Convenience steel pipe plastic coating system for once curing in inner and outer spraying

A technology of internal spraying and external spraying, applied in liquid spraying equipment, spray booths, spraying devices, etc., can solve the problems that the load-bearing pile cannot touch the outer wall of the steel pipe, and the steel pipe of the load-bearing pile cannot be in contact with the two stick shafts, so as to increase the uniformity of spraying The effect of preventing powder leakage and keeping the operating space clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot sequentially limit the protection scope of the present invention.

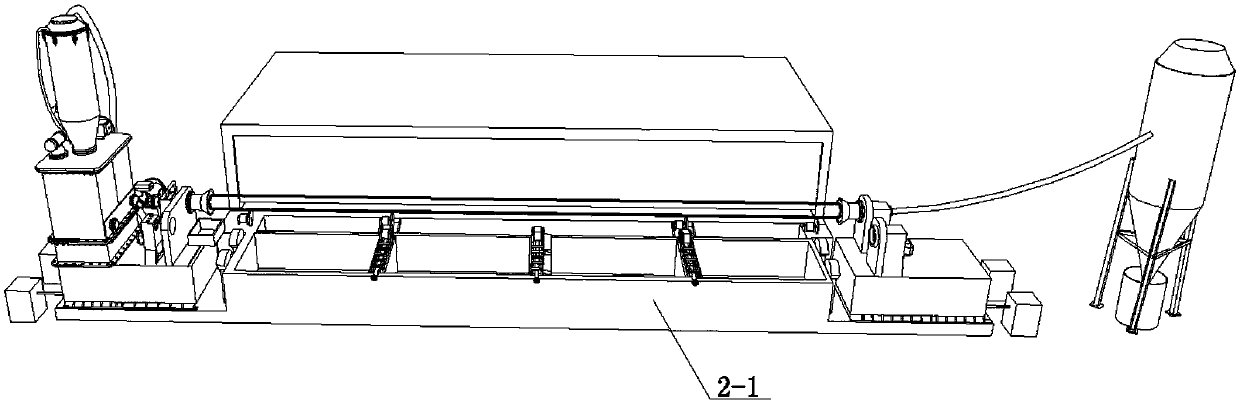

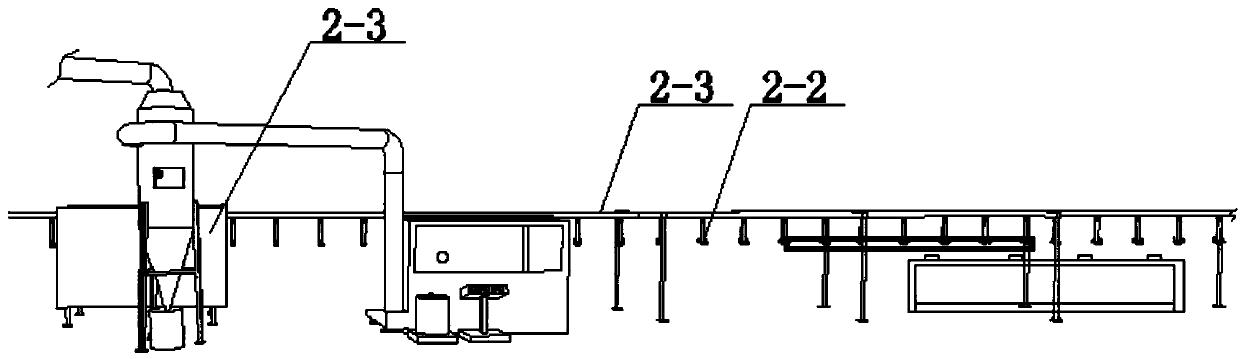

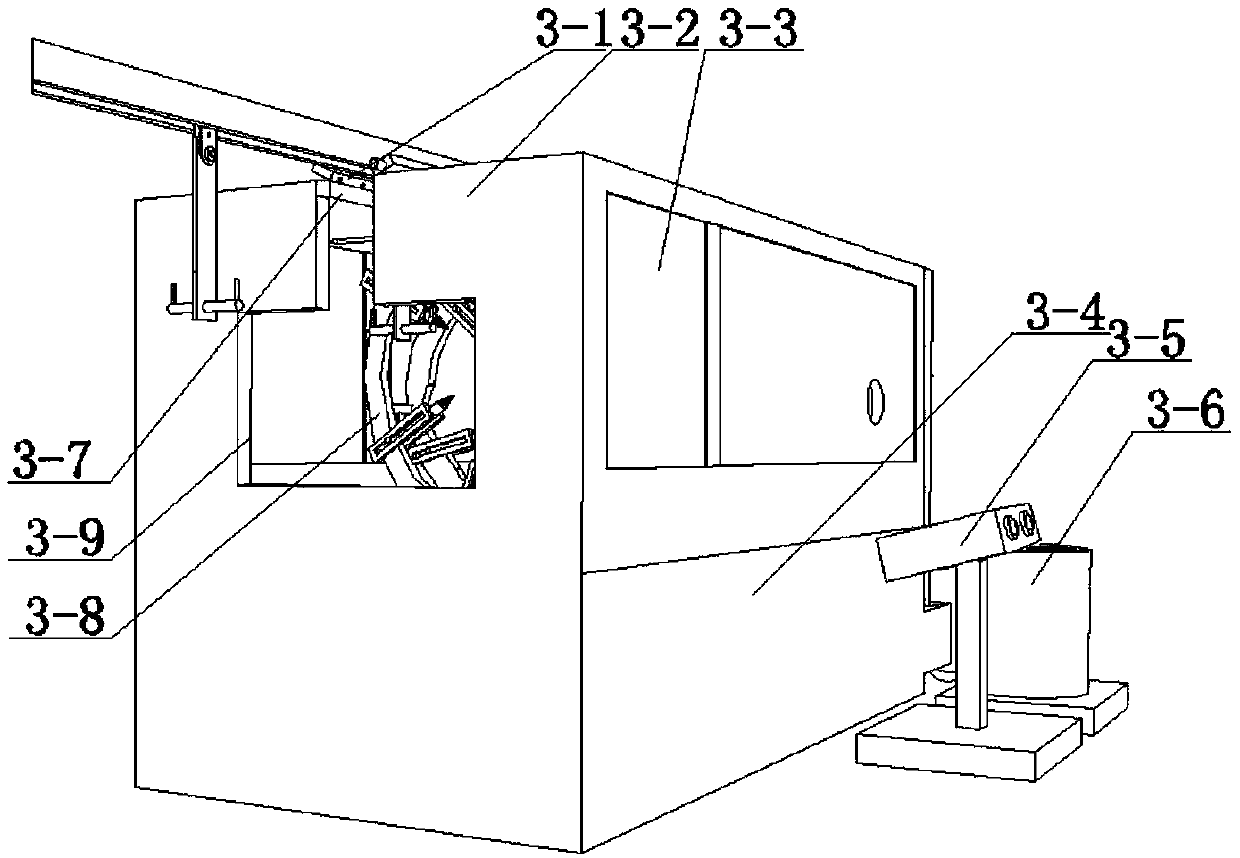

[0027] A convenient steel pipe plastic coating system with internal and external spraying and one-time curing, including a horizontal conveying frame, a steel pipe conveying frame, an internal spraying system, an external spraying system and a high-temperature curing furnace 2-3, and the horizontal conveying frame conveys the steel pipe from the preheating furnace to the Inner spraying system, the inner surface of the steel pipe is sprayed in the inner spraying system, and then the steel pipe is transported to the transport frame by the horizontal conveying frame. The steel pipe is transported to a high-temperature curing furnace for high-temperature curing.

[0028] The horizontal conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com