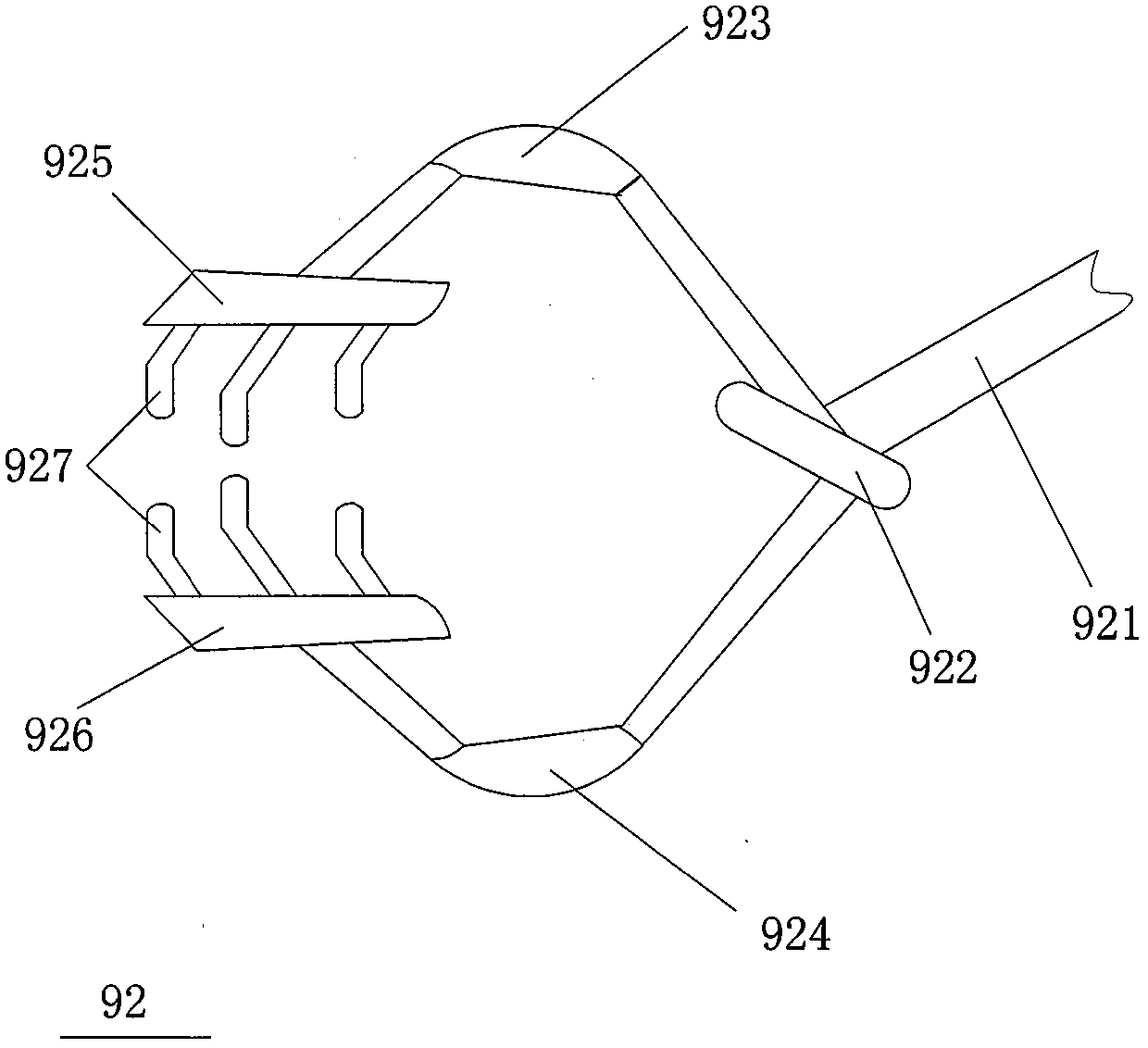

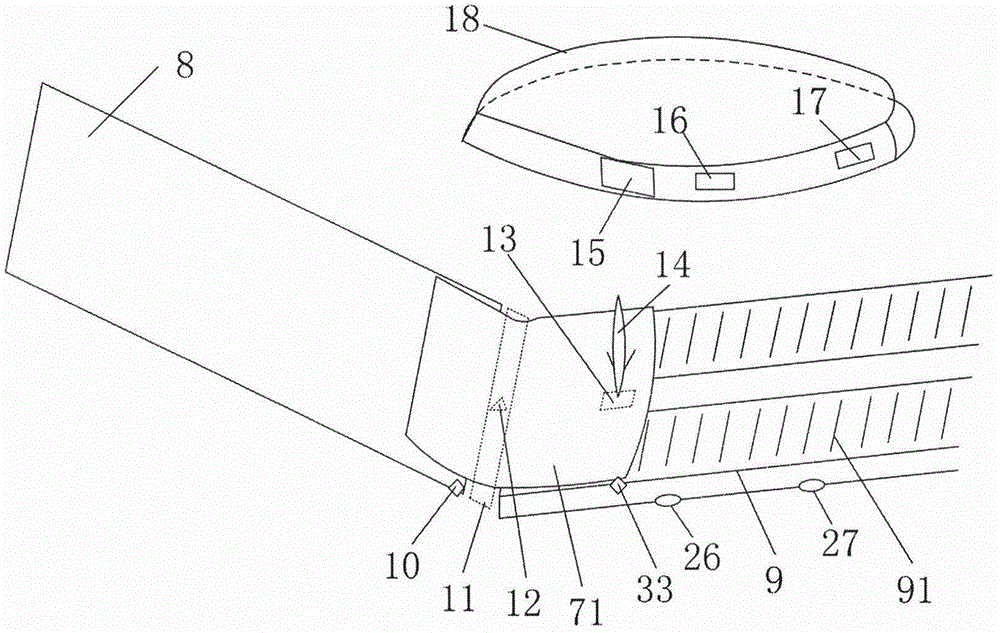

Bag taking-off plate and beverage brewing equipment with bag taking-off plate

PendingCN107184102AUnpacked implementationRealize automatic unpackingBeverage vesselsElastic componentBrewing

The invention relates to a bag taking-off plate. The bag taking-off plate comprises a base part used for being installed on a machine base of beverage brewing equipment, and the base part is provided with two arm parts arranged in a spaced mode. The bag taking-off plate is characterized in that the arm parts are elastic, the arm parts can extend to pop up and retract inwards to be automatically reset through the elasticity, blocking parts stretching inwards and used for being in blocking fit with the annular edge of a beverage bag are arranged on the inner sides of the arm parts, in the state that the arm parts bear force and extend to pop up, the annular edge of the beverage bag can pass through the position between the two blocking parts from the position in front of the arm parts, and in the state that the arm parts retract inwards to be automatically reset, the two blocking parts can block the annular edge, behind the blocking parts, of the beverage bag. The bag taking-off plate does not need to be matched with other elastic parts, and bag taking-off can be completed after the bag taking-off plate is directly installed on the beverage brewing equipment. The invention further relates to the beverage brewing equipment with the bag taking-off plate.

Owner:NINGBO SCISHARE TECH CO LTD

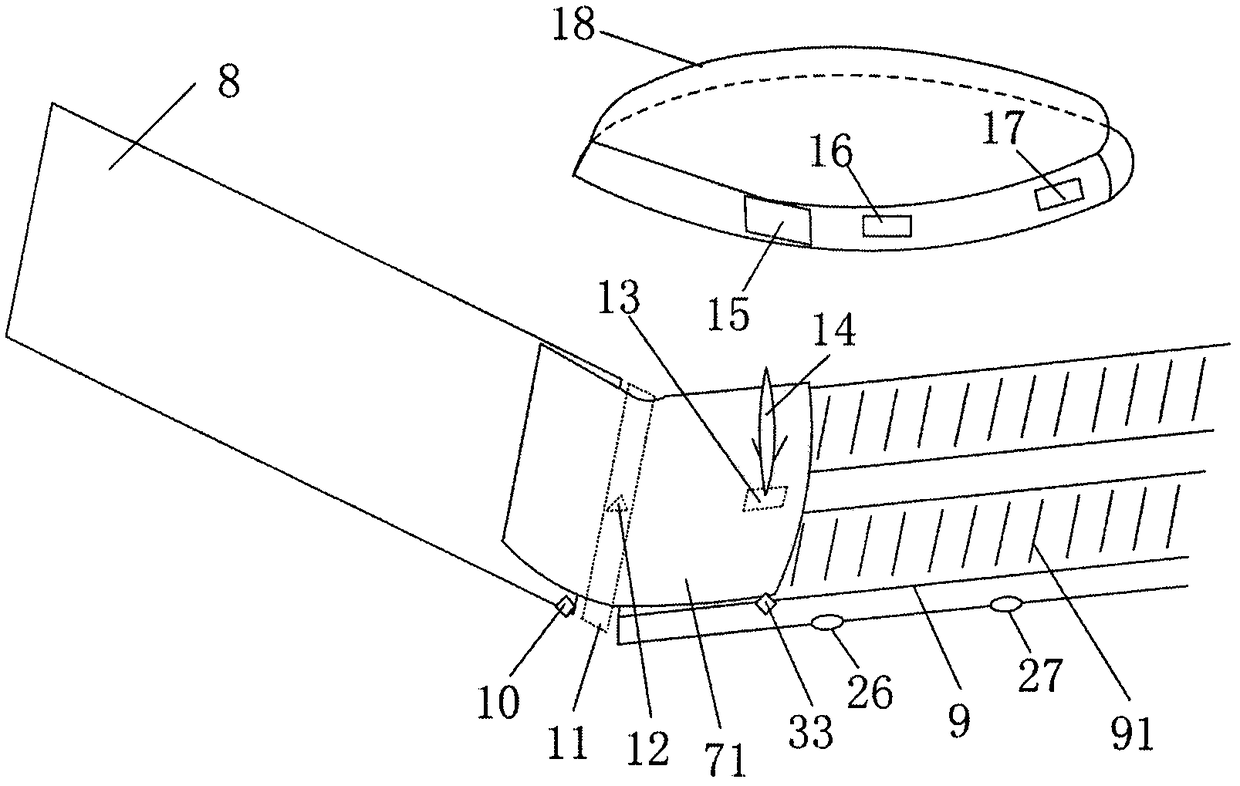

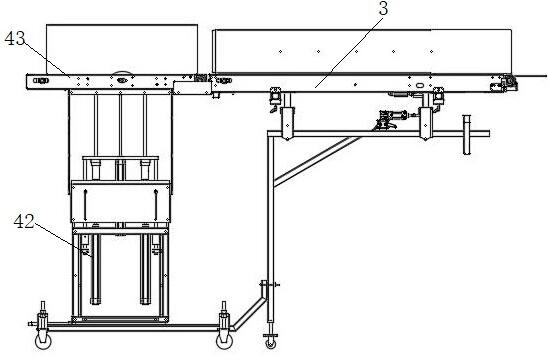

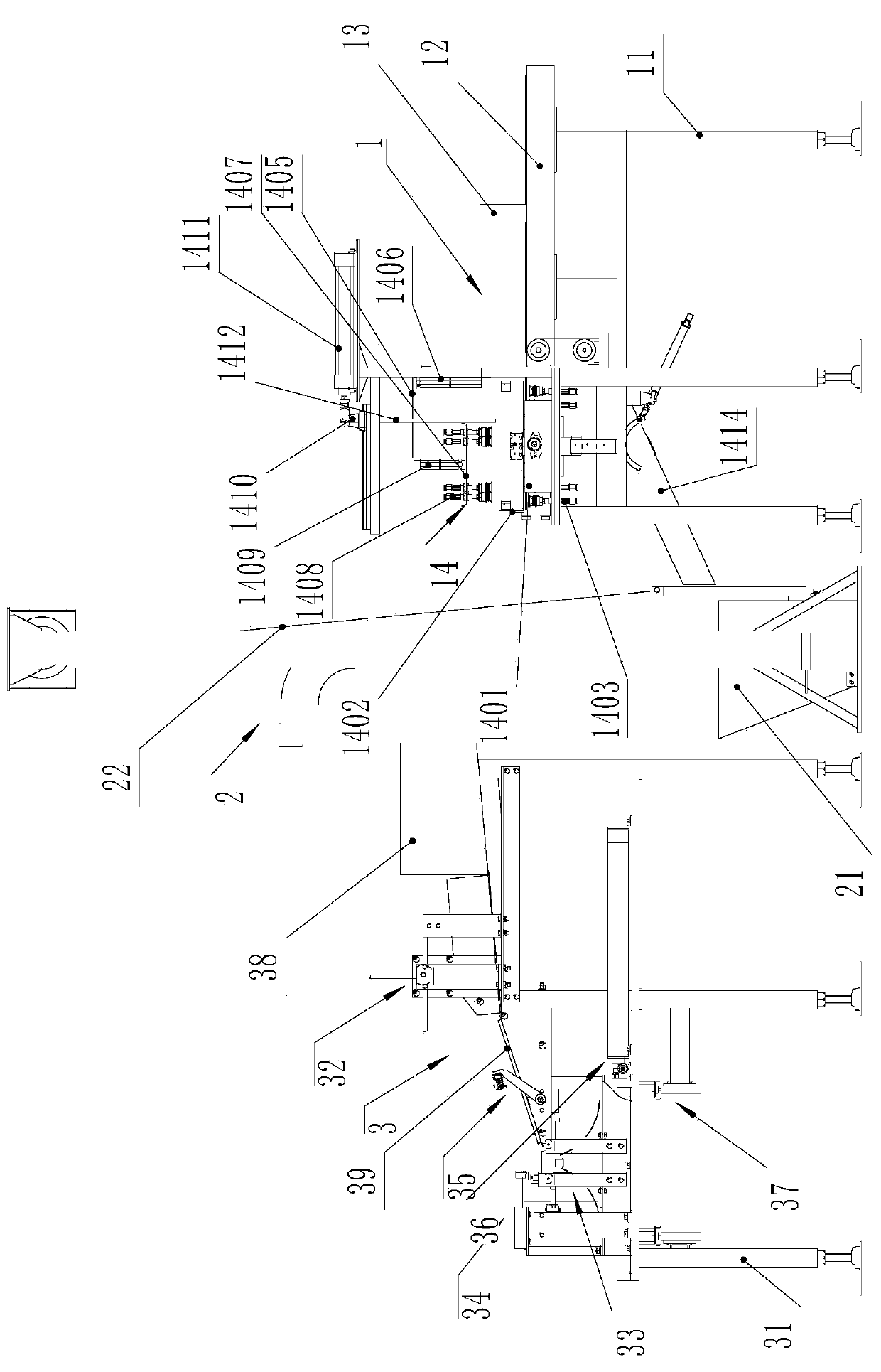

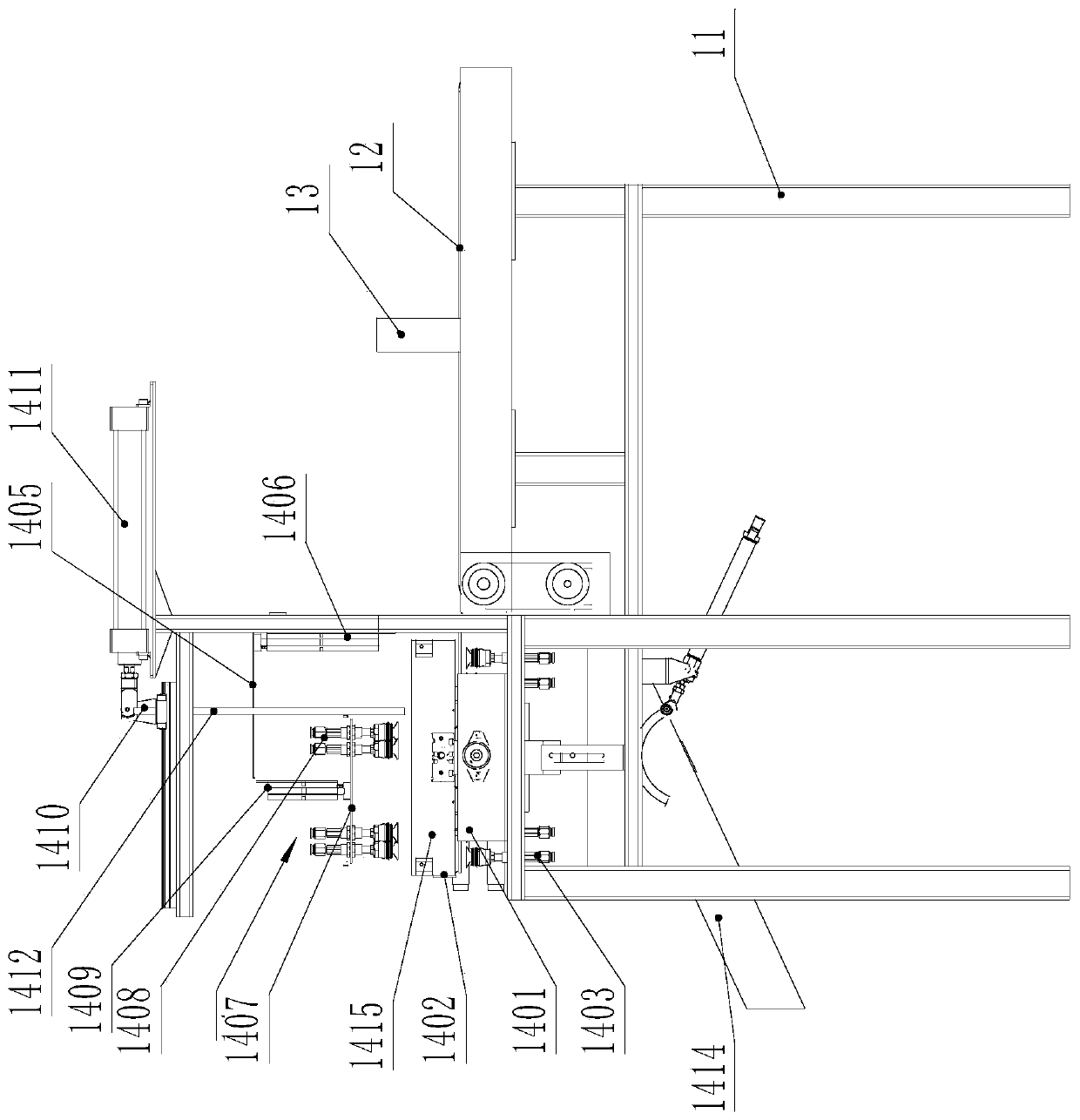

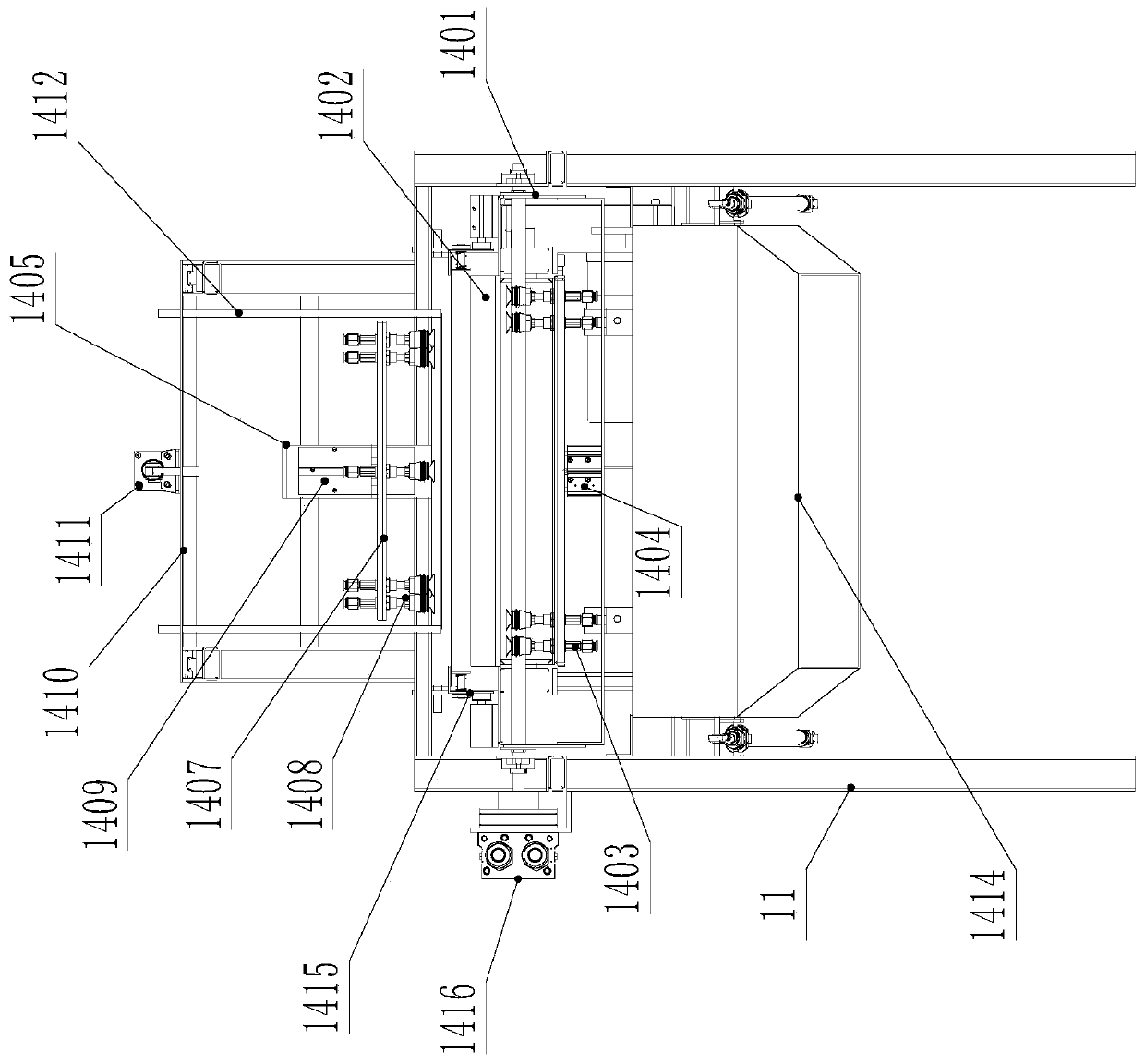

Unpacking and bottle straightening production line for penicillin bottles

ActiveCN108100392AGood unscrambling effectUnscramble bottles quicklyConveyorsUnpacking by heatingProduction linePenicillin

The invention discloses an unpacking and bottle straightening production line for penicillin bottles. The unpacking and bottle straightening production line comprises an unpacking machine, a lifting conveyor and a bottle straightening machine. The unpacking and bottle straightening production line has the advantages that penicillin bottle groups can be unpacked on the unpacking machine and then can be conveyed onto the bottle straightening machine by the aid of the lifting conveyor, the penicillin bottles in a collecting hopper can be sorted by the bottle straightening machine by the aid of asorting device and then can be fed onto a bottle carrying frame, bottle insertion actions can be carried out by left and right insertion needles in movement in opposite directions, and then the penicillin bottles can be driven to rotate by 90-degree angles, can be supported by a right arc-shaped slide plate to stand up, then can fall into an output groove and can be pushed out by a bottle pushingmechanism; the penicillin bottle groups can be unpacked and then conveyed onto the bottle straightening machine by the unpacking and bottle straightening production line, the bottles can be sorted onthe bottle straightening machine, manual unpacking can be omitted, the bottles can be straightened without consideration on the orientation of openings of the penicillin bottles, and accordingly the efficiency of the integral unpacking and bottle straightening production line for the penicillin bottles can be improved.

Owner:HIT SMART FACTORY CO LTD

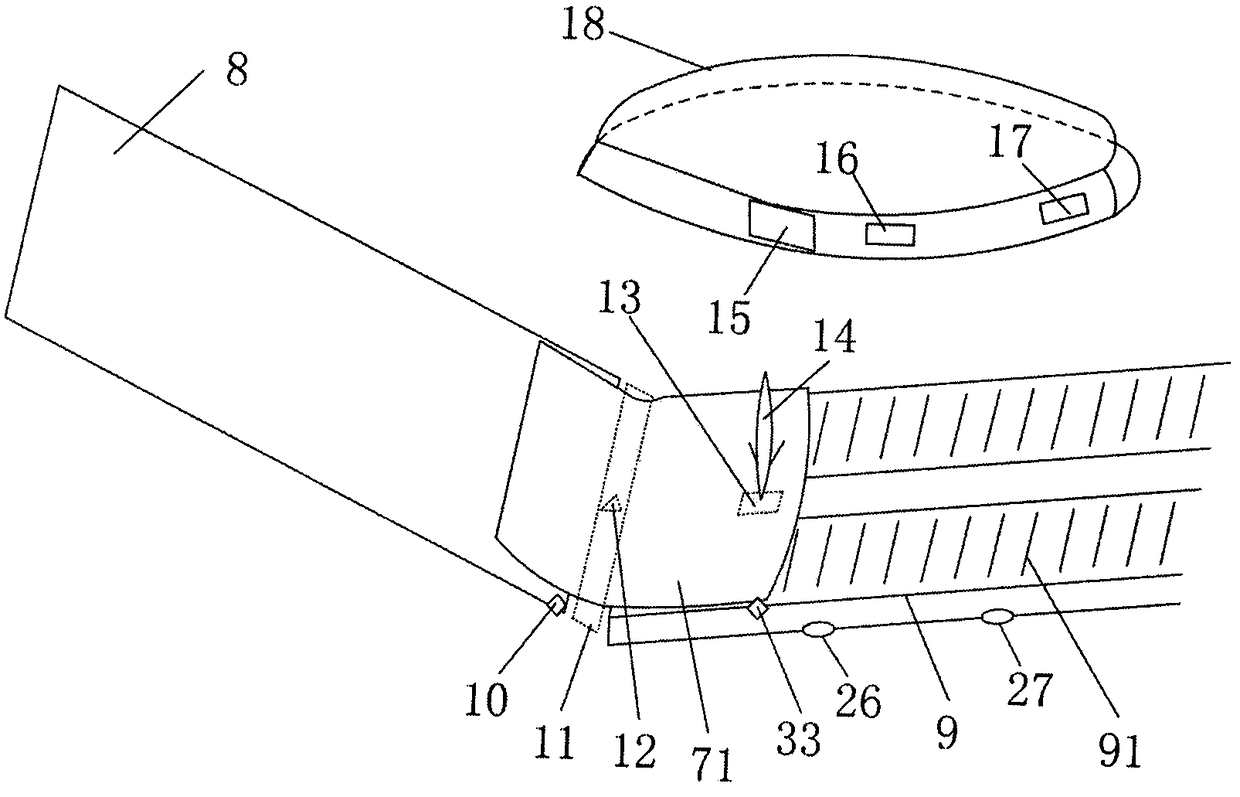

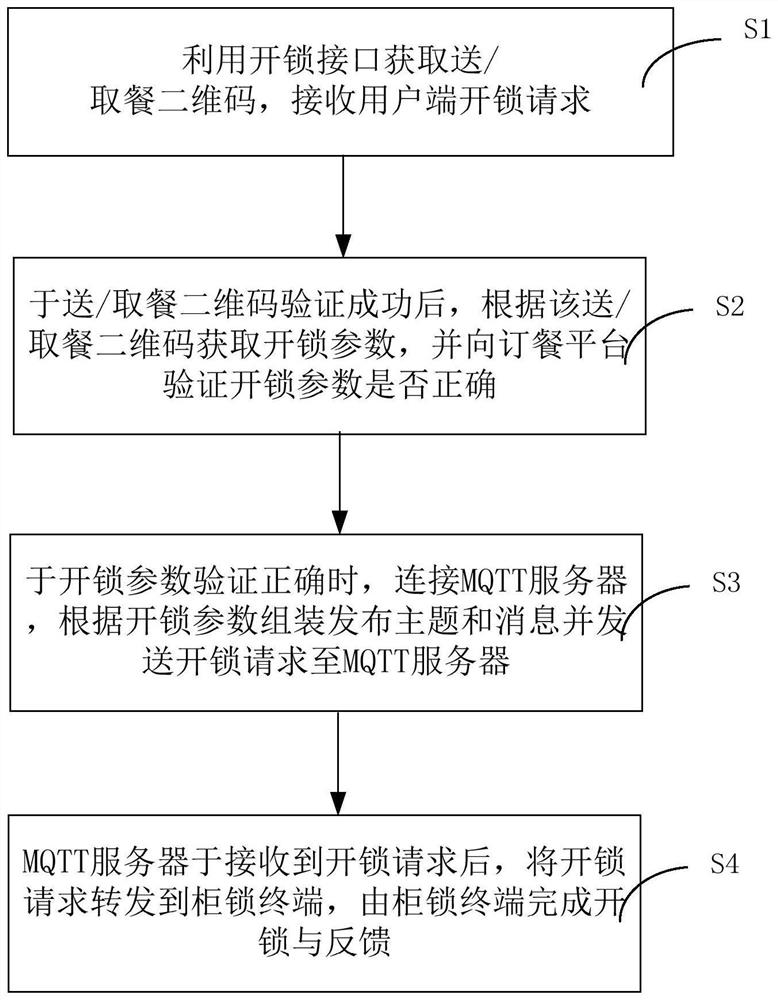

Unlocking control method and system for insulation can

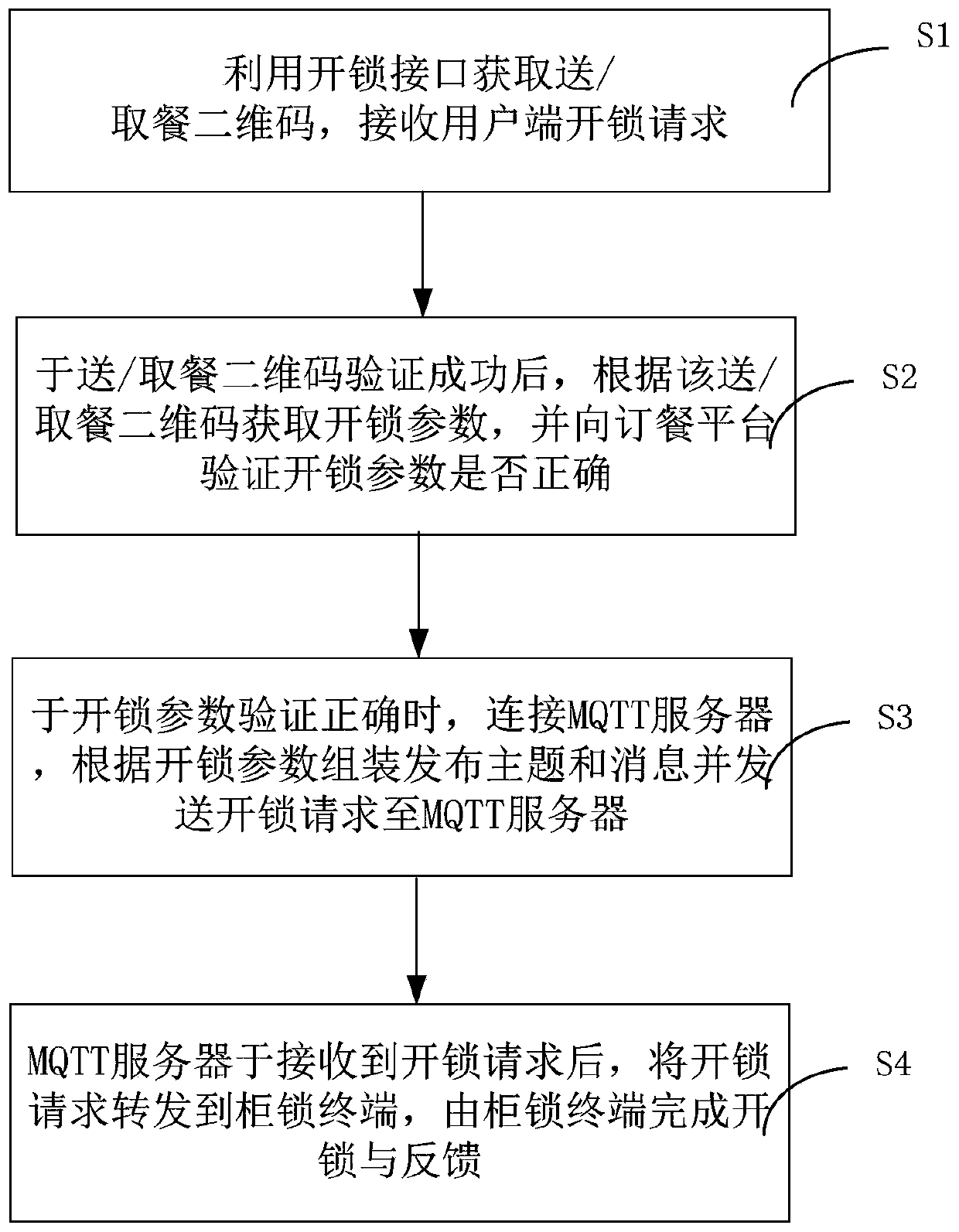

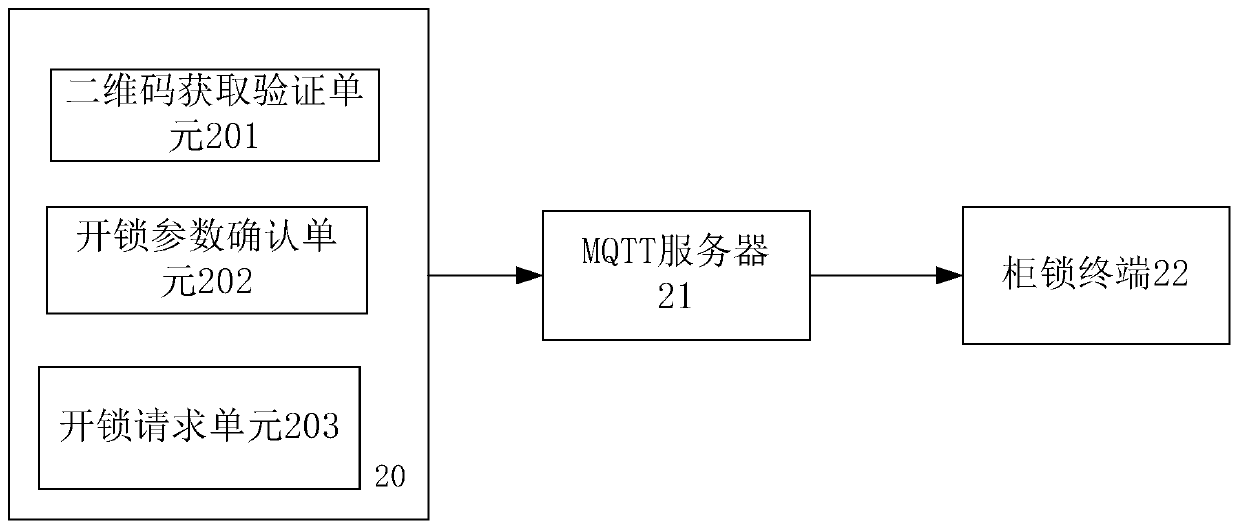

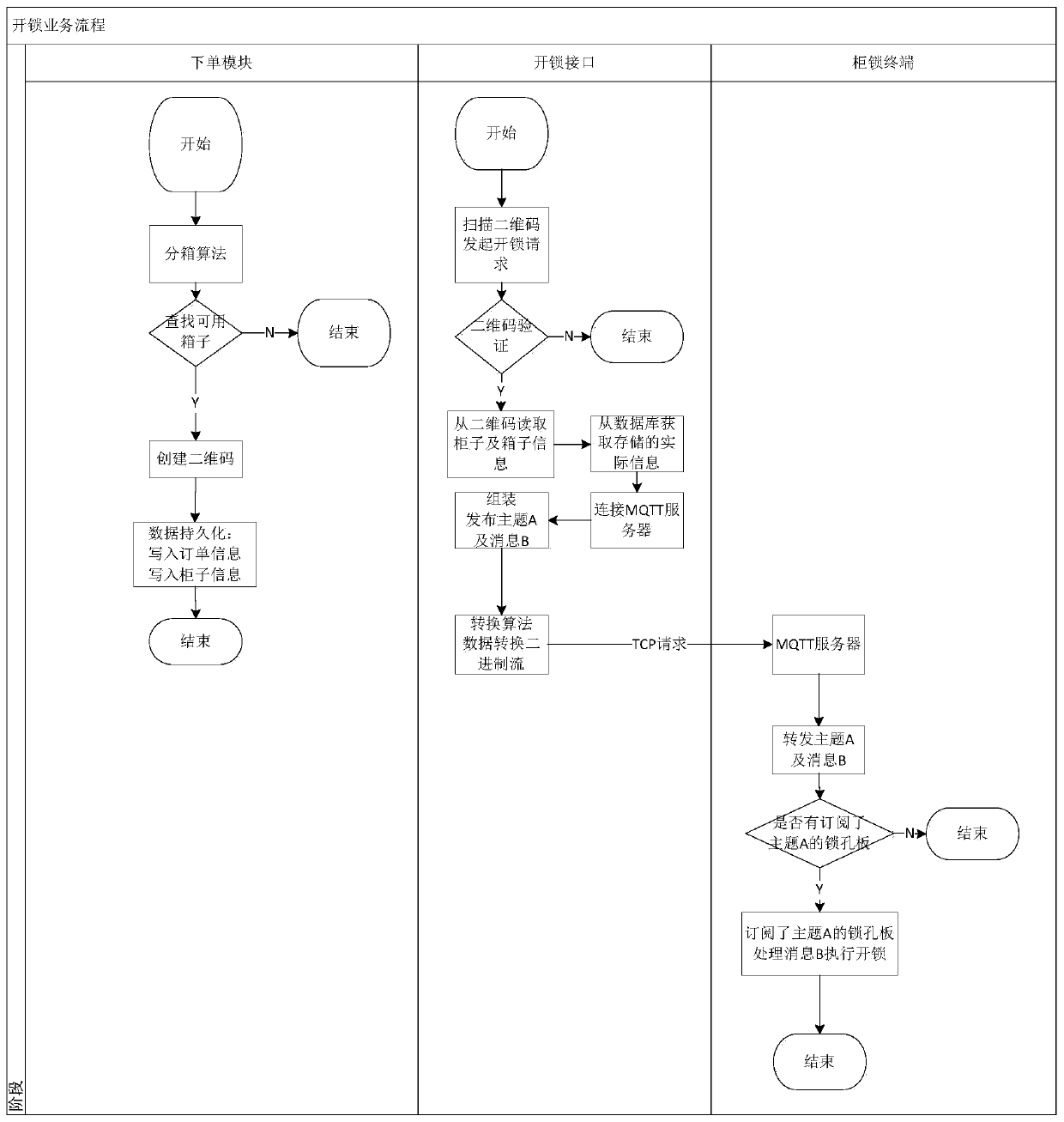

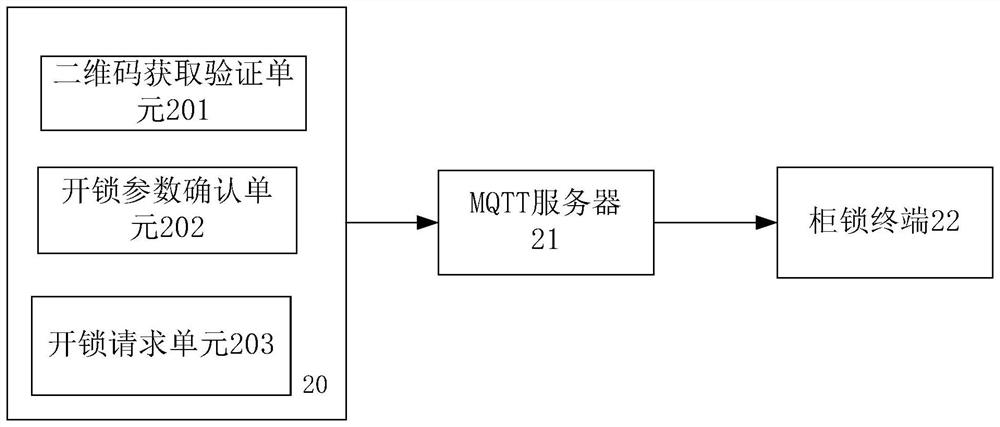

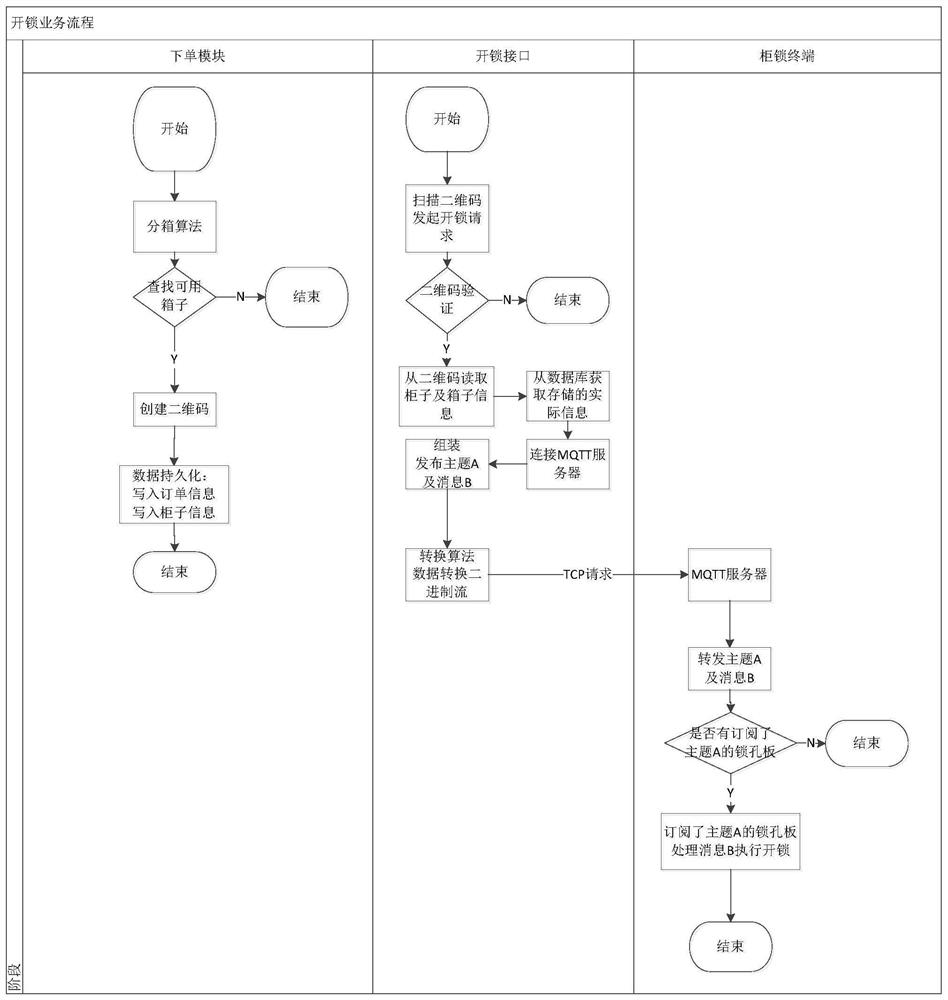

ActiveCN109872433AImprove delivery/pickup efficiencySave human resourcesApparatus for meter-controlled dispensingIndividual entry/exit registersEmbedded systemMeal

The invention discloses an unlocking control method and system for an insulation can. The method comprises the following steps of step S1, acquiring a meal delivery / taking two-dimensional code by utilizing an unlocking interface, and receiving a user side unlocking request; step S2, after the meal delivery / taking two-dimensional code is successfully verified, acquiring unlocking parameters according to the meal delivery / taking two-dimensional code, and verifying whether the unlocking parameters are corrected or not to an ordering platform; step S3, when the unlocking parameters are verified correctly, connecting an MQTT server, assembling and publishing a theme according to the unlocking parameters and sending an unlocking request to the MQTT server; and step S4, after the MQTT server receives the unlocking request, forwarding the unlocking request to a cabinet locking terminal, and completing unlocking and feedback by the cabinet locking terminal. According to the method and the system, the automatic opening and closing of the insulation can by meal delivery / taking personnel can be realized, the meal delivery / taking efficiency can be improved, and the manpower resources are saved.

Owner:广州大学华软软件学院

Vibrational residue removal type automatic unpacking and unloading method

ActiveCN108910197ARealize automatic unpackingWill not polluteBags openingUnpacking by cuttingEngineeringRaw material

The invention discloses a vibrational residue removal type automatic unpacking and unloading method. The method comprises the following steps that material bags are moved onto a conveying belt; the surface of the conveying belt slopes downwards, and the conveying belt is used for conveying the material bags to a bag cutting bin located at the rear end of the conveying belt; the bag cutting bin isvertically arranged, and an opening is formed at the bottom of the bag cutting bin; after the material bags enter the bag cutting bin, a cutting mechanism, mounted close to the rear end of the conveying belt and located below the bag cutting bin, penetrates through the opening at the bottom of the bag cutting bin, and the material bags are cut open; after cutting is completed, a bag vibrating mechanism located on the outer side of the bag cutting bin functions, and the material bags are vibrated and patted to promote discharging of residue; and when the material bags are vibrated and patted bythe bag vibrating mechanism, the material bags are caught and dragged upwards by a bag dragging mechanism, and the material bags are dragged away from the conveying belt when the residue is emptied.By means of the vibrational residue removal type automatic unpacking and unloading method, automatic unpacking is achieved; packaging bag scrap pollution is not generated to a particle material; and non-residual blanking is achieved, and waste of raw materials is prevented.

Owner:CHINA JILIANG UNIV

Cover dismounting device

The invention discloses a cover dismounting device which comprises a positioning and clamping mechanism arranged on a workbench and used for positioning and clamping a carton on the workbench. The cutting knife mechanism is used for cutting a carton cover of the carton open; the carrying mechanism is used for moving away the box cover and the rest part of the paper box from the workbench after the box cover is cut by the cutter mechanism; the moving mechanism is arranged on the workbench, is connected with the cutting knife mechanism and the carrying mechanism and is used for driving the cutting knife mechanism and the carrying mechanism to move, so that the box cover is cut in the moving process of the cutting knife mechanism, and the box cover and the rest part of the paper box are moved away from the workbench in the moving process of the carrying mechanism; and the control mechanism is used for controlling the operation of the positioning and clamping mechanism, the cutting knife mechanism, the carrying mechanism and the movement mechanism. According to the cover dismounting device, cover dismounting of the carton can be automatically completed, manual participation is not needed, and the labor intensity of workers can be reduced.

Owner:安徽省配天机器人集团有限公司

Automatic explosive unpacking device

PendingCN113686219ARealize automatic unpackingAvoid contactConveyorsBlastingExplosive AgentsStructural engineering

The invention relates to the field of blasting, in particular to an automatic explosive unpacking device which comprises a controller, a conveying frame and two parallel barbed nail conveying belts arranged on the conveying frame and driven by a driving mechanism to act synchronously, barbed nails are arranged on the barbed nail conveying belts, a packing bag cutting knife is further arranged on the conveying frame, and the packing bag cutting knife is positioned between the two barbed nail conveying belts and is higher than the upper belt surfaces of the barbed nail conveying belts. According to the automatic explosive unpacking device, an explosive bag is driven to advance through the two barbed nail conveying belts and the barbed nails, the lower side of the explosive bag is automatically cut open through the packing bag cutting knife, and explosives fall down from a cut opening under the action of gravity, so that automatic unpacking of the explosive bag is achieved, the unpacking efficiency is effectively improved, and the labor cost is reduced; and meanwhile, the powdery explosives are prevented from being in contact with the human body, influences on human life health are prevented, and safety is improved.

Owner:六盘水华安爆破工程有限公司

Automatic opening device for envelope cover

The invention discloses an automatic opening device for an envelope cover. The automatic opening device comprises a workbench and a conveying chain arranged on the workbench; and the conveying chain is provided with a plurality of micro clamping claws, a spacing between the two adjacent micro clamping claws is larger than the length of an envelope, a crossbeam crossing the upper side of the conveying chain is arranged on the workbench, a flanging part used for guiding the envelope cover to open is arranged on the right side of the crossbeam, the flanging part has a flanging head arranged in the reverse transmission direction of the conveying chain, and the left side of the crossbeam is provided with a pressing piece arranged in the transmission direction of the conveying chain and a guidepressing rod used for guiding the envelope cover to unfold. According to the automatic opening device, the structure is simple, the design is ingenious, automatic opening of the envelope cover is realized, the efficiency is high, the workload of staff is greatly reduced, and automatic production demands of mail automatic packaging production lines are met.

Owner:中国邮政速递物流股份有限公司黄石市分公司

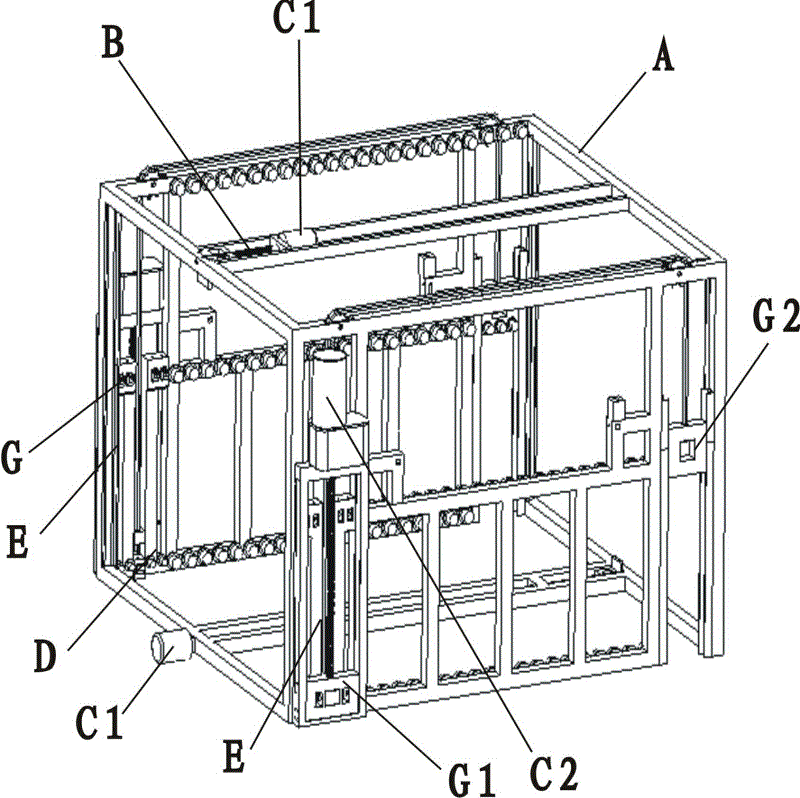

Automatic box reversing device

InactiveCN102114953BNot limited by space conditionsRealize automatic unpackingLarge containersProgrammable logic controllerElectric machinery

The invention relates to an automatic box reversing device which comprises a frame of a container body; a horizontal conveying mechanism is arranged in the depth direction of the frame and comprises a motor, a sensor, and a screw rod and a screw nut which are driven by the motor; a sliding rail formed by roller wheels is arranged on the inner side edge in the depth direction of the frame, and twoside edges in the depth direction of the frame are symmetrically provided with at least one sliding rail; the two side edges in the depth direction of the frame are provided with a lifting mechanisms, the lifting mechanism comprises a lifting guide rail fixed on the frame, a sensor, a lifting rope connected with the motor, and support hooks which can move up and down along the lifting guide rail and are connected with two ends of the lifting rope respectively; and a support pin which can stretch along with the extrusion of a box body is arranged at a position with equal altitude between the lifting mechanism and the sliding rails between the side edges of the frame; and the horizontal conveying mechanism and the lifting mechanism are both connected with a PLC (programmable logic controller). With the adoption of the structure, the automatic box reversing device has the advantages of realizing automatic box reversing, and simultaneously, being not limited by spatial condition.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

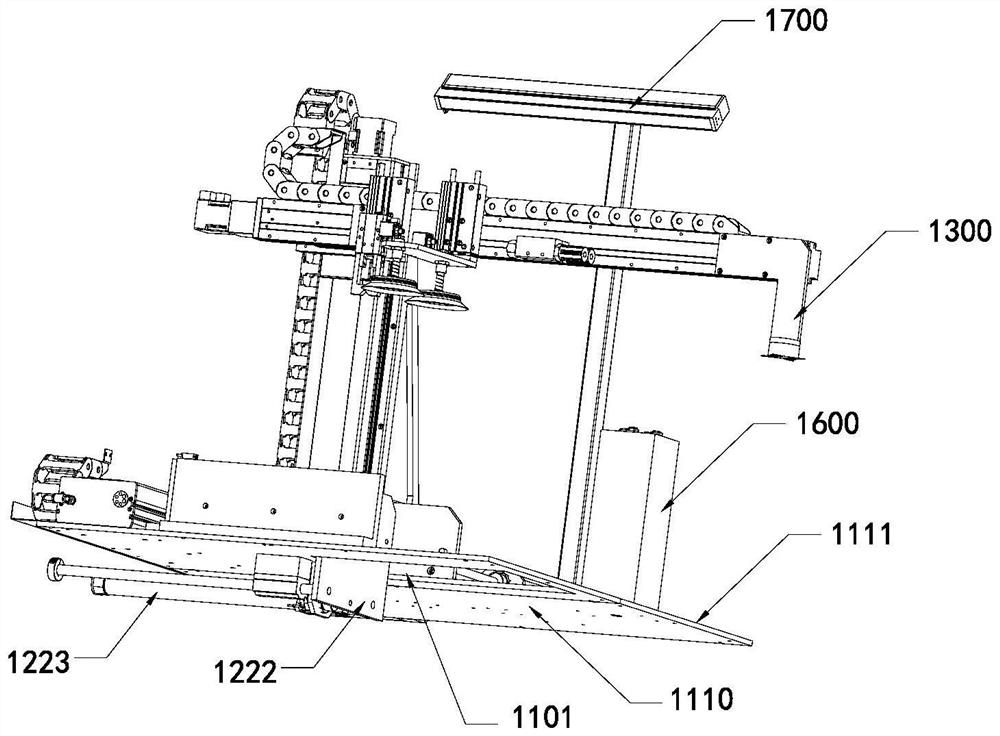

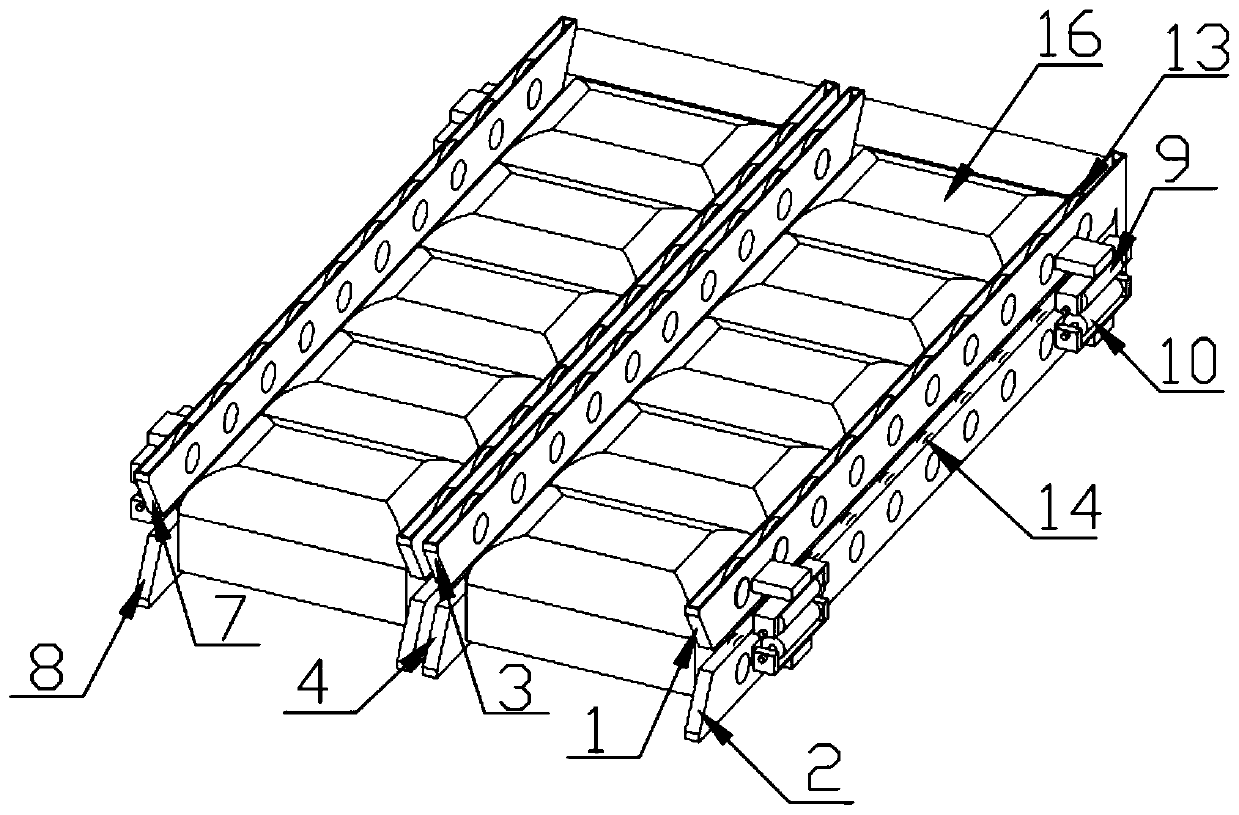

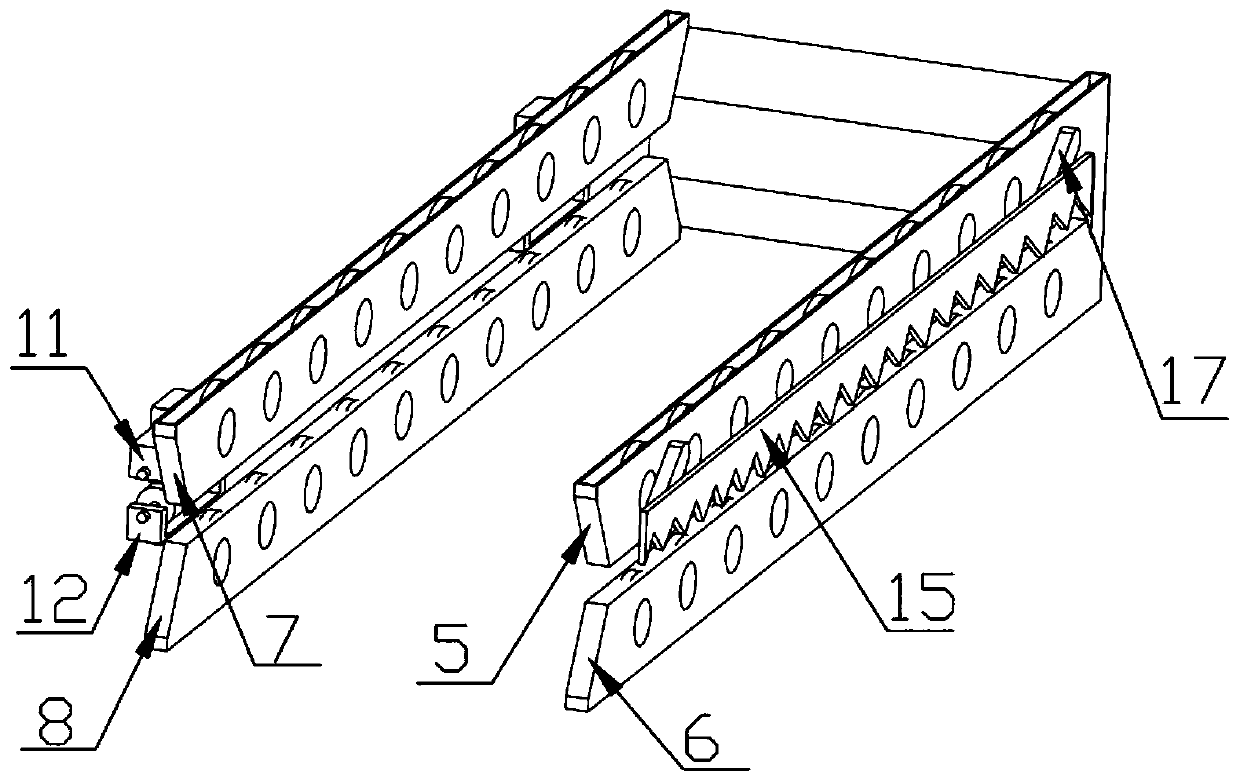

Automatic unpacking feeding device and unloading mechanism

InactiveCN106428856BRealize automatic unpackingWill not polluteBags openingStructural engineeringMechanical engineering

The invention discloses an automatic unpacking and feeding device and a material unloading mechanism, comprising: a bale moving machine, used for automatically carrying material bags, and transporting them to the unloading mechanism; Cutting and unpacking, lifting and lowering the material bag to empty the material bag to realize automatic unloading; the collecting and feeding mechanism is used to receive the unloaded material, collect and transport it, so as to realize automatic feeding . The invention realizes automatic unpacking, unpacking, unloading and loading, and does not cause packaging bag debris pollution to granular materials; realizes no residual blanking, and prevents waste of raw materials.

Owner:CHINA JILIANG UNIV

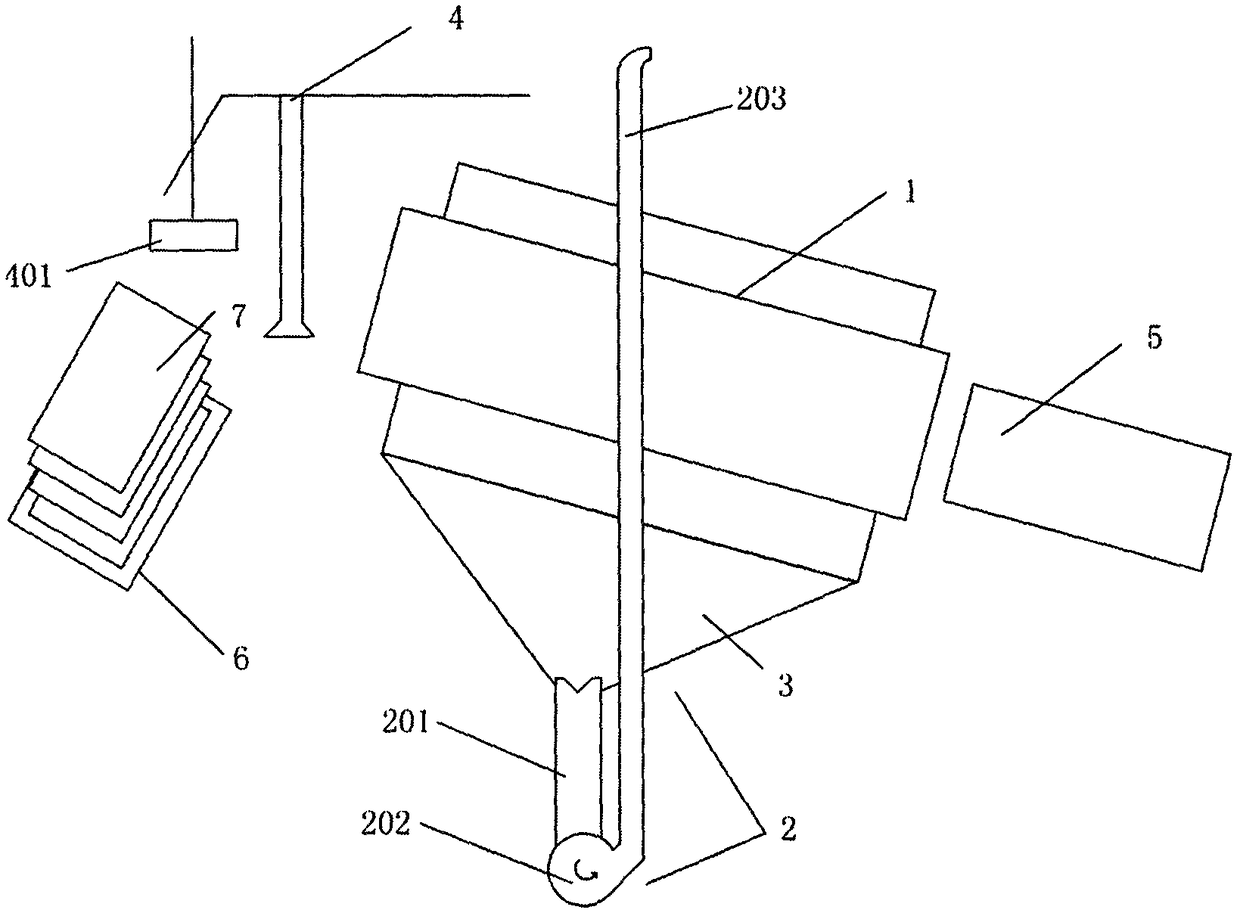

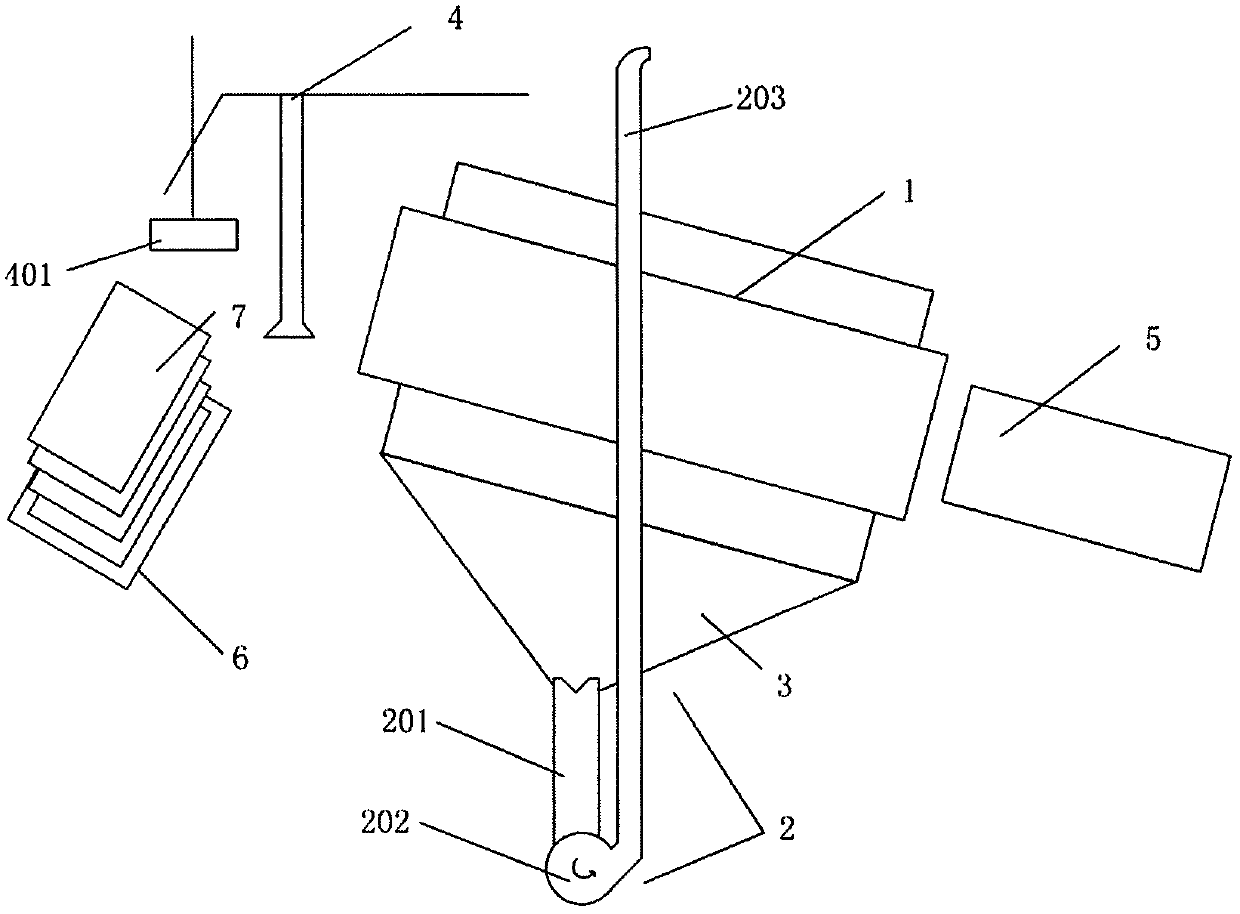

Beverage extraction plant extracting vertically

InactiveCN101849771BRealize automatic unpackingEasy to useBeverage vesselsAgricultural engineeringEngineering

The invention relates to a beverage extraction plant extracting vertically, comprising a stand, a first machine element and a second machine element, wherein, the second machine element is arranged at the lower part in the stand and can glide relative to the first machine element up and down. The beverage extracting device is characterized by also comprising a push rod, a blocking rod, a scrapingpiece, a connection shaft, a torsional spring and two blocking pieces, wherein, the push rod is movably arranged on the second machine element passing through the bottom wall of a concave cavity; theblocking rod is arranged at the bottom of the stand and is supported by a spring and keeps moving upwards; the scraping piece is provided with a horizontal driving lever and a connection rod positioned at two ends of the driving lever and extending downwards, and the bottom of the connection rod is provided with an elastic blocking part; the connection shaft is arranged at the lower part of the second machine element, and the lower end of the connection rod is sheathed at the two ends of the connection shaft in a rotating manner; the torsional spring is sheathed on the connection shaft and acts on the scraping piece; and the two blocking elements are respectively inserted on the inner end faces at the left side wall and the right side wall of the stand, and are matched with the elastic blocking part. The beverage extracting device can realize automatically packaging and has convenient use.

Owner:NINGBO AAA GROUP ELECTRIC APPLIANCE

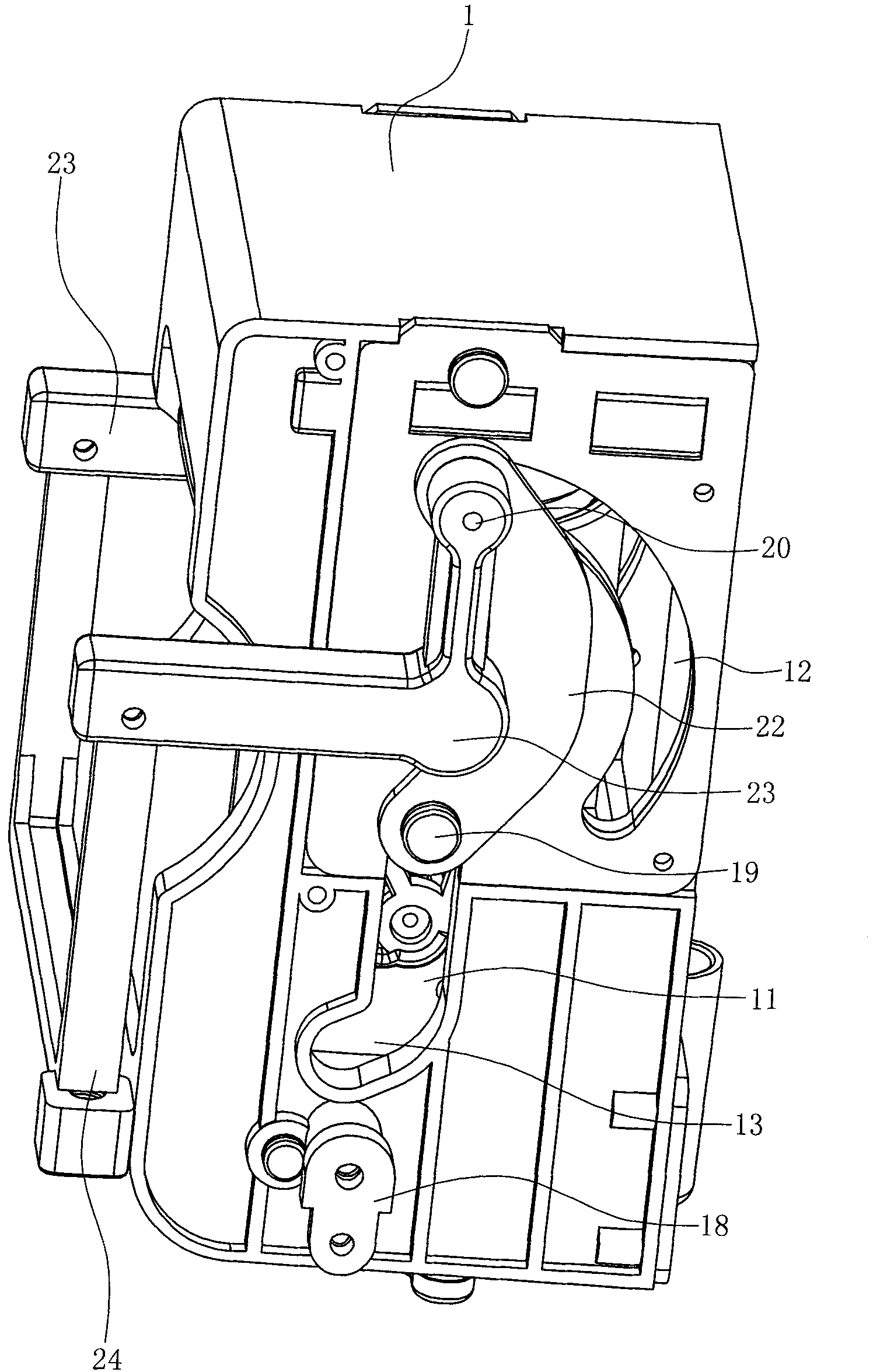

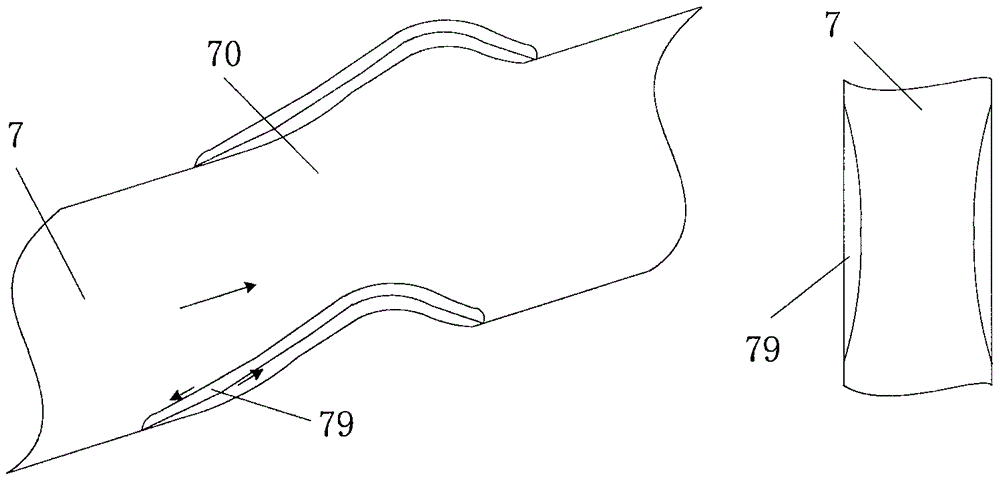

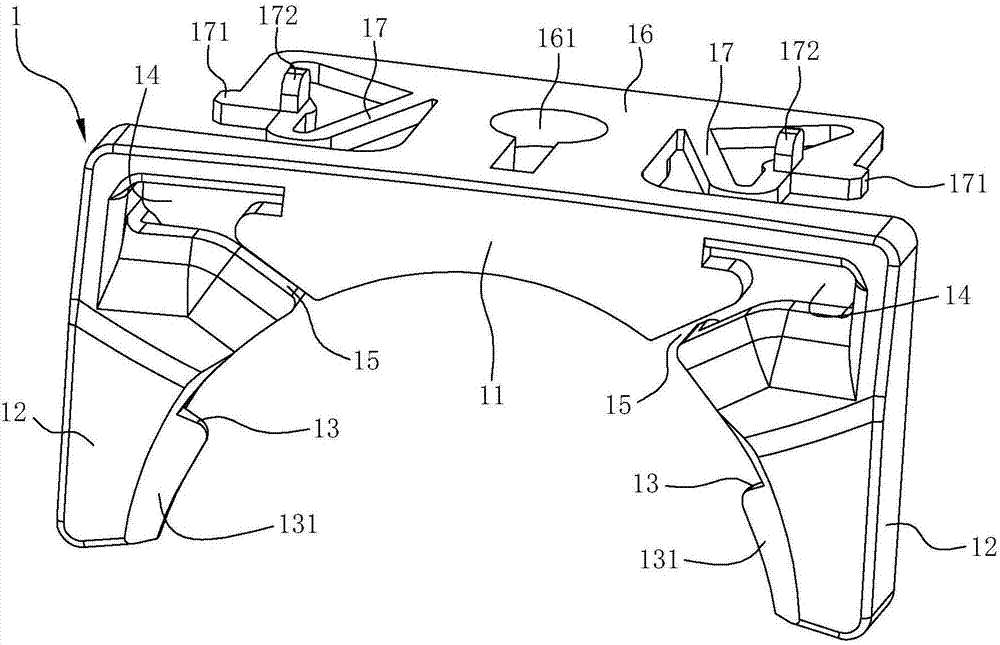

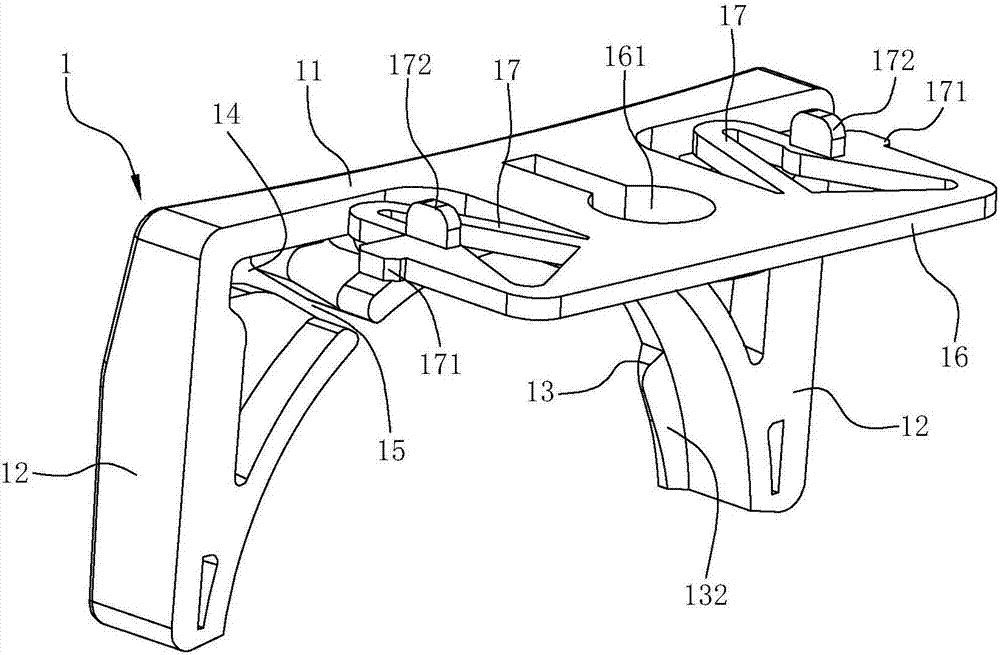

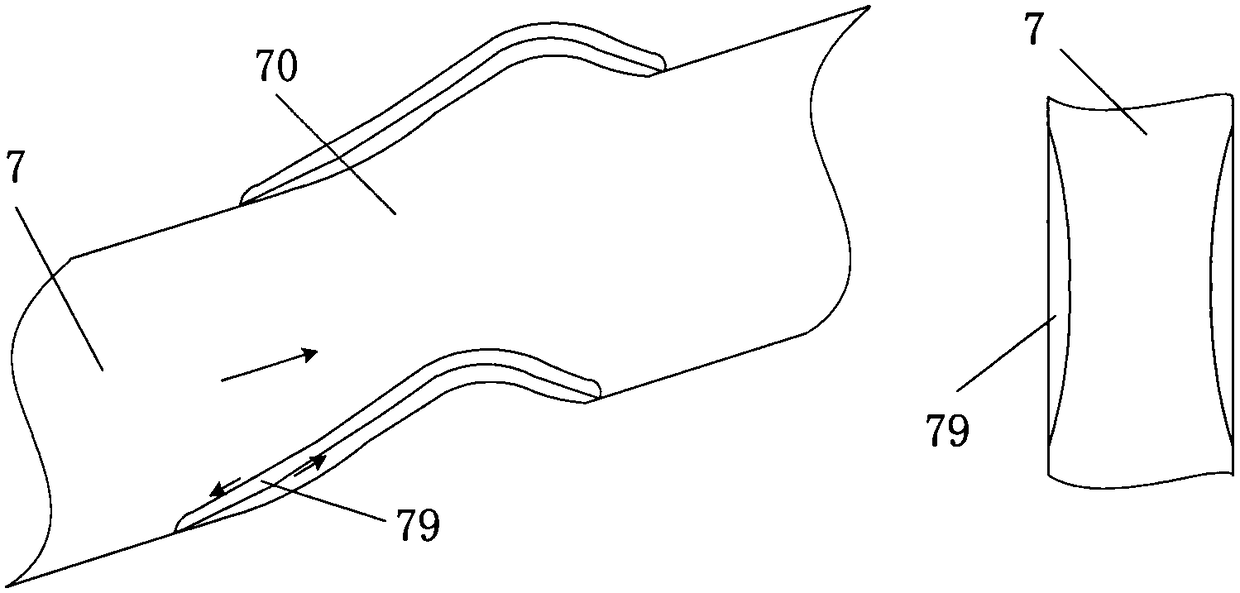

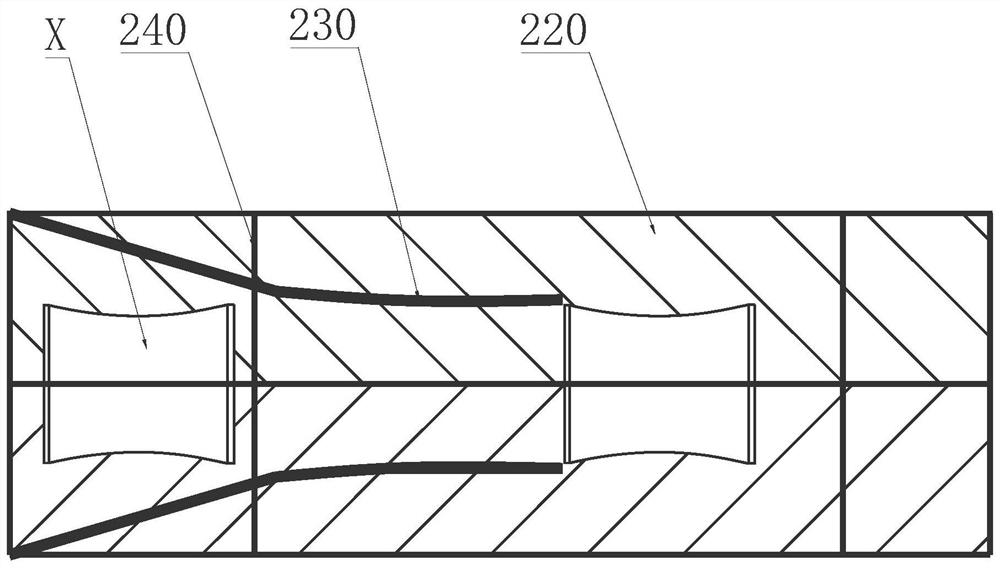

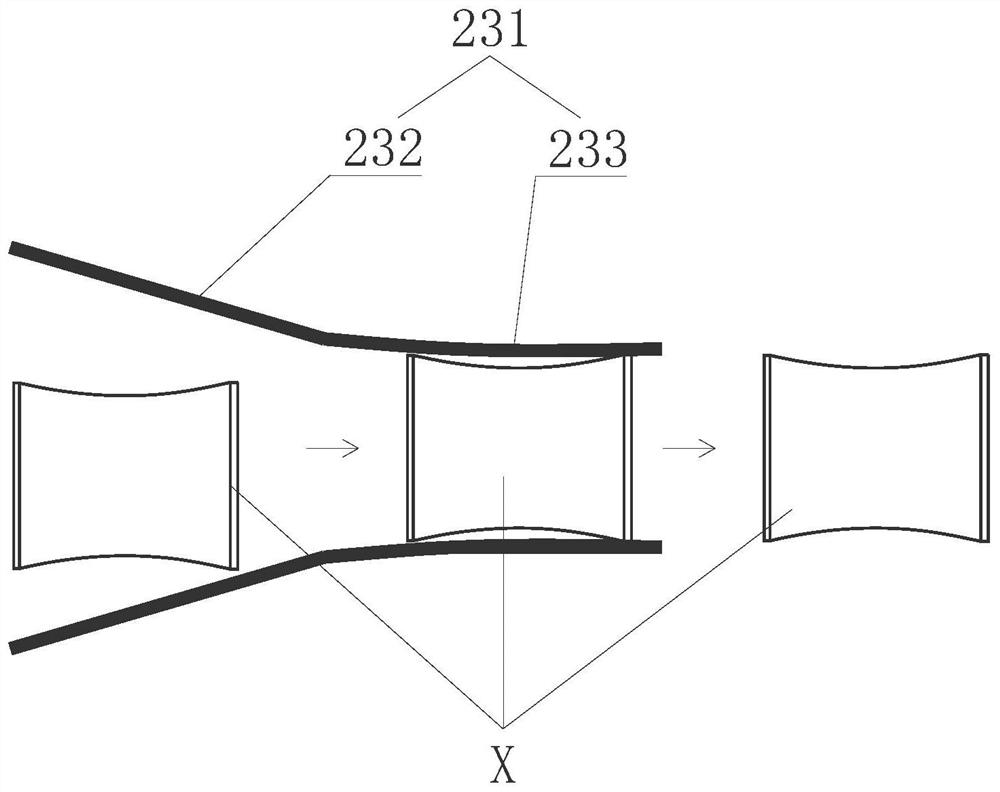

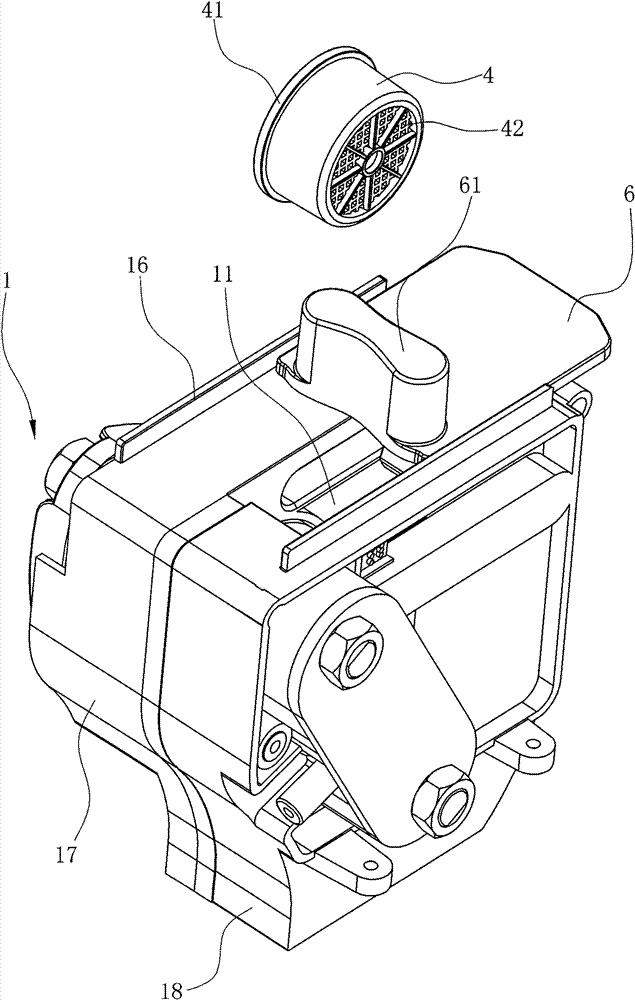

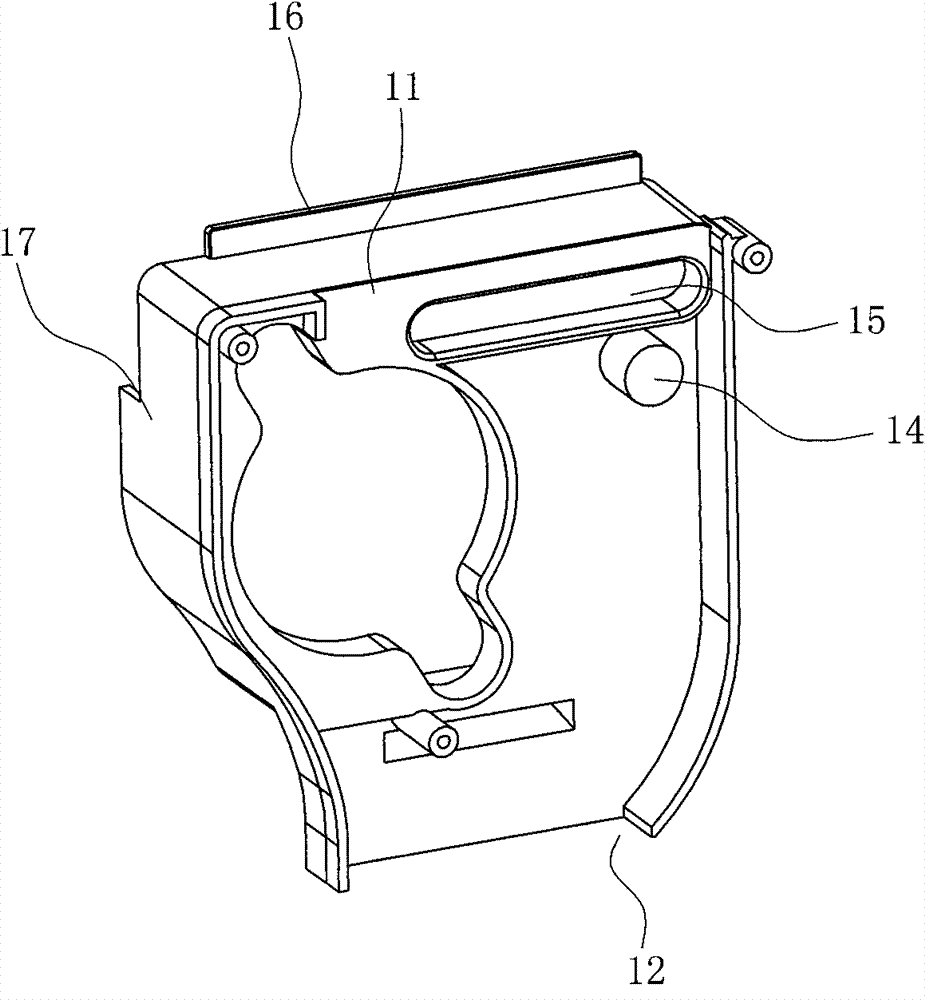

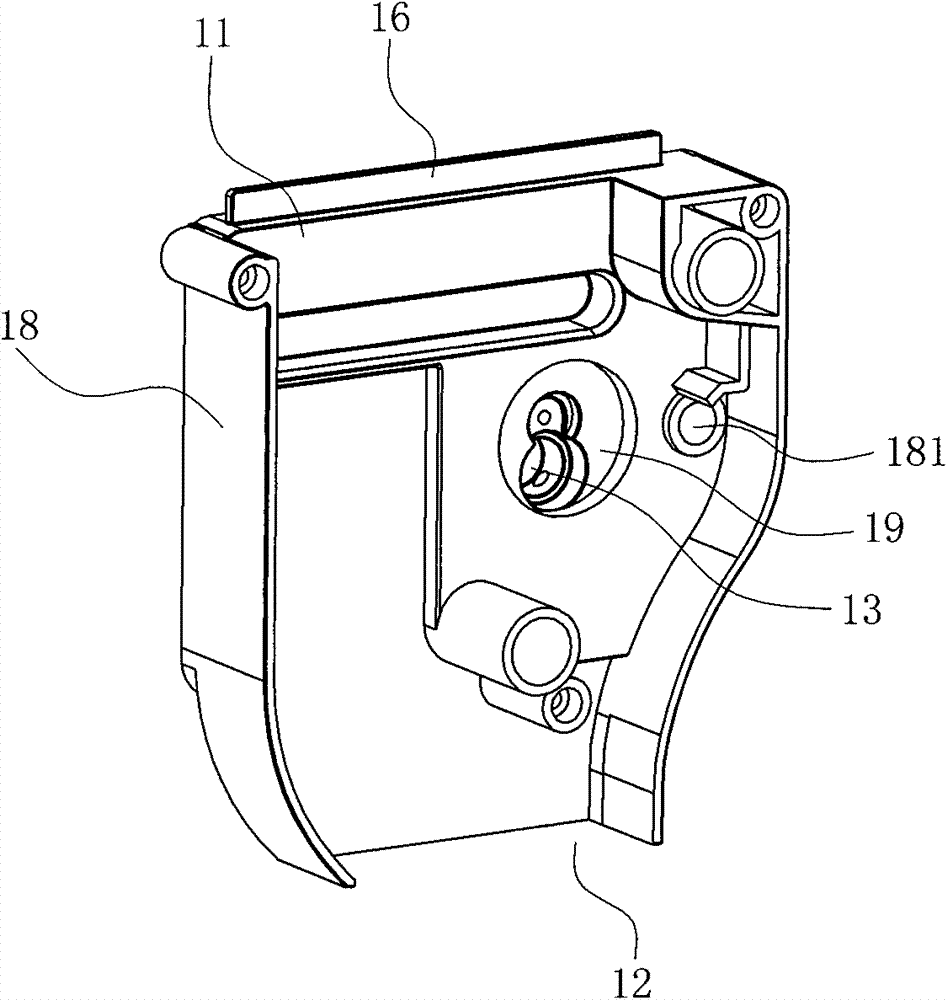

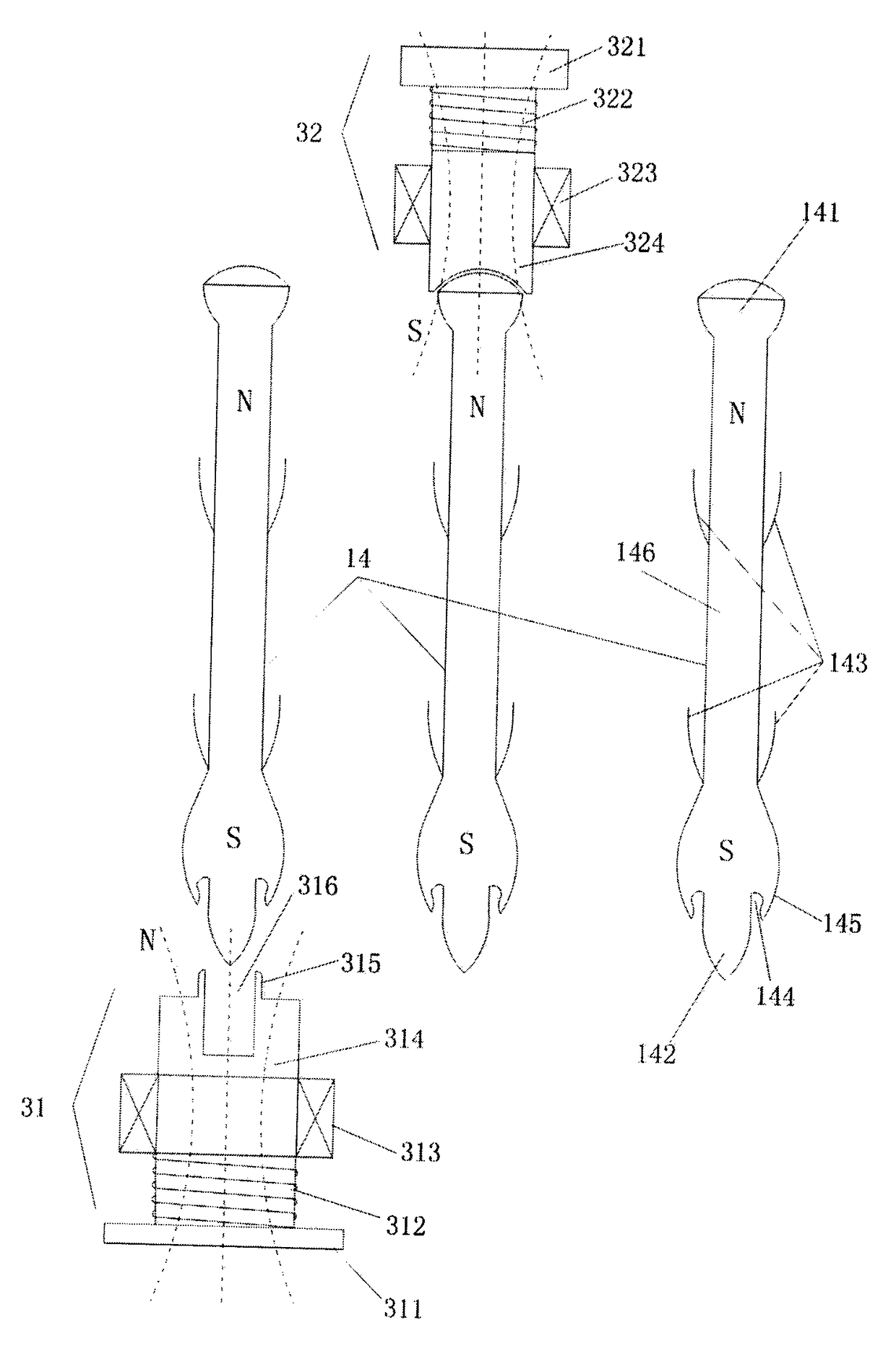

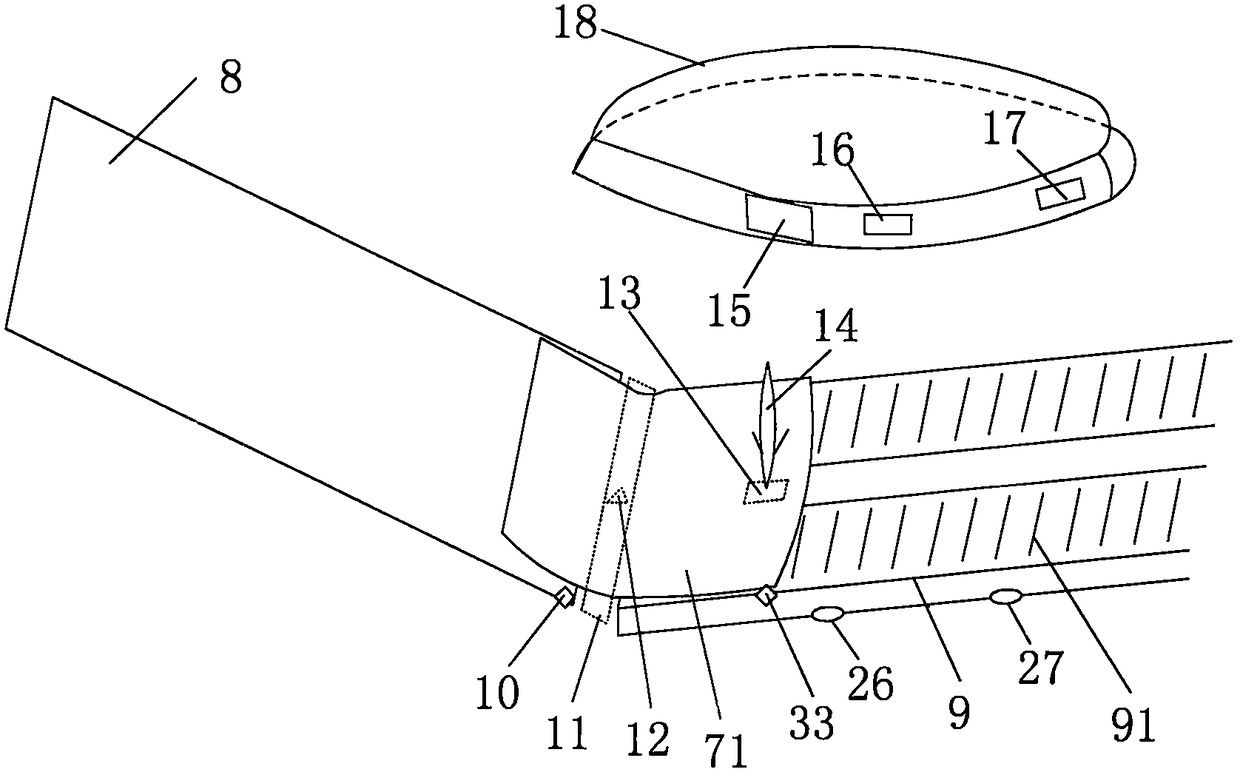

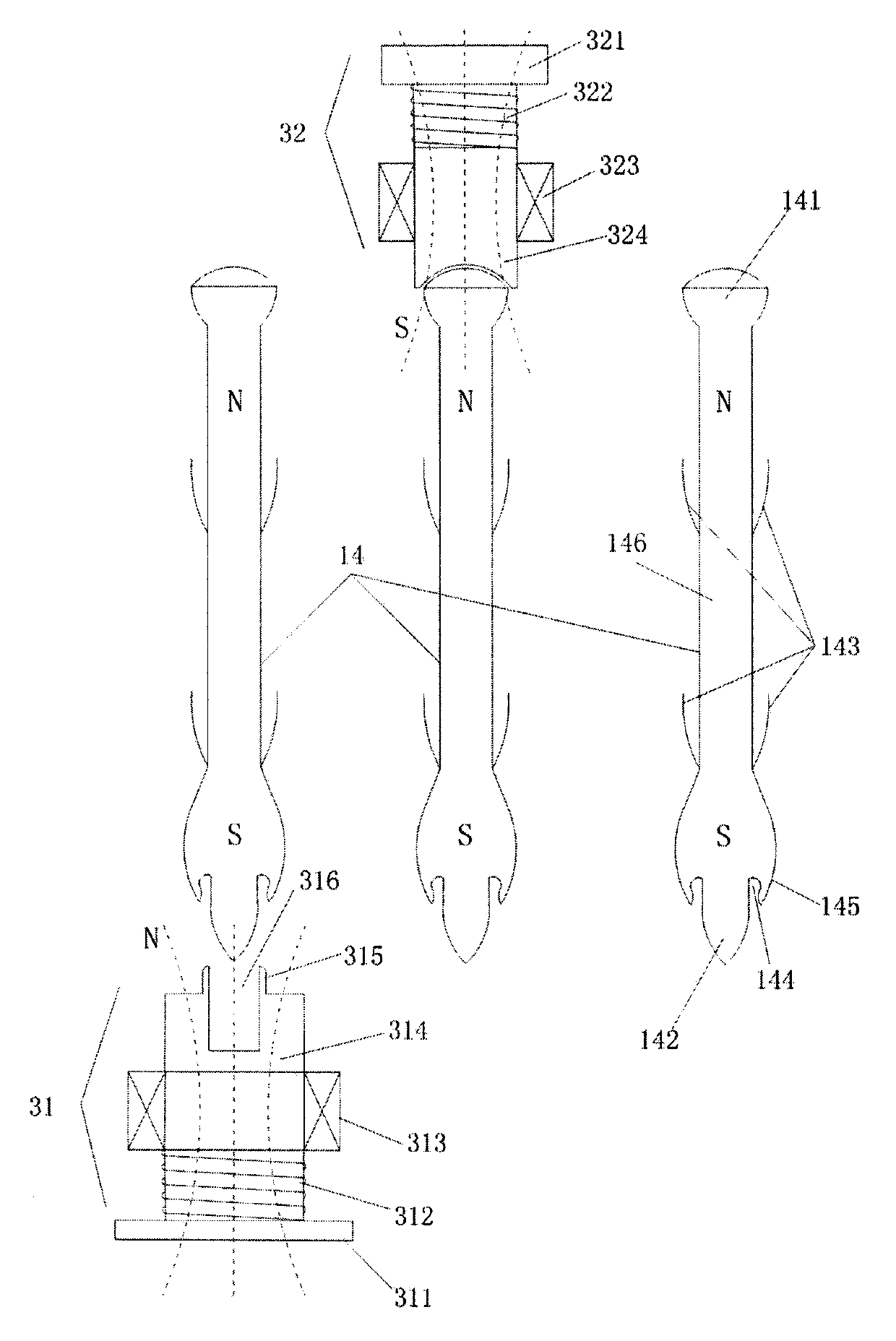

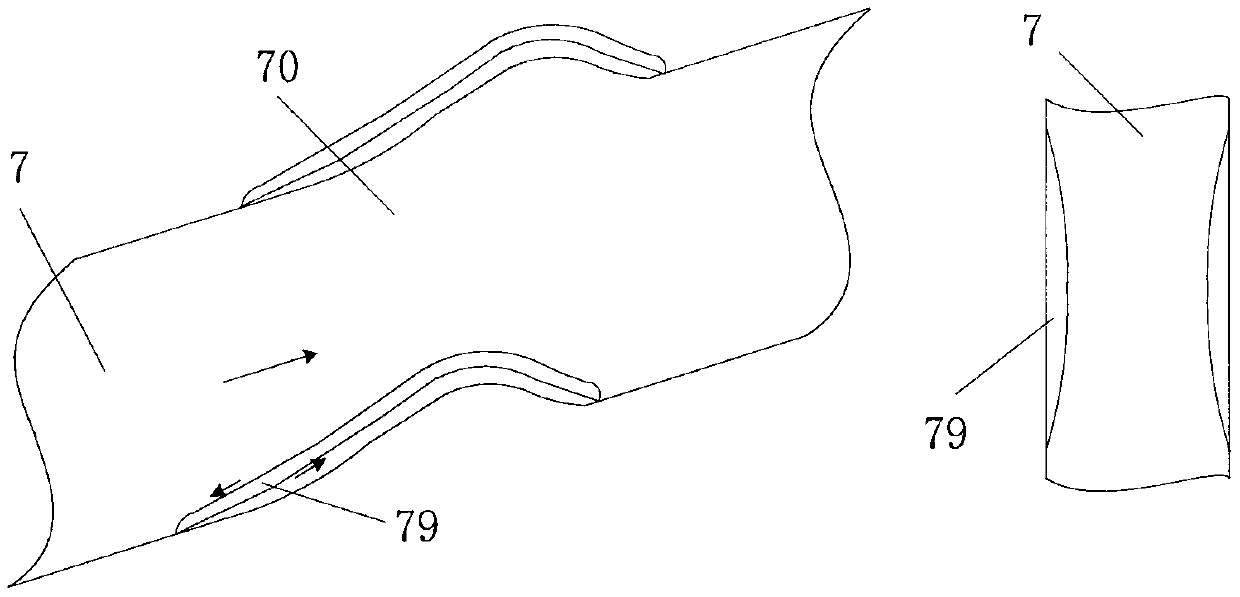

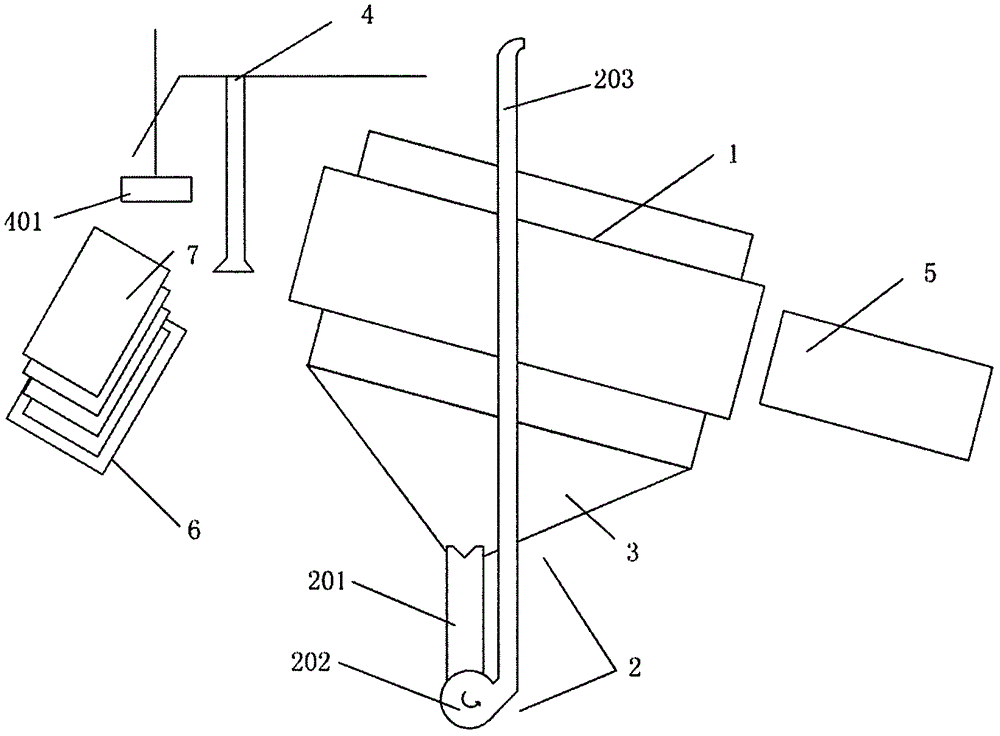

Coffee machine convenient for removing bags

InactiveCN102133045BReduce volumeRealize automatic unpackingBeverage vesselsMachine partsVertical plane

A coffee machine convenient for package removing, comprising a casing (1) having a package inlet (11) and a package outlet (12), and characterized by further comprising: a first machine part (2), constrained in the casing (1) and capable of horizontally sliding left and right along the casing (1), the lower portion of the first machine part (2) having a first arc-shaped notch (21), and an opening end of the first arc-shaped notch (21) being obliquely disposed downwards; a second machine part (3), rotatably disposed in the casing (1) and capable of rotating in a vertical plane, the upper portion of the second machine part (3) having a second arc-shaped notch (31), and an opening end of the second arc-shaped notch (31) being obliquely disposed upwards and being opposite to the package inlet (11) for a coffee packet (4) having a circular edge (41) to be laid thereon; a torsion spring (5), acting on the second machine part (3) so that the opening end of the second arc-shaped notch (31) on the second machine part (3) maintains obliquely upward. The coffee packet is automatically removed through the movement of the first machine part (2) and rotation of the second machine part (3). The packet can be successfully removed without the need for an additional auxiliary component for jointly clamping the packet. The structure is simpler, and the volume thereof is greatly reduced.

Owner:NINGBO SEAVER ELECTRIC APPLIANCE

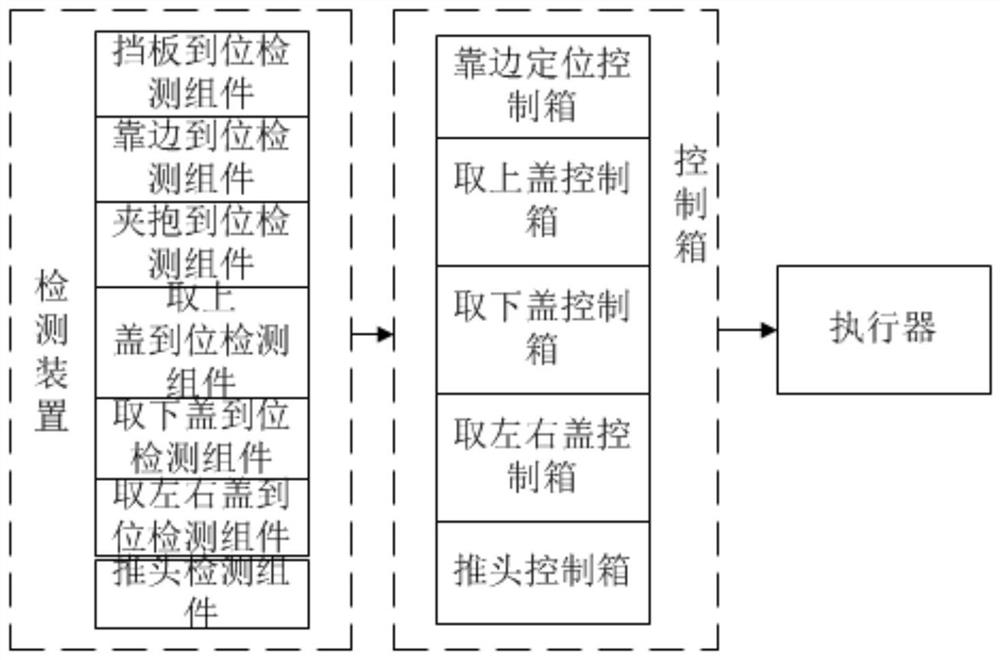

Control system and method for full-standard case unpacker

ActiveCN114180173ARealize automatic unpackingAutomatic launchArticle unpackingMachine controlControl system

The invention discloses a full-standard case unpacking machine control system which is characterized by comprising a detection device, a control box and an execution device. The execution device is used for receiving a control instruction sent by the control box and controlling the box unpacking machine to work; the detection device comprises a baffle in-place detection assembly, a side in-place detection assembly, a clamping in-place detection assembly, an upper cover taking in-place detection assembly, a lower cover taking in-place detection assembly, a left and right cover taking in-place detection assembly and a push head detection assembly. The control box comprises a side positioning control box, an upper cover taking control box, a lower cover taking control box, a left and right cover taking control box and a push head control box. By controlling the case unpacking machine, the problem that an existing case unpacking machine cannot conduct automatic case unpacking and cigarette pushing on standard cigarettes and special-shaped cigarettes is solved, automatic case unpacking of full-specification cigarette cases is achieved, and the sorting and case unpacking requirements of a cigarette logistics distribution center are met.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

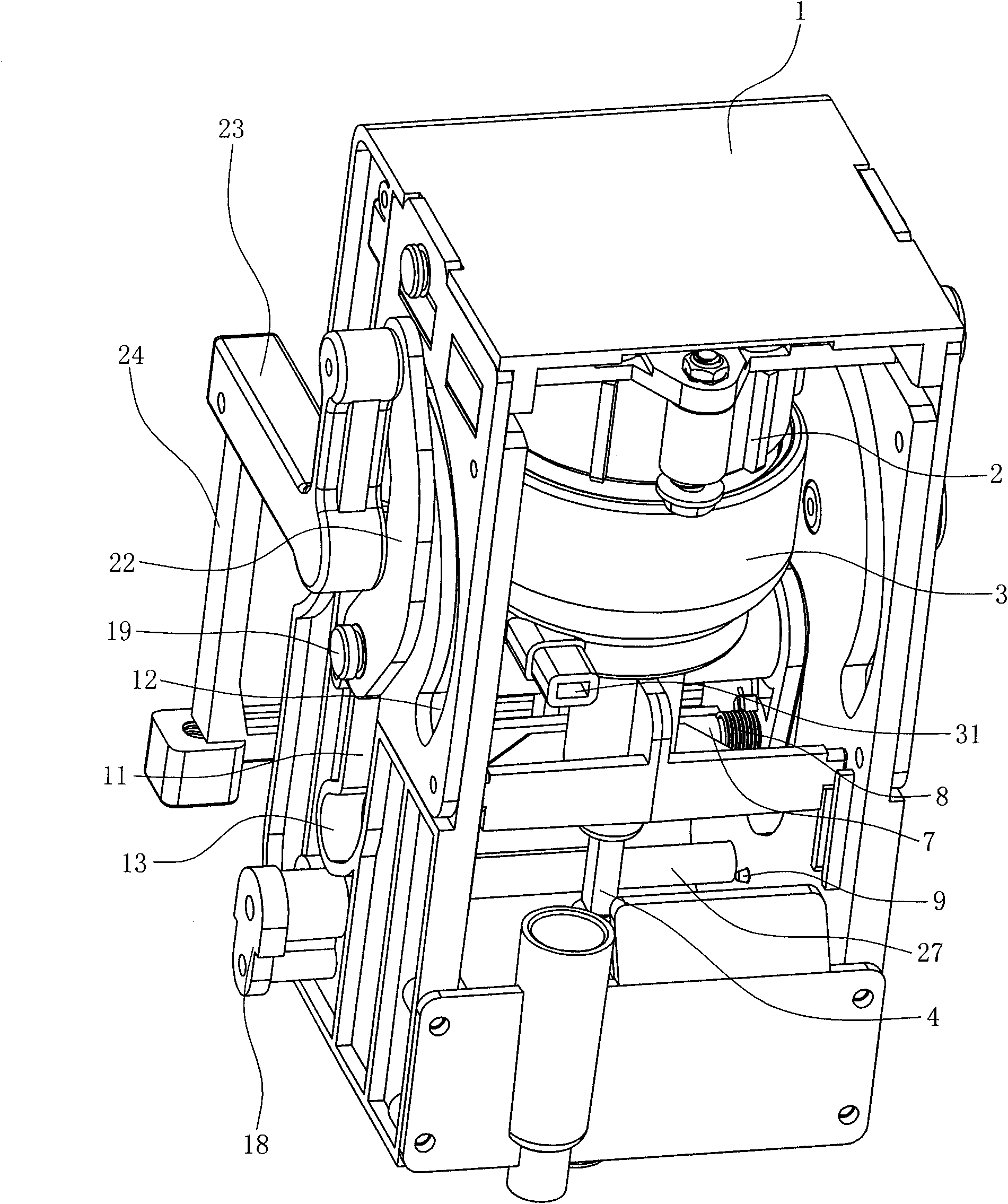

A coffee machine capable of automatically removing bags

The invention discloses a coffee machine capable of making a coffee package fallen off automatically. The coffee machine comprises an engine base which is provided with a package falling port, a brewing part with a pricking pin and a moving plate which is arranged in the engine base and provided with a concave part, wherein a lower pricking pin is fixed at the bottom of the concave part; and a liquid outlet hole is formed at the bottom of the concave part. The coffee machine is characterized by also comprising a bracket, a flooring socket, a splint, a multi-connecting rod structure and a limit part, wherein the bracket is restrained on the front part of the moving plate, can move up and down, is supported by a first spring and always moves upwards; the flooring socket is arranged in the engine base and can slide horizontally relative to the engine base; the splint is restrained on the front part of the flooring socket and can move up and down; the front end face of the splint is an arc notch with radian of more than 180 DEG; the splint is supported by a second spring and always moves upwards; the multi-connecting rod structure is arranged in the engine base; one end of the multi-connecting rod structure is rotatably connected with the moving plate, while the other end is rotatably connected with the flooring socket; and the limit part is arranged on the rear part of the package falling port. The coffee machine capable of making the coffee package fallen off automatically has a novel structure and is suitable for extracting the gel-like packing box-shaped coffee package.

Owner:NINGBO SEAVER ELECTRIC APPLIANCE

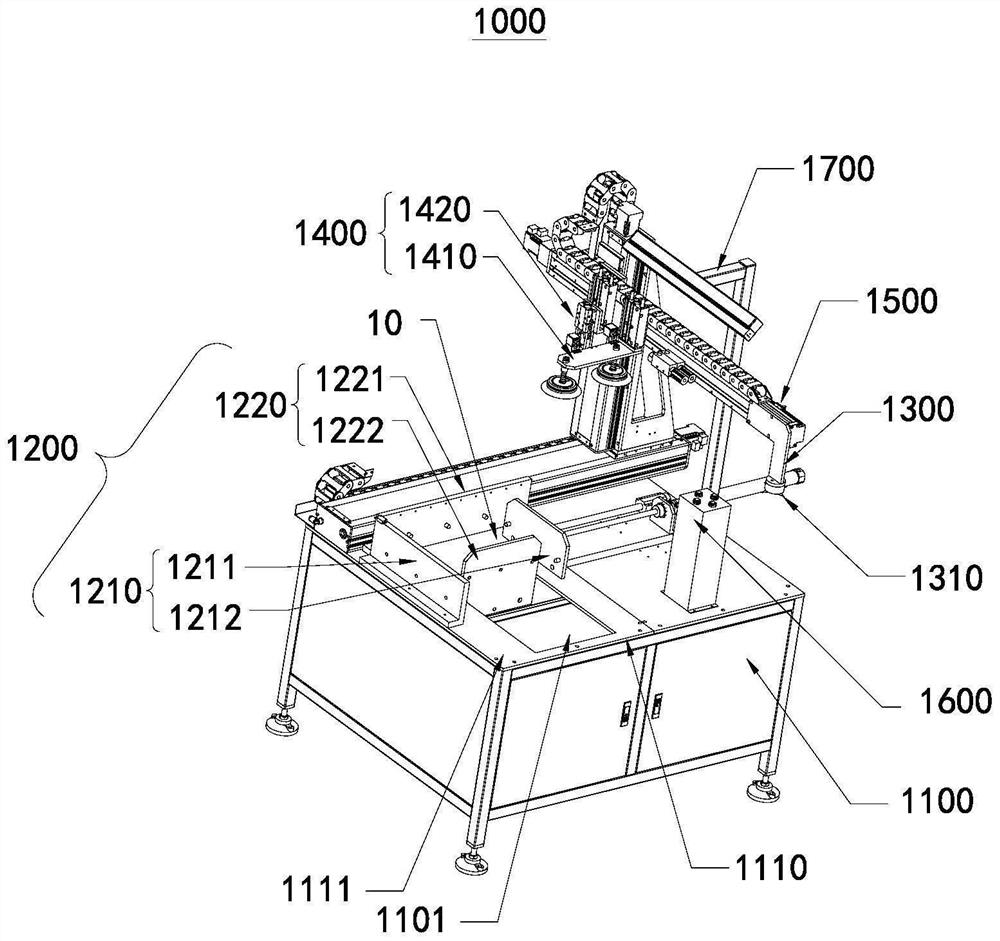

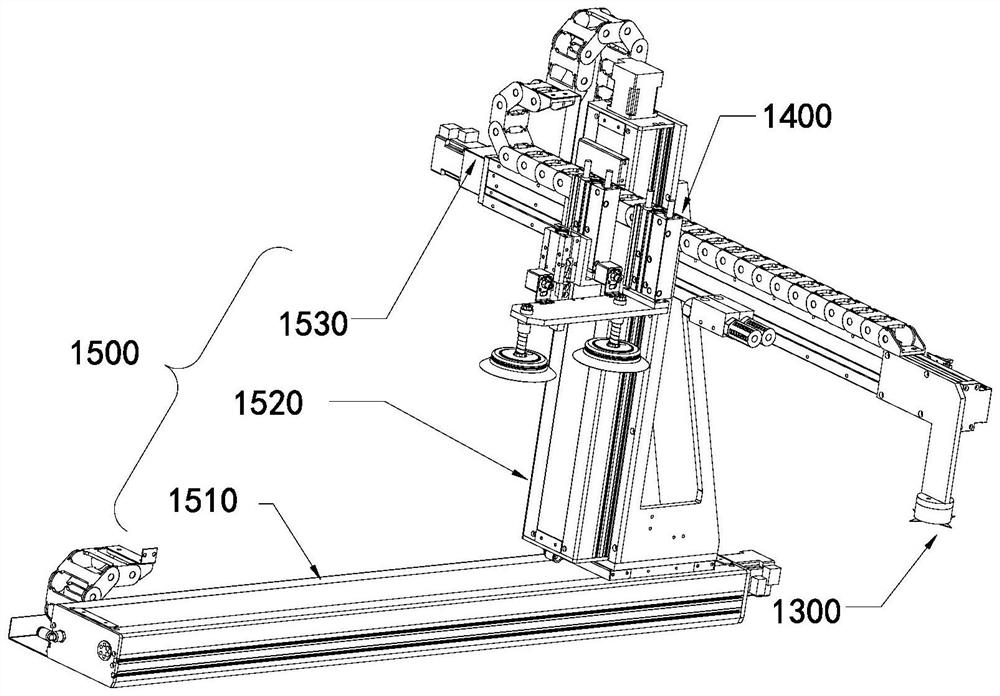

Novel case unpacking machine for large-capacity beverage production line

ActiveCN114229115ARealize automatic unpackingHigh degree of automationPackaging bottlesPackaging machinesCartonHot-melt adhesive

The invention discloses a novel large-capacity beverage production line case unpacking machine which comprises a main body plate feeding device used for feeding and conveying a main body plate, a partition plate feeding device used for feeding and conveying an H partition plate material, and an H partition plate material folding mechanism arranged at an outlet of the partition plate feeding device. The first hot melt glue gun is used for spraying hot melt glue on the material folding surface of the H partition plate; a main body plate folding mechanism and a second hot melt glue gun for spraying hot melt glue on the bonding surface of the main body plate are arranged at an outlet of the main body plate feeding device; a mold assembly used for assisting H partition plate materials and main body plate folding forming is arranged in the main body plate folding mechanism, and the main body plate and an H partition plate are bonded and formed on the mold assembly. According to the forming device, the forming process of the H-shaped partition plate type fixed carton can be rapidly and stably completed, whole-process automation is achieved, and much manual intervention is not needed.

Owner:NANJING HUACHUANG PACKAGING MACHINERY

A method for automatic unpacking and feeding

InactiveCN106428855BRealize automatic unpackingWill not polluteUnpacking by cuttingEngineeringMechanical engineering

The invention discloses an automatic unpacking and loading method. The method applies the bag conveyor to convey the material bag, and feed the bag to the unloading mechanism. The unloading mechanism automatically cuts and unpacks the bags conveyed upon it, hoists up the bags, lowers down the bags to empty the bags to achieve the automatic material unloading. Material gathering and conveying mechanisms are used to accept the unloaded material and collect and convey the unloaded materials to achieve the material loading. The method achieves the automatic unpacking, unloading and loading with no contamination caused by broken packing bag pieces to the particle materials thus achieving the non-residue material unloading, and preventing the squandering of material.

Owner:CHINA JILIANG UNIV

A method and system for controlling unlocking of an incubator

ActiveCN109872433BRealize automatic unpackingImprove delivery/pickup efficiencyApparatus for meter-controlled dispensingIndividual entry/exit registersSoftware engineeringOperating system

The invention discloses an unlocking control method and system for an incubator. The method includes the following steps: step S1, using the unlock interface to obtain a two-dimensional code for delivering / taking meals, and receiving a request for unlocking from a user terminal; step S2, for delivering / taking meals After the verification of the QR code is successful, obtain the unlock parameters according to the QR code for delivery / pickup, and verify whether the unlock parameters are correct to the ordering platform; step S3, when the unlock parameters are verified to be correct, connect to the MQTT server, and assemble and publish topics according to the unlock parameters and message and send the unlocking request to the MQTT server; step S4, after receiving the unlocking request, the MQTT server forwards the unlocking request to the cabinet lock terminal, and the cabinet lock terminal completes the unlocking and feedback. The automatic unpacking of the incubator improves the efficiency of delivery / pickup and saves human resources.

Owner:广州大学华软软件学院

Automatic unpacking and feeding method

InactiveCN108891701ARealize automatic unpackingWill not polluteUnpacking by cuttingEngineeringAutomatic testing

The invention discloses an automatic unpacking and feeding method, which automatically transports a packing bag through a packing conveyor and transports the packing bag to a discharging mechanism. The unloading mechanism automatically cuts and unpacks the packages conveyed to it, hangs the packages, lowers and empties the packages to realize automatic unloading; Aggregate feeding mechanism is used to receive the discharged materials and collect and transport them to realize automatic feeding. The invention realizes automatic unpacking, unloading and feeding, and does not produce packaging bagdebris pollution to the granular material. No residual blanking is realized, and the waste of raw materials is prevented.

Owner:CHINA JILIANG UNIV

A kind of unpacking and sorting production line of vials

ActiveCN108100392BGood unscrambling effectUnscramble bottles quicklyConveyorsUnpacking by heatingBiochemical engineeringSlide plate

The invention discloses an unpacking and bottle straightening production line for penicillin bottles. The unpacking and bottle straightening production line comprises an unpacking machine, a lifting conveyor and a bottle straightening machine. The unpacking and bottle straightening production line has the advantages that penicillin bottle groups can be unpacked on the unpacking machine and then can be conveyed onto the bottle straightening machine by the aid of the lifting conveyor, the penicillin bottles in a collecting hopper can be sorted by the bottle straightening machine by the aid of asorting device and then can be fed onto a bottle carrying frame, bottle insertion actions can be carried out by left and right insertion needles in movement in opposite directions, and then the penicillin bottles can be driven to rotate by 90-degree angles, can be supported by a right arc-shaped slide plate to stand up, then can fall into an output groove and can be pushed out by a bottle pushingmechanism; the penicillin bottle groups can be unpacked and then conveyed onto the bottle straightening machine by the unpacking and bottle straightening production line, the bottles can be sorted onthe bottle straightening machine, manual unpacking can be omitted, the bottles can be straightened without consideration on the orientation of openings of the penicillin bottles, and accordingly the efficiency of the integral unpacking and bottle straightening production line for the penicillin bottles can be improved.

Owner:HIT SMART FACTORY CO LTD

An automatic unpacking and unloading method

InactiveCN106672357BRealize automatic unpackingWill not polluteBags openingUnpacking by cuttingStructural engineeringConveyor belt

Owner:CHINA JILIANG UNIV

Automatic unpacking and feeding method based on vibration removal method

ActiveCN106628460BRealize automatic unpackingWill not polluteBags openingTransmission beltStructural engineering

The invention discloses an automatic unpacking and feeding method based on vibration removal of residual material, which comprises the following steps: moving the material bag to the conveyor belt; the surface of the conveyor belt is inclined upward, and a device for detecting the material bag The first material bag sensor; set the collector under the transmission belt, collect the material before loading; the material bag enters the front end of the conveyor belt, and the middle part of the lower side of the material bag is cut by the cutting mechanism installed near the front end of the conveyor belt. Carry out cutting; the cut material bag continues to be conveyed, when it is detected that the material bag reaches the predetermined position at the rear end of the conveyor belt, the vibration bag mechanism located at the rear end of the conveyor belt works, vibrates and beats the material bag to promote the discharge of residual materials; in the vibration bag mechanism While vibrating and beating the bale, the dragging mechanism grabs the bale and drags it forward, pulling the bale off the conveyor belt as the remnant is emptied. The invention realizes automatic unpacking, does not produce packaging bag debris pollution to granular materials; realizes no residual blanking, and prevents waste of raw materials.

Owner:CHINA JILIANG UNIV

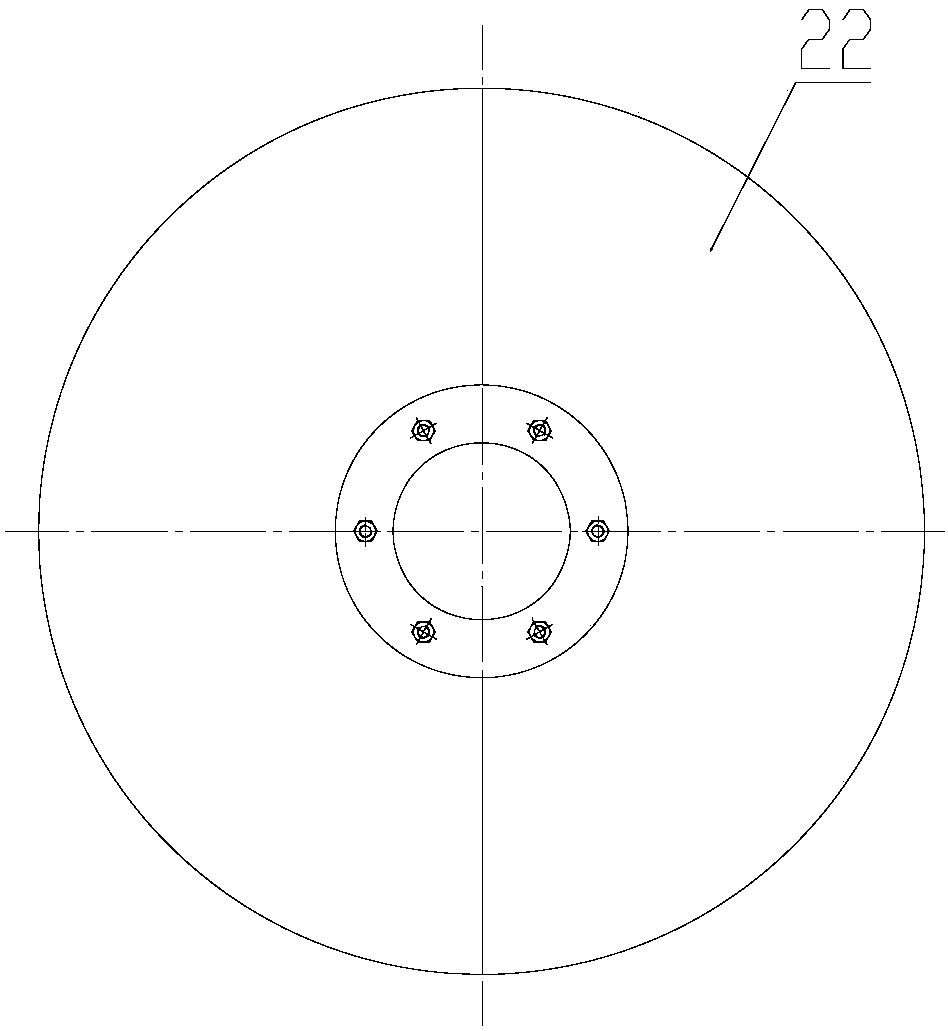

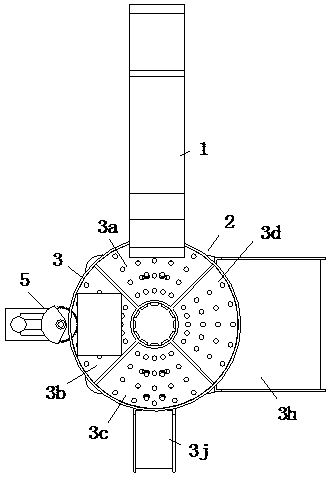

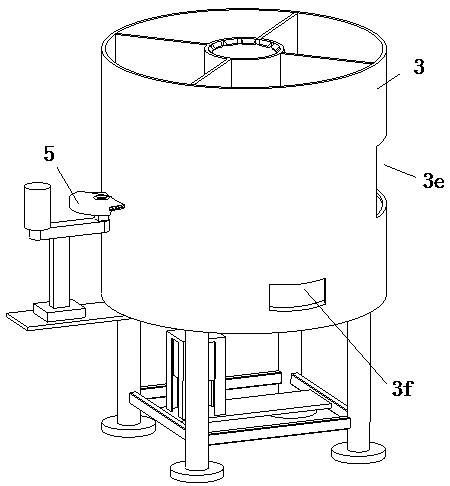

Cement unpacking machine

InactiveCN107758024ARealize automatic unpackingPhysical impactUnpacking by cuttingEngineeringAutomation

The invention relates to the field of construction machinery, in particular to a cement unpacking machine which comprises a cement elevator and an unpacking machine body. The cement elevator is arranged beside the unpacking machine body, the unpacking machine body comprises a cylinder body, a conical filtering plate is arranged in the cylinder body, and four partition plates which are uniformly distributed in the circumferential direction are arranged above the filtering plate. A loading station, an unpacking station, a vacancy and a removing station are arranged on the cylinder body in the circumferential direction, a cutting machine is arranged on the cylinder body and corresponds to the unpacking working position, a cement bag discharging opening is formed in the cylinder body, and a cement discharging opening is formed in the cylinder body corresponding to the removing working position. A cement discharging opening communicated with the lower-layer space is further formed in the cylinder body, and the unpacking machine body further comprises a driving device used for driving the filtering plate to rotate. According to the cement unpacking machine, automatic unpacking of cementis realized, and automatic operation is adopted in the whole process. Only one person needs to operate the machine, the efficiency is high, the labor cost is low, and the body of workers cannot be influenced.

Owner:王山友

Vibration removal type automatic unpacking and feeding device

ActiveCN106829100BRealize automatic unpackingWill not polluteBags openingEngineeringMechanical engineering

The invention discloses an automatic unpacking and loading device for removing residues by vibration. The device comprises a pack carrying machine, a conveying belt, a collector, a cutting mechanism, a pack vibration mechanism and a pack towing mechanism, wherein the pack carrying machine is used for carrying packs onto the conveying belt; the surface of the conveying belt is upwards inclined for conveying the packs; the length directions of the packs are perpendicular to the conveying direction of the conveying belt; a first pack sensor for detecting the packs is arranged on the conveying belt; the collector is arranged below the conveying belt; when the packs enter the front end position of the conveying belt, the cutting mechanism is controlled to cut the middle parts of the lower side edges of the packs; the pack vibration mechanism is positioned at the back end of the conveying belt; when the packs are detected to reach a preset position at the back end of the conveying belt, the packs are vibrated and flapped to accelerate discharge of the residues; when the pack vibration mechanism vibrates and flaps the packs, the pack towing mechanism grabs and tows the packs to advance; and when the residues are emptied, the packs are towed away the conveying belt. The device realizes automatic unpacking, cannot generate the packing bag chip pollution for particles, realizes no-residue falling, and prevents raw material wastes.

Owner:CHINA JILIANG UNIV

Automatic seal breaking device for bread bags

InactiveCN111056099ARealize automatic unpackingBags openingUnpacking by cuttingElectric machineryEngineering

The invention relates to an automatic seal breaking device for bread bags. The device comprises a pair of left and right brackets and a cutting blade for cutting the bread bags, upper row pressing wheels are arranged in upper brackets on the two sides of the left bracket and the right bracket correspondingly, lower row pressing wheels are arranged in lower brackets correspondingly, upper rows of movable rollers and lower rows of fixing rollers are correspondingly arranged on the front and rear portions of the upper and lower brackets on the outer sides of the left and right brackets, an up-down moving mechanism is arranged on the upper row of movable rollers, and the upper row of movable rollers are controlled by the up-down moving mechanism to move up and down to compress or loosen the bread bags, the cutting blade is mounted on the outer side surface of the inner side upper bracket of the left bracket, the cutting blade is connected with a connecting rod mechanism, the cutting bladeis driven by the connecting rod mechanism to cut the bread bags, the upper rows of movable rollers and the lower rows of fixing rollers are connected with a motor, and the upper rows of movable rollers and the lower rows of fixing rollers are driven by the motor to rotate, so that the cut bread bags are taken out.

Owner:上海西派埃智能科技有限公司 +1

Automatic unpacking and unloading method

InactiveCN106672357ARealize automatic unpackingWill not polluteBags openingUnpacking by cuttingBiomedical engineeringRaw material

The invention discloses an automatic unpacking and unloading method. A conveying belt is adopted to convey material packages, and is provided with a material package sensor for detecting the material packages and a magnetic needle head matching body matched with a magnetic needle head part; when the material packages are conveyed to a preset position, a cutting mechanism is adopted to cut and unpack the material packages; a package lifting mechanism is arranged above the conveying belt, and is provided with a magnetic needle emitting mechanism and a magnetic needle tail matching body matched with a magnetic needle tail part in sequence; when a magnetic needle is in an initial state, the magnetic needle is positioned in the magnetic needle emitting mechanism; in the conveying process of the cut and unpacked material packages, after the material package sensor detects the positions of the material packages, the magnetic needle emitting mechanism emits out the magnetic needle onto the material packages, and the magnetic needle head part is matched with the magnetic needle head matching body; and the magnetic needle tail matching body on the package lifting mechanism sucks the magnetic needle to realize lifting of the material packages. The automatic unpacking and unloading method realizes automatic unpacking, cannot generate the packing bag chip pollution to particles, realizes no-residue falling, and prevents raw material wastes.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com