Spray coprecipitation method for preparation of Y2O3 based transparent ceramic powder

A technology of transparent ceramics and co-precipitation, which is applied in the field of nano-powder preparation to achieve the effect of weak agglomeration, less demanding experiment schedule, and excellent powder molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

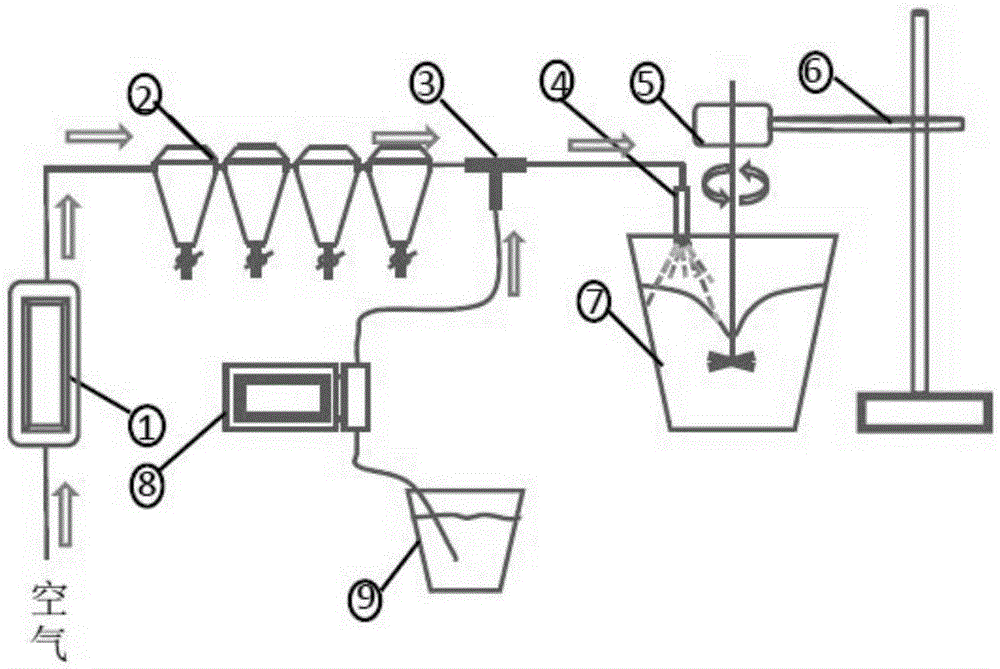

Method used

Image

Examples

Embodiment 1

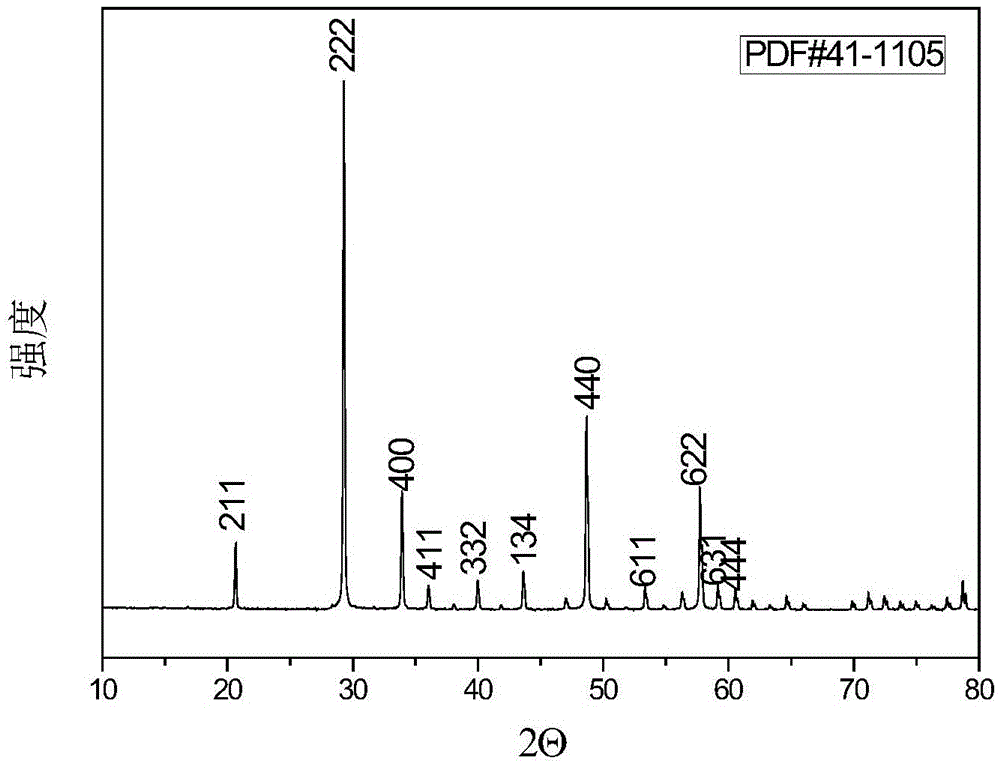

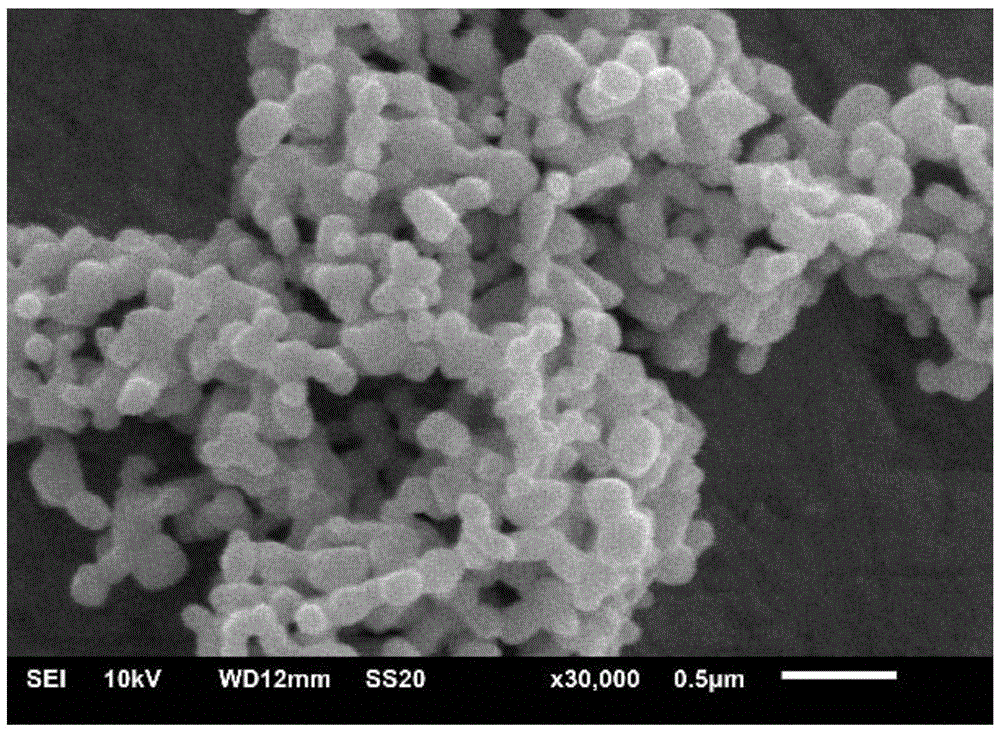

[0031] Example 1: Pure Y 2 o 3 Powder

[0032] Prepare yttrium nitrate solution with a concentration of 3.0mol / L, spray the mixed solution of 1.5mol / L ammonium bicarbonate and ammonia water into nitric acid with a Teflon nozzle with a diameter of 0.5mm and a stirring rate of 500r / min In the yttrium solution, the molar concentration ratio of ammonium bicarbonate to ammonia water is 1:2, the pressure of the air compressor is 300KPa, the liquid supply rate of the peristaltic pump is 5ml / min, and the pH value is adjusted to 8 with a 4-stage air filter.

[0033] Stirring was continued for 10 minutes after sparging had ended. The resulting solution was statically aged at room temperature for 12 h. Suction filtration after the aging, the suction filtration speed is 60ml / min, obtain the precursor, wash the obtained precursor with deionized water 3 times, wash 3 times with absolute ethanol, to fully remove impurities such as residual acid ions, remove The volume ratio of ionized wa...

Embodiment 2

[0035] Embodiment 2: (Nd 0.05 Y 0.95 ) 2 o 3 Transparent ceramic powder

[0036] Rare earth nitric acid solution is prepared in the ratio of n(Nd):n(Y)=0.05:0.95, the concentration is 0.05mol / L, adopting the polytetrafluoroethylene nozzle of 0.1mm in the situation that stirring rate is 300r / min The mixed solution of 10.0mol / L ammonium bicarbonate and ammonia water is sprayed into the yttrium nitrate solution, the molar concentration ratio of ammonium bicarbonate and ammonia water is 1:5, the pressure of the air compressor is 100KPa, and the liquid supply rate of the peristaltic pump is 2ml / min. 3-stage air filter, adjust pH to 7.

[0037] Stirring was continued for 10 minutes after sparging had ended. The resulting solution was statically aged at room temperature for 12 h. Suction filtration after aging, the suction filtration speed is 50ml / min, to obtain the precursor, the precursor is washed 5 times with deionized water, and 4 times with absolute ethanol to fully remov...

Embodiment 3

[0039] Embodiment 3: (Ho 0.15 Y 0.85 ) 2 o 3 Transparent ceramic powder

[0040] Rare earth nitric acid solution is prepared in the ratio of n(Ho):n(Y)=0.15:0.85, and concentration is 5.0mol / L, adopts the polytetrafluoroethylene nozzle of 1.0mm to be 600r / min under the situation of stirring speed The mixed solution of 0.05mol / L ammonium bicarbonate and ammonia water is sprayed into the yttrium nitrate solution, the molar concentration ratio of ammonium bicarbonate and ammonia water is 2:1, the pressure of the air compressor is 800KPa, and the liquid supply rate of the peristaltic pump is 20ml / min. 5-stage air filter, adjust pH to 9.

[0041] Stirring was continued for 10 minutes after sparging had ended. The resulting solution was statically aged at room temperature for 48 h. Suction filtration after aging, the suction filtration speed is 80ml / min, to obtain the precursor, wash the precursor 4 times with deionized water, wash 5 times with absolute ethanol, in order to fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com