Washing type automatic unpacking system

An automatic and self-cleaning technology, which is applied in the directions of packaging, transportation and packaging, cleaning methods and utensils, etc., can solve the problems of unable to automatically clean the cleaning liquid, difficult blades, overflow, etc., to improve processing capacity, shorten length, open or close Simple, fast and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

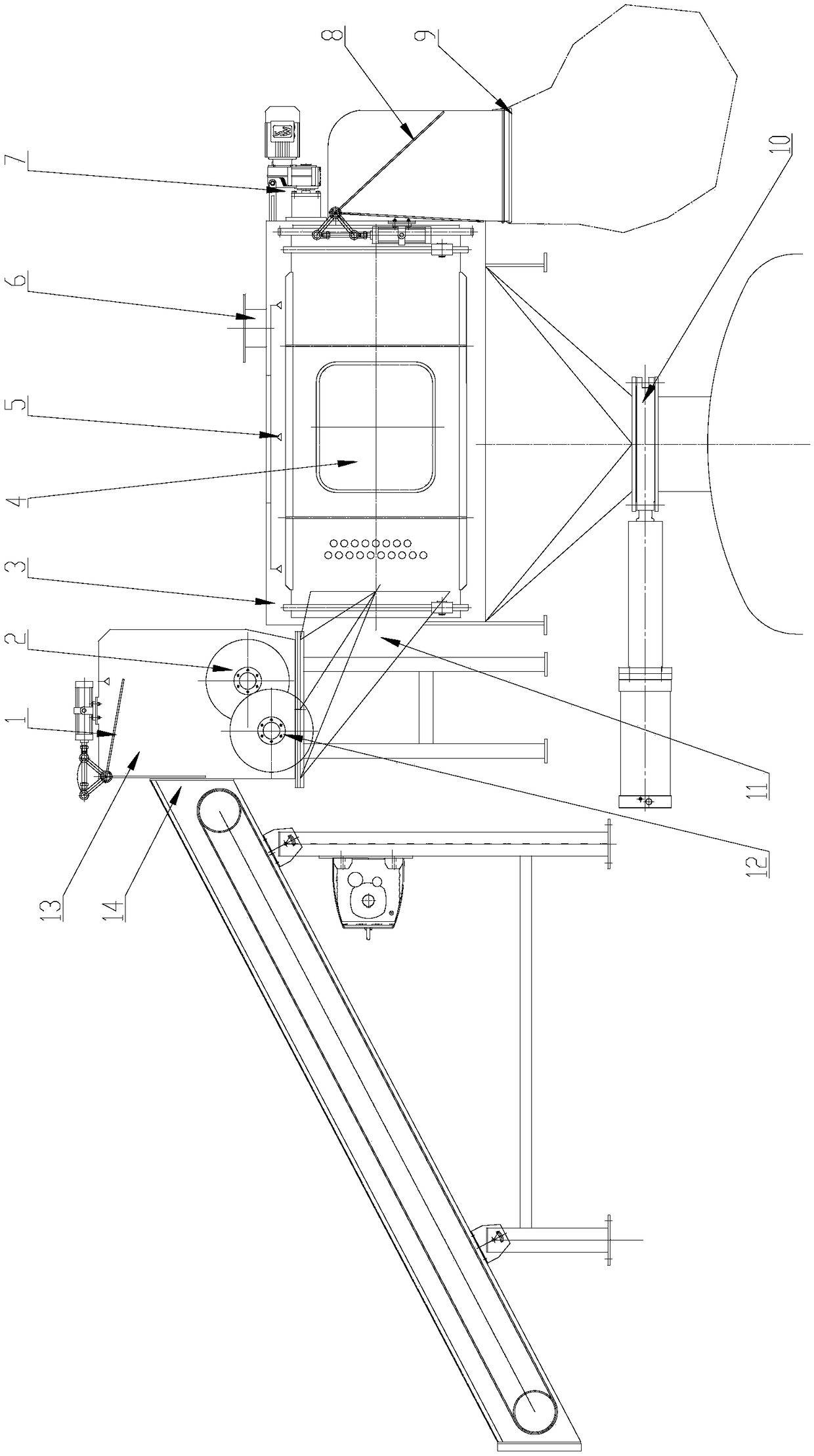

[0035] The present invention will be further described below in conjunction with the drawings:

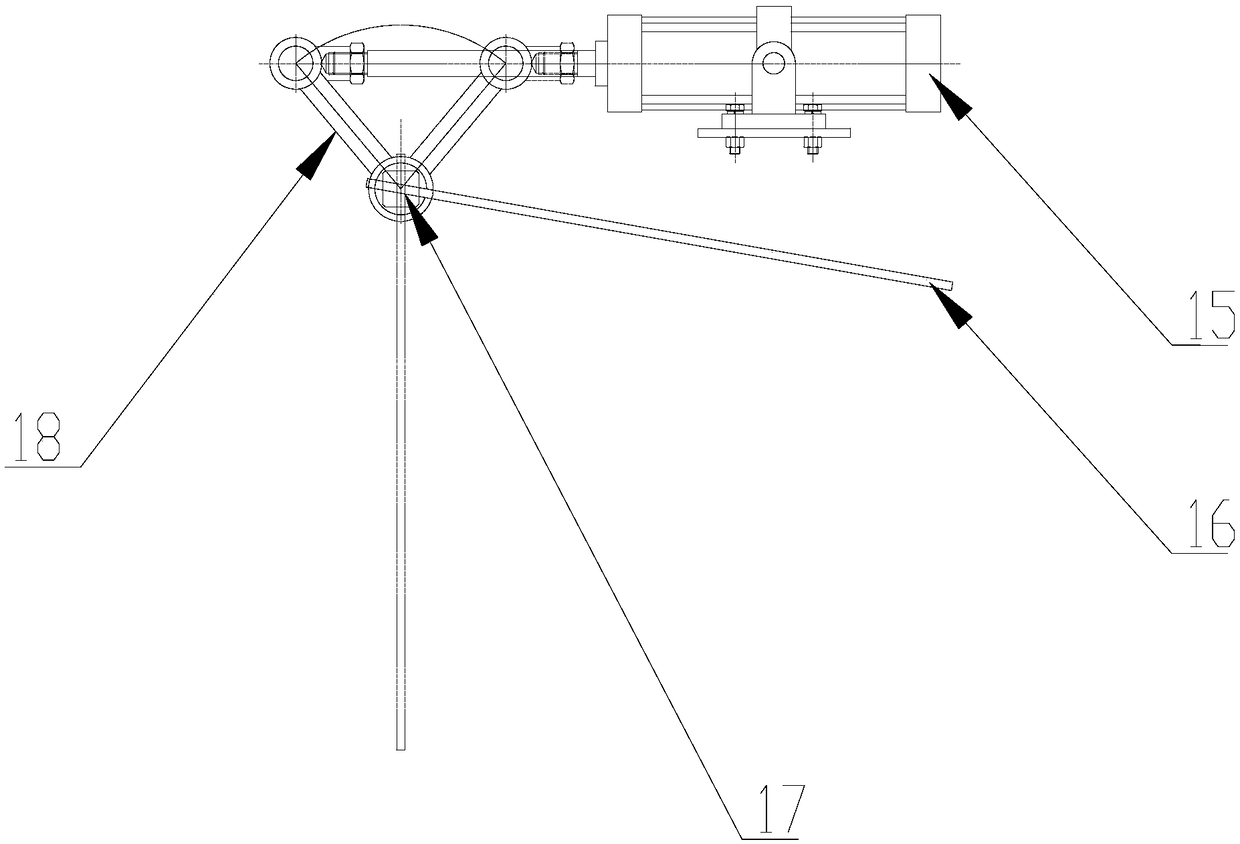

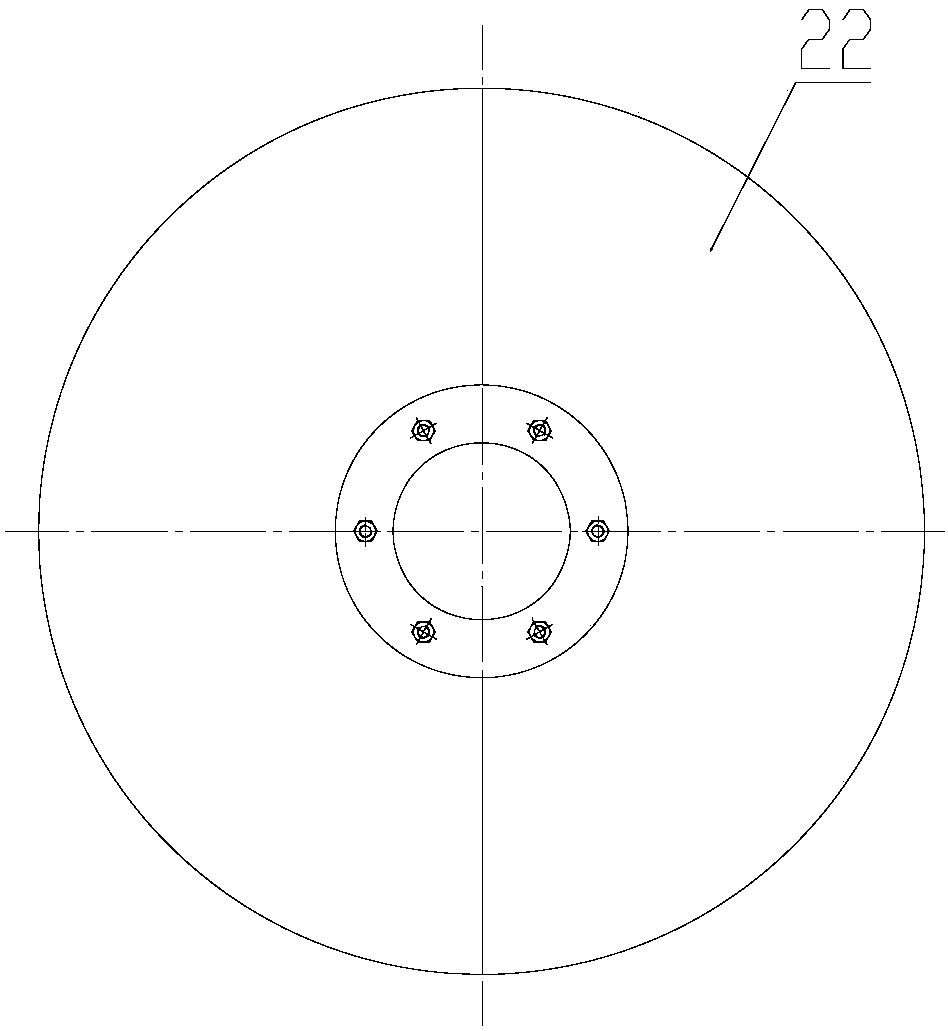

[0036] As shown in the drawings, the present invention includes an entrance sealing mechanism 1, a quick-change cutter mechanism 2, an integrated box body 3, a quick-opening observation and inspection door 4, a 360-degree automatic cleaning system 5, a dust removal port 6, a rear drive screening mechanism 7. Automatic control switch door for waste bag outlet 8. Bag-breaking mechanism 12 with lip seal. Integrated box 3 includes feeding chute 11, screening cylinder box 31, waste bag outlet 32, lower hopper 33, screening cylinder A feed chute 11 is installed on the feed side of the front end of the box body 31, a waste bag outlet 32 is provided at the rear end of the screening cylinder box body 31, a waste bag outlet automatic control switch door 8 is installed at the waste bag outlet 32, and a waste bag outlet 32 A rear-driving screening mechanism 7 is provided on the upper part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com