Automatic mail packaging and sorting production line

A production line and mail technology, which is applied in the field of logistics sorting equipment, can solve the problems of heavy workload, low degree of automation, and low work efficiency, and achieve the effects of improving efficiency, facilitating bagging operations, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

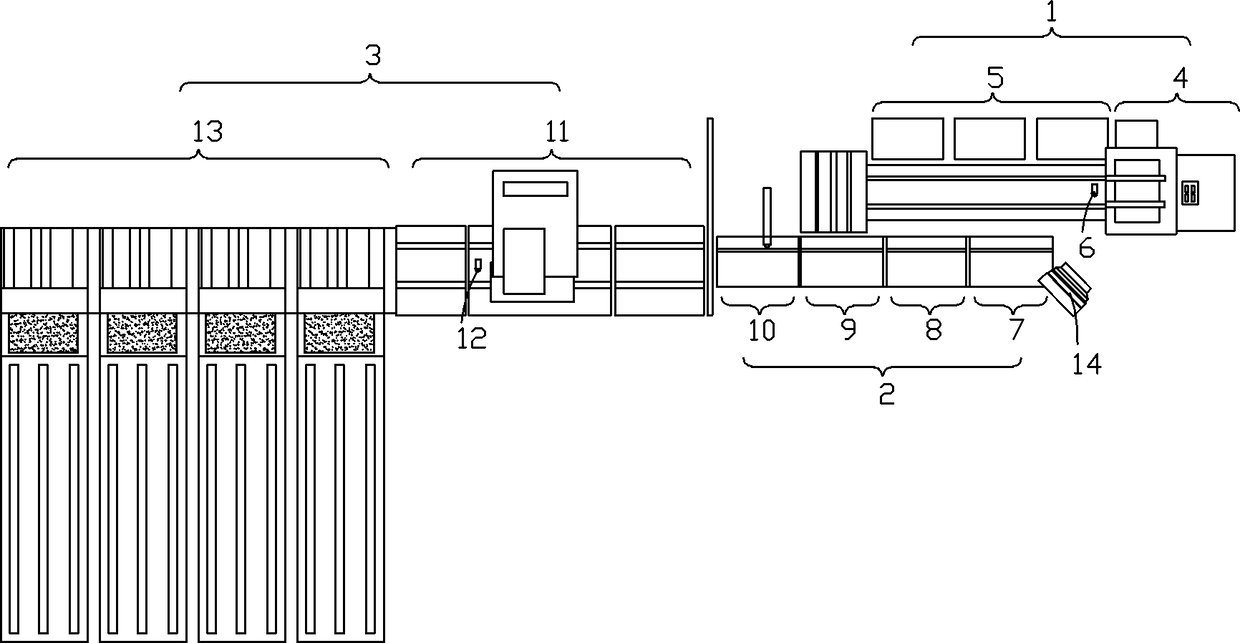

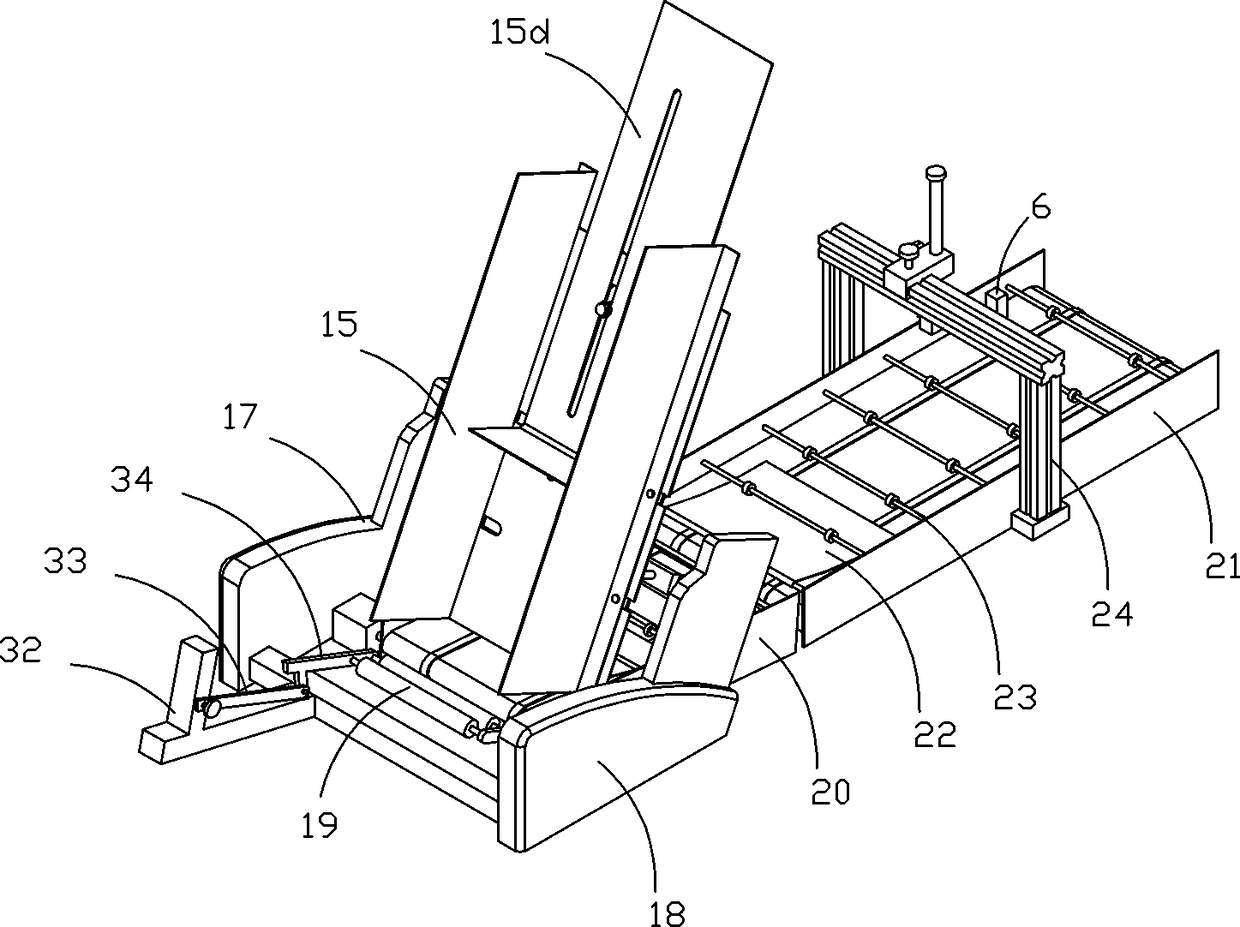

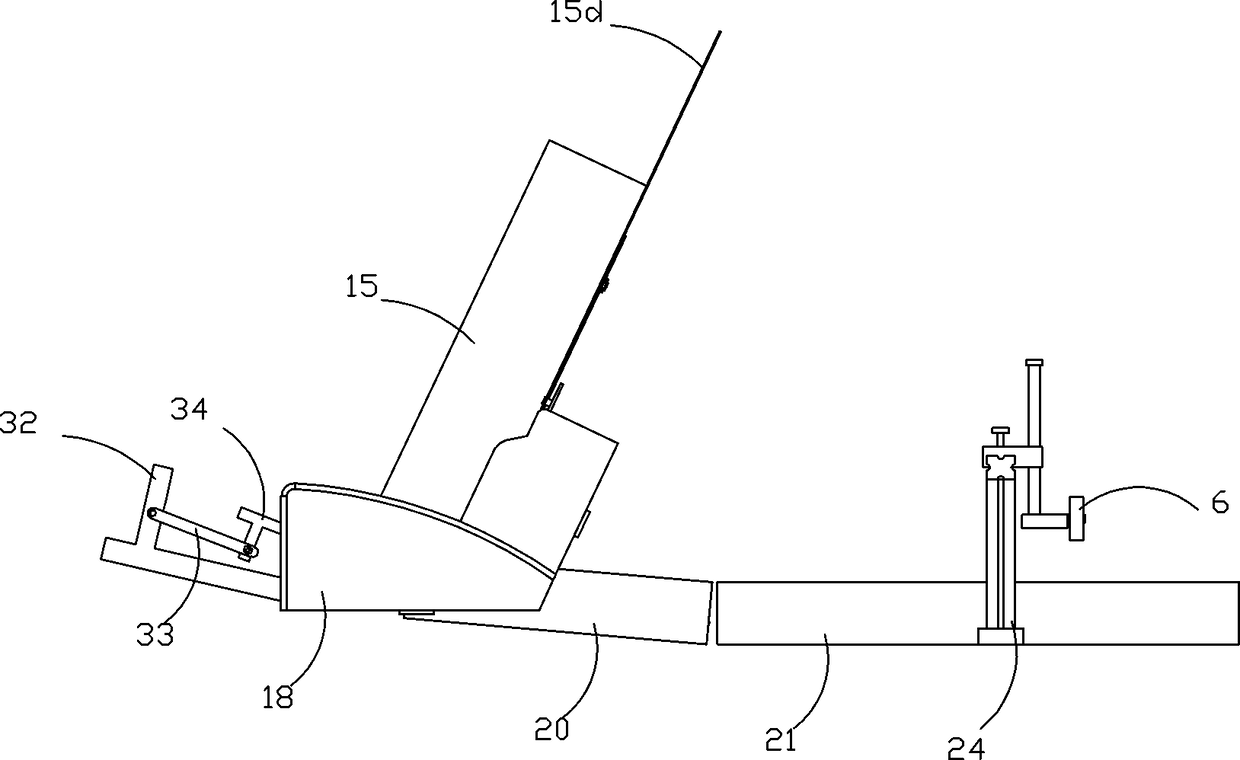

[0057] see figure 1, an automatic packaging and sorting production line for mail, including a conveyor line A1, a conveyor line B2 arranged side by side, and a conveyor line C3 arranged at the end of the conveyor line B2, and both the conveyor line A1 and the conveyor line C3 use belt conveyors , the conveying line B2 has a conveying table 51, which is provided with a conveying chain 53 which is flush with its table surface, and several miniature grippers 54 are installed on the conveyance chain 53, and the clamping mouths of the miniature grippers 54 all face the right side Arrangement, the spacing of two adjacent miniature jaws 54 is greater than the length of the mail; On the conveying line A1, along its conveying direction, be respectively provided with the letter conveying device 4 and the insert feeding device 5 that are used for credit card letter, insert feeding, and Equipped with a barcode scanner A6 for reading the barcode information on the letter; on the conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com