Circulating backflow type paint spraying device for automobile part production

A technology for circulating backflow and auto parts, which is applied to spray devices, liquid spray devices, etc., can solve the problems of decreased spray quality, easy clogging of spray guns, and increased viscosity, so as to improve mixing efficiency, improve uniformity, and reduce viscosity. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

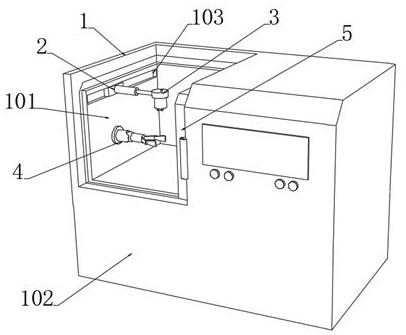

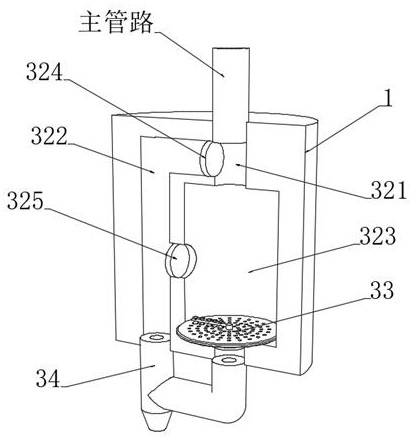

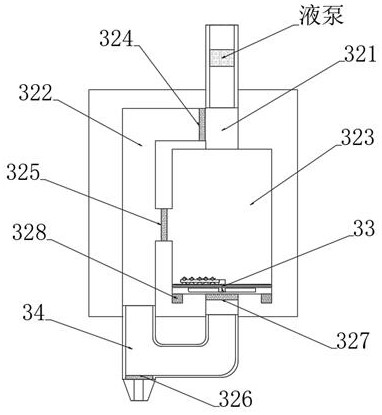

[0043] see Figure 1-6 , a kind of paint spraying device used for the production of auto parts, including a spraying box 1, the spraying box 1 includes a spraying chamber 101 opened at its upper end and a collection cavity 102 opened at its lower end, and the inner side wall of the spraying chamber 101 is slidably connected with a sliding bracket 2. A spray gun body 3 is fixedly connected to the other end of the sliding bracket 2. The spray gun body 3 includes a rotating seat 31 that is fixedly connected to the sliding bracket 2. The lower end of the rotating seat 31 is provided with a spray gun column 32, and a liquid storage chamber 323 is opened inside the spray gun column 32. The upper end of the liquid storage chamber 323 is provided with a main channel 321 that communicates with the outside of the rotating seat 31. The upper end of the main channel 321 is connected to the external paint box through the main pipeline. The side wall of the sub-channel 322 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com