Cement unpacking machine

A technology of unpacking machine and cement, applied in the field of construction machinery, can solve the problems of large dust, heavy workload, low efficiency, etc., and achieve the effect of high efficiency and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

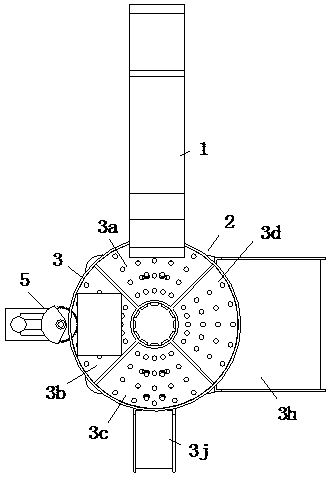

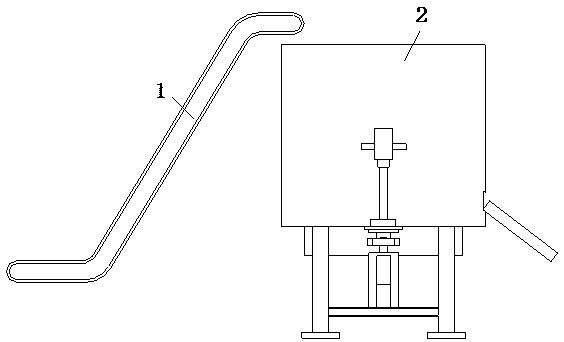

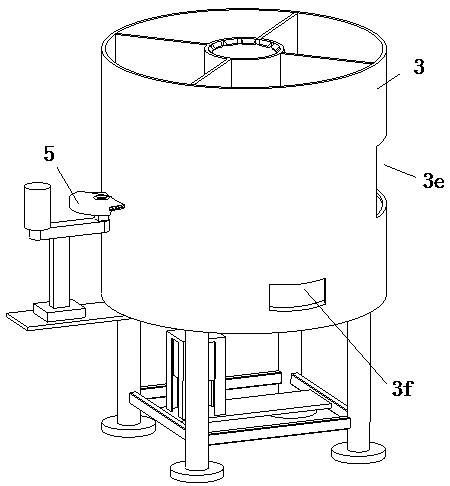

[0022] refer to Figure 1 to Figure 6 A kind of cement unpacking machine shown, comprises cement hoist 1 and unpacking machine body 2, and described cement hoist 1 is arranged on the side of described unpacking machine body 2, and unpacking machine body 2 comprises a cylinder body 3, and this cylinder body 3 is provided with a tapered filter plate 4 inside, and the inside of the cylinder body 3 is divided into an upper and lower space by the filter plate 4. Above the filter plate 4, there are four partitions 4a evenly distributed along the circumference, and the upper space passes through the partition The plate 4a is divided into four independent accommodation chambers, and the cylinder body 3 is provided with a loading station 3a, an unpacking station 3b, an empty station 3c and an unpacking station 3d along the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com