Double-block type automatic spray coating system of sleeper prefabricated de-molding agent

An automatic spraying and release agent technology, which is applied in the direction of spraying devices and liquid spraying devices, can solve the problems affecting the appearance quality of double-block sleepers, the release agent is not sprayed in place, and the spraying is uneven, so as to achieve good spraying effect, Reduce labor costs, good general performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

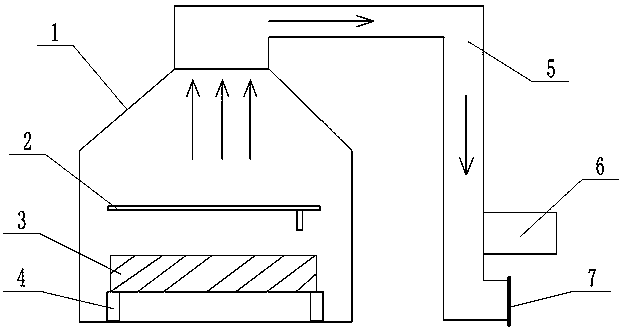

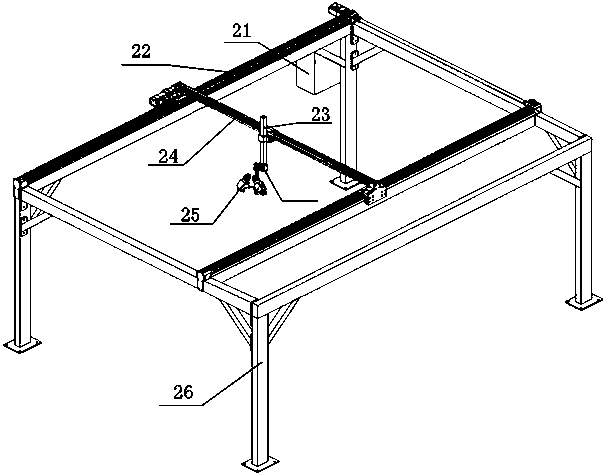

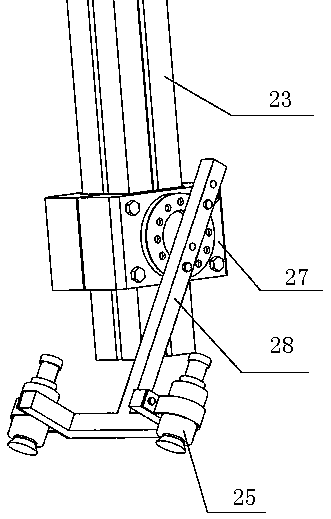

[0026] Such as figure 1 As shown, a double-block sleeper prefabricated release agent automatic spraying system of the present invention includes a pumping system, a spraying system 2 and an oil and gas supply system, and the pumping system includes a closed space composed of a sealing cover 1, a pumping pipe 5, The exhaust fan unit 6 and the oil filter 7, the exhaust system is used to extract the waste gas generated during the spraying process of the release agent and discharge it to the outside of the spraying site after filtering the oil. The spraying system 2 includes a PLC controller, a servo motor, and a spray gun 25. The spraying system 2 is used to spray release agent on the sleeper mold 3 with the movement of the servo motor on the plane formed by two parallel longitudinal rails 22. The oil and gas supply system includes a pneumatic pump station 10, a storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com