Racket automatic spraying system

An automatic spraying and racket technology, which is applied in the direction of coating, spraying device, and device for coating liquid on the surface, etc., can solve the problems of low production efficiency, high work intensity, and difficult quality assurance, and achieve simplified structure and procedures, shortened Spraying time, the effect of avoiding mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

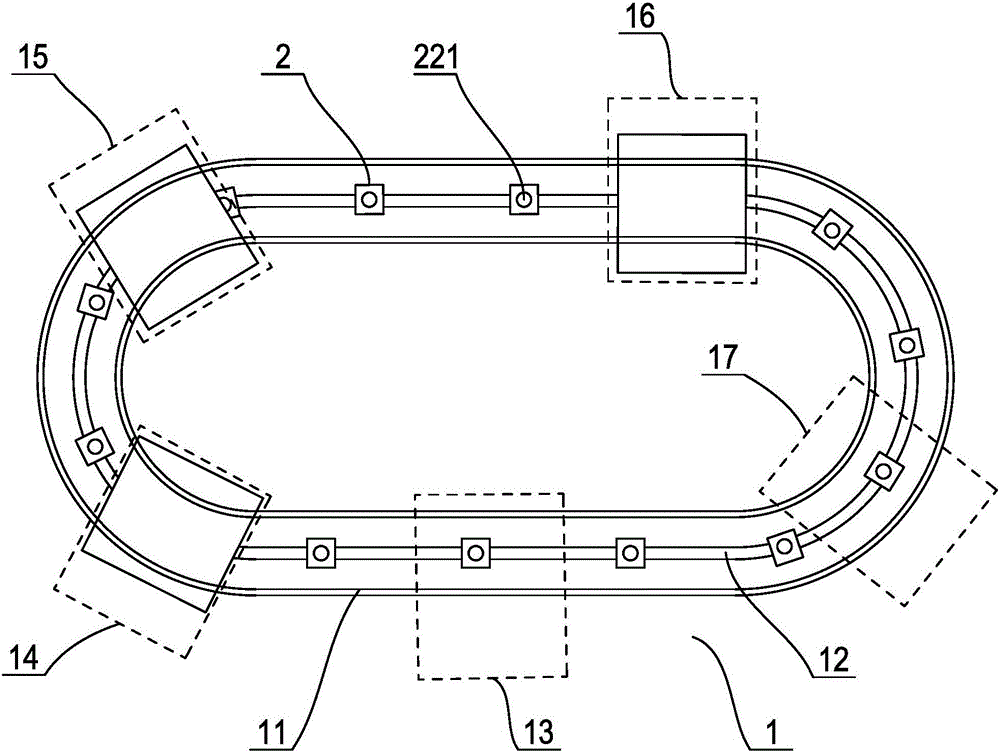

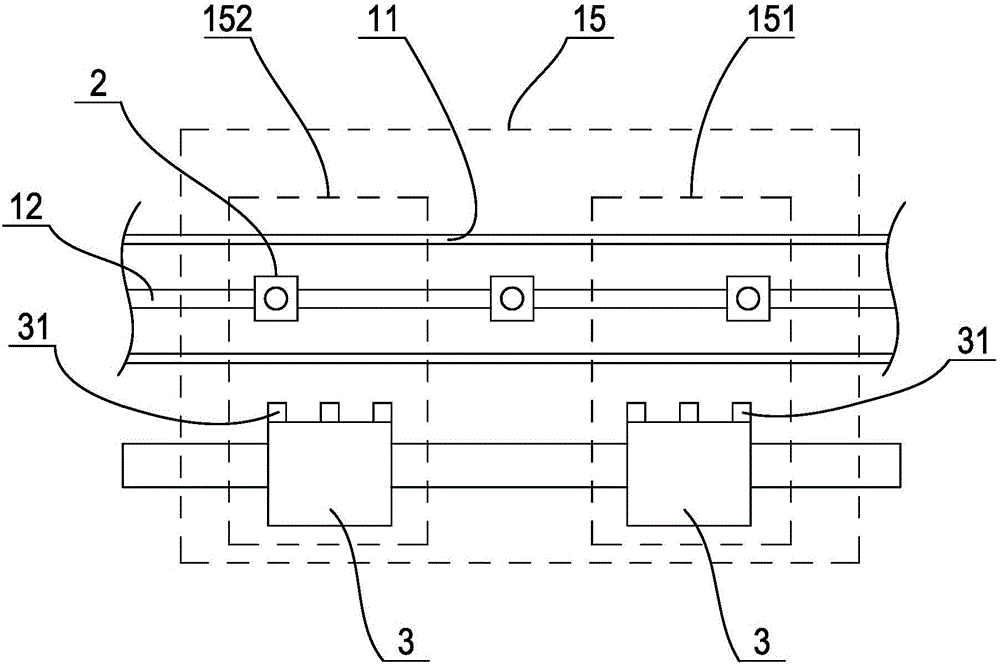

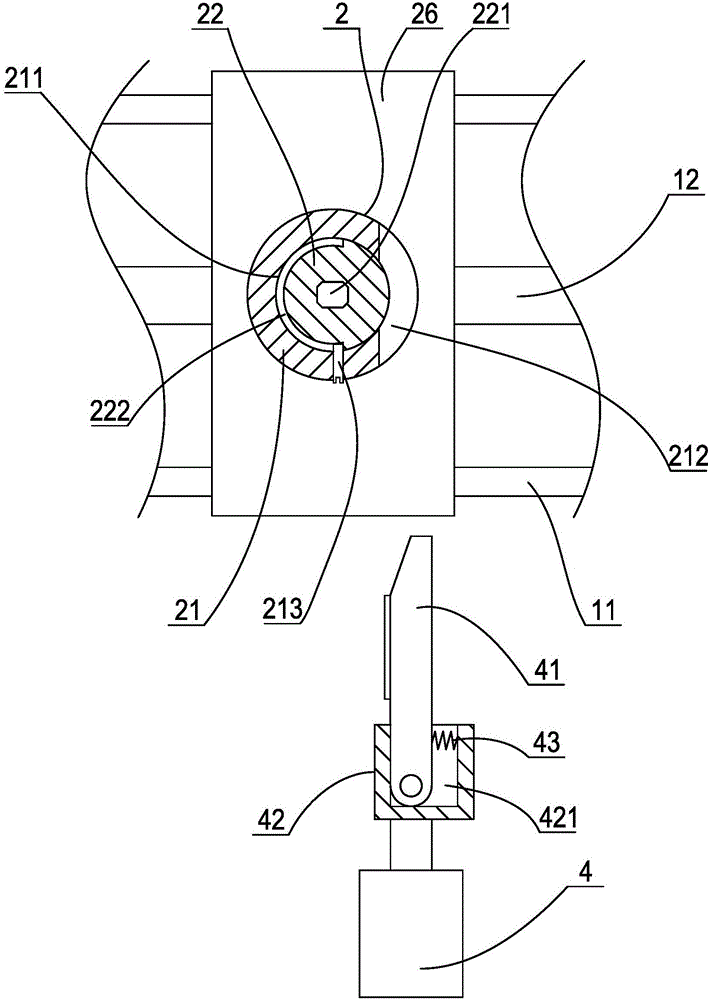

[0037] Such as figure 1 As shown, an automatic racket spraying system is mainly suitable for spraying badminton rackets, and specifically includes a circular conveying production line 1, which has two left and right guide rails 11 parallel to each other and a drive chain 12 between the two guide rails. . Since the endless conveying production line driven by the drive chain belongs to the prior art, it will not be described too much. The conveying production line of the present invention comprises a feeding station 13, a spraying station 15, a curing station 16, and an unloading station 17 arranged in sequence, several racket fixing sleeves 2 are arranged at equal intervals on the driving chain, and the upper side of the racket fixing sleeve is arranged The racket positioning hole 221 extending vertically downwards is adapted to the shape of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com