Polycrystalline crucible automatic spraying method

A technology of automatic spraying and crucible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

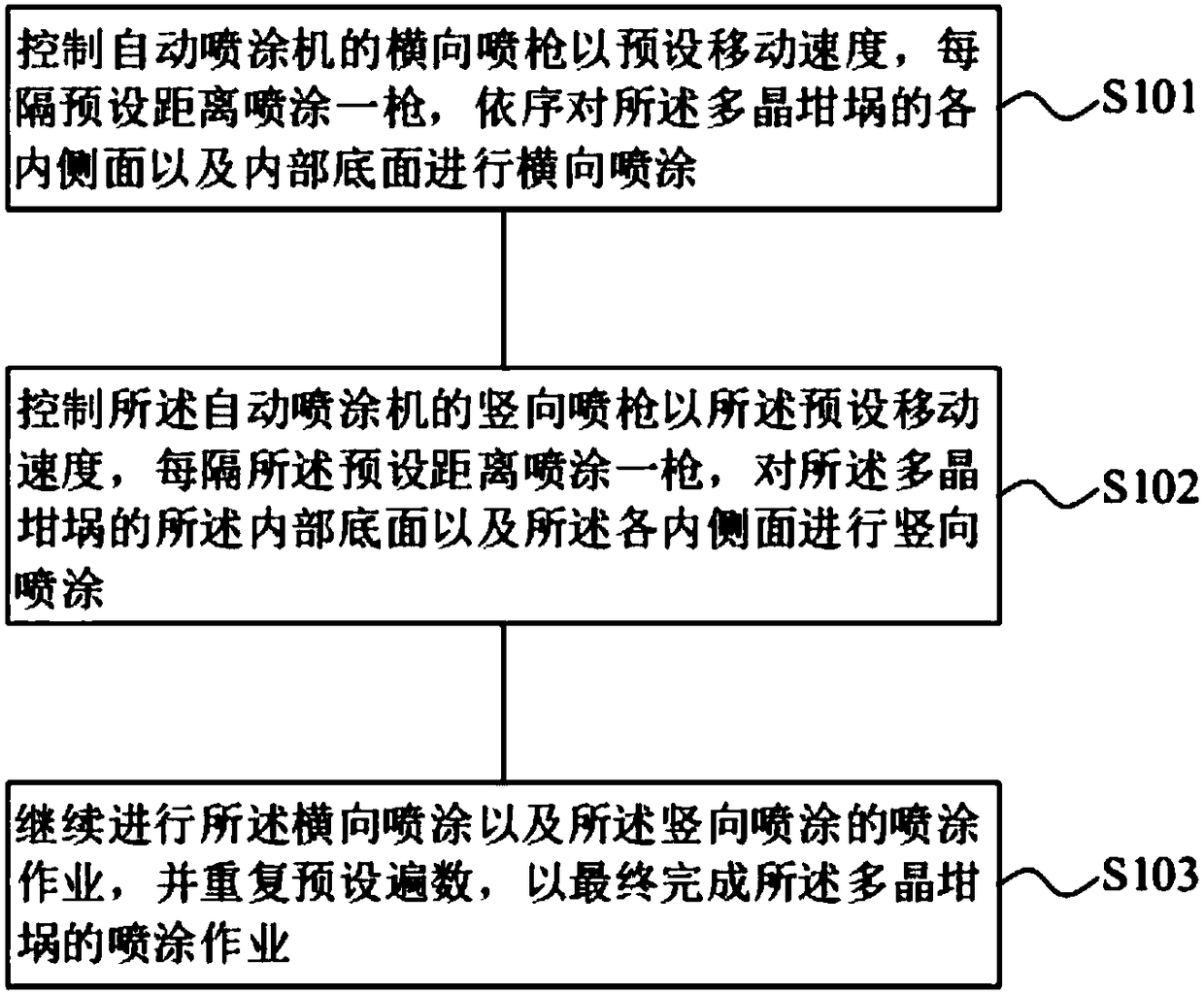

[0035] see Figure 1 to Figure 5 , in order to solve this technical problem, the present invention proposes an automatic spraying method for a polycrystalline crucible, the polycrystalline crucible is a regular container with an opening, specifically, the shape of the polycrystalline crucible is a cuboid, wherein the method Including the following steps:

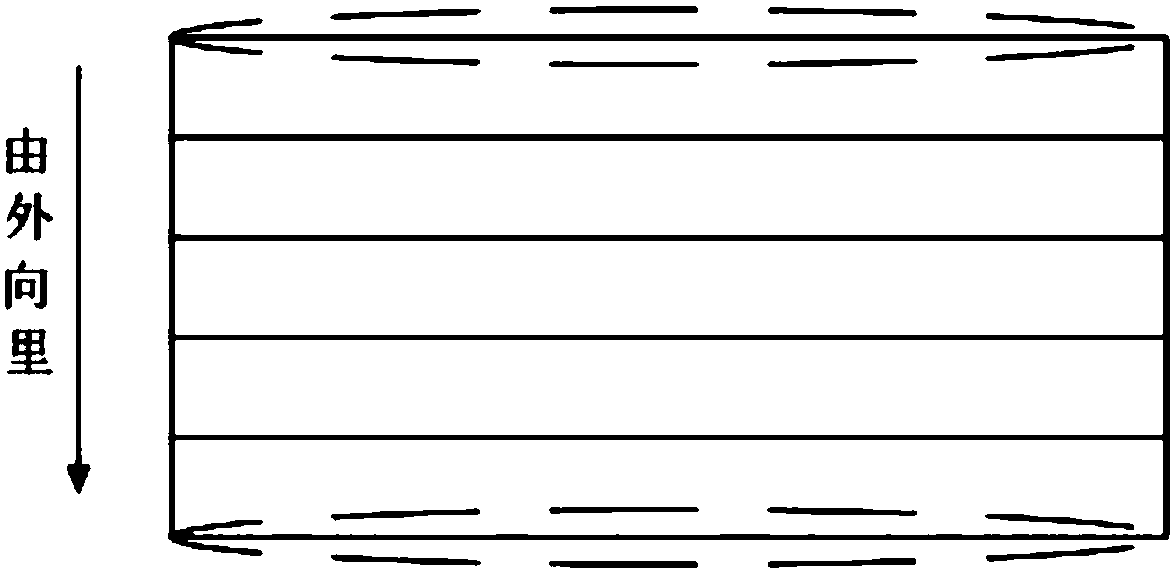

[0036] S101, controlling the horizontal spraying gun of the automatic spraying machine to spray at a preset moving speed, spraying one gun at a preset distance, and sequentially spraying horizontally on each inner surface and inner bottom surface of the polycrystalline crucible.

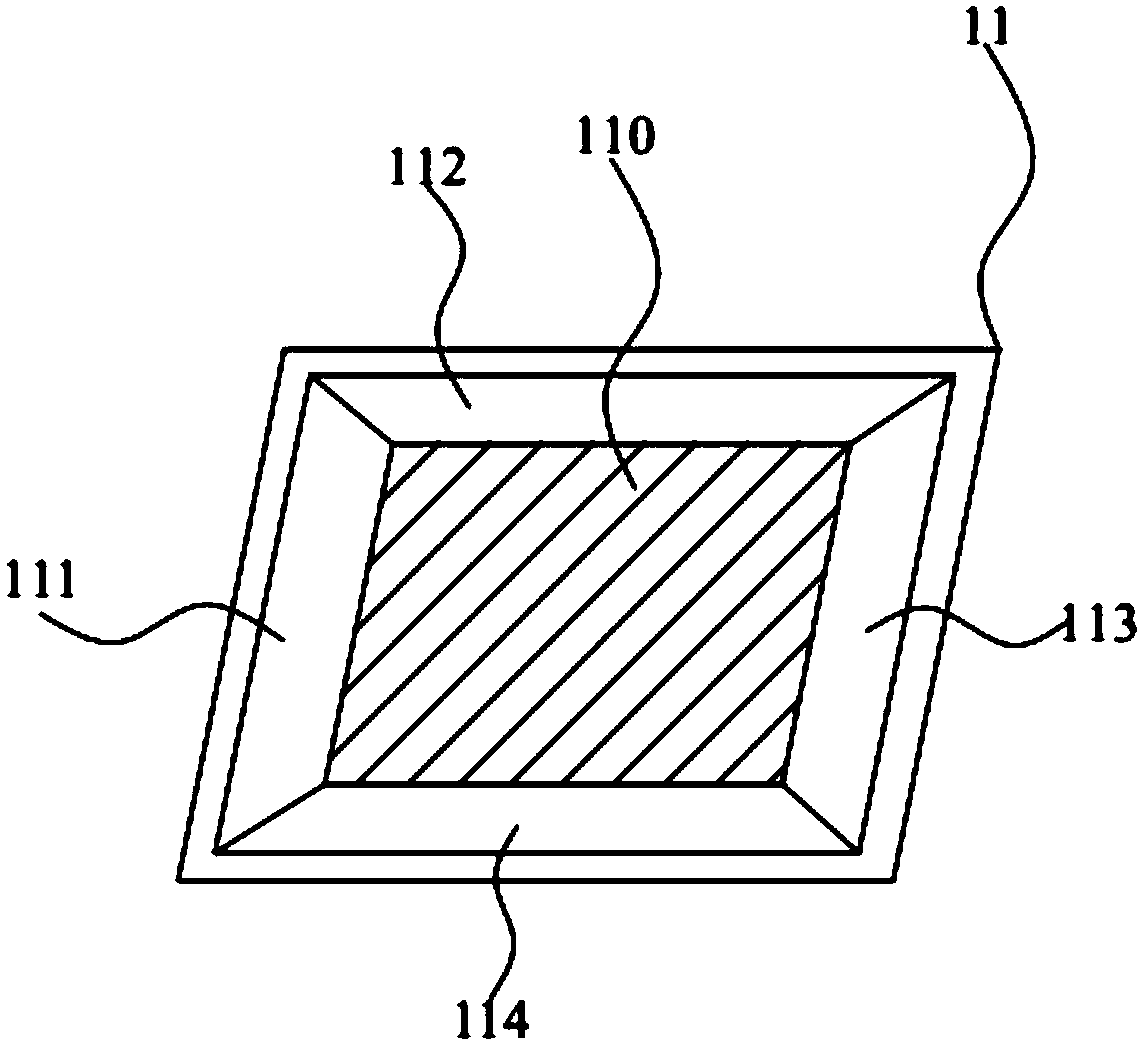

[0037] In this step, the shape of the polycrystalline crucible 11 is a cuboid, wherein the polycrystalline crucible 11 has a length ranging from 1005 to 1015 mm, a width ranging from 1005 to 1015 mm, and a height ranging from 470 to 540 mm. It should be noted here that the actual size of the polycrystalline crucible 11 is customized according to t...

Embodiment 2

[0048] This embodiment proposes an automatic spraying method for a polycrystalline crucible. The polycrystalline crucible is a regular container with an opening. Specifically, the shape of the polycrystalline crucible is a cuboid. The method includes the following steps:

[0049] (1) Control the horizontal spraying gun of the automatic spraying machine to move at a speed of 500mm / s, spray one gun every 100mm, and spray horizontally on each inner surface and inner bottom surface of the polycrystalline crucible in sequence.

[0050] In this step, the shape of the polycrystalline crucible 11 is a cuboid. Wherein, the length of the polycrystalline crucible 11 is 1010mm, the width is 1010mm, and the height is 480mm. It should be noted here that the actual size of the polycrystalline crucible 11 is customized according to the actual application requirements, and there is no strict size limit, and it is specifically manufactured based on the size of the silicon ingot to be contained....

Embodiment 3

[0058] This embodiment proposes an automatic spraying method for a polycrystalline crucible. The polycrystalline crucible is a regular container with an opening. Specifically, the shape of the polycrystalline crucible is a cuboid. The method includes the following steps:

[0059] (1) Control the horizontal spraying gun of the automatic spraying machine to move at a speed of 800mm / s, spray one gun every 100mm, and spray horizontally on each inner surface and inner bottom surface of the polycrystalline crucible in sequence.

[0060] In this step, the shape of the polycrystalline crucible 11 is a cuboid. Wherein, the length of the polycrystalline crucible 11 is 1010mm, the width is 1010mm, and the height is 480mm. It should be noted here that the actual size of the polycrystalline crucible 11 is customized according to the actual application requirements, and there is no strict size limit, and it is specifically manufactured based on the size of the silicon ingot to be contained....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com