A kind of synchronous bottle unscrambling equipment

A bottle unscrambling and equipment technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., to achieve the effects of increasing the bottle unscrambling speed, saving labor costs, and good bottle unscrambling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

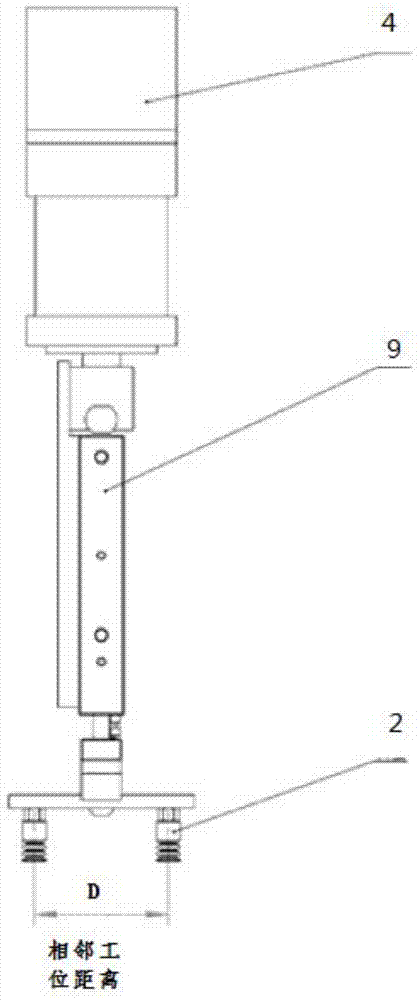

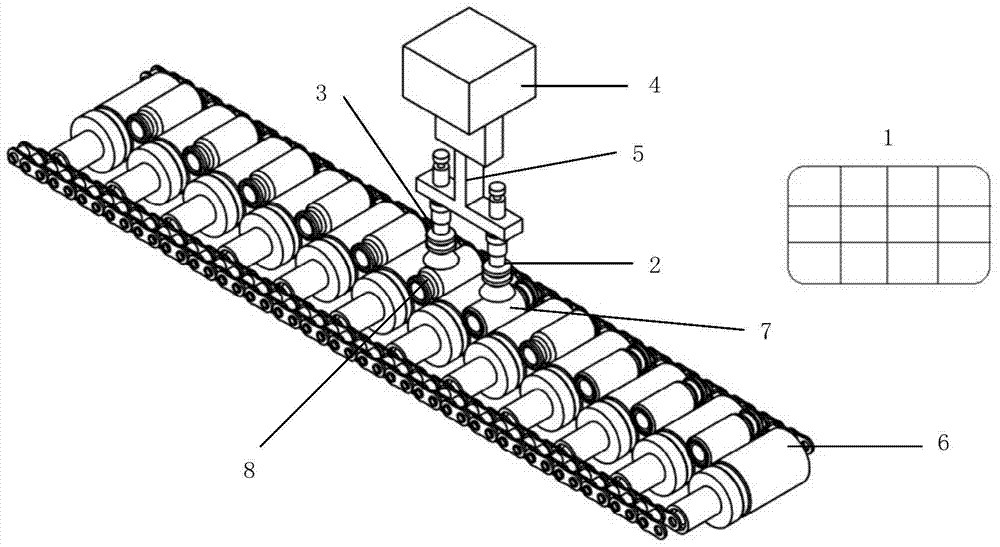

[0024] Embodiment 1 of the present invention provides a kind of synchronous bottle unscrambling equipment, its structure is as follows figure 1 As shown, it includes: a sensor 1 , a first suction cup 2 , a second suction cup 3 , a rotating device 4 and a bracket 5 . It also includes a control device, but it is not shown in the figure.

[0025] The sensor 1 is located upstream of the bottle conveying device 6. The conveying device 6 has a large number of conveying positions, and the interval between any two conveying positions is equal, and each conveying position will convey a bottle. The support 5 is installed below the rotating mechanism 4 , the first suction cup 2 and the second suction cup 3 are installed below the support 5 parallel to each other, and the mouth of the suction cups faces downward. The distance between two suction cups is equal to the distance between two adjacent transmission positions on the transmission device.

[0026] Such as figure 2 As shown, the...

Embodiment 2

[0033] In this embodiment, the synchronization device adopts a structure similar to that of Embodiment 1, including: a control device, a sensor, a first suction cup, a second suction cup and a rotating device.

[0034] Only in this embodiment, the first suction cup and the second suction cup are installed directly below the rotating mechanism, and the first suction cup and the second suction cup respectively have their own telescopic mechanisms, and the two telescopic mechanisms can work separately under the control of the controller. In this way, when a certain suction cup does not need to work, it will not fall, reducing the interference between the suction cup and the bottle body.

Embodiment 3

[0036] In this embodiment, the synchronization device also adopts a structure similar to that of Embodiment 1, including: a control device, a sensor, a first suction cup, a second suction cup and a rotating device.

[0037] However, in this embodiment, the first suction cup and the second suction cup are powerful suction cups, so they do not need to cooperate with the telescopic mechanism, and the bottle body can be sucked up at a certain distance from the bottle body.

[0038] It can be seen from the specific embodiment of the present invention that the present invention uses a sensor to detect the direction of the bottle, and then controls a group of moving devices to make the direction of the bottle consistent after the products with different directions of the bottle are jacked up and rotated, and then the bottle can be conveyed. In the process, the arrangement of the bottle body is completed, with ingenious structure, high efficiency and good applicability. Moreover, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com