Unpacking and bottle straightening production line for penicillin bottles

A technology of vials and production line, which is applied in the field of equipment for unpacking and unpacking vials, which can solve the problems of unreasonable structure, low unpacking accuracy, low unpacking efficiency, etc., and achieve rapid unpacking and bottle unscrambling effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below through specific examples.

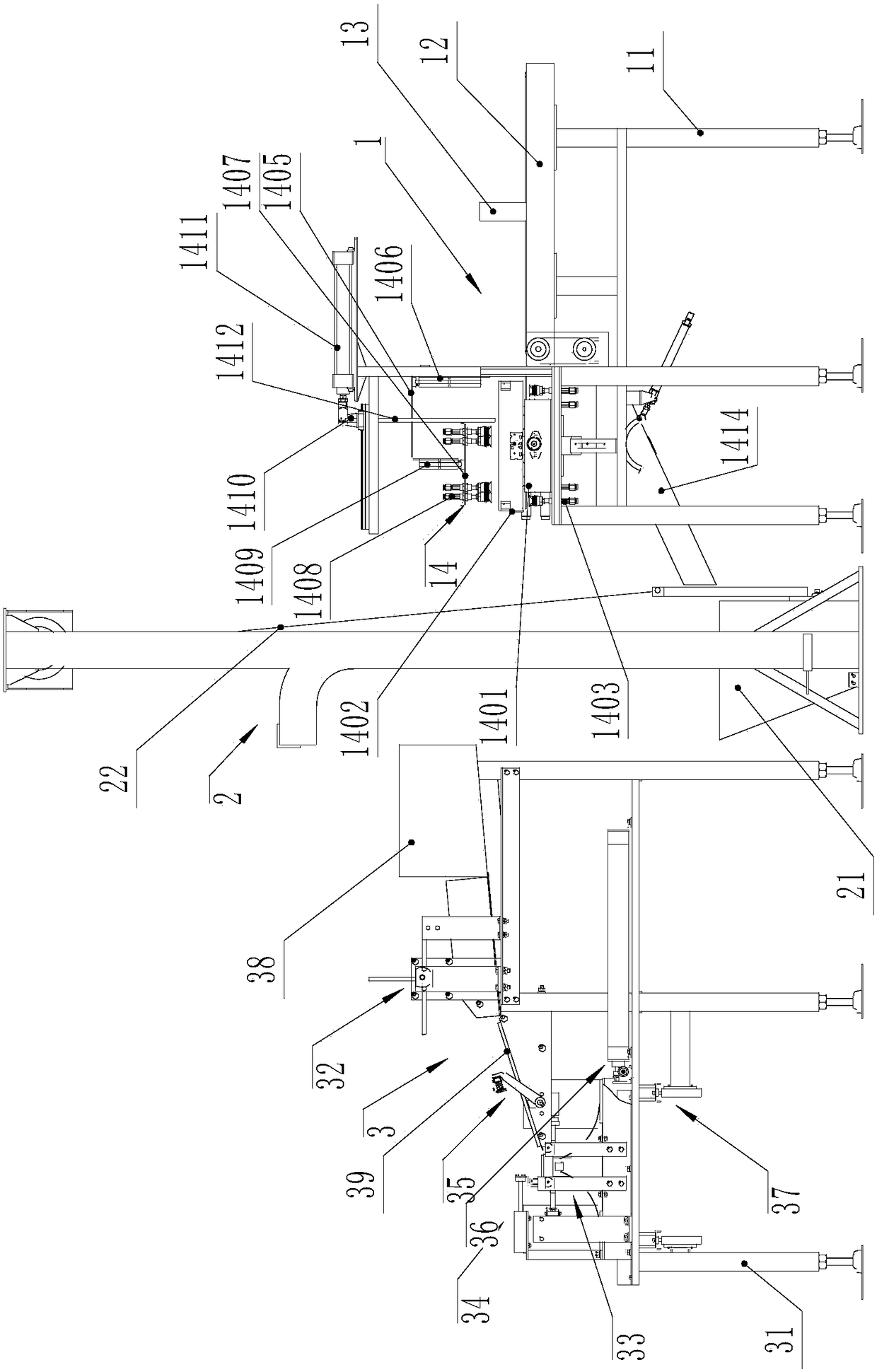

[0045] like Figure 1 to Figure 14 As shown, an unpacking and unscrambling production line for vials 41 includes an unpacking machine 1 , a lifting conveyor 2 and a bottle unscrambling machine 3 .

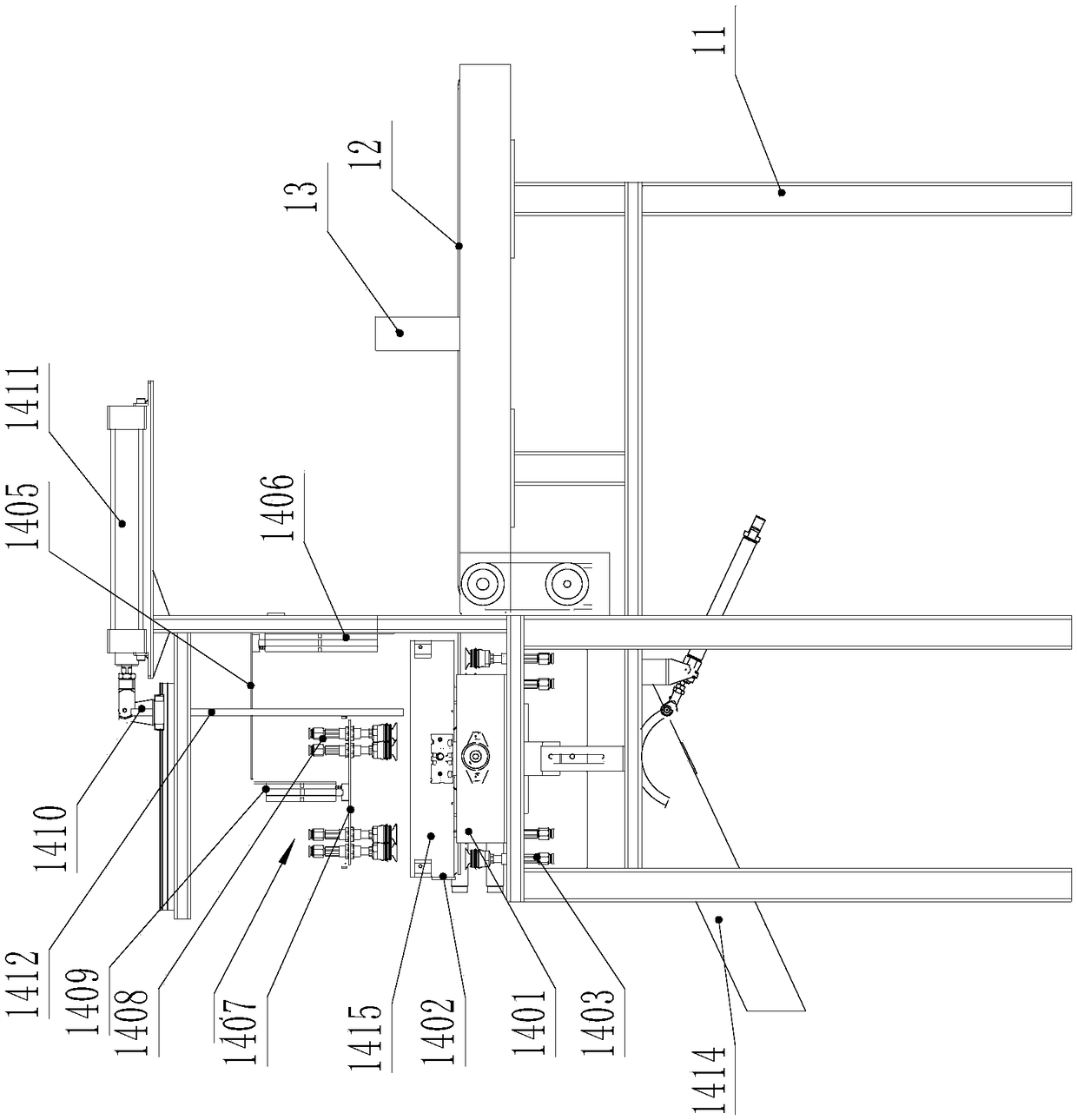

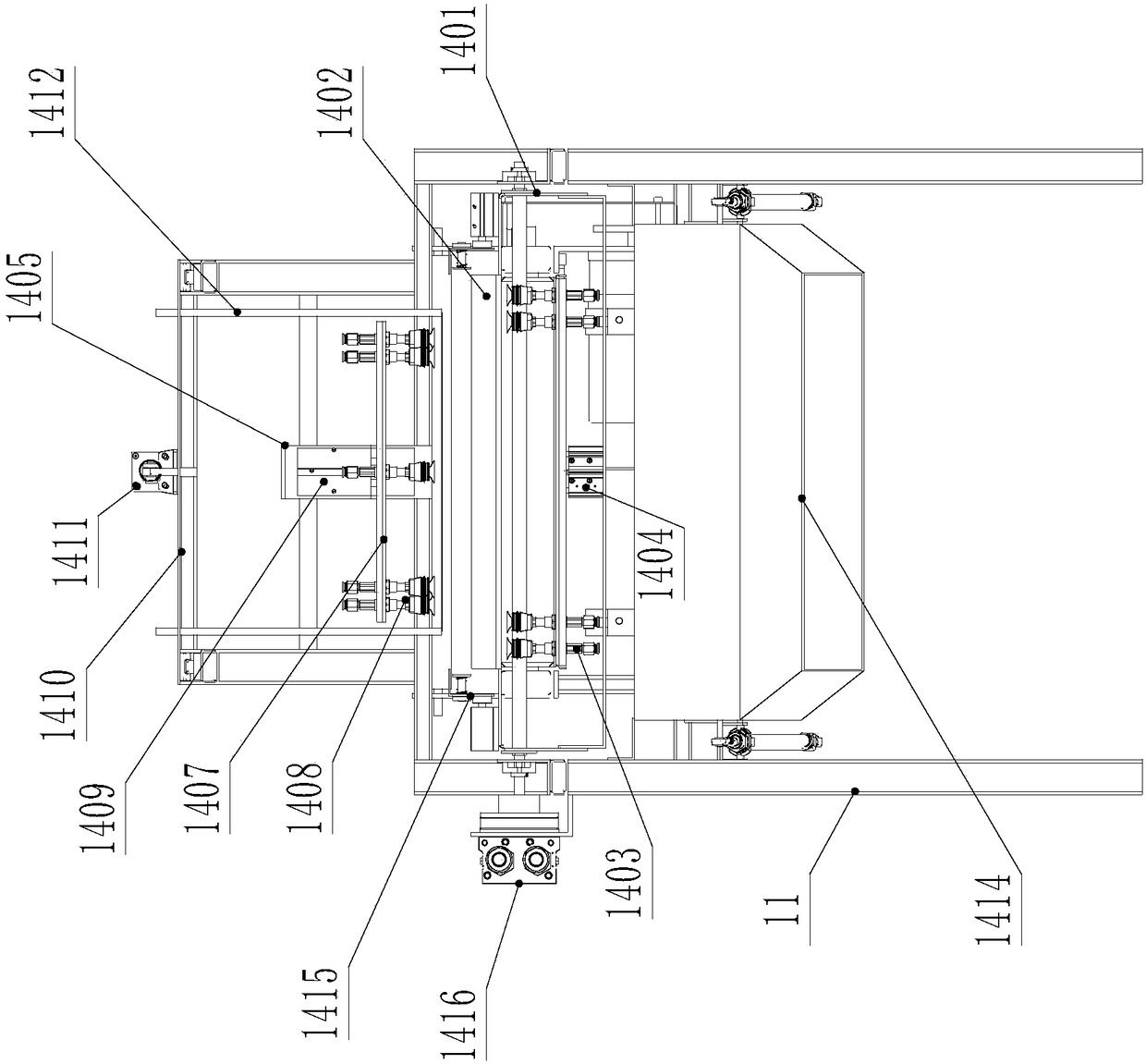

[0046] Described unpacking machine 1 comprises unpacking frame 11, and described unpacking frame 11 is provided with the conveyer belt 12 that is used to convey vial group 4, is positioned at the downstream of conveyer belt 12 on described unpacker 1 mechanism and is provided with vial group The unpacking and pouring device 14 that the packaging film of 4 is removed and dumped.

[0047] The unpacking and dumping device 14 includes a material turning frame 1401 rotating on the unpacking frame 11. The material turning frame 1401 is turned over by a material turning power device 1416, and the material turning power device 1416 is driven by a rotary cylinder. Of course, it can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com