A soft bottle packing machine

A technology for bottled luggage and soft bottles, which is applied in packaging, packaging bottles, transportation and packaging, etc., can solve the problems of increased labor costs, low efficiency, and soft bottles falling to and fro, so as to achieve stable and efficient working process, reduce labor costs, and avoid falling down The effect of the bottle phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

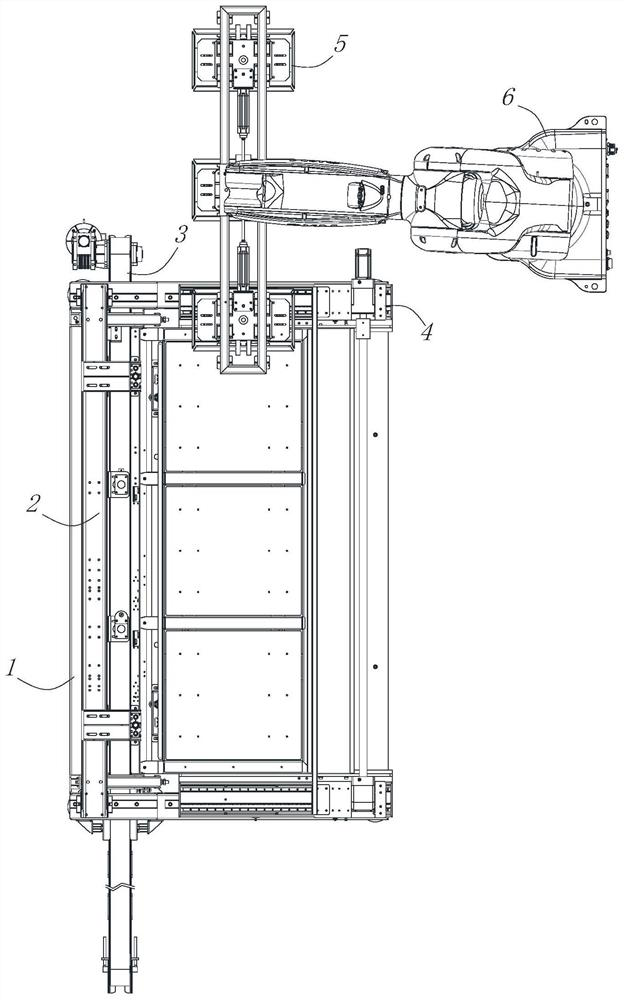

[0031] See figure 1 , the soft bottle case packaging machine of the present invention comprises a base 1, on which a belt conveyor 3, a bottle clamp feeding device 2 and a bottle receiving device 4 are connected, and also includes a bottle grasping manipulator for grabbing the soft bottles distributed in an array 5. This embodiment also includes a mechanical arm 6 arranged outside the base 1 , and the bottle grabbing robot 5 is connected to the mechanical arm 6 .

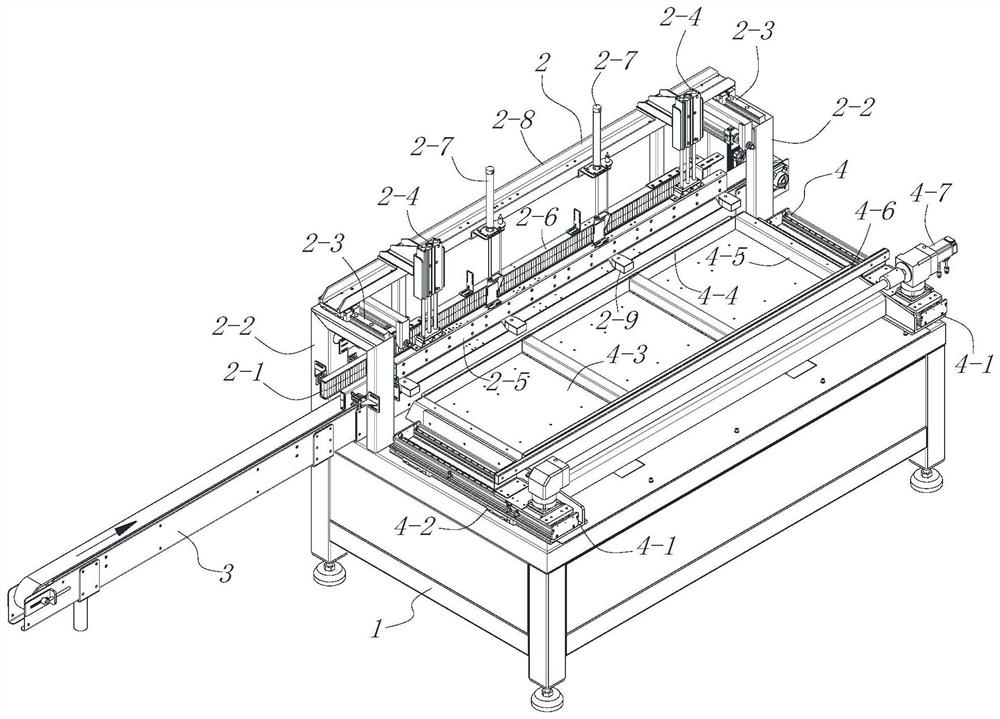

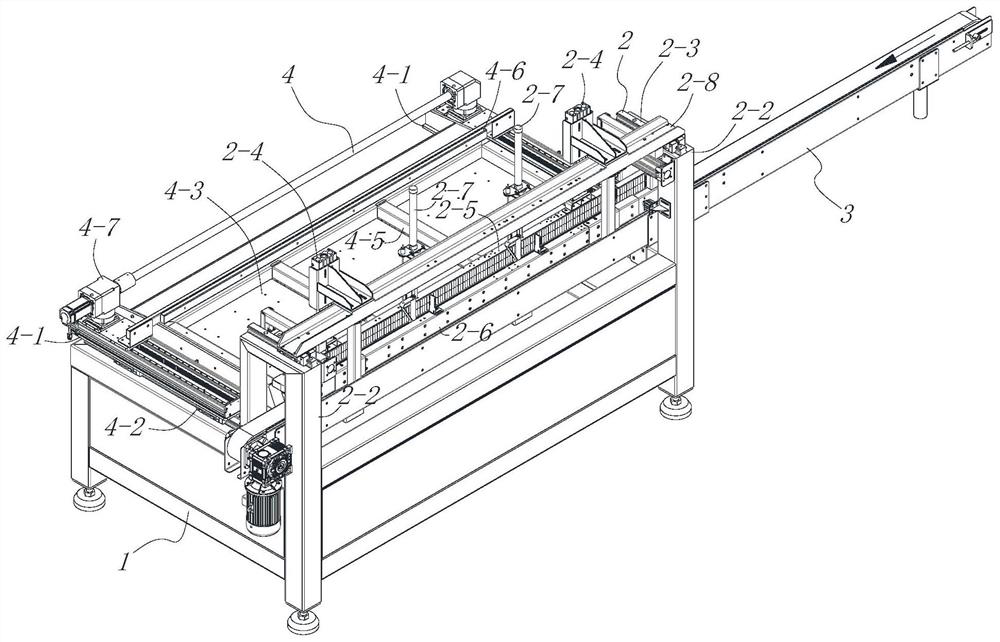

[0032] Such as figure 2 with image 3 As shown, the clamping bottle feeding device 2 includes two groups of door-shaped brackets 2-2 fixedly connected across the belt conveyor 3 on the base 1, and a mounting crossbeam 2-8 is slidably connected to the door-shaped bracket 2-2. In this embodiment, a bottle clamping roller structure for clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com