Belt conveyor with falling sand recovery function for quartz sand purification

A technology of belt conveyor and quartz sand, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., and can solve problems such as the impact on the health of workers and the pollution of the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

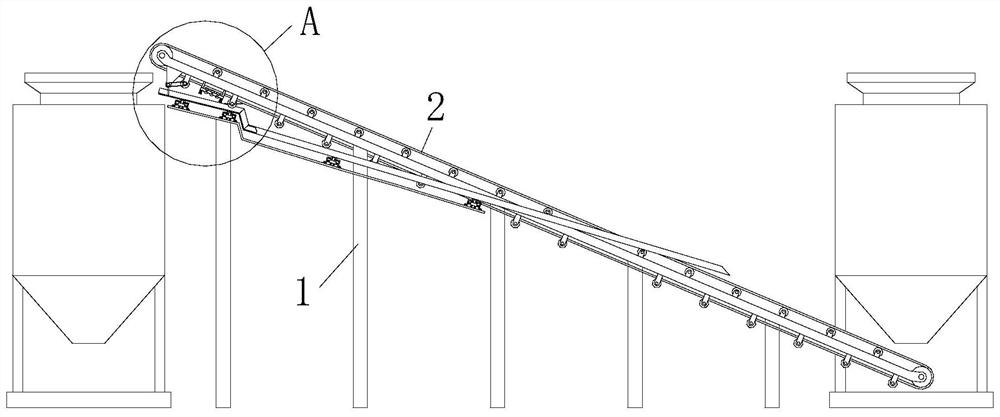

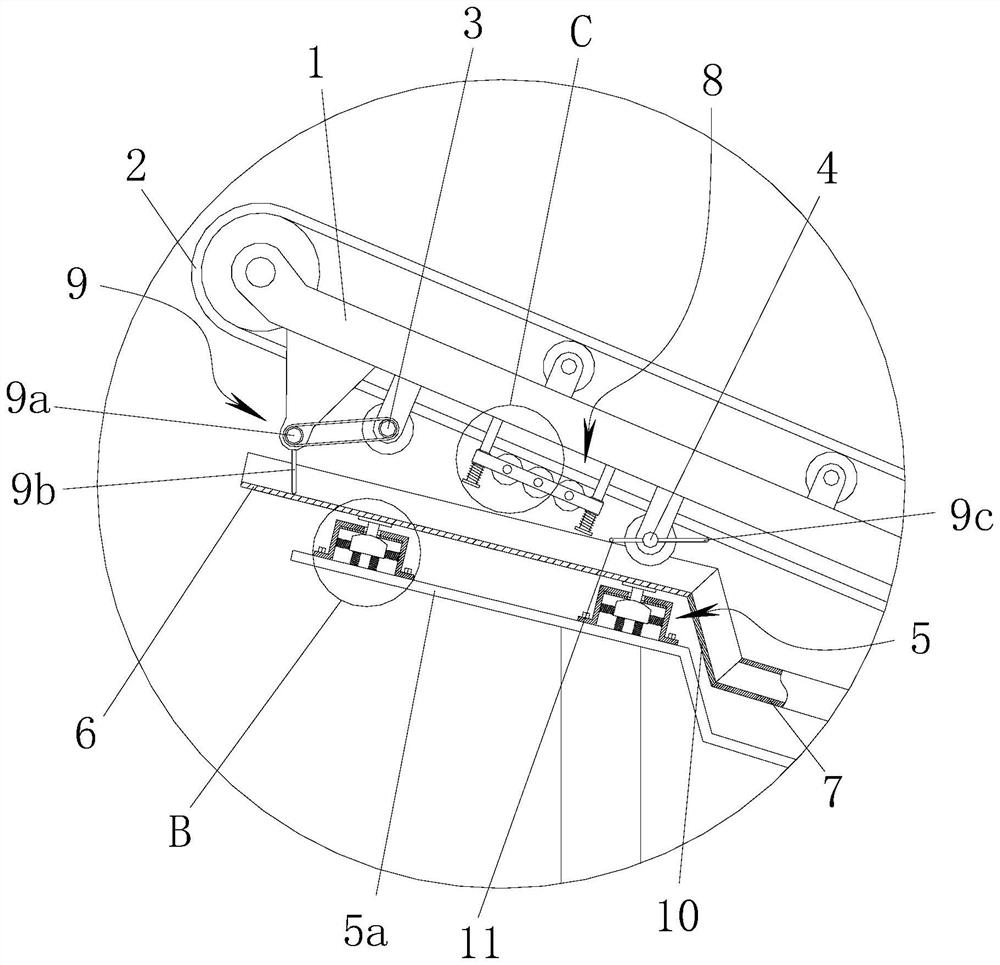

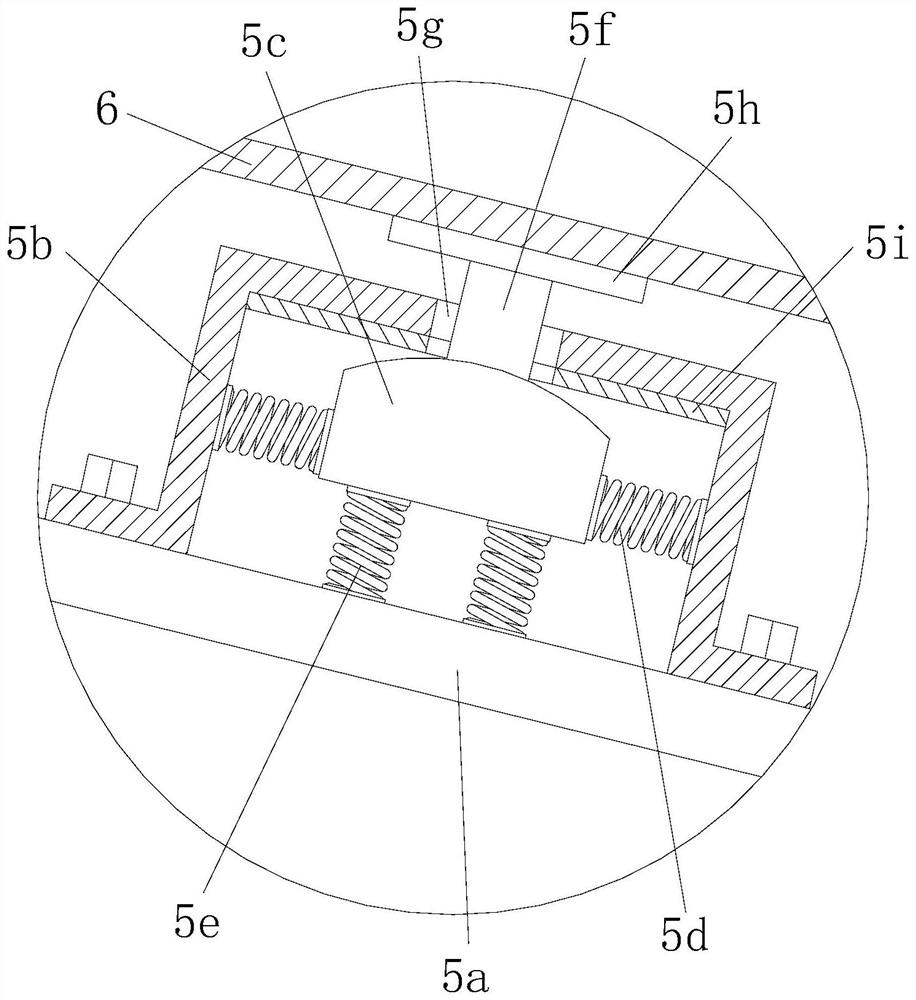

[0032] refer to Figure 1 to Figure 6 As shown, a belt conveyor for purification of quartz sand with the function of falling sand recovery of the present invention includes a frame 1 arranged obliquely and a conveyor belt 2 arranged on the frame 1, and at the near end of the high end of the frame 1 The first idler roller 3 and the second idler roller 4 matched with the conveyor belt 2 are arranged at intervals, and the frame 1 is connected with the first idler roller 3 and the second idler roller 4 through the rebound vibration mechanism 5. The sand connecting plate 6 is installed obliquely and the lower end is connected with a quartz sand recovery conveying pipe 7, and the quartz sand recovering conveying pipe 7 is obliquely arranged on the frame and the free end is bent around by the conveyor belt 2 below To the upper side of the conveying surface of the proximal end portion of the lower end of the conveyor belt 2.

[0033] An auxiliary cleaning mechanism 8 compatible with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com