Patents

Literature

44results about How to "Increase spray rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulosic particle for pharmaceuticals preparation

InactiveUS20040043964A1Reduce probabilityLight weightBiocideOrganic active ingredientsCelluloseDegree of polymerization

Cellulosic particles for pharmaceutical preparation which comprise at least 10 wt. % crystal cellulose having an average degree of polymerization of 60 to 350 and have an apparent tap density of 0.60 to 0.95 g / mL, a degree of sphericity of 0.7 or higher, a shape factor of 1.10 to 1.50, and an average particle diameter of 10 to 400 mum.

Owner:ASAHI KASEI KK

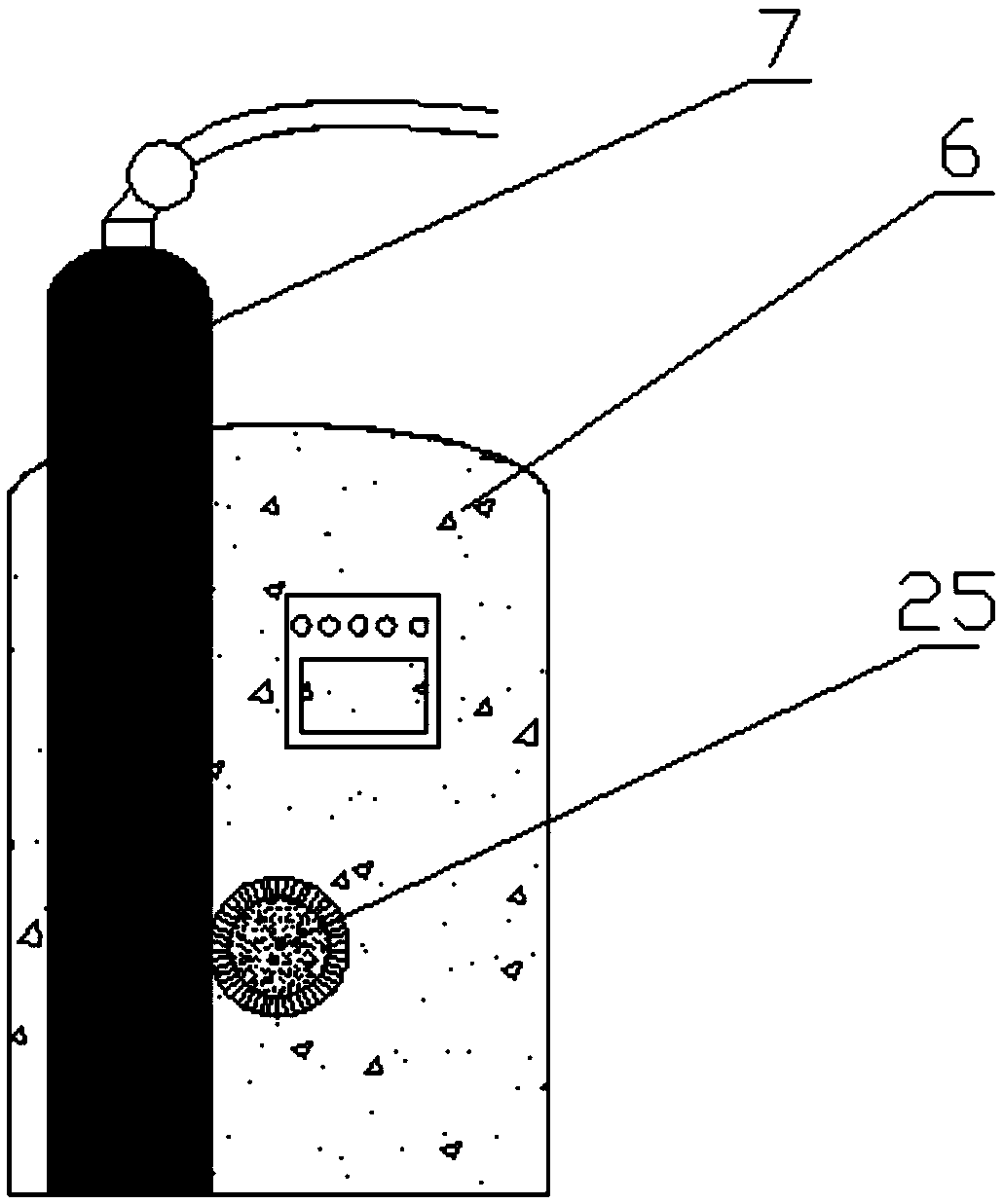

Foam extinguishing agent capable of automatically foaming and preparation method of foam extinguishing agent

The invention provides a foam extinguishing agent capable of automatically foaming. The foam extinguishing agent is prepared from a foaming agent, a film forming agent, a foam stabilizer, a pour point depressant, a thickening agent, a preservative and water. The foam extinguishing agent does not need to suck air and carbon dioxide is dissolved in the extinguishing agent; when the pressure is reduced, the carbon dioxide is released from the extinguishing agent so that foams are generated. The foaming multiple of the foam is related to the content of the dissolved carbon dioxide, and is not influenced by the flow speed and pressure of foam liquid; and the formed foam is fine and smooth, and uniform and stable, and the liquid dissolving time is long.

Owner:CHINA PETROLEUM & CHEM CORP +1

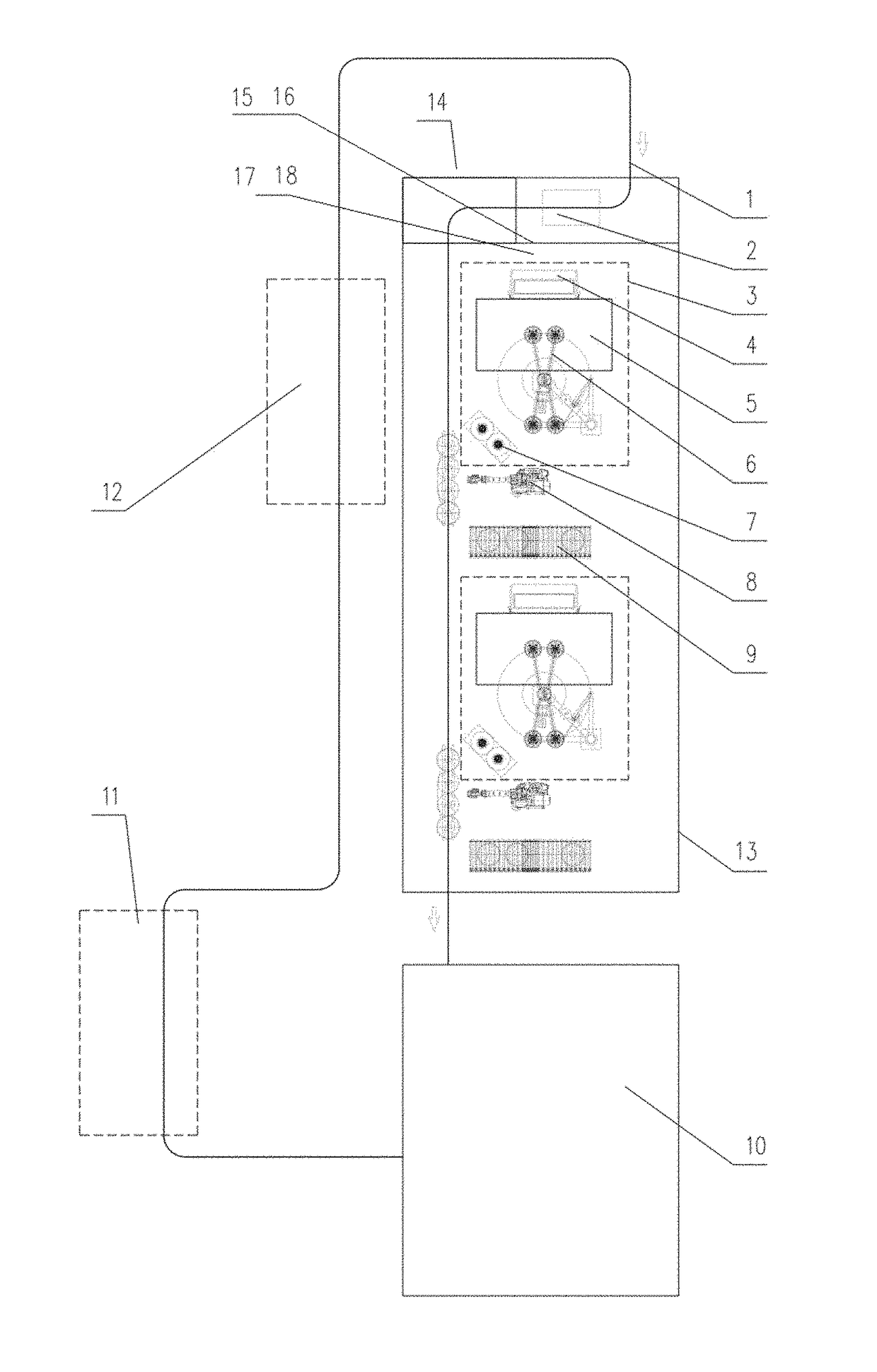

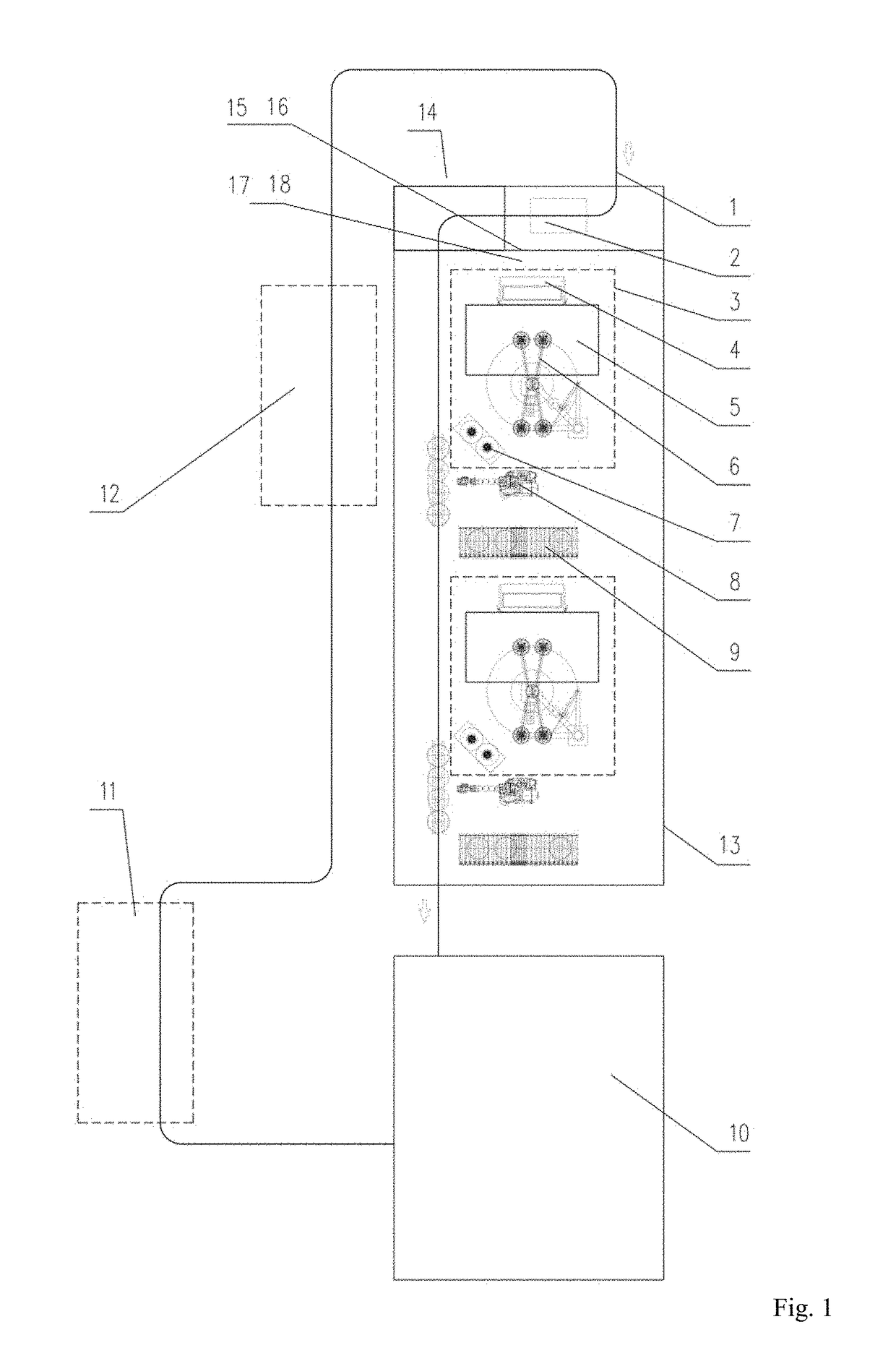

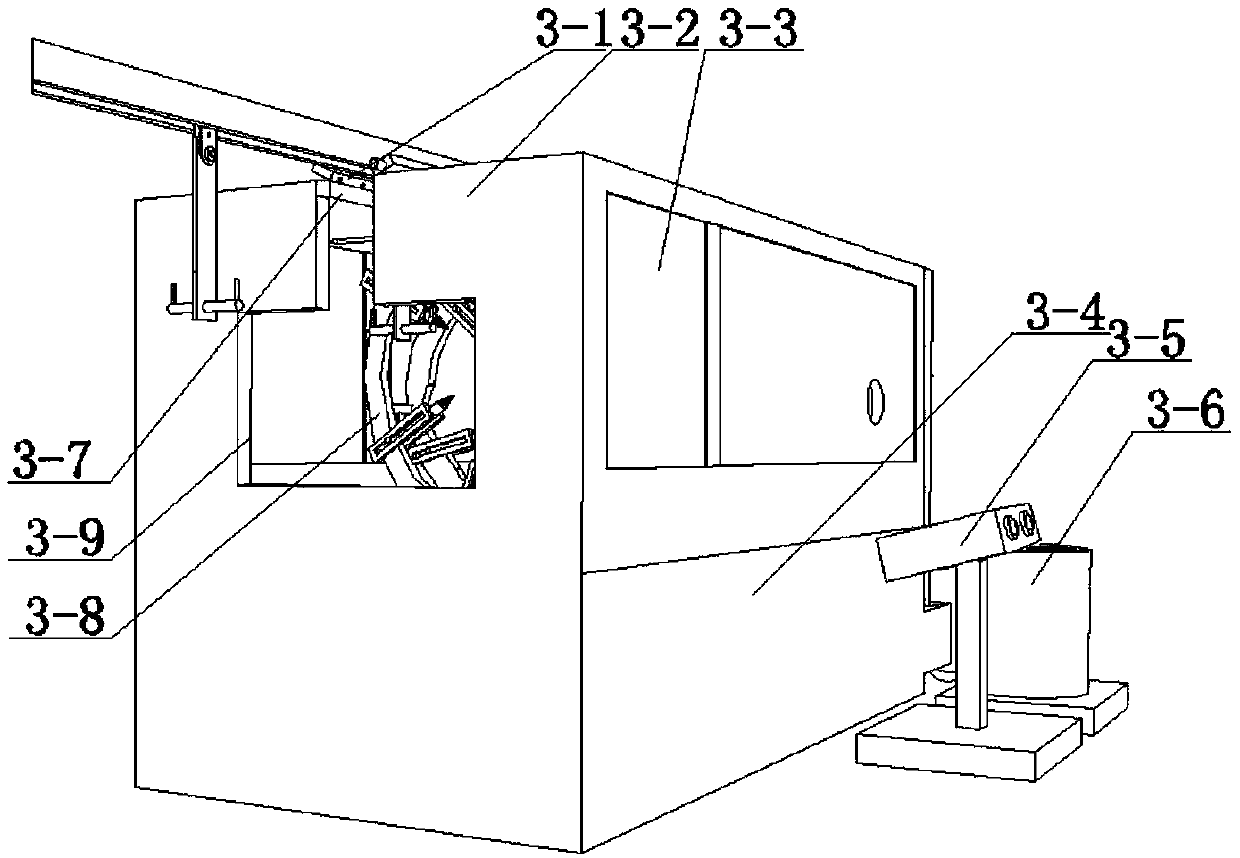

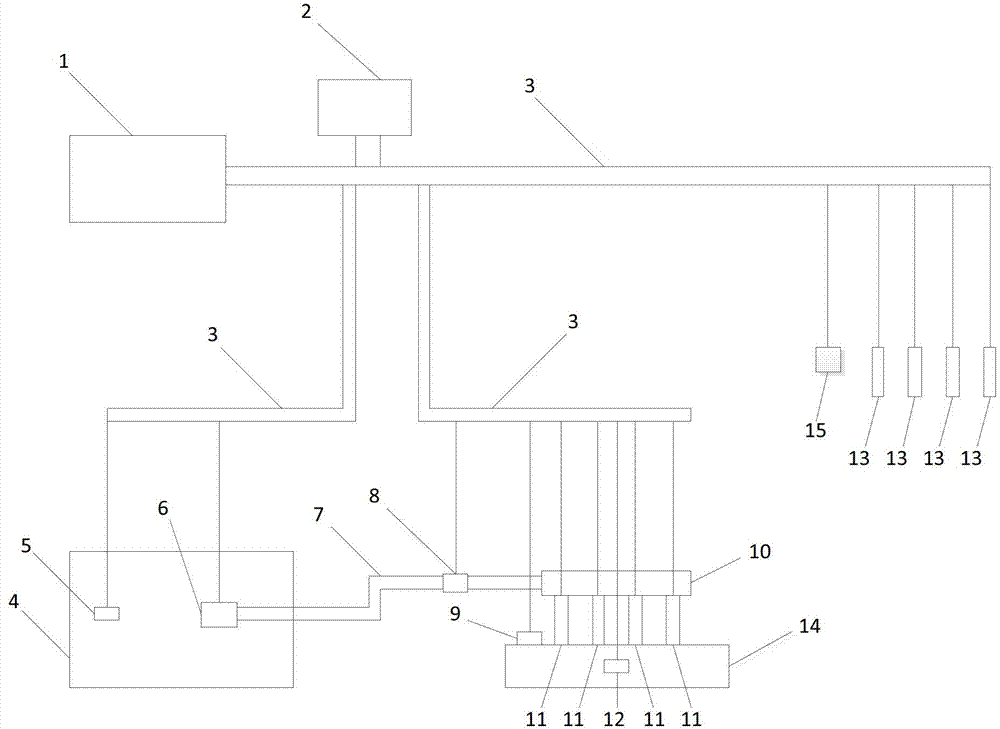

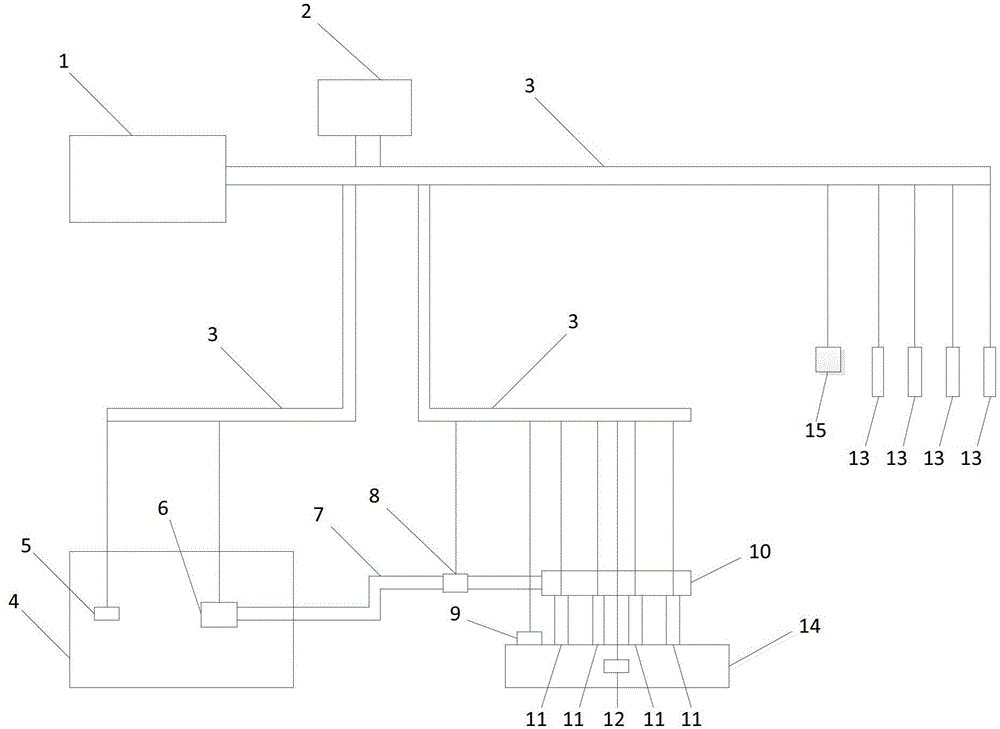

Intelligent flexible hub powder spraying line and process

ActiveUS20180243780A1Improve efficiencyQuality improvementLiquid surface applicatorsWheel holding meansControl systemEngineering

The present application discloses an intelligent flexible hub powder spraying line and process. The intelligent flexible hub powder spraying line comprises a control system, a wheel type recognition system, a brace recognition system, a conveying chain, off-line carrying robots, a powder spraying isolation area, an oven, an on-line area, an off-line area and accessory equipment, wherein the conveying chain comprises a chain, braces and a driving mechanism. By applying a plurality of powder spraying units and the recognition systems, multiple kinds of powder can be simultaneously sprayed with different parameters.

Owner:CITIC DICASTAL

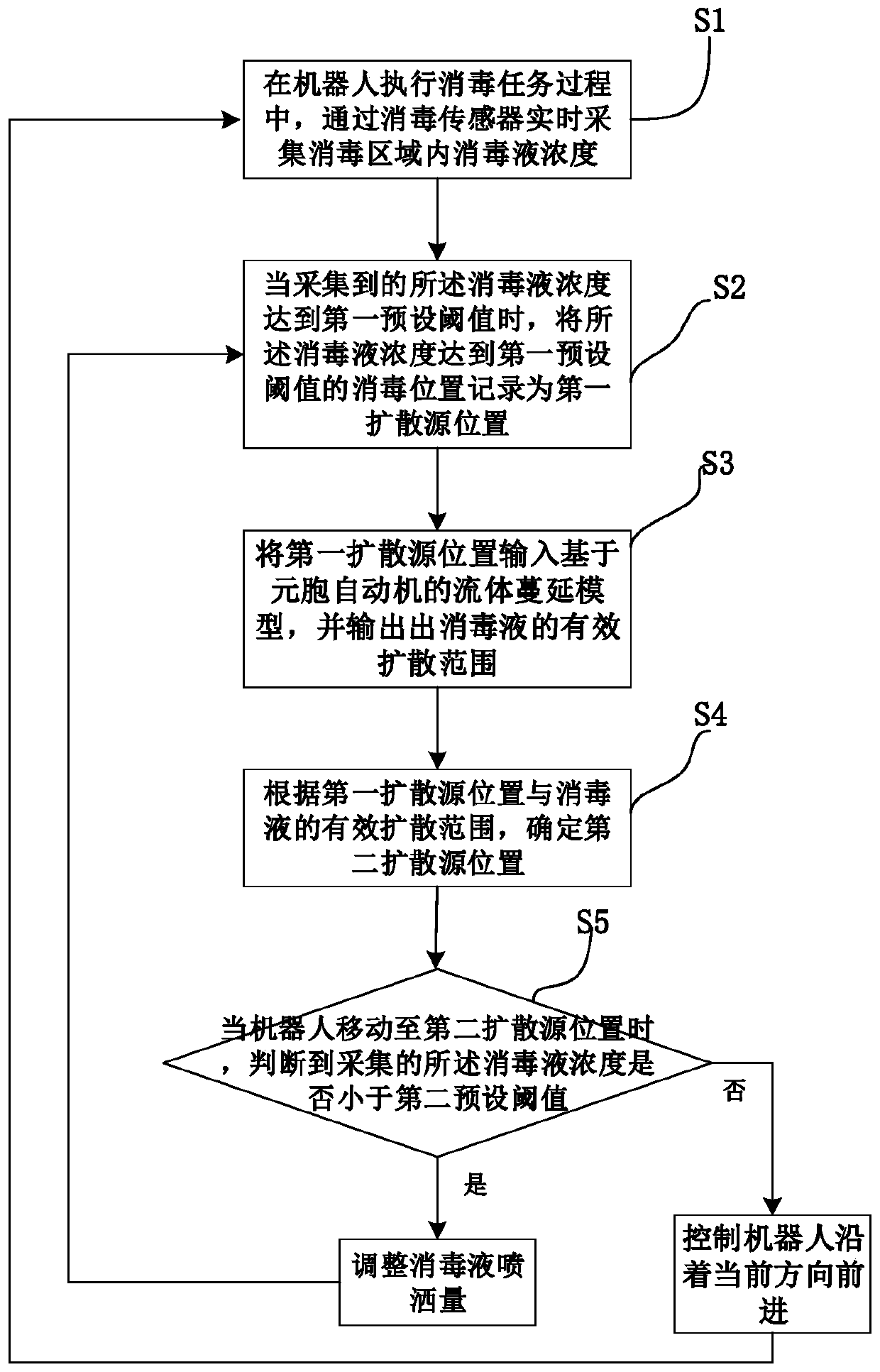

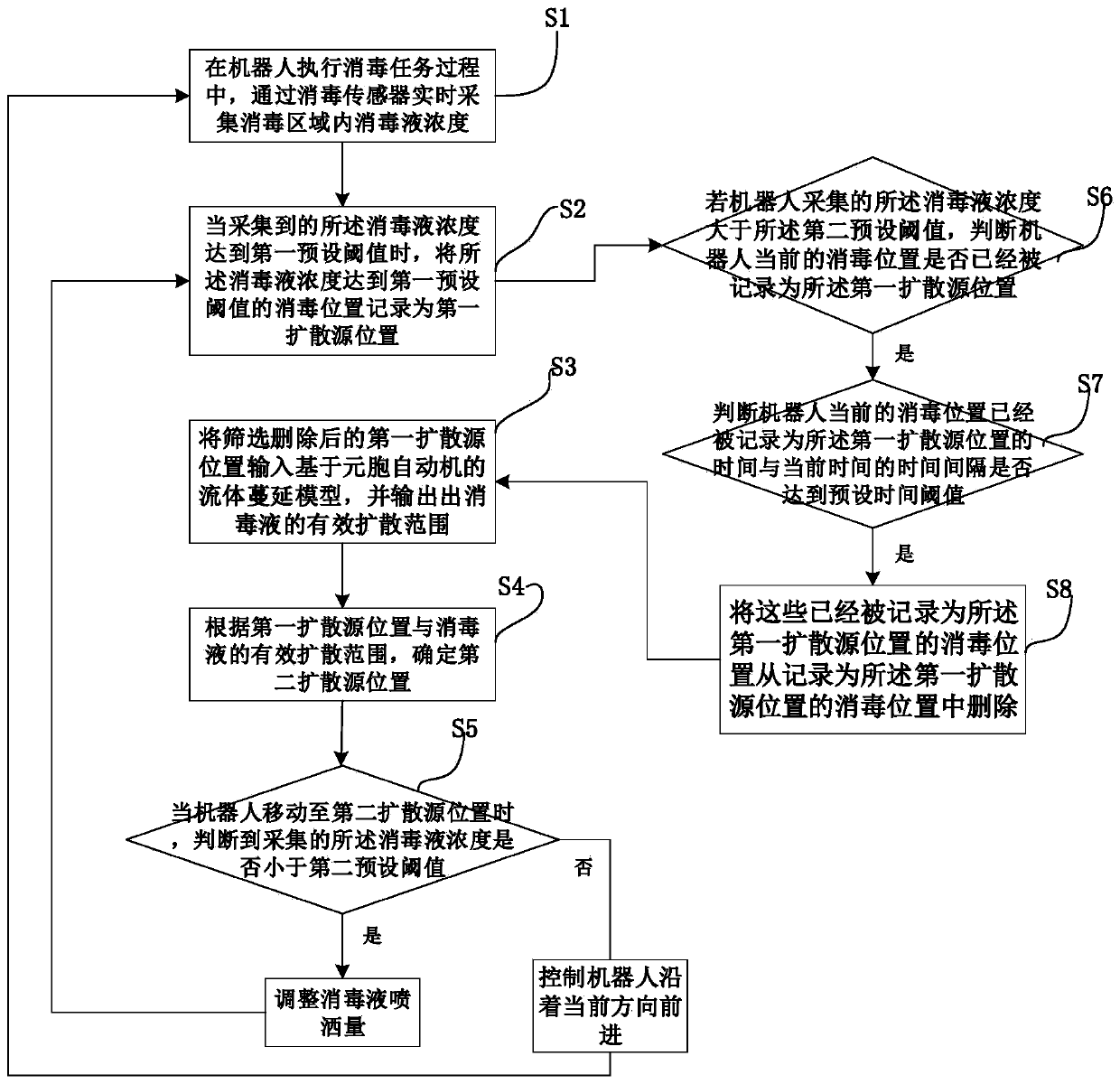

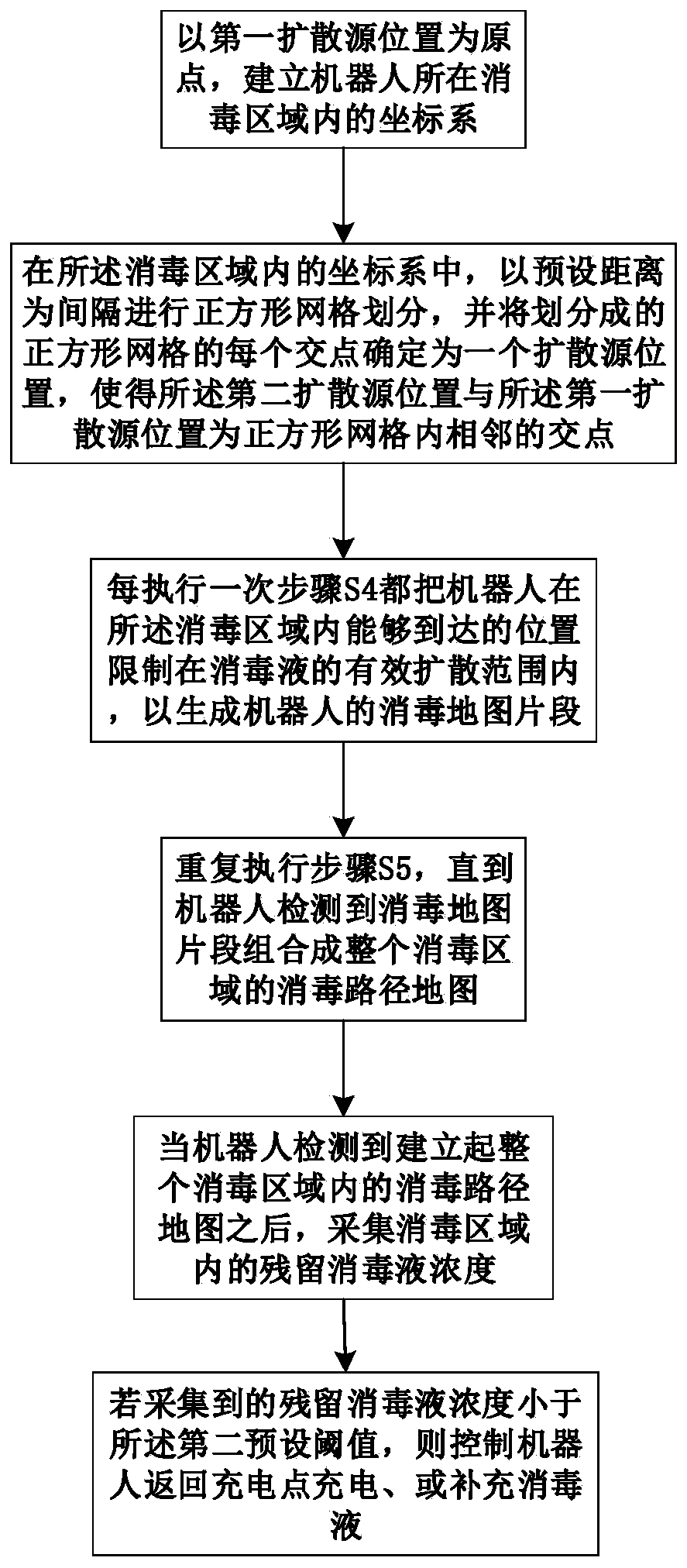

Disinfection method with robot

ActiveCN111317846AGuaranteed validityAvoid re-sterilizationLavatory sanitoryAtomized substancesCellular automationSimulation

The invention discloses a disinfection method with a robot. The method comprises the following steps: S1, the robot collects concentration of a disinfection solution in a disinfection area in real time through a disinfection sensor; S2, when the collected concentration reaches a first preset threshold value, recording a disinfection position where the concentration reaches the first preset threshold value as a first diffusion source position; S3, inputting the position of the first diffusion source into a fluid spreading model based on a cellular automata, and outputting an effective diffusionrange of the disinfection solution; S4, determining a second diffusion source position according to the first diffusion source position and the effective diffusion range of the disinfection solution;S5, when the robot moves to the second diffusion source position, judging whether the collected concentration of the disinfection solution is smaller than a second preset threshold value, if so, adjusting the spraying amount of the disinfection solution, returning to step S2, otherwise, controlling the robot to advance along the current direction, and returning to step S1; wherein the first preset threshold value is larger than the second preset threshold value.

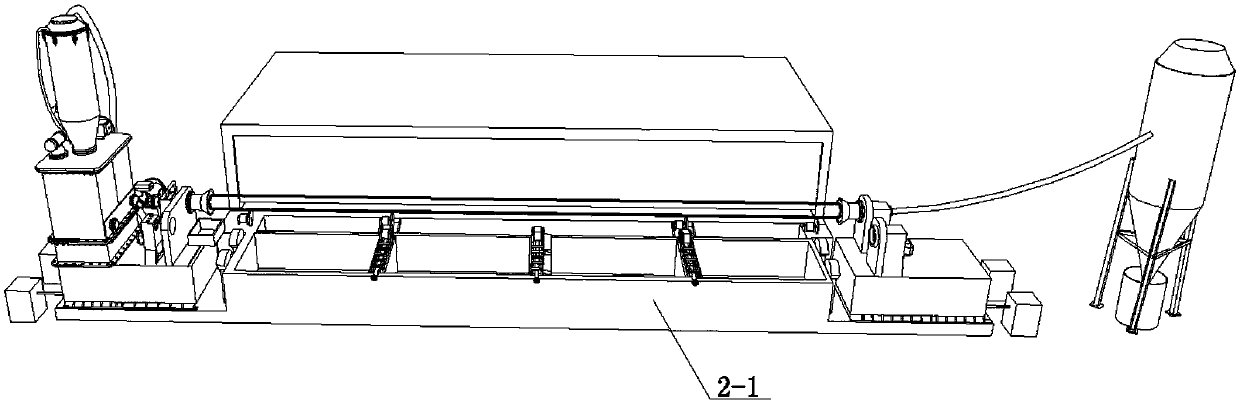

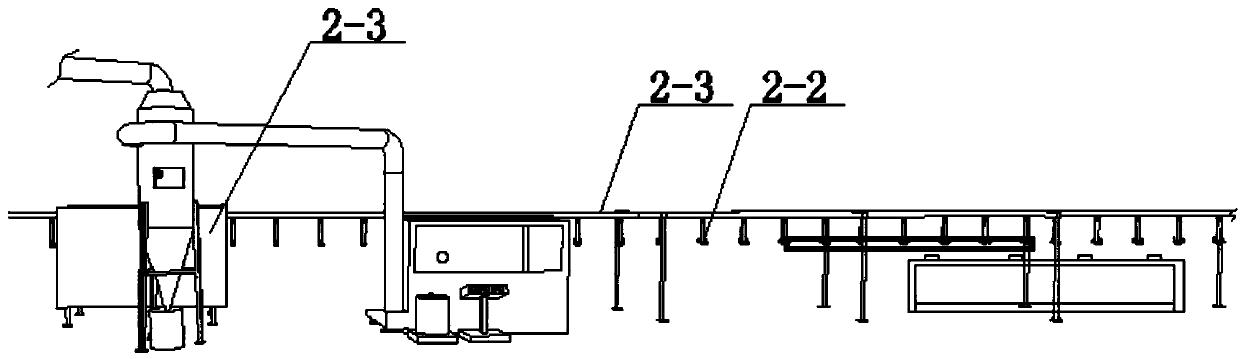

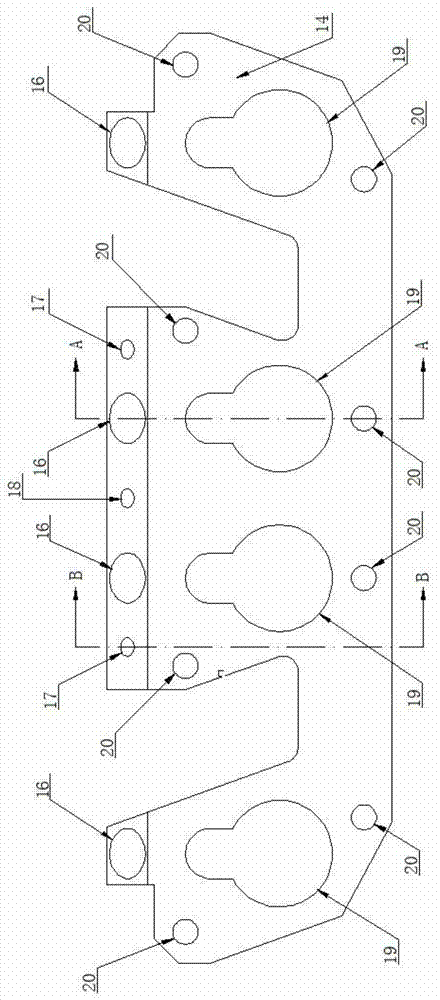

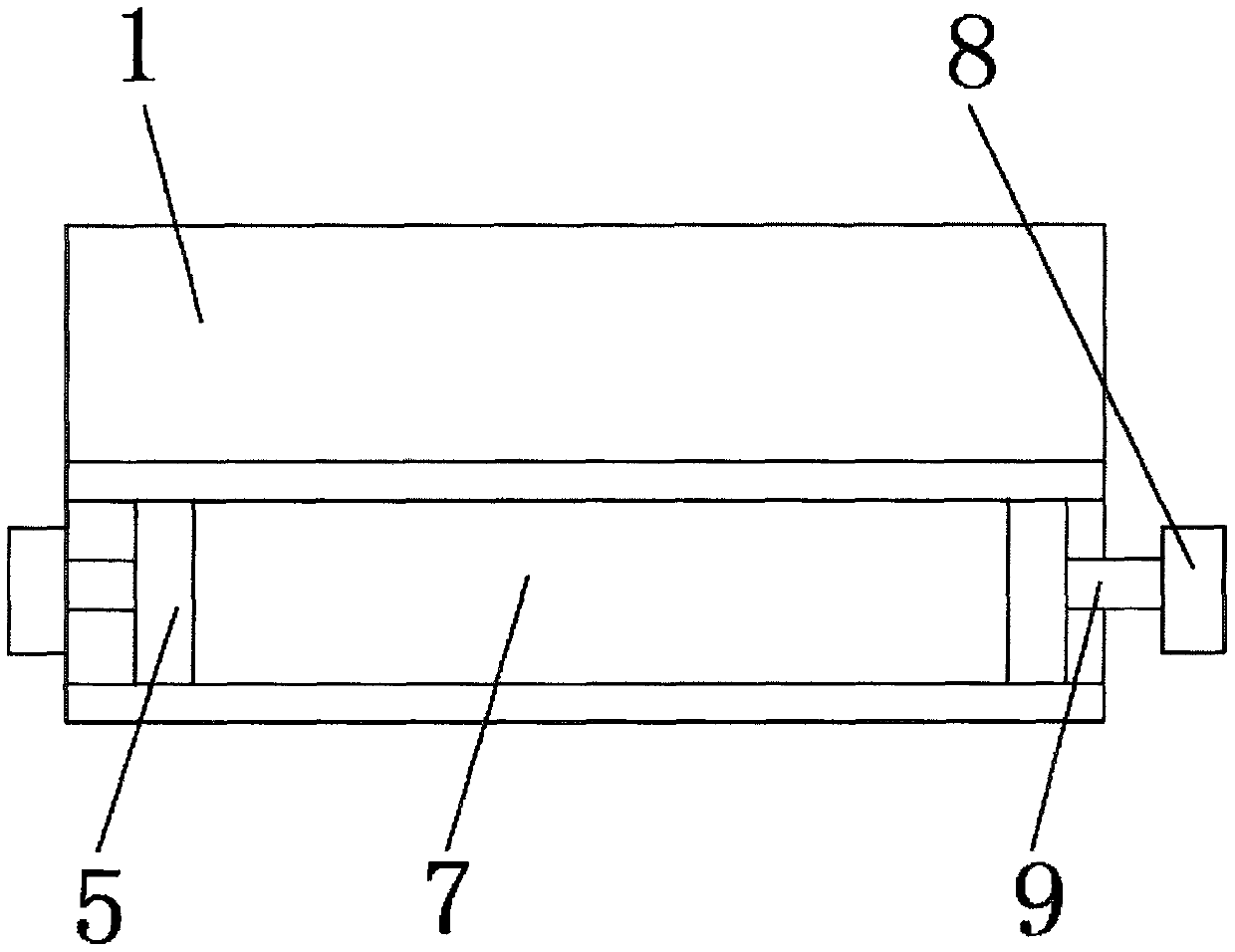

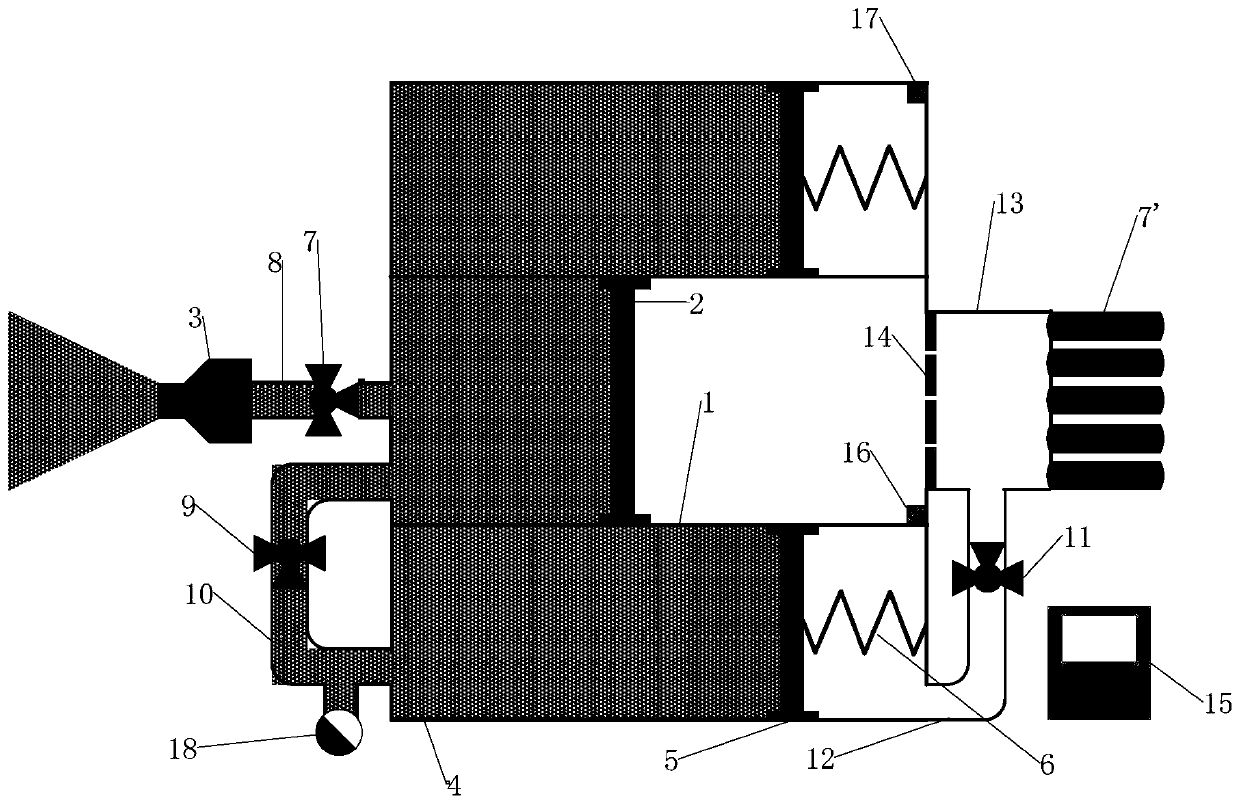

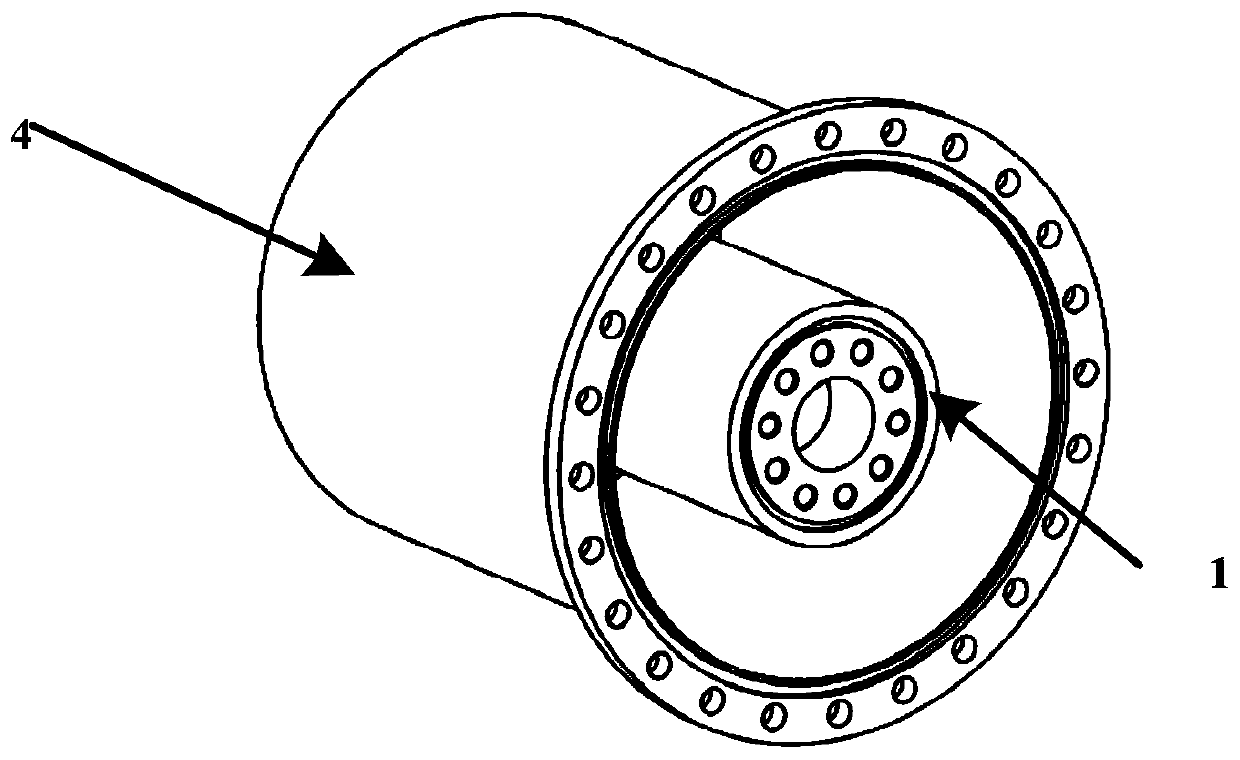

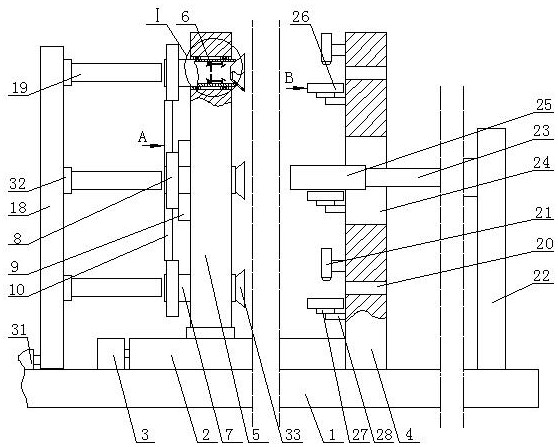

Convenience steel pipe plastic coating system for once curing in inner and outer spraying

InactiveCN107899837AHigh outputSpeed up the gas flowLiquid spraying plantsSpray boothsCoating systemEngineering

The invention relates to a convenience steel pipe plastic coating system for once curing in inner and outer spraying. The system comprises a horizontal conveying frame, a steel pipe conveying frame, an inner spraying system, an outer spraying system and a high-temperature curing furnace; the horizontal conveying frame conveys steel pipes from a preheating furnace to the inner spraying system; theinner surfaces of the steel pipes are sprayed in the inner spraying system; the horizontal conveying frame conveys the steel pipes to a transporting frame; the transporting frame supports and hangs the steel pipes to the steel pipe conveying frame; and the steel pipes are transported to the outer spraying system for outer spraying. Spraying-uniform steel pipe outer plastic coating equipment is provided with an imaginary air blowing rod on the upper surface for preventing outward splashing of dust; and negative pressure is generated in a box on the lower bottom surface of the plastic coating equipment for negative-pressure absorption of the powder to further prevent leakage of the powder so as to maintain cleanness of operation space.

Owner:天津市源泉钢塑管有限公司

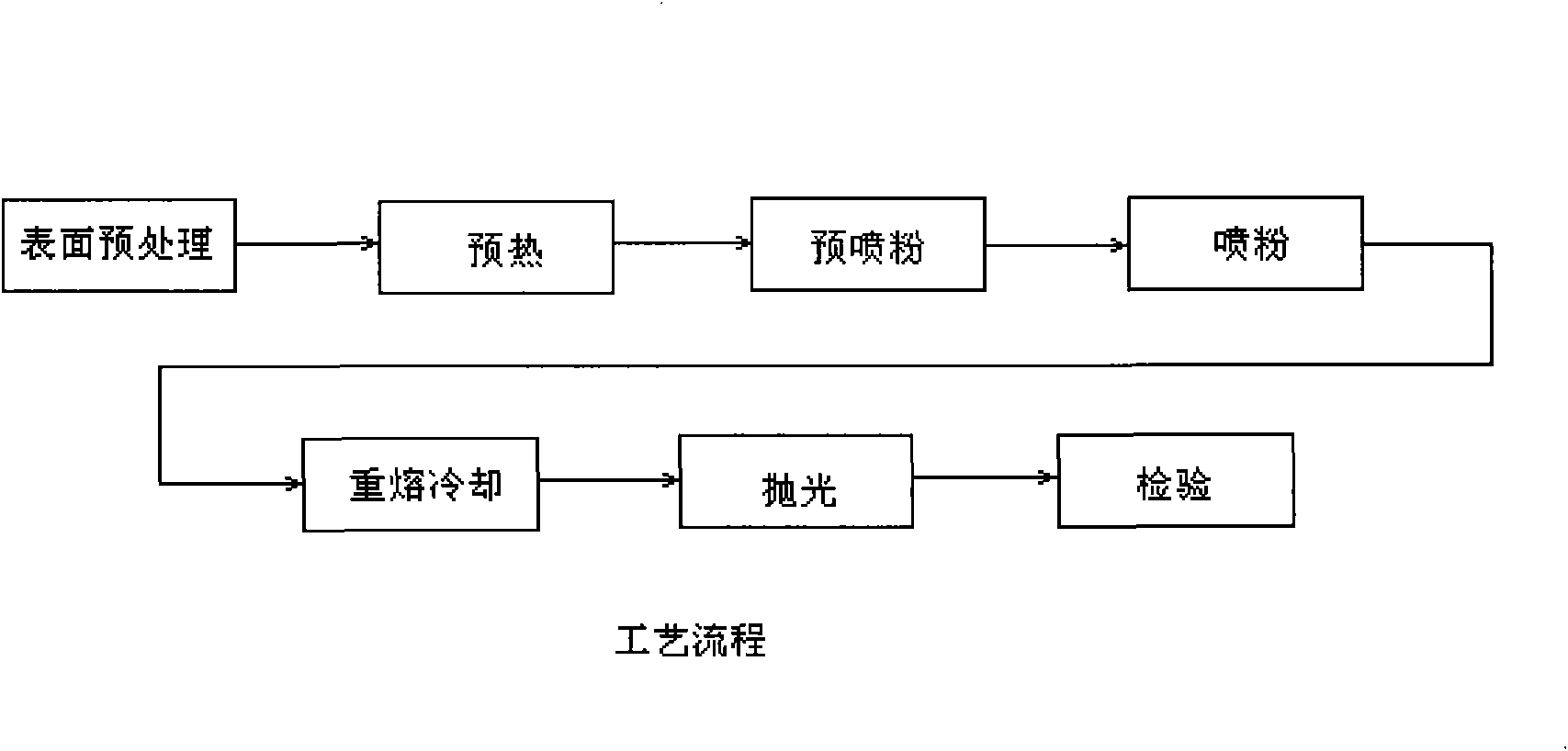

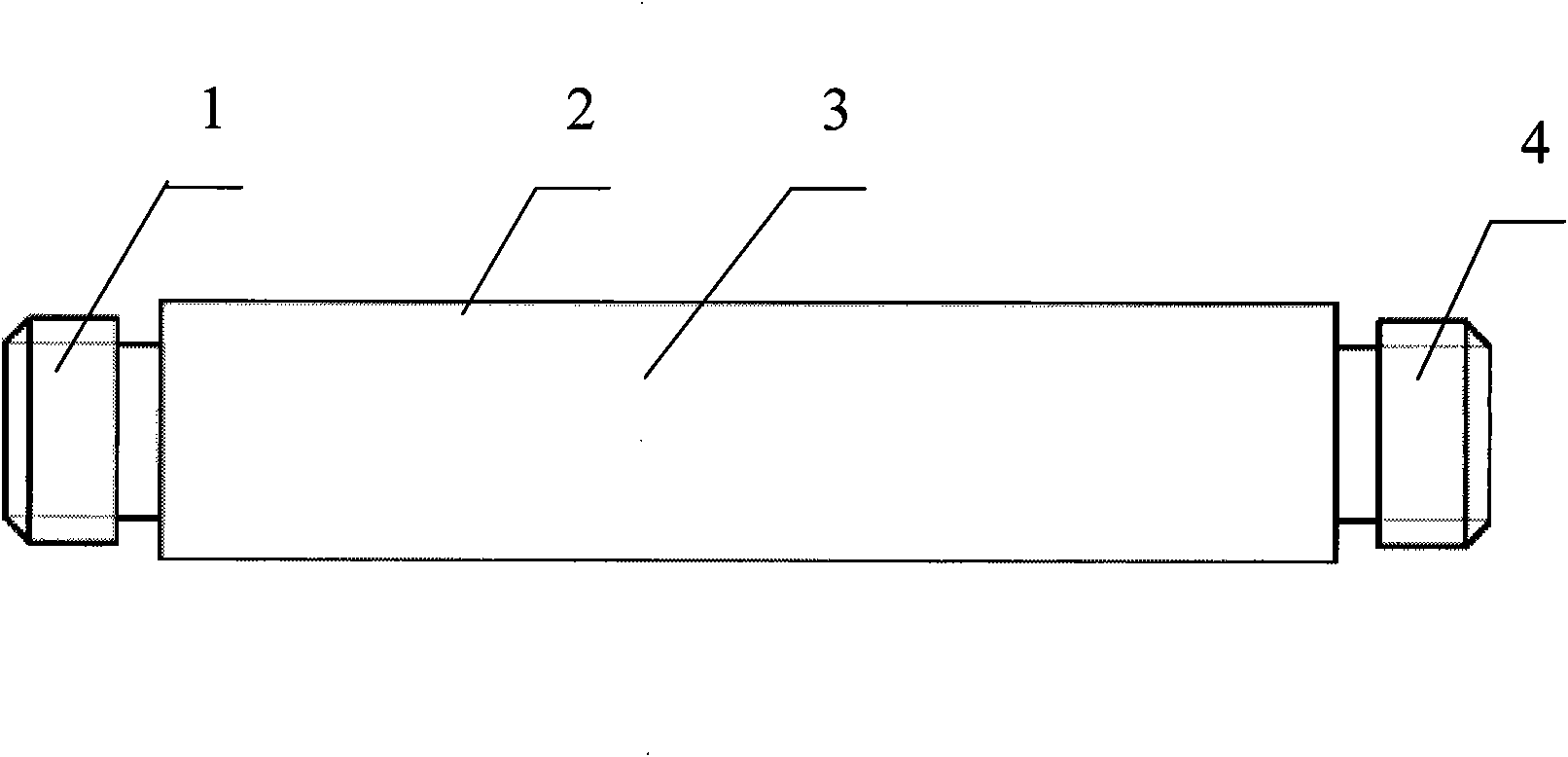

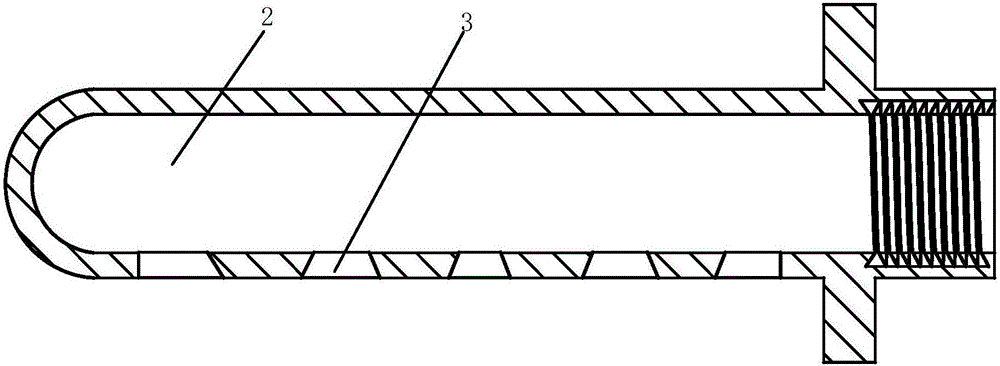

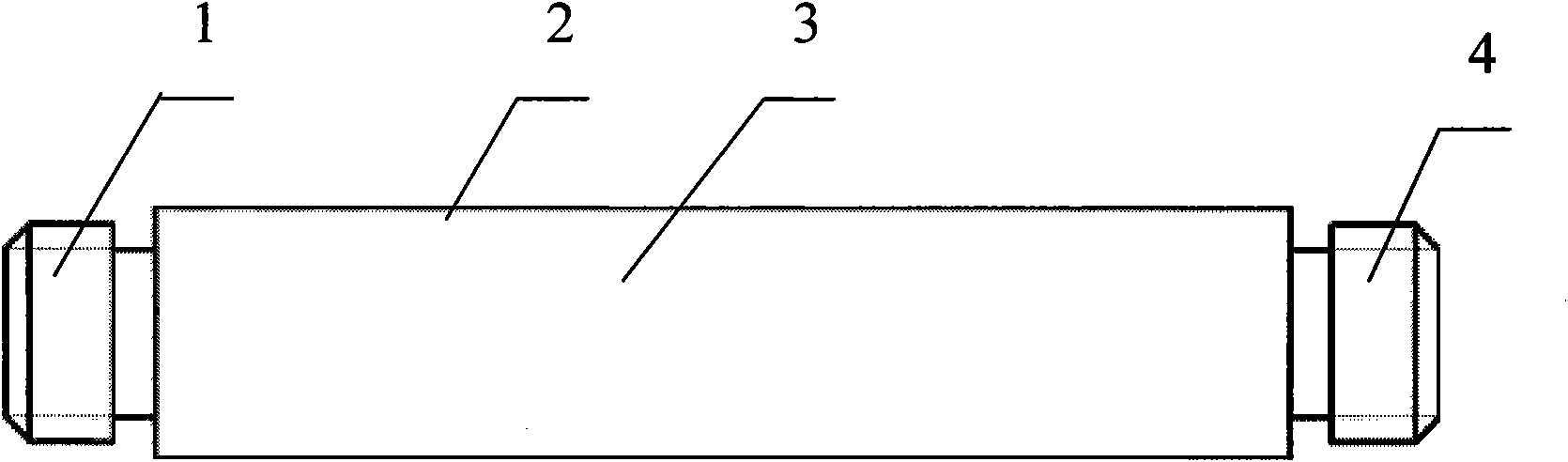

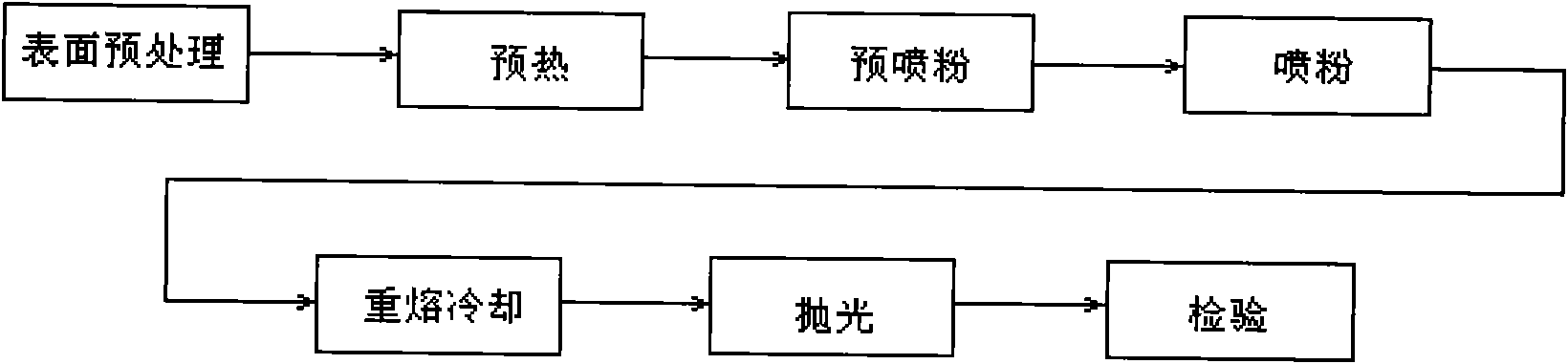

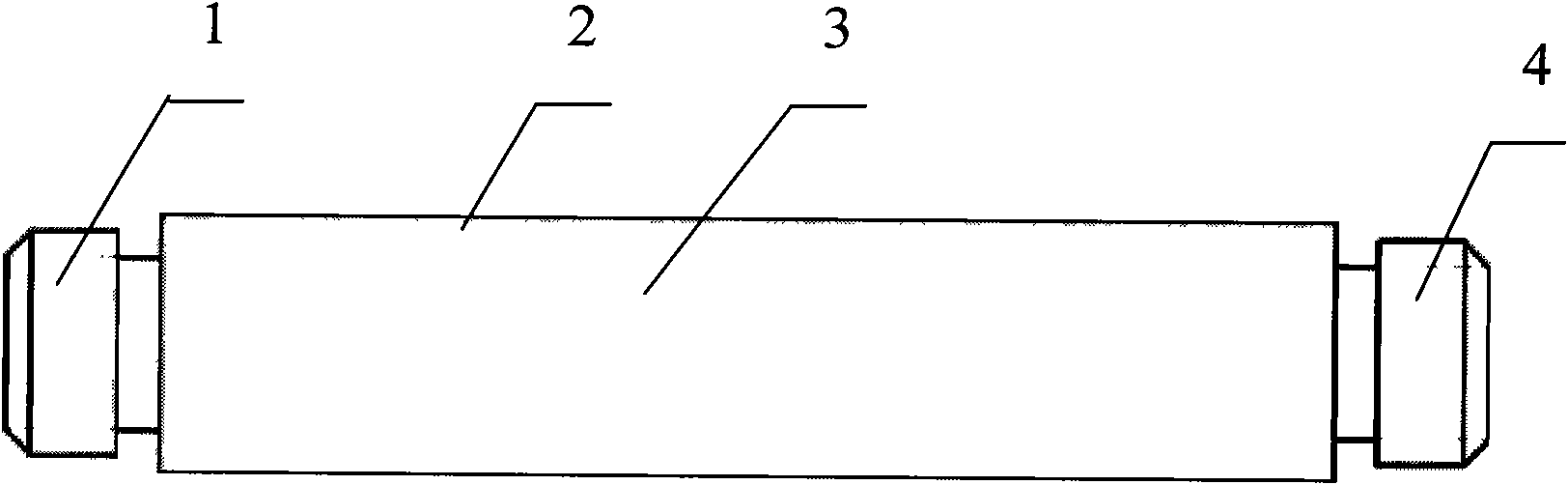

Bidirectional protecting oil pump plunger and hot spray processing technique for alloy coating of same

InactiveCN101586558ALess powderTightly boundMolten spray coatingPositive displacement pump componentsWear resistantAlloy coating

The invention relates to a bidirectional protecting oil pump plunger and a hot spray processing technique for an alloy coating of the same. The protecting oil pump plunger comprises a long cylinder, wherein two ends of the cylinder are provided with external threads and are connected with a valve cover; and the surface of the plunger is sprayed with a corrosion-resistant and wear-resistant AOC alloy coating; the thickness of the alloy coating is more than 0.25mm; the alloy coating comprises the following components: 14 to 17 percent of chromium, less than 8 percent of iron, 3.5 to 5 percent of silicon, 2.8 to 3.8 percent of boron, 0.5 to 1 percent of carbon and 65.2 to 78.9 percent of nickel; and after the working procedures of surface roughening activating treatment, spraying, remelting and polishing, a wear-resistant and corrosion-resistant coating is formed on the surface of the plunger. The process has simple and convenient operation; the coating is combined closely after spraying; the performance of a basal body of the plunger is not influenced during spraying; and the thickness of the coating is more than 0.25 mm, and the coating can resist outside wearing and corrosion, and reduce the wearing to the inner surface of a pump cylinder of an oil well pump.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

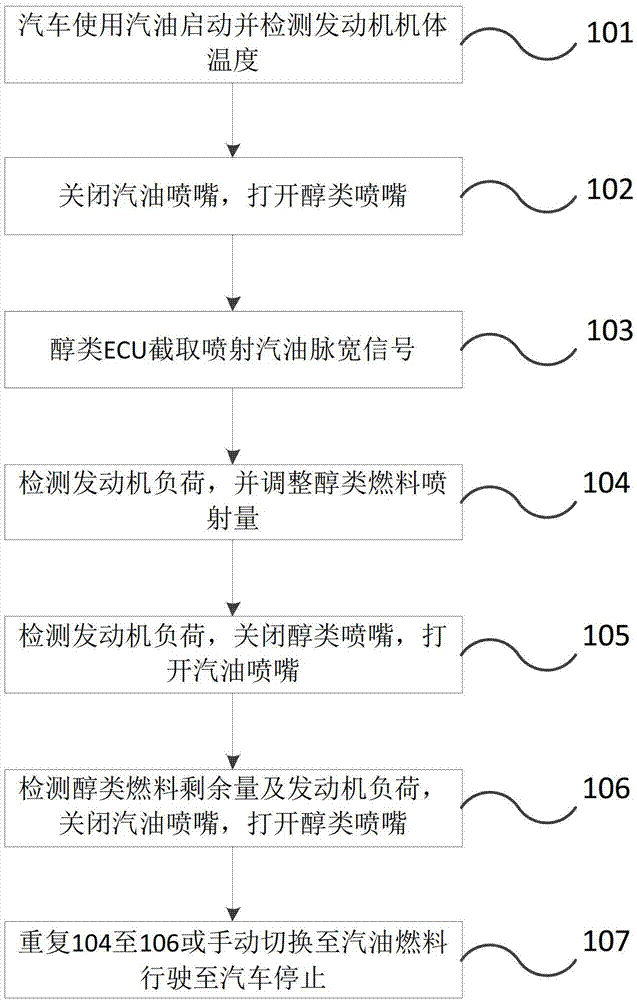

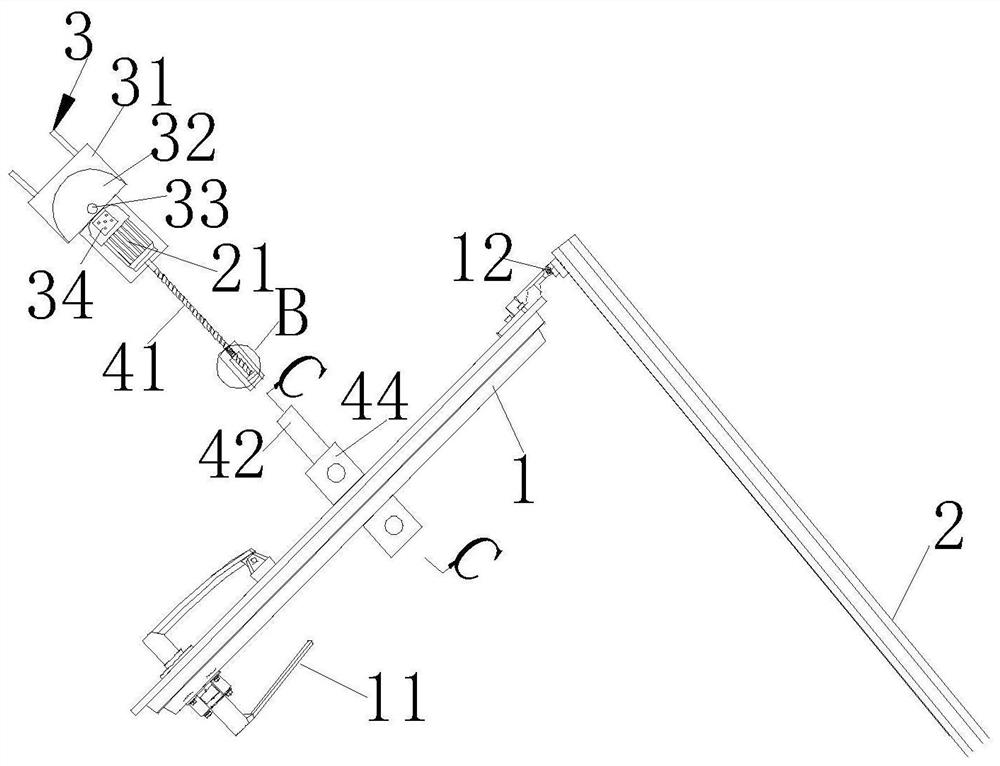

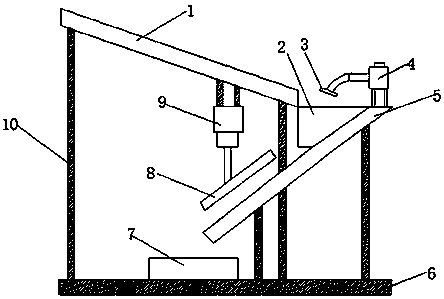

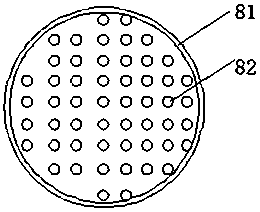

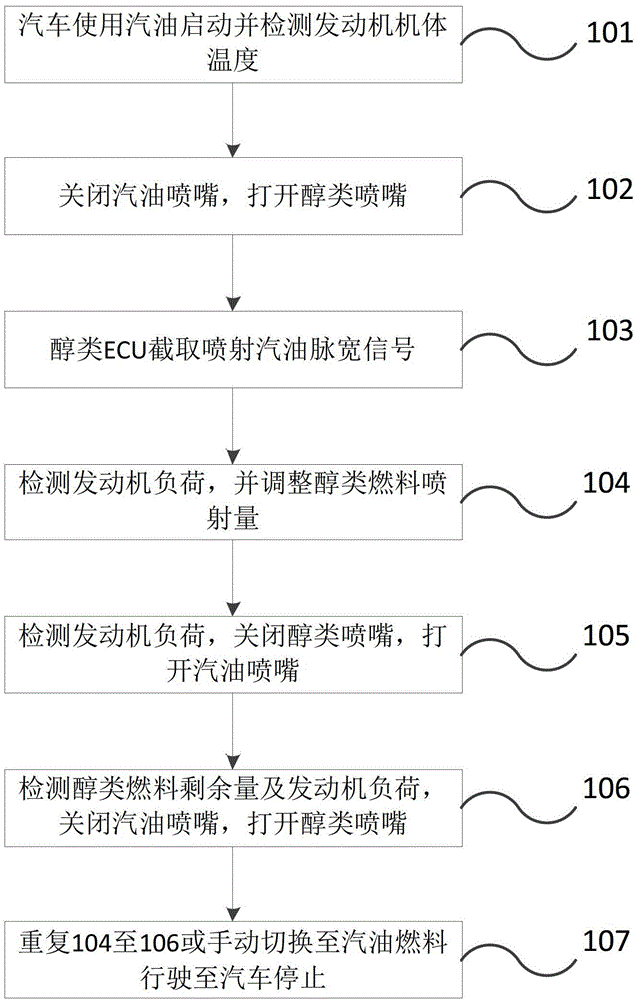

Automobile gasoline and alcohol dual-fuel supply control method and system and fixing cushion block

InactiveCN102953847ALow renovation costReduce lossInternal combustion piston enginesFuel injection apparatusCurrent loadAlcohol

The invention relates to the field of engine dual fuels, in particular to an automobile gasoline and alcohol dual-fuel supply control method and system and a fixing cushion block. After an engine is started, when the temperature of an engine body reaches the combustion temperature of the alcohol fuel, a gasoline spraying nozzle is automatically closed by an additional alcohol ECU (electronic control unit), an alcohol spraying nozzle is opened, and a gasoline spraying pulse width signal generated by a gasoline ECU is intercepted and is converted into an alcohol spraying pulse width signal according to the conversion ratio of the gasoline fuel to the alcohol fuel. When the amount of the fuel needed by the current load of the engine exceeds the maximum alcohol spraying amount or the alcohol fuel is totally consumed, the alcohol spraying nozzle is automatically closed by the alcohol ECU, the gasoline spraying nozzle is opened, and the engine continuously uses the gasoline fuel. On the premise of not losing the automobile property, the alcohol fuel is fully used, the cost of the automobile fuel is saved, the retrofit cost of the automobile is reduced, the retrofit difficulty is reduced, the loss of the engine is reduced, the environment pollution is reduced, and the automobile safety is improved.

Owner:林长军

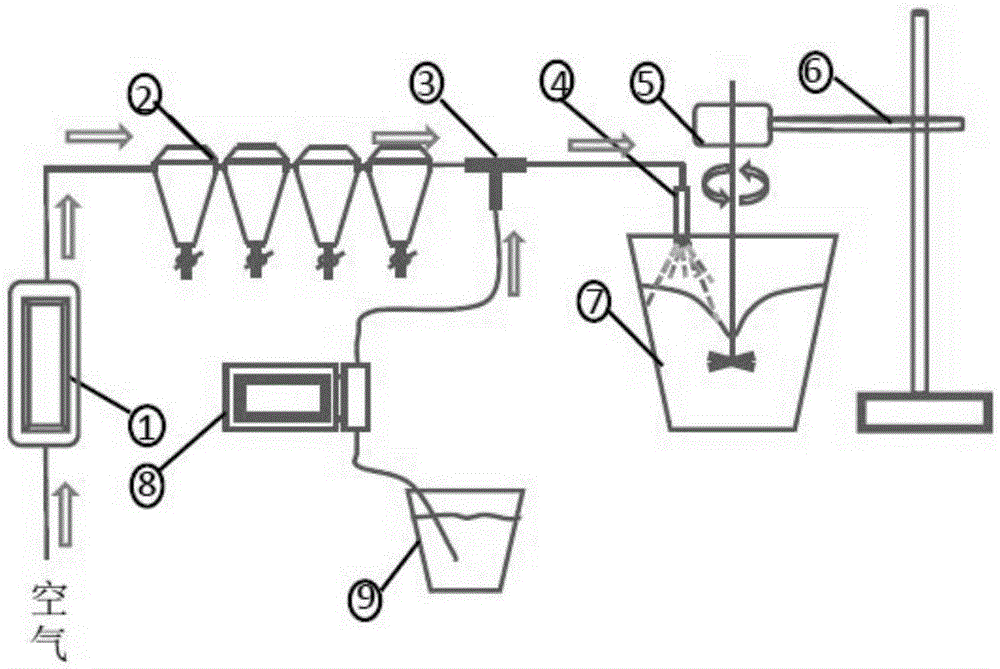

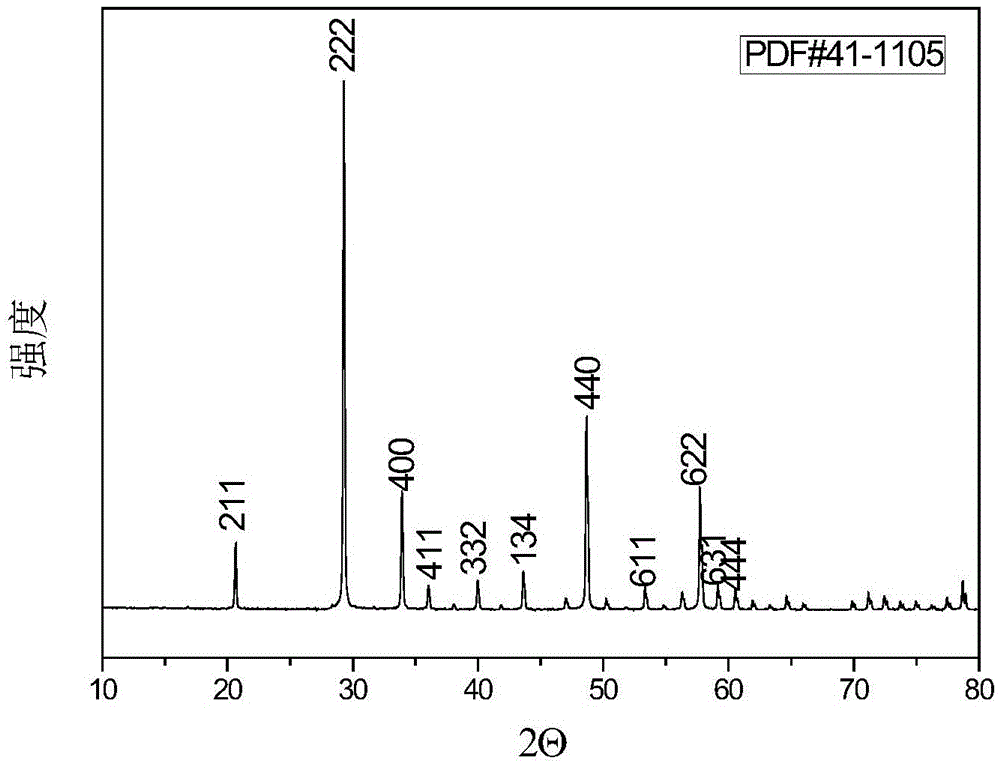

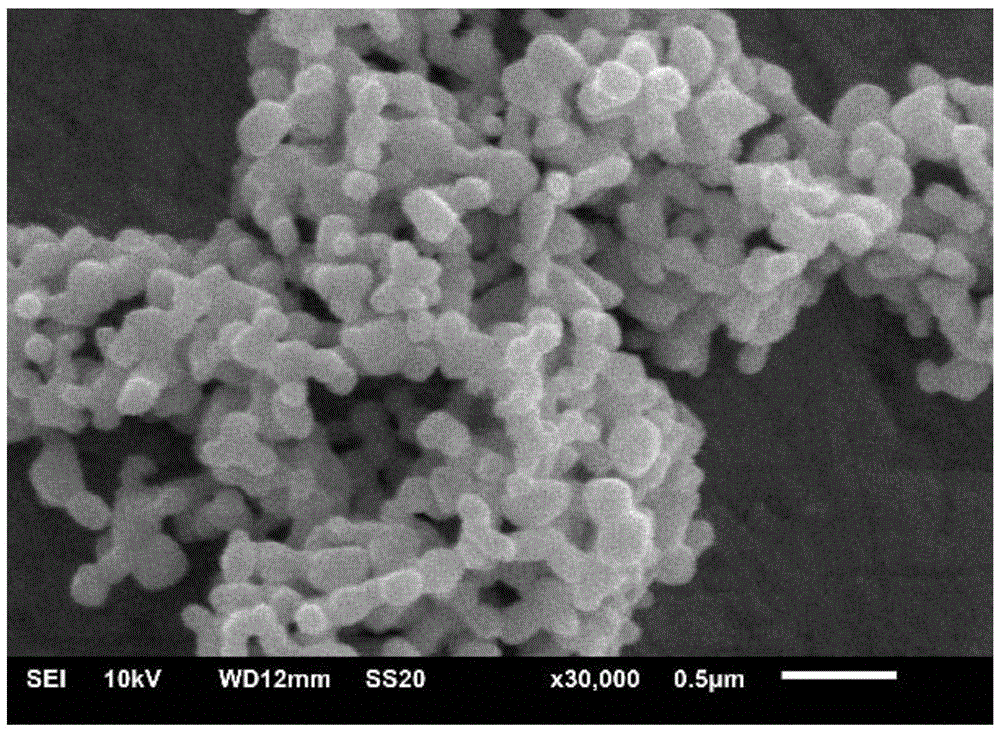

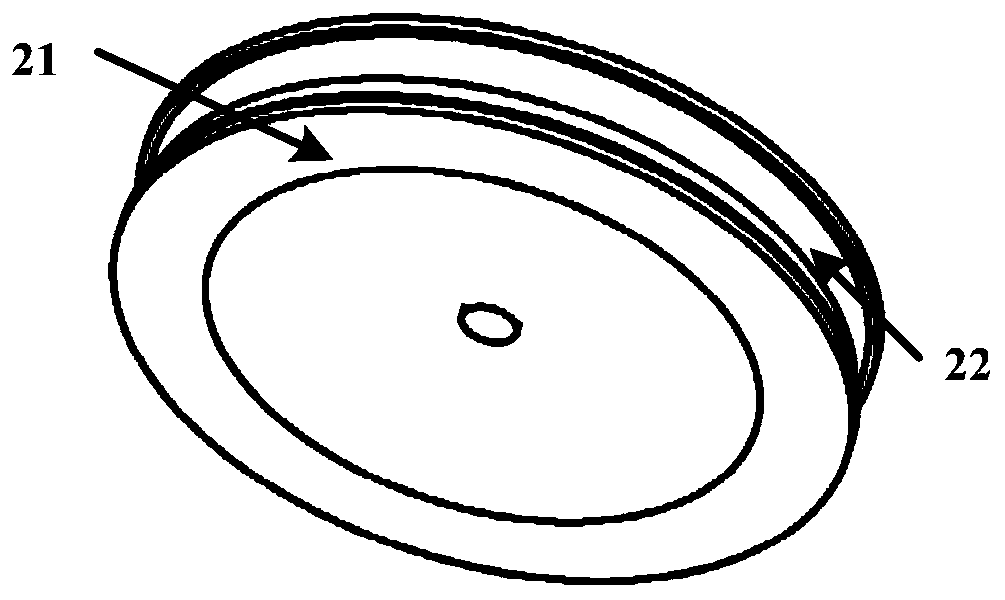

Spray coprecipitation method for preparation of Y2O3 based transparent ceramic powder

The present invention relates to a spray coprecipitation method for preparation of a Y2O3 based transparent ceramic powder. The method is as below: first preparing a rare earth ion (including Y<3+> and RE<3+>) nitrate solution and a compound precipitating agent solution containing aqueous ammonia and ammonium bicarbonate; then injecting the precipitating agent solution into the rare earth ion nitrate solution in a spray way, and terminating the co-precipitation process when the pH value is at 7-9; finally, standing, aging, adding deionized absolute ethyl alcohol, conducting suction filtration, drying and calcining to obtain a nano nearly spherical Y2O3 based transparent ceramic powder. The Y2O3 based transparent ceramic powder prepared by the method provided by the present invention has small particles, uniform particle distribution, weak agglomeration, particle size of 80-150nm and excellent powder molding. The method is very applicable to (semi) industrial production of Y2O3 based transparent ceramic material.

Owner:XUZHOU NORMAL UNIVERSITY

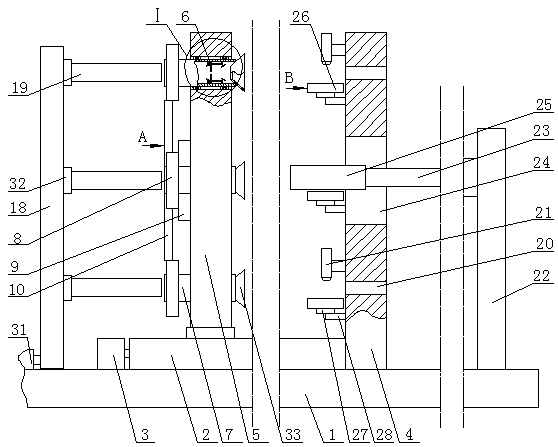

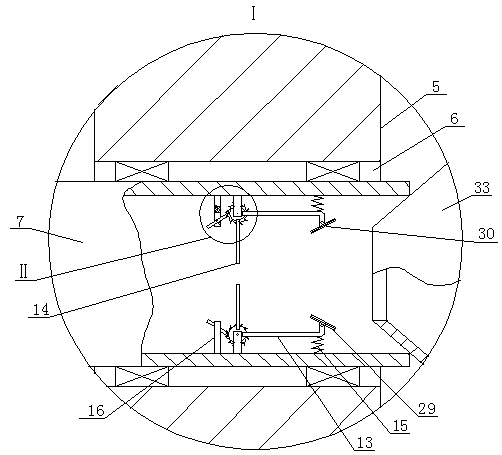

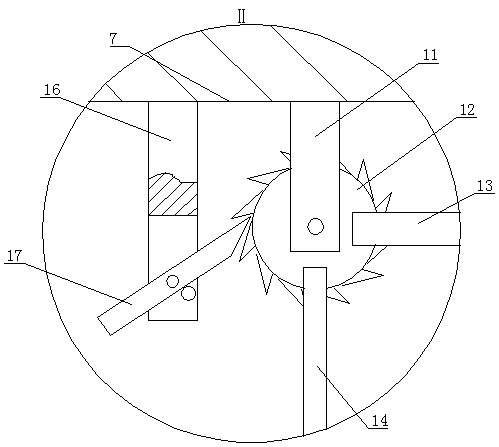

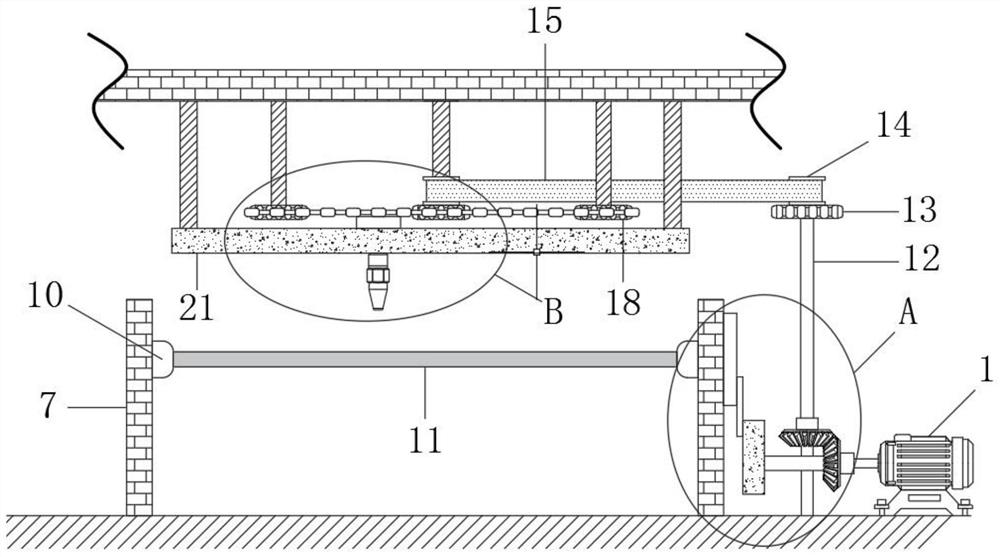

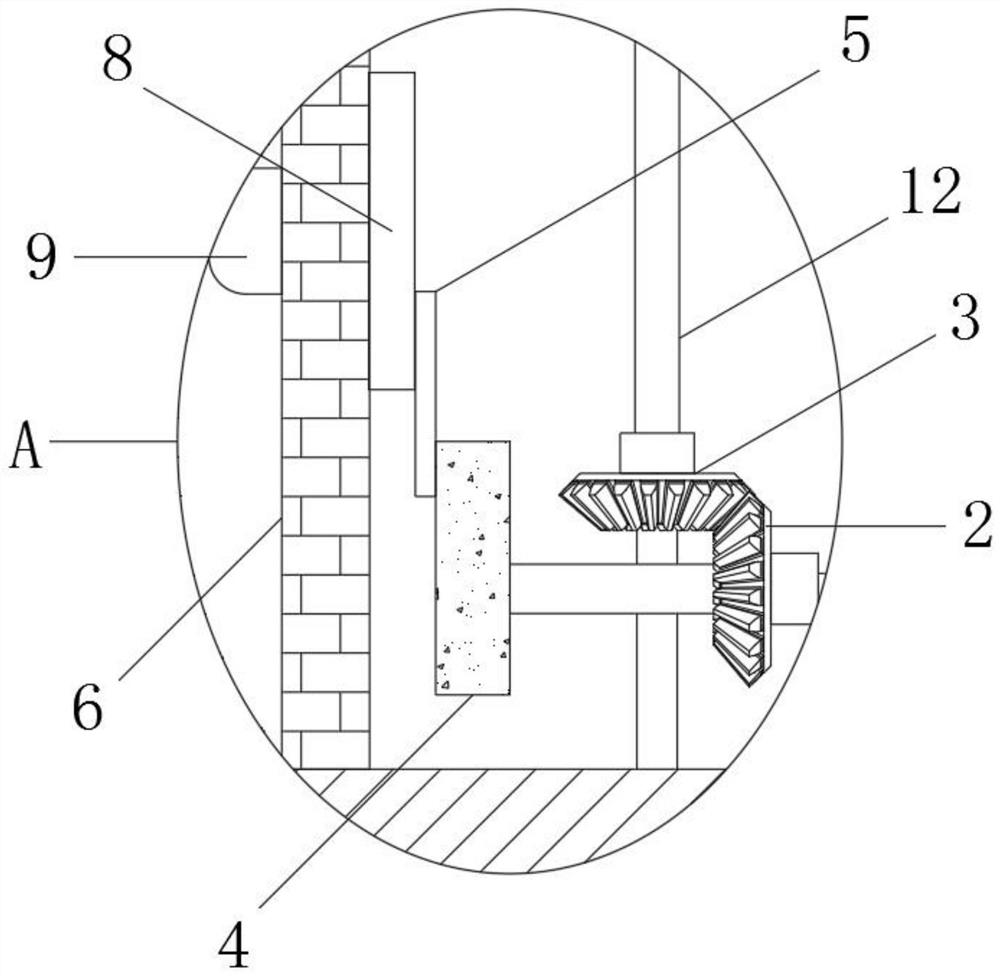

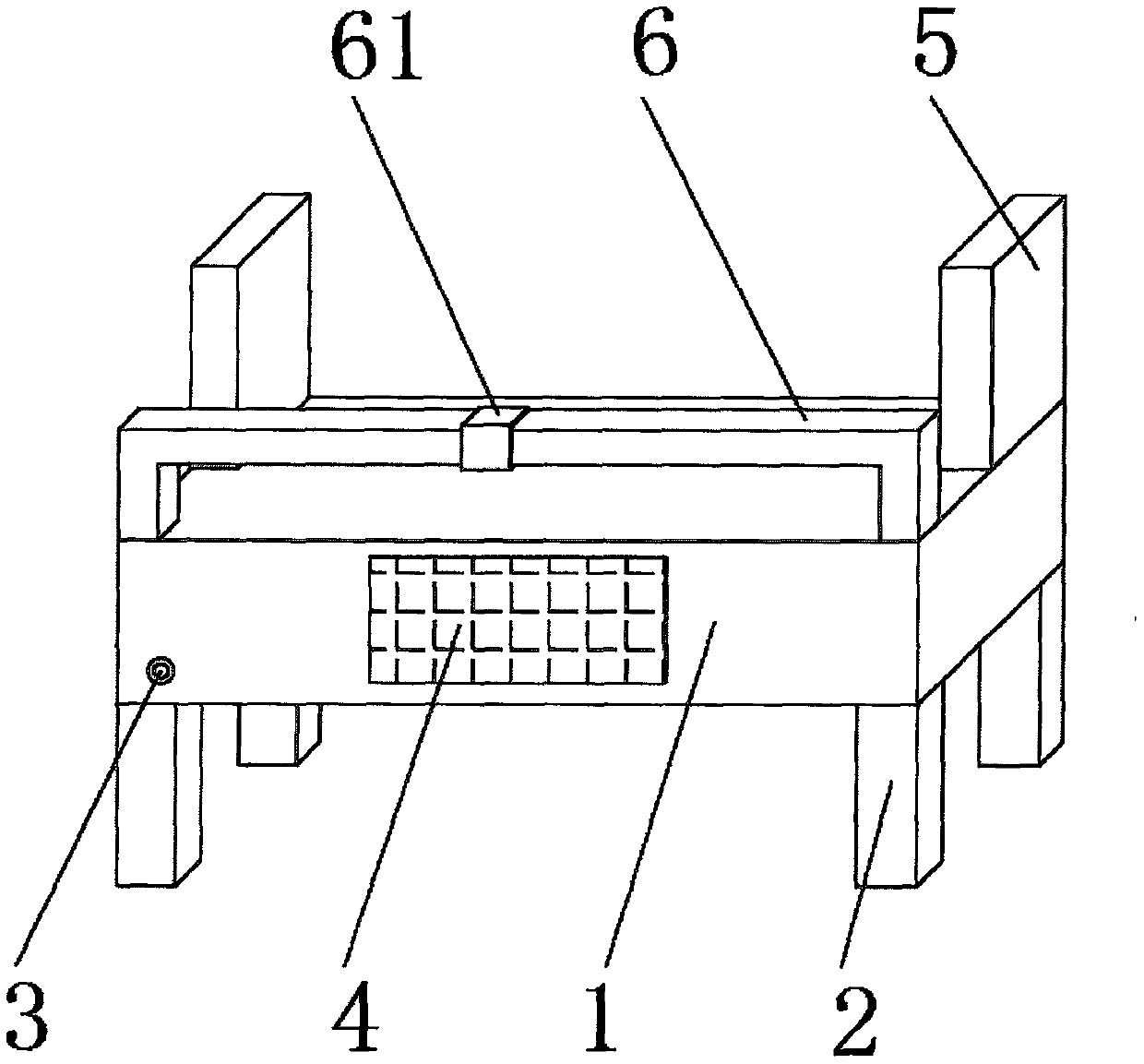

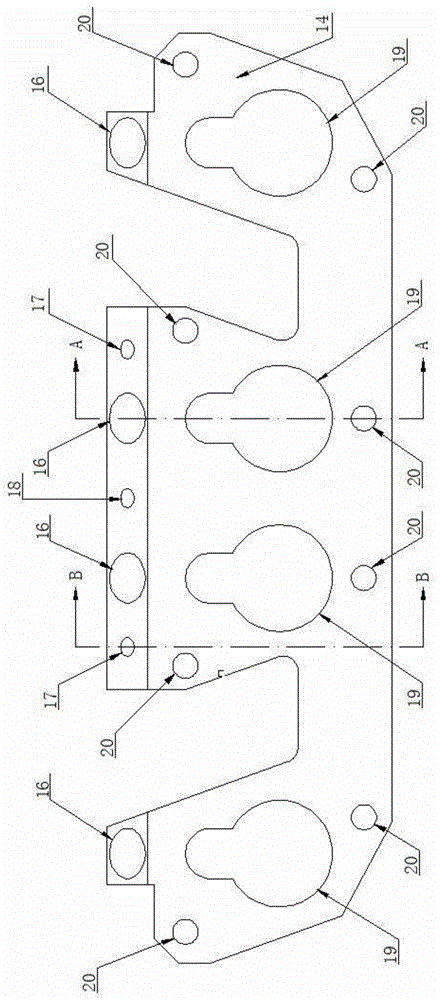

Plastic pipe surface spraying device

ActiveCN109127210ASimple structureIncrease the rate of sprayingSpraying apparatusCorrosion preventionMechanical engineeringEngineering

A plastic pipe surface spraying device comprises a base. The top side of the base is fixedly provided with a transverse horizontal moving device. The left end of a power shaft of the horizontal movingdevice is fixedly connected with the right end of a rotating shaft of a first motor. The right side of the top side of the base is fixedly connected with the bottom side of a supporting plate. The top side of a movable platform of the horizontal moving device is fixedly connected with the bottom side of a movable plate. The right side of the movable plate is evenly provided with a plurality of first through holes which are distributed circumferentially. The first through holes are internally provided with transverse pipes through bearings. The left ends of the peripheries of the transverse pipes are fixedly provided with annular gears. The left side of the movable plate is fixedly provided with a second motor. The left side of a rotating shaft of the second motor is fixedly provided witha gear. The plastic pipe surface spraying device is simple in structure, capable of spraying a plurality of plastic pipes at the same time, the spraying speed is greatly increased, by means of the rotation and the movement of the plastic pipes, the spraying of the peripheries of the plastic pipes is completed, and the situation that the spraying error is increased due to the mutual action of the deviation of the plastic pipes during moving and the deviation of a spray gun during rotating is avoided.

Owner:山东陆宇塑胶有限公司

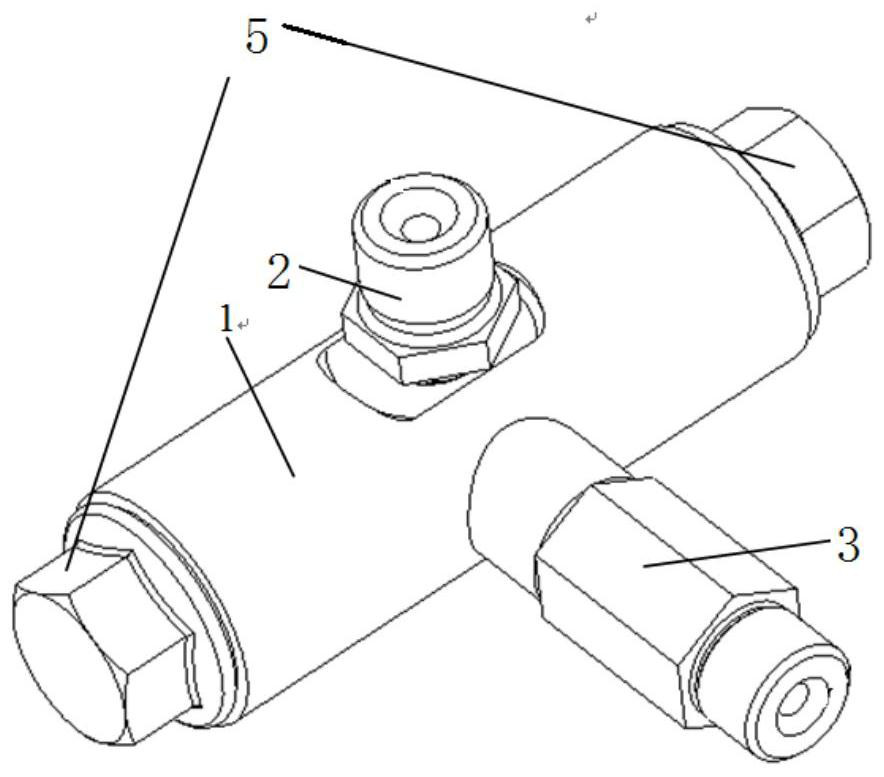

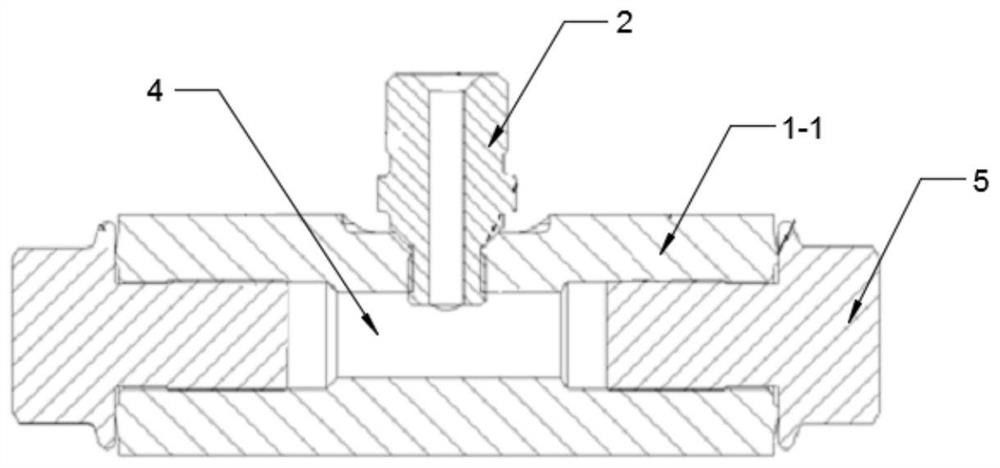

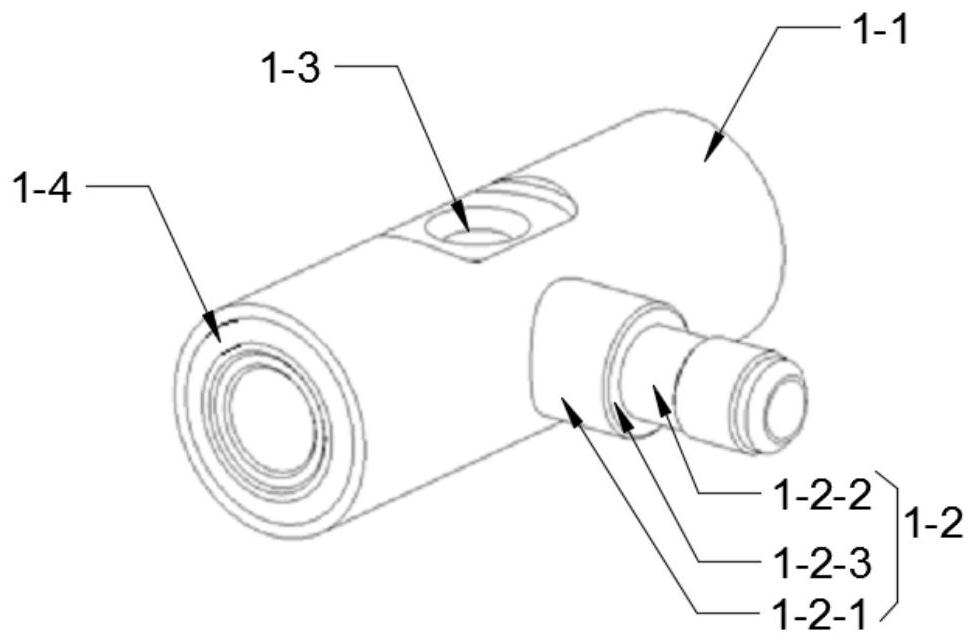

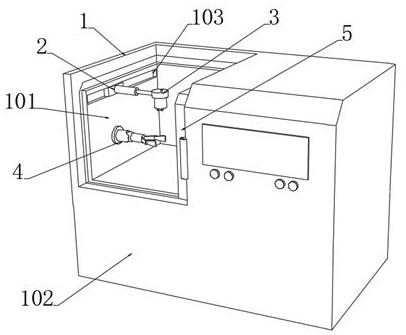

Segmented rail for high-pressure common rail system and control method of segmented rail

PendingCN112267964AImprove stabilityIncrease spray rateElectrical controlFuel injection apparatusCommon railSprayer

The invention discloses a segmented rail for a high-pressure common rail system. The segmented rail comprises a segmented rail body, a high-pressure conversion connector and a one-way valve, wherein the high-pressure conversion connector and the one-way valve are installed on the segmented rail body in a sealed mode; the segmented rail body is hollow to form a pressure accumulation volume cavity used for containing high-pressure fuel oil, and the high-pressure fuel oil enters the pressure accumulation volume cavity in a one-way mode through the one-way valve; and the high-pressure fuel oil inthe pressure accumulation volume cavity flows out through the high-pressure conversion connector and enters an electric control oil sprayer; and the volume of the pressure accumulation volume cavity is larger than or equal to 40 times of the maximum oil spraying amount per cycle of the electric control oil sprayer. According to the segmented rail for the high-pressure common rail system, high-pressure fuel oil pressure drop caused by oil spraying each time can be effectively reduced, the stability of fuel oil spraying can be improved, and the fuel oil spraying speed can be increased. Meanwhile, due to the effect of the one-way valve in the segmented rail for the high-pressure common rail system, the pressure change of the high-pressure fuel oil in the pressure accumulation volume cavity cannot influence the pressure of the high-pressure fuel oil in the pressure accumulation volume cavity in the adjacent segmented rail, and the consistency of fuel oil spraying of the high-pressure common rail system can be effectively improved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

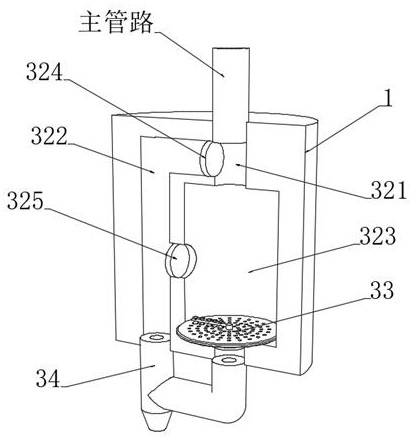

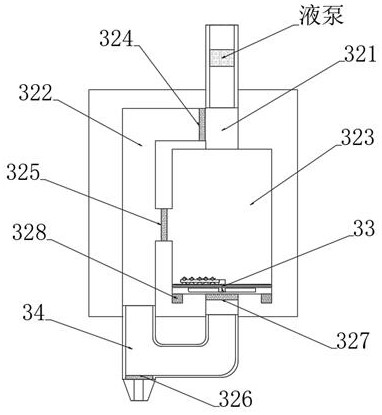

Circulating backflow type paint spraying device for automobile part production

ActiveCN114653501AAvoid cloggingReduce viscosityLiquid spraying apparatusElectromagnetic valveIndustrial engineering

The invention discloses a circulating backflow type paint spraying device for automobile part production, and belongs to the technical field of paint spraying. According to the scheme, a nozzle is blocked through a second electromagnetic valve, and then new paint washes a pipeline through a branch channel, so that old paint remaining in the pipeline is pushed into the bottom of a liquid storage cavity; the phenomenon that due to the fact that the viscosity of old paint is too high, a spray head is blocked is effectively avoided, a plurality of slow release holes are formed in a disc and matched with a magnetic block to attract a magnetic ring, the old paint can be slowly squeezed to the position above the disc to be mixed with new paint entering from the position above a liquid storage cavity, the viscosity of the old paint is effectively reduced, and the use efficiency of the paint is improved; and after the internal pressure of the liquid storage cavity reaches a threshold value, the one-way electromagnetic valve is opened, and the first electromagnetic valve is closed, so that the mixed paint is ejected out through the one-way pressure valve and the spray pipe, the mixing degree of new and old paint is effectively improved, and color difference is reduced.

Owner:海门市华洋汽车配件制造有限公司

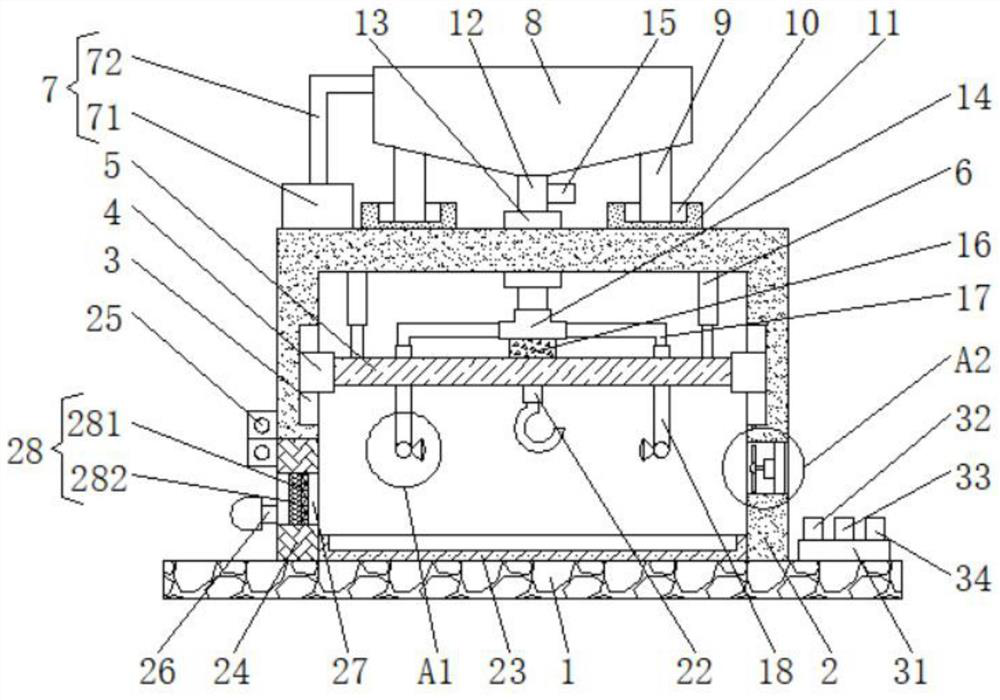

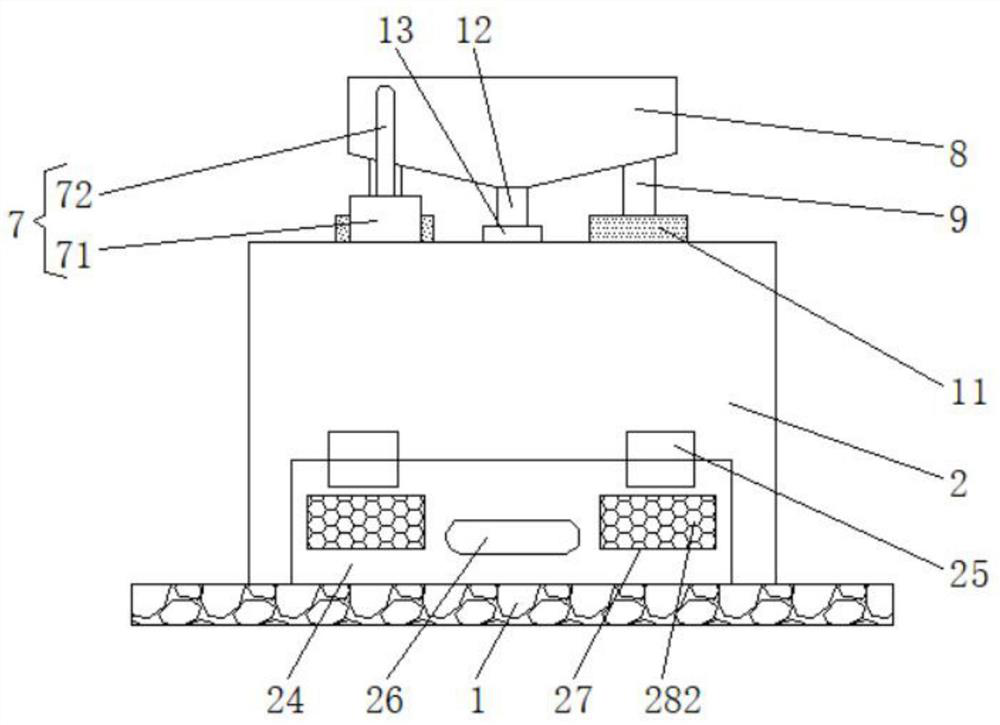

New energy automobile part spraying device with high spraying efficiency

The invention discloses a new energy automobile part spraying device with high spraying efficiency, and relates to the technical field of new energy automobile part processing. The new energy automobile part spraying device comprises a bottom plate, wherein the upper surface of the bottom plate is fixedly connected with the lower surface of a box body, sliding grooves are formed in the left side face and the right side face of the inner wall of the box body, and sliding blocks are slidably connected into the sliding grooves; and the opposite faces of the two sliding blocks are fixedly connected with the left side face and the right side face of a carrier plate correspondingly. The new energy automobile part spraying device capable of achieving uniform spraying is provided with the bottom plate, the box body, a pressurizing device, a material tank, a first supporting rod, a first discharging pipe, a pipe sleeve, a three-way pipe, a valve, a fixing block, a second discharging pipe, a third discharging pipe, a fourth discharging pipe, a second supporting rod, an atomizing spray head, a hook, a box door, a hinge, a handle, a power source and a second switch, so that the left side faceand the right side face of a part can be sprayed, the spraying speed of the part is increased, the production time is shortened, and the production efficiency is improved.

Owner:诸暨英科宏升弹簧有限公司

Pesticide spraying device capable of uniformly mixing pesticides

InactiveCN113749082AConsistent mixing ratioIncrease spray rateSpraying apparatusInsect catchers and killersEnvironmental engineeringCentrifugal force

The invention relates to the technical field of biology, and discloses a pesticide spraying device capable of uniformly mixing pesticides. A sensing device, a control system, a pesticide inlet pipe and a pesticide adjusting belt wheel are arranged in a control box, a mixing box is fixedly connected with the bottom of the control box, mixing wheel blades are arranged in the mixing box, a spraying head is movably connected with the bottom of the mixing box, and an accelerating device is fixedly connected into the spraying head. According to the pesticide spraying device capable of uniformly mixing the pesticides, an adjusting belt wheel rotates, the adjusting belt wheel drives a pesticide adjusting belt wheel to rotate through a belt, the pesticide adjusting belt wheel rotates to drive a center shaft to rotate, after the center shaft rotates, balance is broken due to the effect of centrifugal force, a swing rod begins to approach a corresponding cloth rolling shaft, the higher the flow speed of water is, the higher the rotating speed of the center shaft is; the larger an opening of an agent inlet pipe is, the larger the agent inlet speed is, and therefore the effect of automatically adjusting the agent inlet speed according to the water flow speed is achieved.

Owner:邳州市朗硕农业发展有限公司

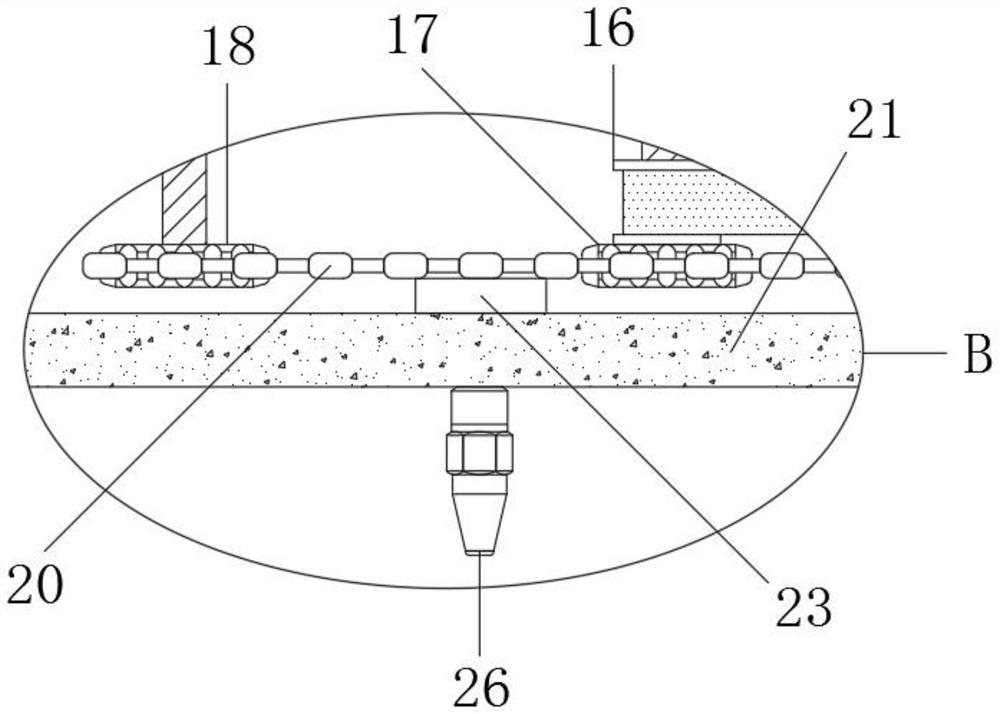

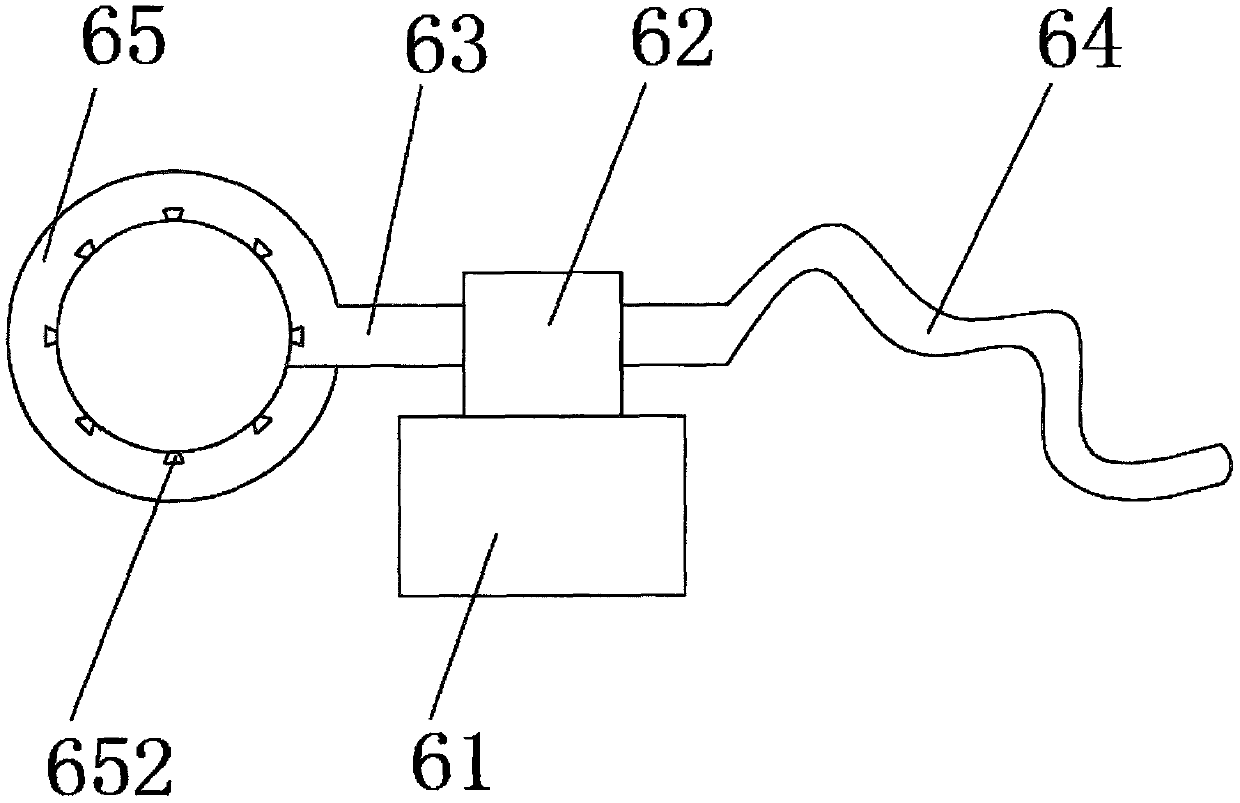

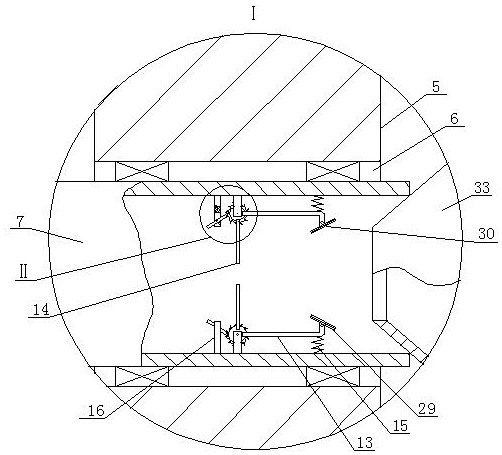

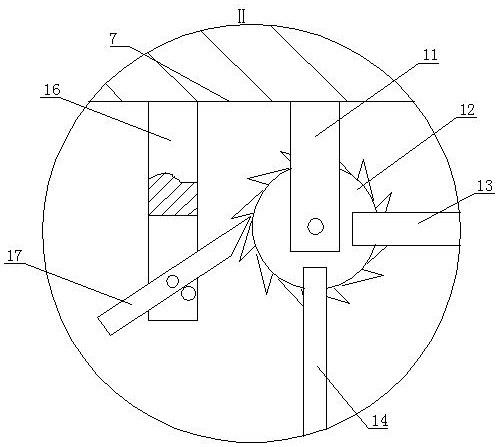

Efficient spraying device used for table and chair manufacturing and capable of automatically turning over to-be-sprayed parts

InactiveCN112138901AExpand the spraying areaIncrease spray rateSpraying apparatusSprayerControl engineering

The invention relates to the technical field of chairs and discloses an efficient spraying device used for table and chair manufacturing and capable of automatically turning over to-be-sprayed parts.The spraying device comprises a motor, the output end of the motor is fixedly connected with a first bevel gear, and the left end of the first bevel gear is fixedly connected with a driving plate. Theside surface, away from the first bevel gear, of the driving plate is fixedly connected with a driving rod. A first supporting column and a second supporting column are arranged on the left side of the drive plate, and a grooved wheel is movably connected to the side, close to the driving plate, of the first supporting column. According to the efficient spraying device used for table and chair manufacturing and capable of automatically turning over the to-be-sprayed parts, three chain wheels are matched to drive a transmission chain to move, a transmission sliding block fixedly connected withthe transmission chain drives a second sliding rail accordingly, and therefore, the second sliding rail drives a spraying sliding block to reciprocate, so that a sprayer reciprocates along with the spraying sliding block; and a to-be-sprayed part arranged below the sprayer in a matched mode is driven by a grooved wheel mechanism to roll over intermittently, and therefore, the effects that the to-be-sprayed part can be turned over automatically, automatic reciprocating spraying is achieved, and the spraying efficiency is improved are achieved.

Owner:赵崇辉

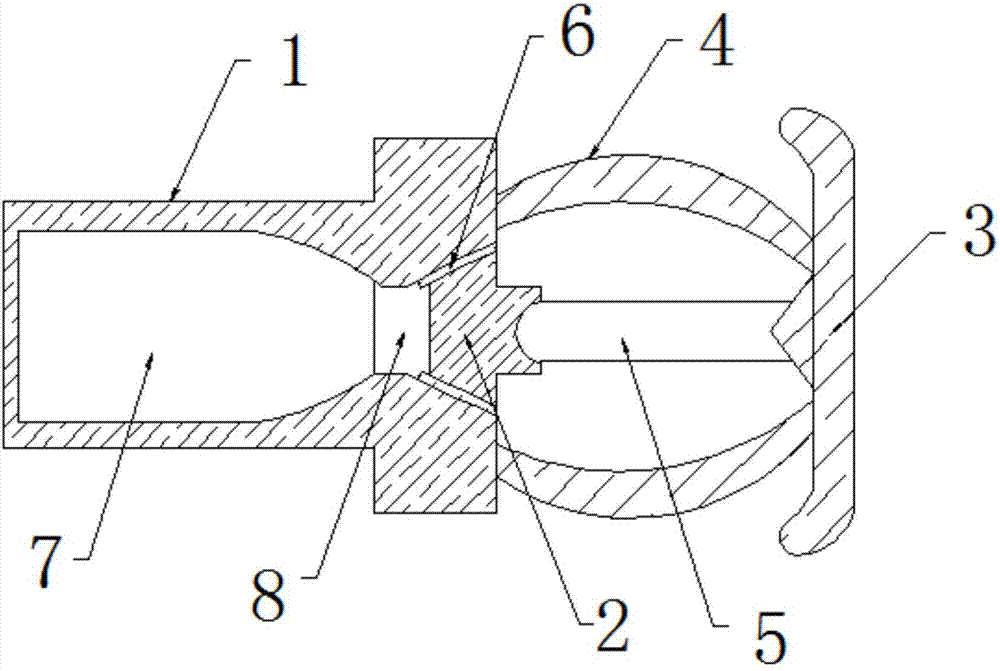

Firefighting pressurizing sprinkler head

The invention discloses a firefighting pressurizing sprinkler head which comprises a spraying head base, a glass body and a water spraying disc. A pressurizing cavity is formed in the spraying head base. A spraying hole is formed in the front end of the spraying head base and communicates with the front end of the pressurizing cavity. A plunger is inserted into an inner cavity of the spraying hole in a connected manner. A rubber sealing pad is arranged between the plunger and the spraying hole. The water spraying disc comprises a water spraying outer disc and a water spraying inner disc. The water spraying inner disc is located in an inner cavity of the water spraying outer disc. Balls are clamped between the water spraying outer disc and the water spraying inner disc. A glass body fixing base is arranged in the middle of the water spraying inner disc. A plurality of water spraying wings are uniformly arranged on the surface of the water spraying outer disc. The glass body is installed between the plunger and the glass body fixing base. The water spraying inner disc is fixedly connected with the spraying head base through an arm frame. The firefighting pressurizing sprinkler head is simple in structure, convenient and practical, fully utilizes water pressure to carry out firefighting, enlarges the spraying range and reduces damage to the water spraying disc.

Owner:江苏南亚家居有限公司

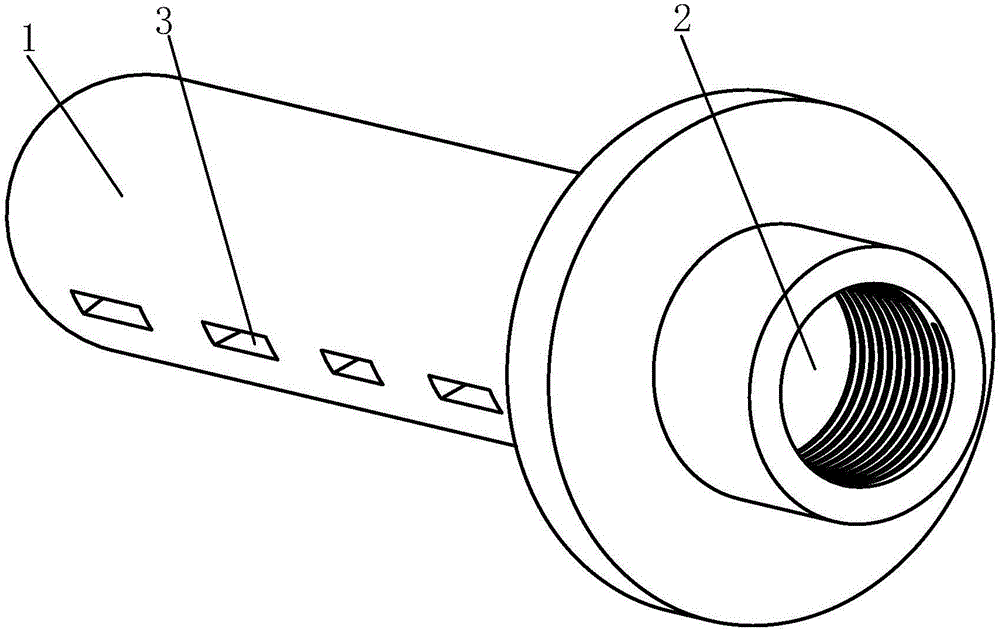

Drawing fluid spraying pipe for drawbench

The invention relates to a drawing fluid spraying pipe for a drawbench. The drawing fluid spraying pipe for the drawbench comprises a pipe body. One end of the pipe body is provided with a cavity. A plurality of water outlets with rectangular horizontal sections are formed in the lower end of the cavity. The left end surface of the water outlet in the leftmost side is a vertical surface, and the right end surface of the water outlet in the leftmost side is an inclined surface at an obtuse angle relative to the horizontal plane. The right end surface of the water outlet in the rightmost side is a vertical surface, and the left end surface of the water outlet in the rightmost side is an inclined surface at an acute angle relative to the horizontal plane. The left end surfaces of the other water outlets are all inclined surfaces at acute angles relative to the horizontal plane, and the right end surfaces of the other water outlets are all inclined surfaces at obtuse angles relative to the horizontal plane. The spraying direction of drawing fluid flowing out of the water outlets is controlled through changes of the angles of the side edges of the water outlets, the drawing fluid is made to be in a water curtain shape along the cross section, and therefore the drawing fluid is sufficiently and evenly spayed on metal wires in any positions. Compared with a pipe simply provided with a strip-shaped groove, the strength of the spraying pipe is improved in the position with a through hole, the spraying pressure intensity of the drawing fluid is improved, and therefore the spraying speed of the drawing fluid is increased.

Owner:ANHUI YUSHENG HAOHAN ELECTRONICS TECH

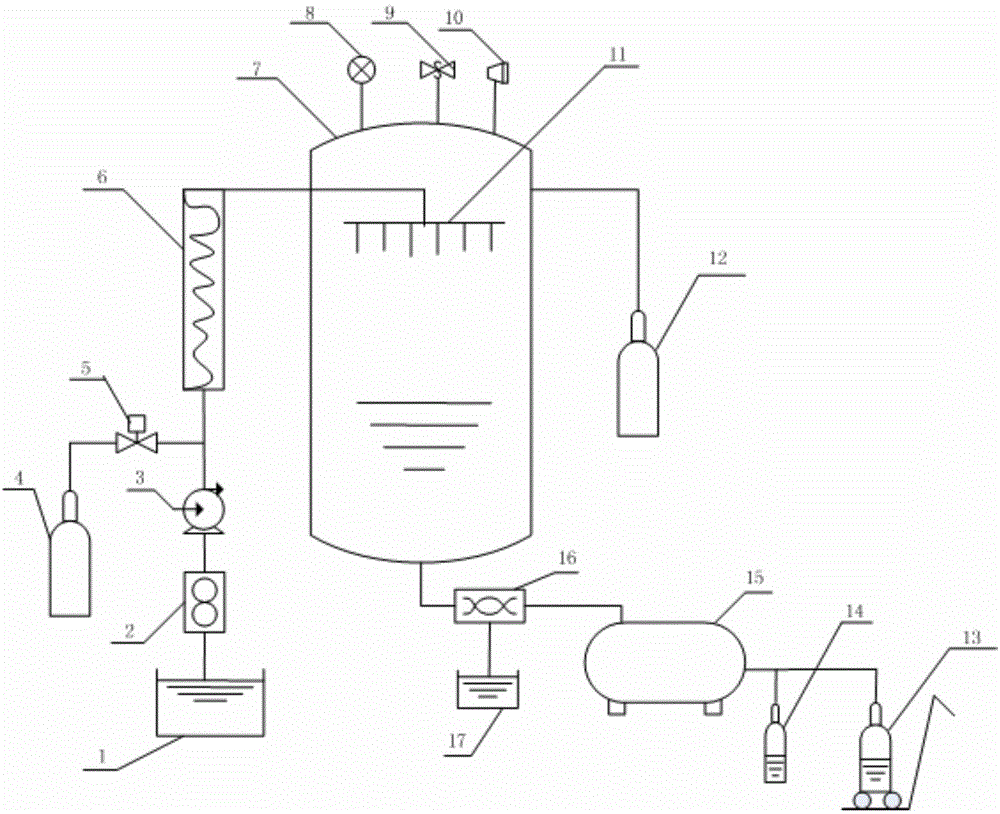

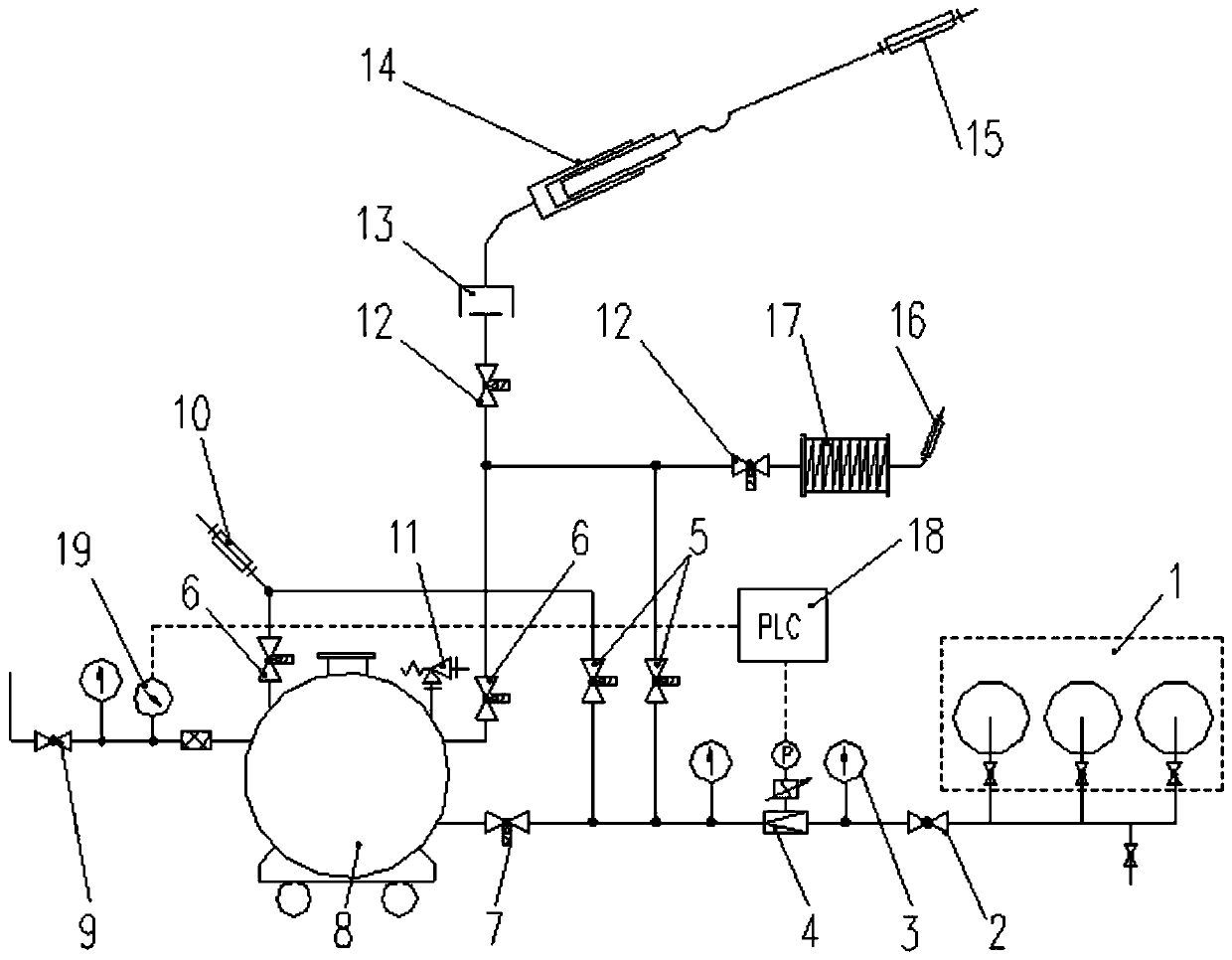

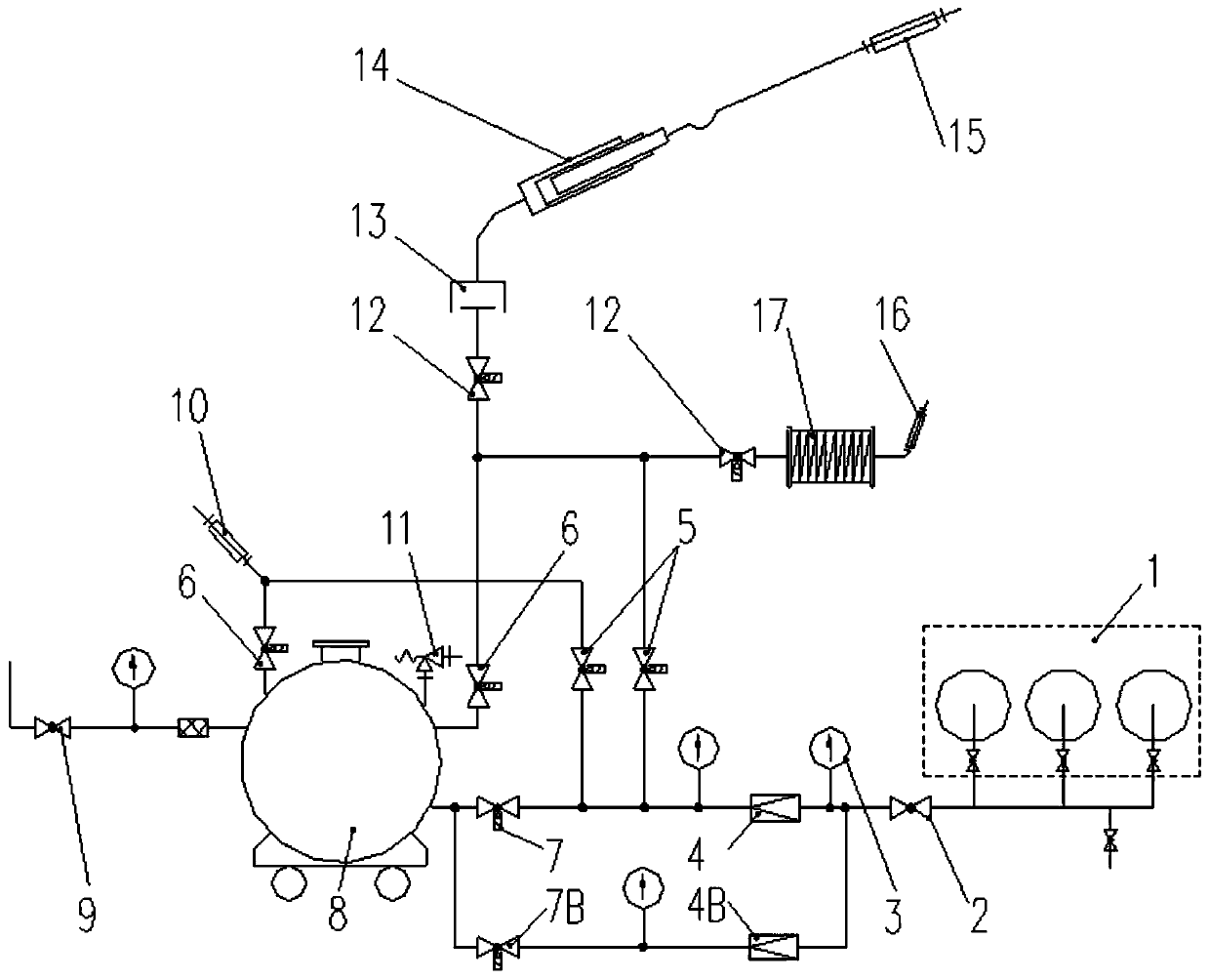

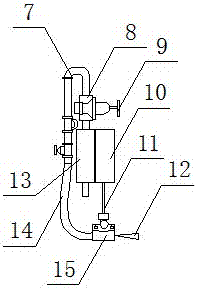

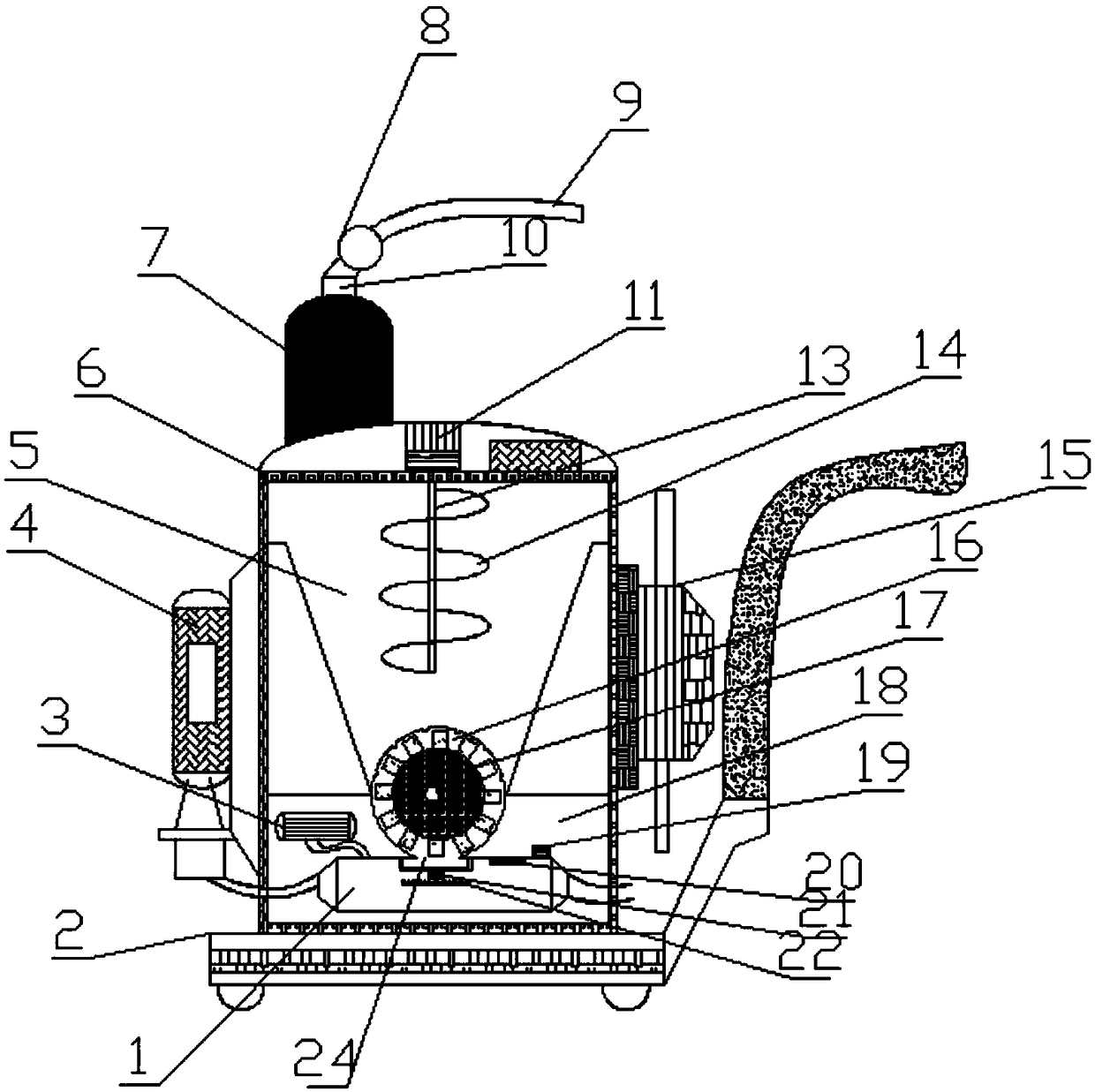

Dry powder spray feeding system and lifting fire truck

PendingCN110870960AImprove powder output efficiencyAvoid reduction in conveying speedFire rescueInjectorDry powder

The invention relates to a dry powder spray feeding system. The dry powder spray feeding system comprises a high pressure air source, a dry powder pot, a dry powder ejector, a first decompressing valve and a flow equilibrium assembly, wherein the dry powder pot comprises an air inlet opening and a power outlet opening, and the air inlet opening communicates with the high pressure air source; the dry powder ejector communicates with the powder outlet opening; the first decompressing valve is connected between the air inlet opening and the high pressure air source; and the flow equilibrium assembly is placed between the high pressure air source and the dry powder pot, and can enable the flow of air flowing through the air inlet opening and the powder outlet opening to be the same by controlling the air inlet amount from the high pressure air source to the dry powder pot. Therefore, according to the dry powder spray feeding system provided by the embodiment of the application, spraying and sending pressure of the dry powder pot can be maintained to be stable in the spraying process, and the difficult problem that a conventional dry powder spray feeing system is easy to cause underpressure for lifting spray feeding at the later-stage spray feeding caused by pressure-reduced spray feeing, can be solved.

Owner:XCMG CONSTR MACHINERY +1

Coarse sand-blasting machine for removing residual gypsum on surface of casting

PendingCN107020579AWeight increaseIncrease spray rateBlast gunsAbrasive blasting machinesSand blastingSpray nozzle

The invention discloses a coarse sand-blasting machine for removing residual gypsum on the surface of casting. The coarse sand-blasting machine comprises a machine case, an operation table, a placing slot, a bottom tank, a water tank, a telescopic spray ring, a sand blasting device, a supercharging chamber, a pushing rod, a first fan, a guide tube, a spray nozzle, a second fan, an air tube and a spray head. The coarse sand-blasting machine has the beneficial effects that: the water tank is mounted on the top of the machine case, the telescopic spray nozzle is connected below the water tank, water is atomized and sprayed onto gravels through the telescopic spray ring, so that the gravels can be pre-wetted, and therefore, weight of the gravels is increased, gravitational acceleration when the gravels are sprayed is increased, and removal efficiency of gypsum is improved. The first fan is used for guiding air into the spray head through the guide tube, so that airflow circulation is always kept at a spray head tube opening, and therefore, the spray head tube opening is prevented from being blocked, and an injection rate of gravels is increased. A pipeline is arranged below the first fan, and air is blown into the gravels, so that the gravels are changed into a flowing state from a static state, and therefore, the spray head tube opening is prevented from being blocked.

Owner:鹰普罗斯叶轮(宜兴)有限公司

Energy-saving and environment-friendly omnibearing sound box spraying device

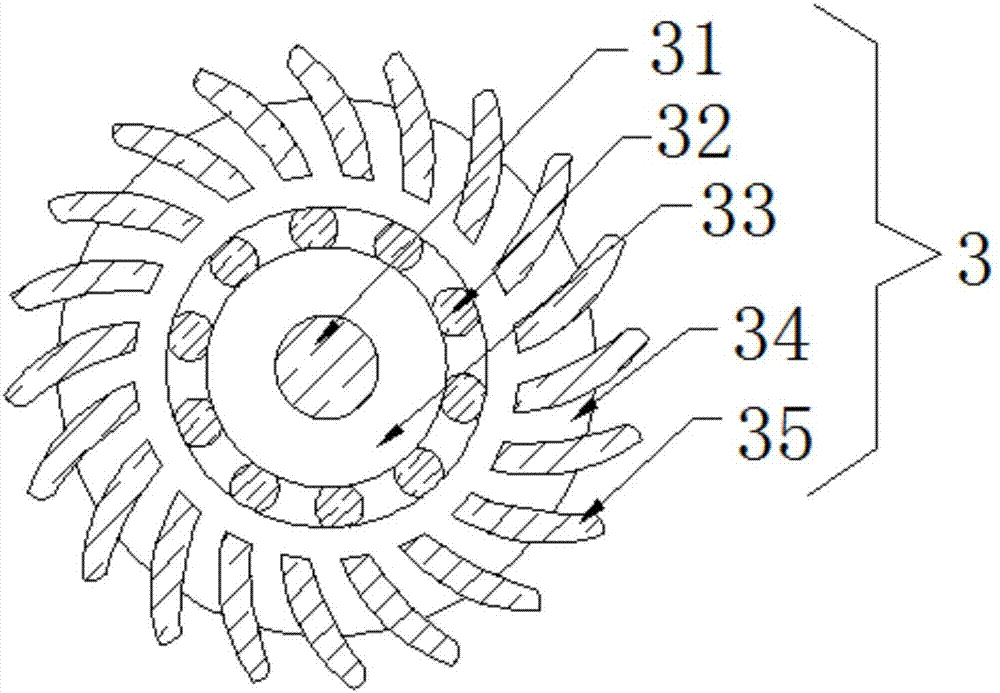

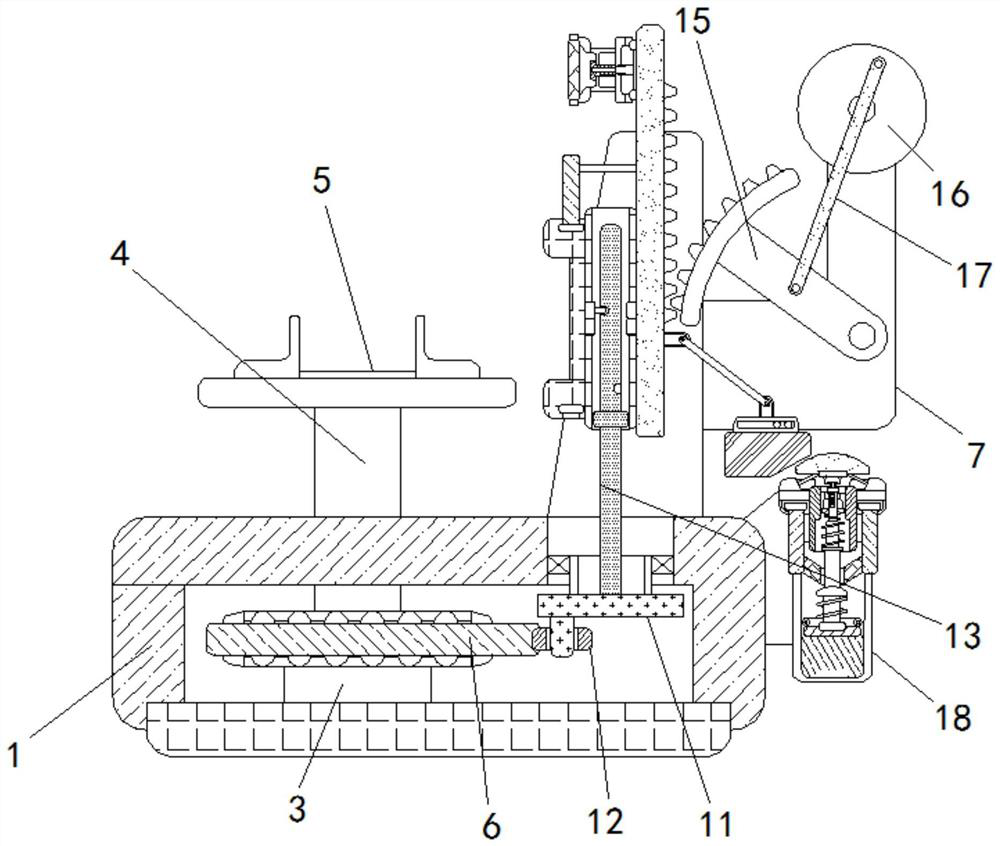

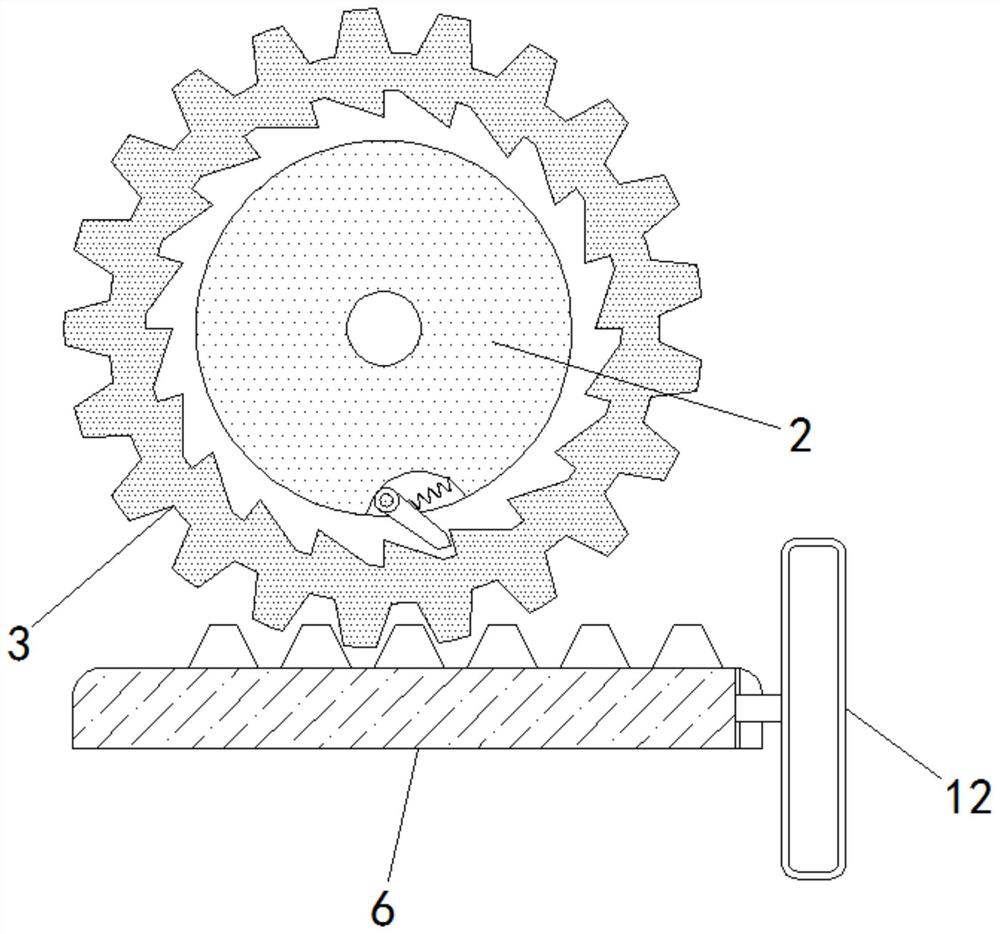

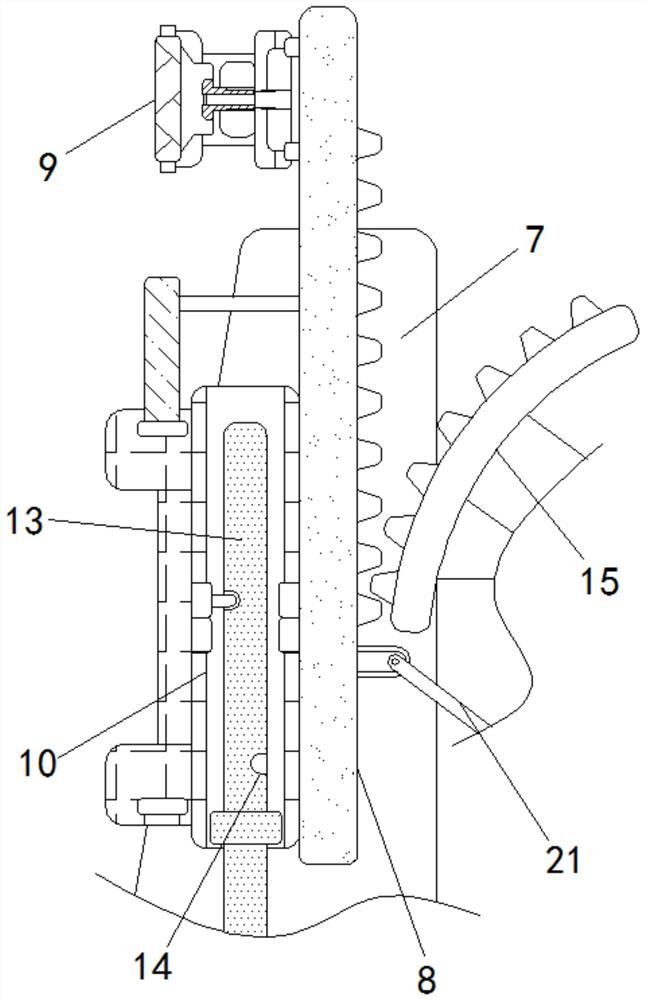

InactiveCN112547351AIncrease profitGuarantee the quality of sprayingLiquid spraying apparatusRatchetGear wheel

The invention relates to the technical field of combined sound equipment, and discloses an energy-saving and environment-friendly omnibearing sound box spraying equipment. The energy-saving and environment-friendly omnibearing sound box spraying equipment comprises a base, a ratchet disc is rotatably connected to the rear portion of an inner cavity of the base, a ratchet wheel connected to the ratchet disc in a sleeve mode is rotatably connected to the rear portion of the inner cavity of the base, a supporting column is fixedly connected to the upper end of the ratchet disc, a positioning plate is fixedly installed at the upper end of the supporting column, a rack is slidably connected to the front portion of a ratchet wheel in the inner cavity of the base, and an auxiliary plate is fixedly connected to the top end of the right side of the base. According to the energy-saving and environment-friendly omnibearing sound box spraying equipment, an output plate drives a main connecting rodto enable a swing tooth section to deflect in a reciprocating mode, a bearing tooth plate drives a spray head to move up and down, and due to the fact that only when the spray head moves downwards, paint liquid in a paint tank is pressed out, the spray head can evenly spray out the paint liquid from top to bottom, therefore, the utilization rate of the paint liquid is effectively increased, the spraying quality is guaranteed, and the corresponding spraying speed is effectively increased.

Owner:泉州东咚嘞商贸有限公司

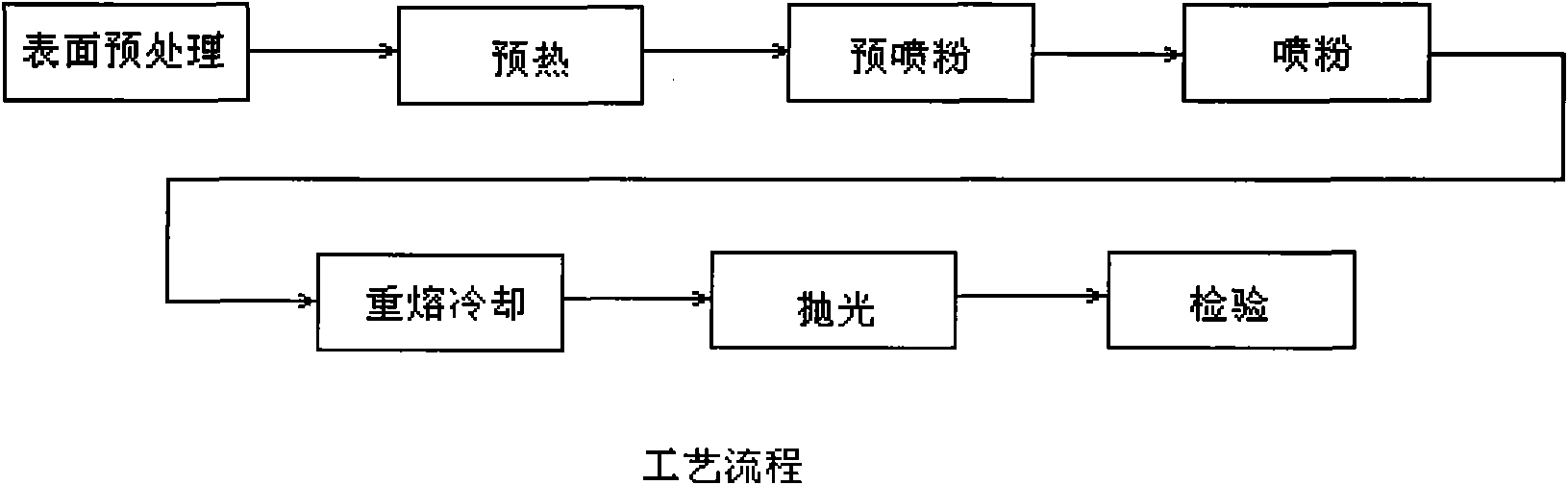

Bidirectional protecting oil pump plunger and hot spray processing technique for surface of same

InactiveCN101586560ALess powderTightly boundMolten spray coatingPositive displacement pump componentsThermal sprayingWear resistant

The invention relates to a directional protecting oil pump plunger and a hot spray processing technique for the surface of the same. The protecting oil pump plunger comprises a long cylinder; two ends of the cylinder are provided with external threads and are connected with a valve cover; the surface of the plunger is sprayed with a layer of corrosion-resistant and wear-resistant AOC alloy coating; the thickness of the alloy coating is more than 0.25 mm; and after the working procedures of surface roughening activating treatment, spraying, remelting and polishing, a wear-resistant and corrosion-resistant coating is formed on the surface of the plunger. The processing technique has simple and convenient operation; the coating is combined closely after spraying; the performance of a basal body of the plunger is not influenced during spraying; and the thickness of the coating is more than 0.25 mm, and the coating can resist outside wearing and corrosion and reduce the wearing to the inner surface of a pump cylinder of an oil well pump.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

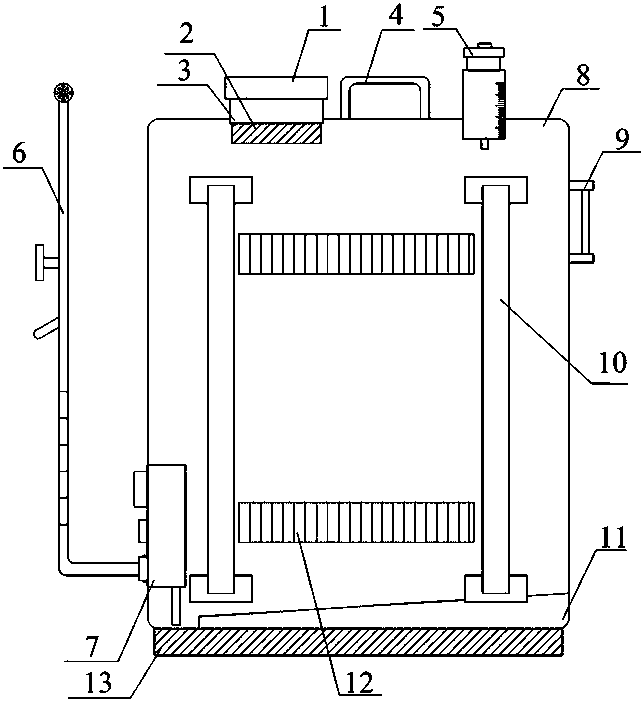

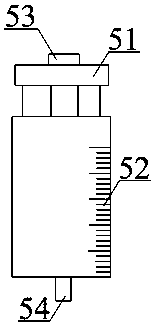

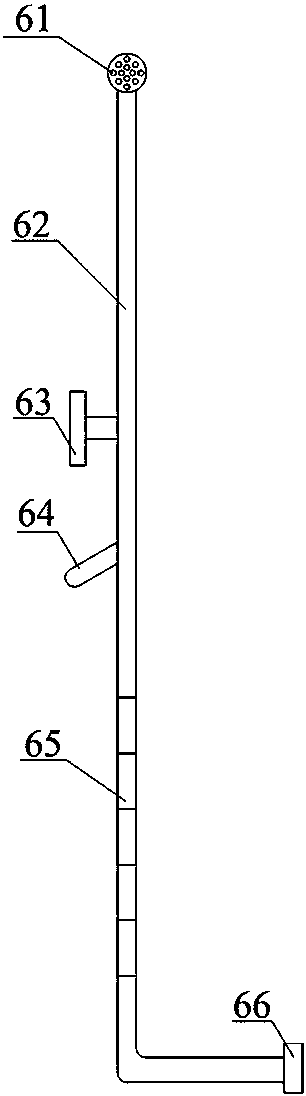

Novel pesticide sprayer

InactiveCN109169604AHigh precisionAvoid affecting the efficacy of the drugInsect catchers and killersVegetationEngineering

The invention provides a novel pesticide sprayer, which comprises a rotary cap, a filter screen, a water inlet, a handle, a dosing device, a spray device, a power device, a water tank, a water level gauge, straps, a throttle plate, a back cushion and a bumper pad. The dosing device is installed by embedding on the right side of the handle. The spray device is buckled to the bottom of the left sideof the water tank. The throttle plate is embedded into the inner lower end of the water tank. Through the setting of the dosing device, the spraying device and the throttle plate, the amount of pesticide added can be precisely calibrated through the scale on an injection pipe, and the problem that the pesticide effect is affected due to too much or too little pesticide is prevented, the spray quality is improved; the spray height can be adjusted through a telescopic rod, so that the sprayer can be applied to the spray operation of high vegetation crops, and the scope of use is expanded; and when the liquid pesticide is too little, the throttle plate can gather the remaining liquid pesticide at a suction pipe so that he suction pipe can suck out the remaining liquid pesticide, and the spray rate is improved. Therefore, the novel pesticide sprayer is suitable for market promotion and application.

Owner:王从卿

Bidirectional protecting oil pump plunger and hot spray processing technique for surface of same

InactiveCN101586559AReduce stressHigh bonding strengthMolten spray coatingPositive displacement pump componentsThermal sprayingWear resistant

The invention relates to a bidirectional protecting oil pump plunger and a hot spray processing technique for the surface of the same. The protecting oil pump plunger comprises a long cylinder, wherein two ends of the cylinder are provided with external threads and connected with a valve cover; and the surface of the plunger is sprayed with a layer of corrosion-resistant and wear-resistant AOC alloy coating. The processing technique comprises the following steps: carrying out surface oil removal treatment on a plunger blank; burnishing and roughening the plunger blank; preheating the plunger blank for surface activation; pre-spraying alloy powder to protect the surface of the plunger from contacting air indirectly; continuously spraying till the ultimate thickness of the coating reaches 0.4 mm; heating the plunger blank after spraying for remelting of the alloy coating; and finally burnishing and polishing the plunger blank to prepare the bidirectional protecting oil pump plunger with the coating of which the thickness is more than 0.25 mm. The processing technique has simple and convenient operation, the coating is combined closely after spraying; the performance of a basal body of the plunger is not influenced during coating; and the thickness of the coating is more than 0.25 mm, and the coating can resist outside wearing and corrosion, and reduce the wearing to the inner surface of a pump cylinder of an oil well pump.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Spraying device for surface tungsten carbide during corrugated roller production

PendingCN110000031APrevent leakageImprove sealingSpraying apparatusEngineeringMechanical engineering

The invention discloses a spraying device for surface tungsten carbide during corrugated roller production. The spraying device comprises a spraying table, supports are fixedly arranged at corner positions of the outer surface of the lower end of the spraying table, a power supply interface is formed in one side of the outer surface of the front end of the spraying table, a control panel is arranged in the middle of the outer surface of the front end of the spraying table, and fixing plates are movably arranged at the rear end positions of the two sides of the outer surface of the upper end ofthe spraying table, the front end of the outer surface of the upper end of the spraying table is fixedly provided with a spraying frame, the outer surface of the spraying frame is movably provided with a stepping motor, the upper end of the stepping motor is movably provided with a hoop, and the rear end of the outer surface of the upper end of the spraying table is provided with a sliding groove. According to the spraying device, a corrugated roller can be sprayed in all directions at the same time, the spraying speed is improved, manual spraying is not needed, the labor intensity is reduced, the error of manual spraying is avoided, and the spraying quality is improved.

Owner:SHANGHAI DASONG CORRUGATING ROLL IND

A multi-spray integrated jet device and jet method

ActiveCN108636646BEnsure full coverageAvoiding Irreparable Problems With Spray MistakesLiquid spraying apparatusGas generatorPiston

The invention relates to an integrated flow jetting device capable of achieving repeated jetting and a flow jetting method, and belongs to the technical field of flow jetting. The integrated flow jetting device comprises a flow jetting tank, a flow jetting tank piston, a nozzle, a supply tank, a supply tank piston, a spring and at least two self-pressurization gas generators. The flow jetting tankis located in the supply tank, and the flow jetting tank and the supply tank are combined to form a nested structure. The flow jetting tank piston is located in the flow jetting tank, and the flow jetting tank piston and the flow jetting tank are combined to form dynamic sealing. The nozzle communicates with the first end of the flow jetting tank, and the self-pressurization gas generators communicate with the second end of the flow jetting tank. The supply tank piston is of an annular structure, is located in an interlayer formed by the supply tank and the flow jetting tank, and is combinedwith the supply tank and the flow jetting tank to form dynamic sealing. The first end of the supply tank communicates with the first end of the flow jetting tank, the second end of the supply tank communicates with the second end of the flow jetting tank. One end of the spring is connected with the supply tank piston, and the other end of the spring is connected with the second end of the supply tank. The integrated flow jetting device can achieve jetting at least twice, and the phenomenon that remediation cannot be achieved after jetting has a fault at the first time is avoided.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Stable powder ion plasma plating equipment

The invention discloses stable powder ion plasma plating equipment. The equipment comprises a base and an outer casing, the top of the base is provided with the outer casing by a bolt, one side of theouter casing is provided with an air compressor through a mounting member, the other side of the outer casing is provided with a heat exchanger through a fixing member, the top of the outer casing isprovided with a stirring motor through a mounting seat, the outer casing is internally provided with a stirring chamber, the stirring chamber is internally provided with a stirring rod, a screw stirring blade is arranged on the stirring rod by the bolt, a blanking passage is arranged at the bottom of the stirring chamber, a blanking turntable is arranged in the blanking passage, a blanking mouthis formed in the bottom of the blanking passage, and the lower end of the stirring chamber is provided with a mounting chamber. The stable powder ion plasma plating equipment has complete functions, small floor space, simple operation and convenient production, effectively improves the efficiency of powder ion plating, and is suitable for widespread popularization and use.

Owner:兆基五金制品(苏州)有限公司

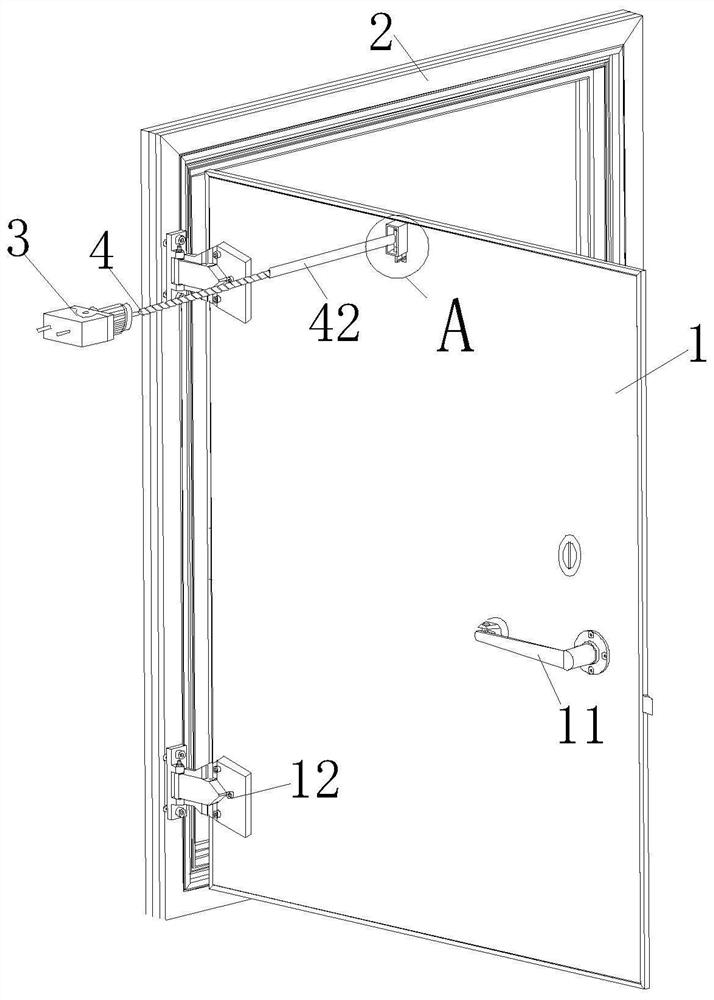

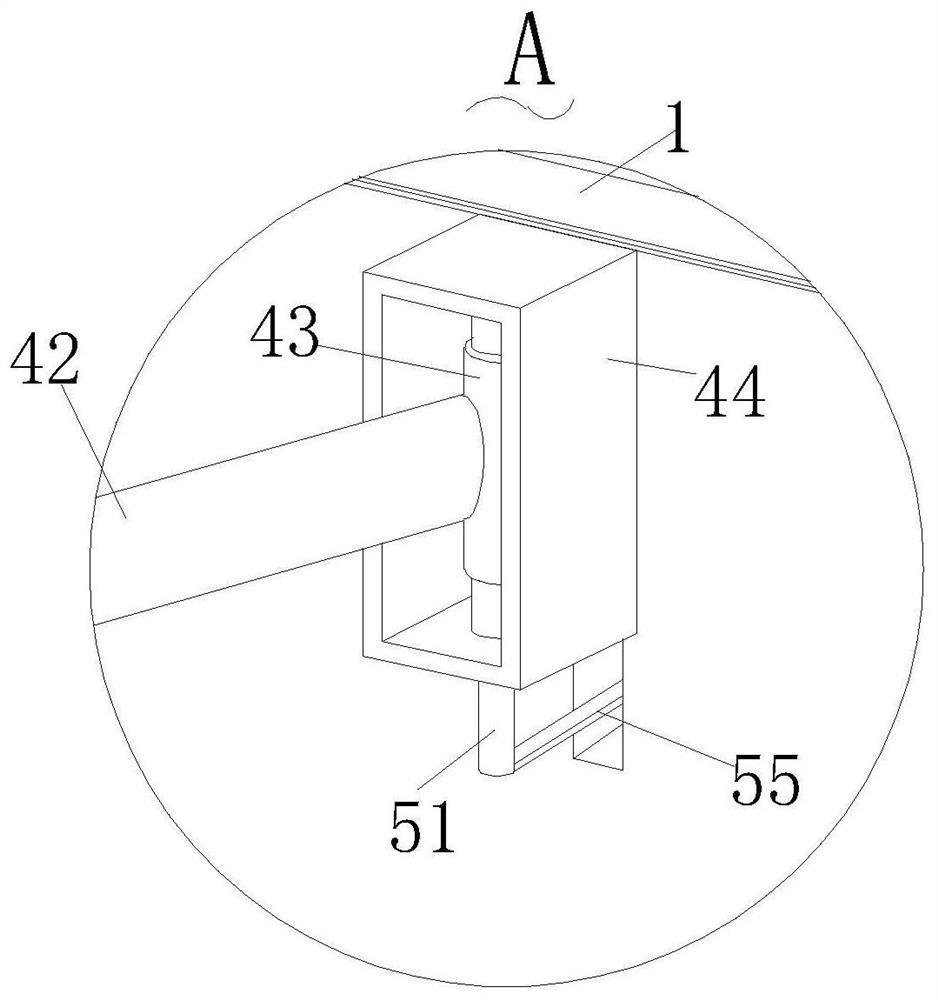

Flame-retardant fireproof door

InactiveCN112727325AAvoid hard to openAvoid contactFireproof doorsFire rescueElectric machineryFire - disasters

The invention relates to the field of fireproof doors, and particularly relates to a flame-retardant fireproof door. The flame-retardant fireproof door comprises a door plate, a door frame, a handle and a hinge which form the fireproof door, wherein a pressurizing assembly is fixedly mounted in the center of the top of the door plate and fixedly connected with an output shaft of a motor, the motor is fixedly connected with a fixing assembly, the fixing assembly is fixed on a wall, a blocking assembly is arranged in the center of the top of the door plate, an outlet of the pressurizing assembly is blocked by the blocking assembly in a sleeving manner, and a switch assembly is fixed on the side edge of a U-shaped column. The problems that when an existing normally closed fireproof door is used, particularly when a fire occurs and the fire is fierce, the door is difficult to open, on one hand, the situation that the door becomes hot due to the fire when the fire occurs is ignored, and survivors cannot smoothly open the fireproof door for escape, and on the other hand, the fireproof door can only prevent the door plate from fire within a certain period of time and cannot open an escape channel for the survivors when the fire is fierce can be solved.

Owner:斯燕方

Spraying device for electric switch element machining

InactiveCN107899803AEasy to drySimple structureSpraying apparatusPretreated surfacesEngineeringMachining

The invention discloses a spraying device for electric switch element machining. The spraying device for electric switch element machining comprises a first element conveying slide way and a second element conveying slide way which are fixed to a supporting base through a support; the discharging end of the first element conveying slide way is arranged above a feeding port of a transition bin; thedischarging end of the transition bin is connected with the feeding end of the second element conveying slide way in a welded manner; the discharging end of the second element conveying slide way islocated above a feeding port of an element storing bin which is fixed to the side wall of the upper side of the supporting base through a screw; an air heater is fixed to the side wall of the bottom of the first element conveying slide way through a support; the air outflow end of the air heater is connected with the air inflow end of an air outflow head in a welded manner through an air guiding pipe; the air outflow head is located above the second element conveying slide way; and a spraying machine is fixed to the second element conveying slide way through the support. The spraying device for electric switch element machining is simple in structure, low in manufacturing cost and high in spraying speed.

Owner:ANHUI KAICHENG ELECTRIC APPLIANCE CO LTD

Automobile gasoline and alcohol dual-fuel supply control method and system and fixing cushion block

InactiveCN102953847BLow renovation costReduce lossInternal combustion piston enginesFuel injection apparatusCurrent loadAlcohol

The invention relates to the field of engine dual fuels, in particular to an automobile gasoline and alcohol dual-fuel supply control method and system and a fixing cushion block. After an engine is started, when the temperature of an engine body reaches the combustion temperature of the alcohol fuel, a gasoline spraying nozzle is automatically closed by an additional alcohol ECU (electronic control unit), an alcohol spraying nozzle is opened, and a gasoline spraying pulse width signal generated by a gasoline ECU is intercepted and is converted into an alcohol spraying pulse width signal according to the conversion ratio of the gasoline fuel to the alcohol fuel. When the amount of the fuel needed by the current load of the engine exceeds the maximum alcohol spraying amount or the alcohol fuel is totally consumed, the alcohol spraying nozzle is automatically closed by the alcohol ECU, the gasoline spraying nozzle is opened, and the engine continuously uses the gasoline fuel. On the premise of not losing the automobile property, the alcohol fuel is fully used, the cost of the automobile fuel is saved, the retrofit cost of the automobile is reduced, the retrofit difficulty is reduced, the loss of the engine is reduced, the environment pollution is reduced, and the automobile safety is improved.

Owner:林长军

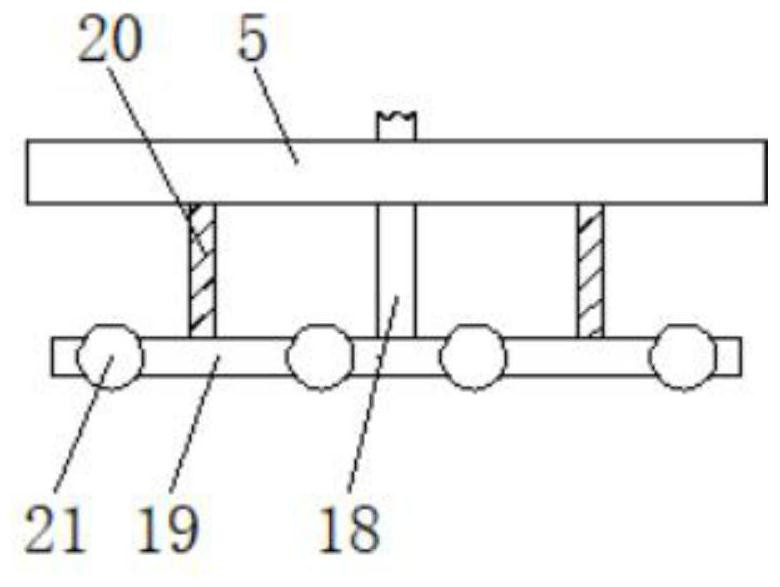

A plastic pipe surface spraying device

ActiveCN109127210BAvoid layoutReduce in quantitySpraying apparatusCorrosion preventionElectric machineGear wheel

A plastic pipe surface spraying device, including a base, a horizontal horizontal movement device is fixedly installed on the top side of the base, the left end of the power shaft of the horizontal movement device is fixedly connected to the right end of the first motor shaft, and the right side of the top side of the base is fixedly connected to a support plate The bottom side of the mobile platform of the horizontal moving device is fixedly connected to the bottom side of the movable plate, and the right side of the movable plate is uniformly opened with several first through holes distributed in a circle, and the first through holes are installed with horizontal tubes and horizontal tubes respectively. The ring gear is fixedly installed on the left end of the pipe periphery respectively, the second motor is fixedly installed on the left side of the movable plate, and the gear is fixedly installed on the left end of the second motor rotating shaft. The invention has a simple structure, can spray multiple plastic tubes at the same time, greatly improves the rate of spraying, completes the spraying of the outer circumference of the plastic tubes through the rotation and movement of the plastic tubes itself, and avoids the deviation when the plastic tubes move and the deviation when the spray gun rotates. Shifting interactions increase spraying errors.

Owner:山东陆宇塑胶有限公司

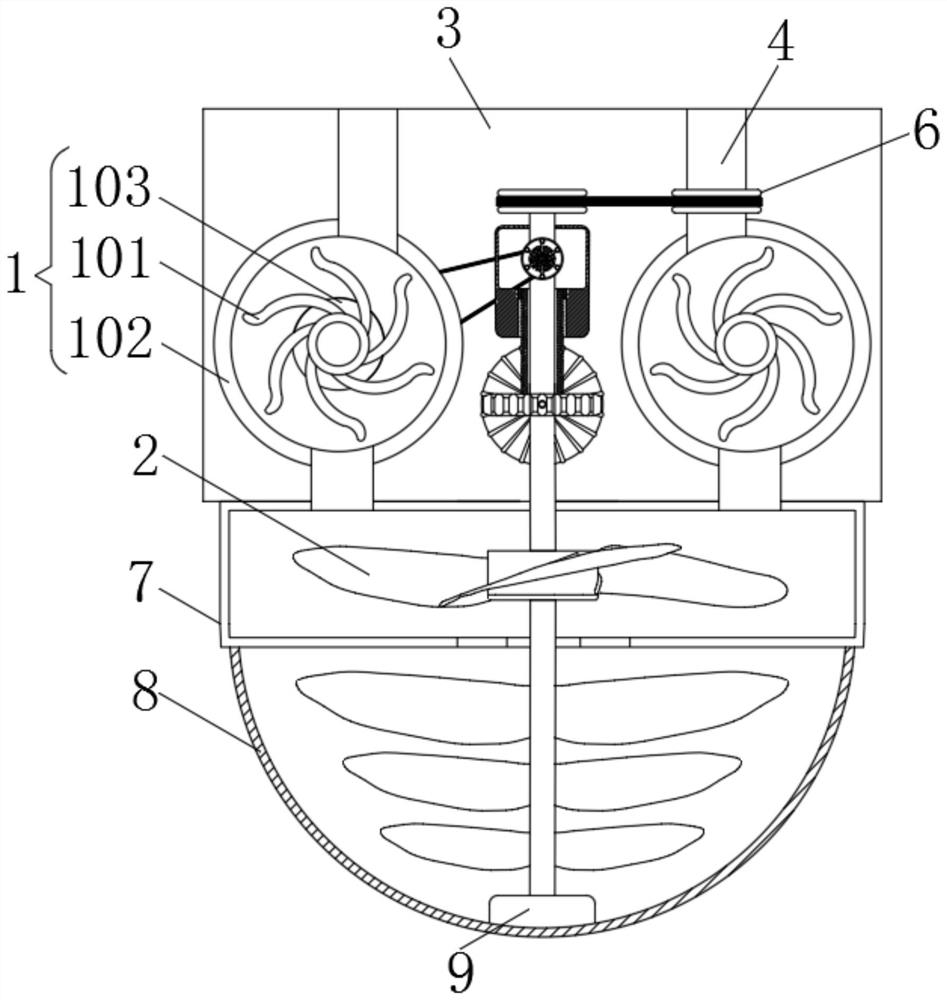

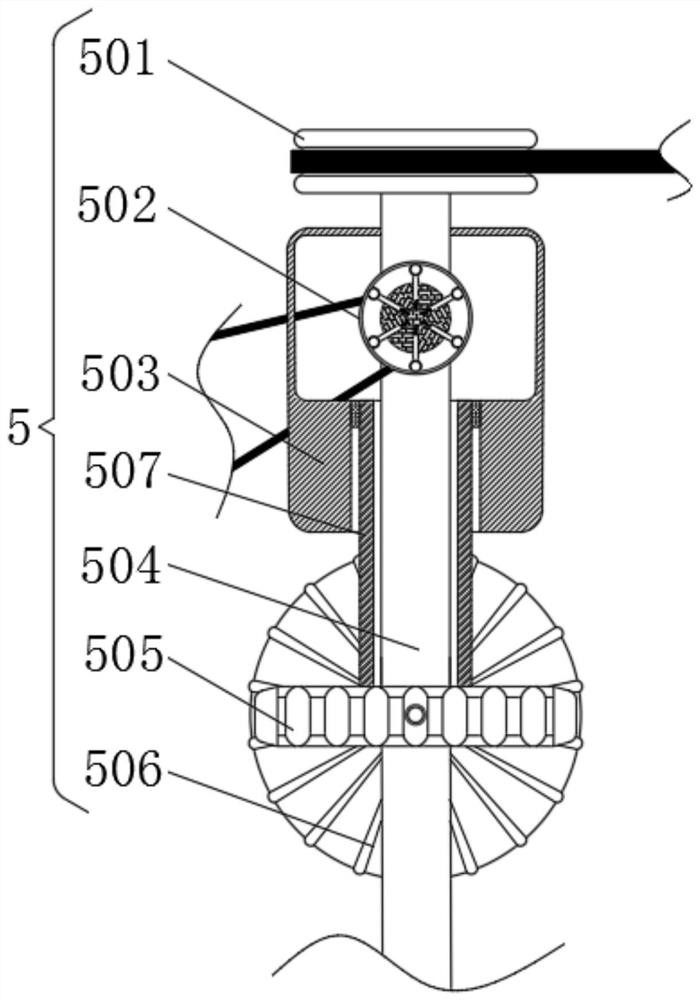

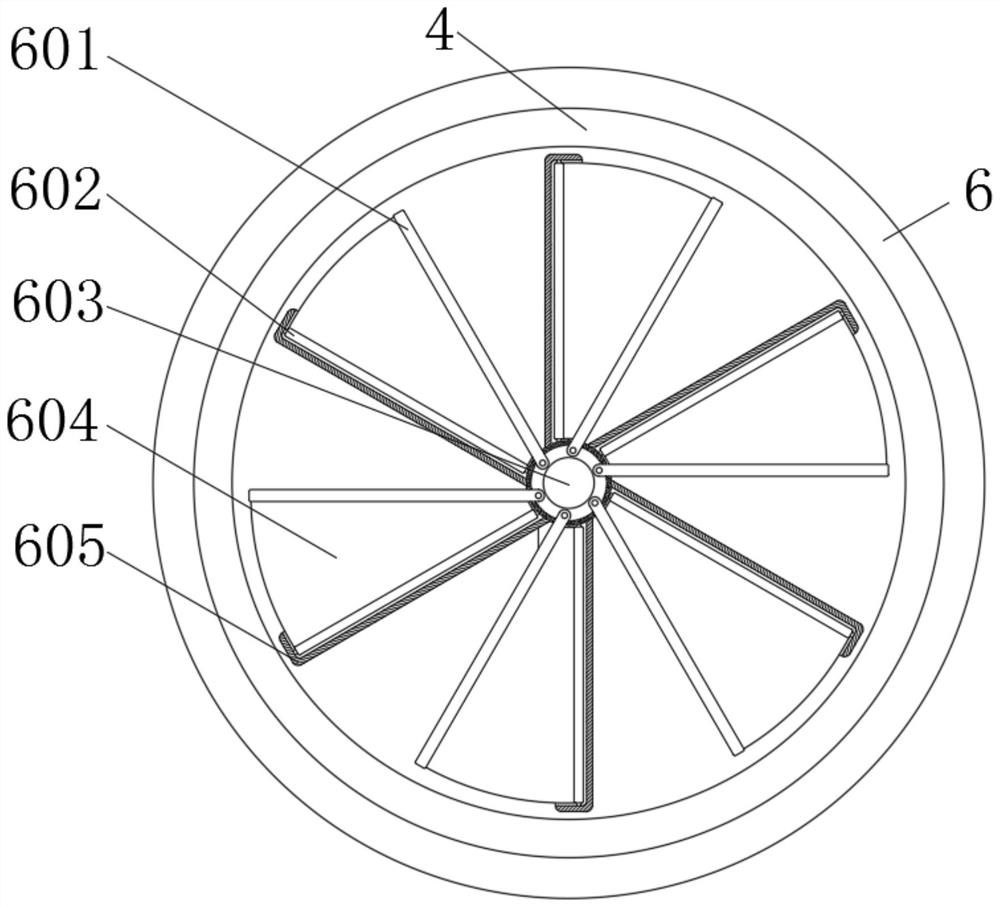

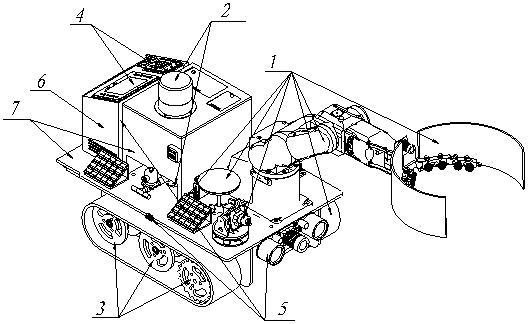

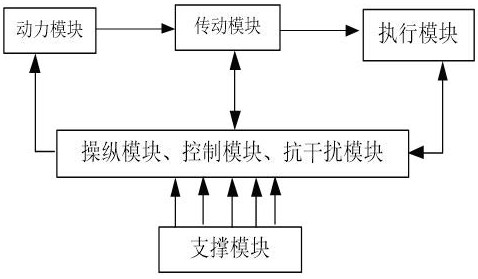

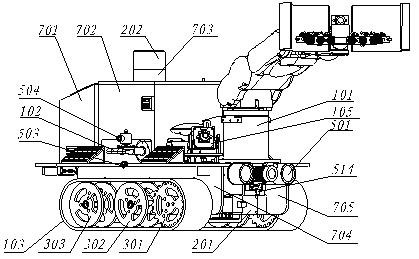

Intelligent spraying robot for trees

PendingCN114310971AImprove spraying efficiencyAdjust sizeRenewable energy machinesManipulatorAgricultural engineeringVisual recognition

The invention discloses an intelligent spraying robot for trees, and relates to a full-automatic spraying robot. The functions of Beidou positioning, visual identification and the like are utilized, and full-automatic spraying of fruit trees is achieved; solar clean energy is used for supplying energy, and the problem that a large amount of manpower and material resources are consumed when trees are whitewashed is solved; a high-precision Beidou positioning system and an internet-of-things module are used for intelligently planning a spraying range; a six-degree-of-freedom mechanical arm and visual identification are used for achieving all-directional spraying of trees, and meanwhile the information is fed back to a control end; the solar panel and the solar panel box are utilized to convert solar energy into electric energy, so that the effects of energy conservation and environmental protection are realized; the crawler belt is used for walking, so that wheel blockage caused by muddy land is avoided; the machine body is provided with an infrared sensor and an ultrasonic sensor, so that the functions of automatic tracking and automatic obstacle avoidance are realized. The device can get rid of a lot of dependence of whitewashing on manpower and material resources, and can utilize clean energy such as solar energy to achieve the purposes of energy conservation and environmental protection.

Owner:YANTAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com