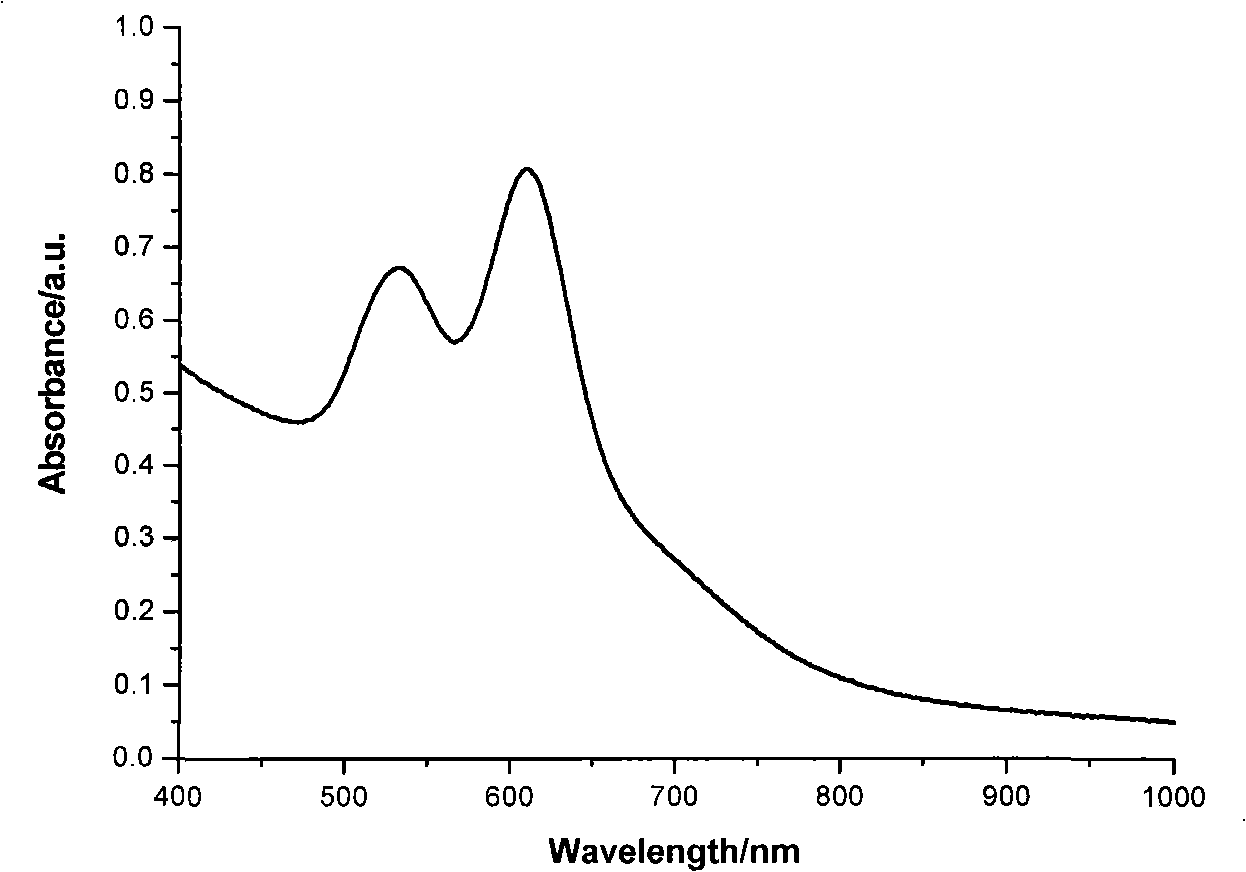

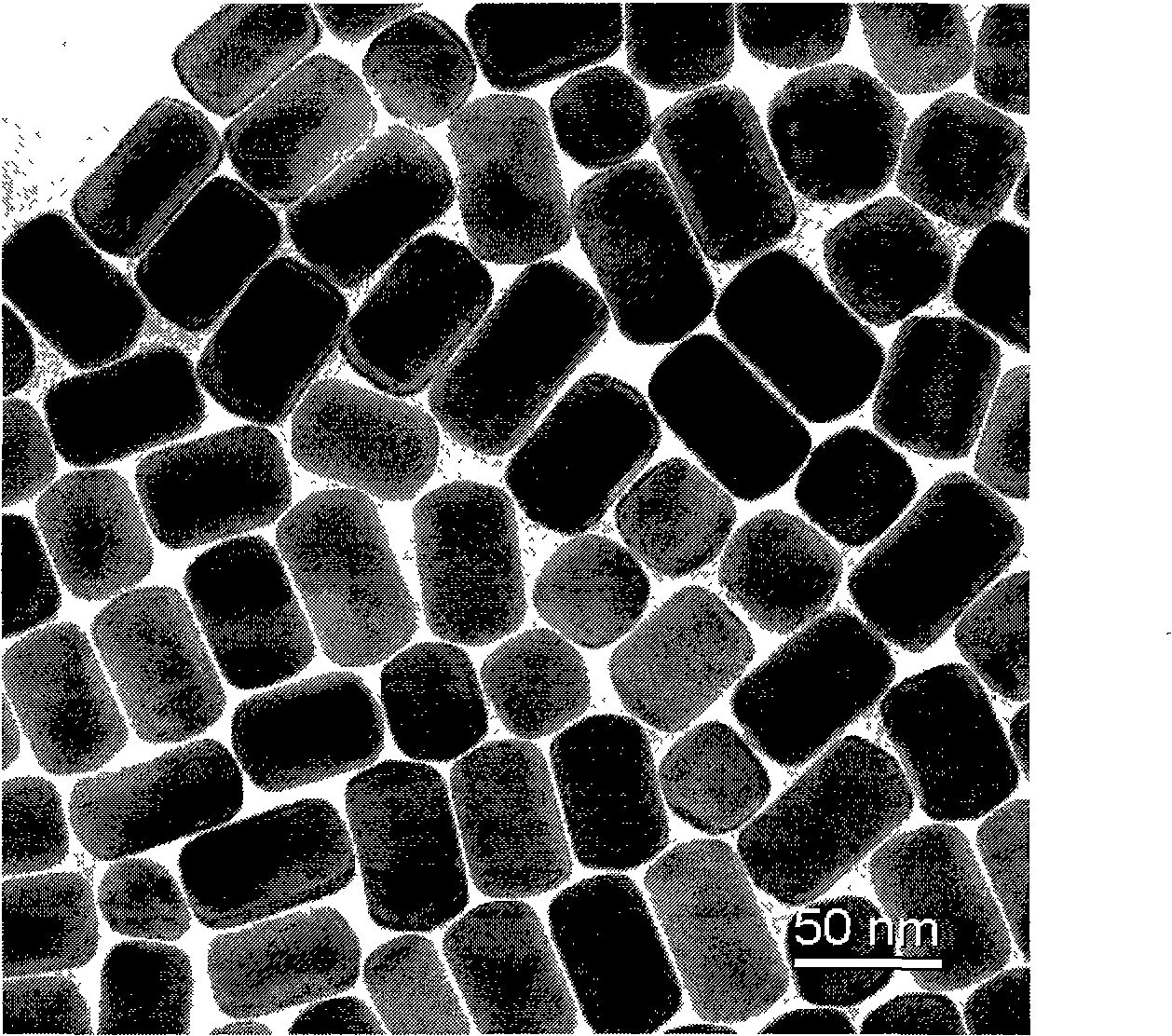

Process for producing golden nano stick with short length-diameter ratio

A technology of short and long gold nanorods, which is applied in the field of preparation of gold nanorods, can solve problems such as the difficulty of biological modification of the surface of gold nanorods, the difficulty of hydrophobicizing the surface of gold nanorods, and the biological toxicity of CTAB molecules, achieving high yield, Product size distribution is narrow, reducing the effect of post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the short aspect ratio gold nanorod of the present invention is realized through the following steps:

[0035] 1). Preparation of gold seed solution: under stirring at room temperature, add a strong reducing agent solution to the mixed solution of cetyltrimethylammonium bromide and tetrachloroauric acid at a concentration of (0.05-0.1mol / L) to control The molar ratio of reducing agent to tetrachloroauric acid is 1.2, the molar concentration of cetyltrimethylammonium bromide in the mixed solution is 0.05~0.1mol / L, and the molar concentration of tetrachloroauric acid is 1×10 -4 ~5×10 -3 mol / L, a strong reducing agent reduces tetrachloroauric acid to obtain a seed solution. Continue to stir the seed solution prepared above for 30 min to escape excess H 2 .

[0036] 2). Preparation of growth solution: prepare a mixed solution of DDAB, tetrachloroauric acid and silver nitrate, the mixed solution is orange-yellow. The molar concentration of DDAB ...

Embodiment 1

[0039] 1). Preparation of gold seed solution:

[0040] Under stirring conditions at room temperature, add 0.01mol / L NaBH fully cooled in an ice-water bath at 0°C to 10ml of a mixed solution of 0.1mol / L cetyltrimethylammonium bromide and 0.0005mol / L tetrachloroauric acid 4 The solution was 0.6ml, and a brown-yellow seed solution was obtained after the reaction. Continue to stir the seed solution prepared above for 30 min to escape excess H 2 .

[0041] 2). Preparation of growth solution: prepare a mixed solution of 10ml DDAB, tetrachloroauric acid and silver nitrate in a clean reactor, wherein the molar concentration of DDAB is 0.005mol / L, and the molar concentration of tetrachloroauric acid is 0.0005mol / L L, the molar concentration of silver nitrate is 10 -4 mol / L, the molar ratio of silver nitrate to tetrachloroauric acid is 0.2. Finally, 80 μL of 0.1 mol / L ascorbic acid solution was added to the mixture, the molar ratio of ascorbic acid to tetrachloroauric acid was contr...

Embodiment 2

[0044] 1). Preparation of gold seed solution: under stirring at room temperature, add 0.1 mol / L hexadecyltrimethylammonium bromide and 0.005 mol / L tetrachloroauric acid mixed solution into 0 ℃ ice-water bath to fully Cooled 0.1mol / L potassium borohydride solution 0.6ml, reacted to obtain a brownish yellow seed solution. Continue to stir the seed solution for 30 min to escape excess H 2 .

[0045] 2). Preparation of growth solution: Prepare 10ml of DDAB, tetrachloroauric acid and silver nitrate mixed solution in a clean reactor, the molar concentration of DDAB in the mixed solution is 0.01mol / L, and the molar concentration of tetrachloroauric acid is 0.005mol / L , the molar concentration of silver nitrate is 0.002mol / L, and the molar ratio of silver nitrate and tetrachloroauric acid is 0.4. Finally, 1.25 mL of 0.1 mol / L ascorbic acid solution was added to the mixture, the molar ratio of ascorbic acid to tetrachloroauric acid was controlled to be 2.5, and the solution was shake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com