Foam extinguishing agent capable of automatically foaming and preparation method of foam extinguishing agent

A foam fire extinguishing agent and foaming agent technology, applied in fire protection equipment and other directions, can solve the problems of poor foaming performance, unrealistic and other problems, and achieve the effects of reducing damage, high supply strength and fine foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

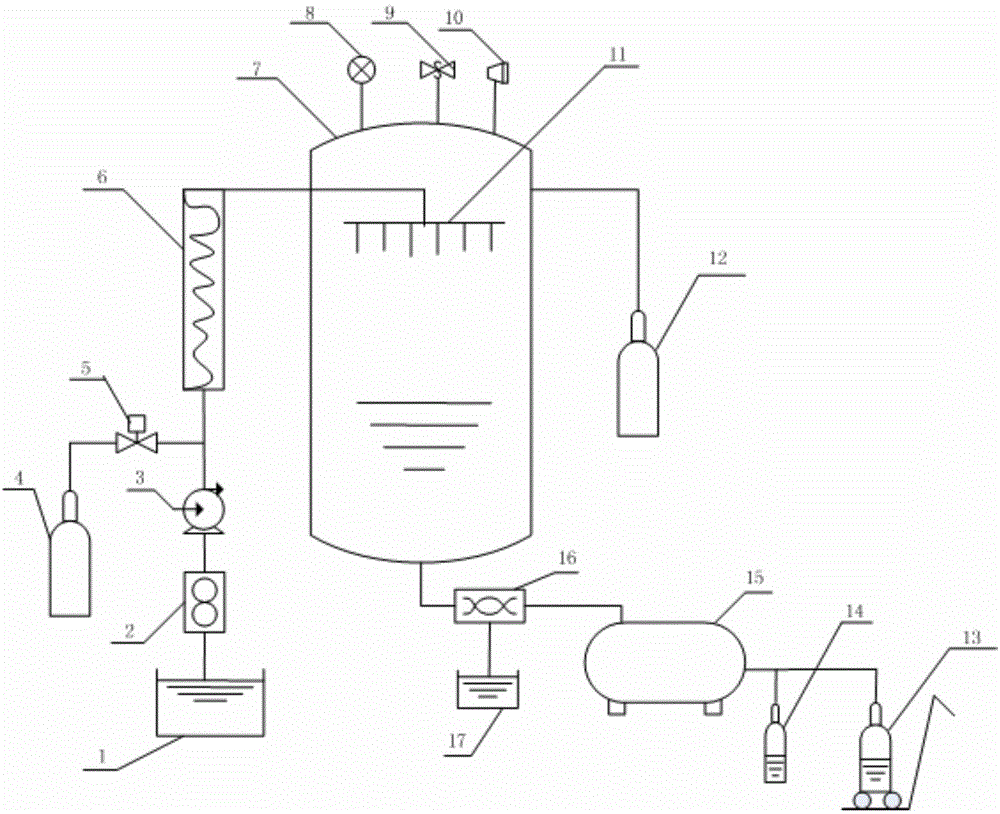

[0044] The present invention also provides a preparation method of the above foam fire extinguishing agent, which includes:

[0045] In the first step, add water to the mixing kettle, then add solid raw materials such as urea, inorganic salts, and organic salts, and stir to dissolve;

[0046] In the second step, further add water-soluble polymer and stir to dissolve;

[0047] In the third step, add co-solvents, pour point depressants, hydrocarbon surfactants, fluorocarbon surfactants, etc. in sequence, and stir evenly;

[0048] In the fourth step, the reactor is sealed and filled with carbon dioxide at 5-10°C under stirring for 0.5-1h to 1.2-1.5MPa. Let it stand for defoaming, and increase the pressure of the kettle by 0.01~0.03MPa, so that the fire extinguishing agent is just pressed into the storage tank. The storage tank is pre-filled with compressed air at a set pressure, and the excess air is discharged through the overflow valve.

[0049] The present invention also provides a pre...

Embodiment 1

[0063] At 5m 3 Add 2560kg of water to the jacketed reactor, heat it to reach 20°C, stop heating. Add 6 kg of hydroxyethyl cellulose and stir for 5-10 minutes.

[0064] Under stirring, slowly add 160 kg of sodium bicarbonate until all of it is dissolved, then add 400 kg of potassium bicarbonate and stir to dissolve for 10-15 minutes; add 800 kg of urea and stir to dissolve.

[0065] Reduce the stirring speed, and slowly add 24kg cocamidopropyl betaine, 20kg alkyl polyglycoside, 12kg fluorocarbon surfactant F1157N, 14kg ethylene glycol butyl ether, and 8kg formaldehyde. The final temperature of the extinguishing agent solution is 10°C.

[0066] Close the reactor and stir slowly. The jacket of the reactor is filled with ice water to maintain the temperature of the fire extinguishing agent solution at 5-8°C. Open the carbon dioxide cylinder and fill it with carbon dioxide at 1.5 MPa for about 45 minutes. Let it stand for defoaming, and increase the pressure of the kettle by 0.01~0.03...

Embodiment 2

[0069] At 5m 3 Add 3840kg of water to the mixing kettle of, and heat to bring the water temperature to 25°C. Add 0.6kg hydrolyzed polyacrylamide (molecular weight 2×10 7 ), stirring for 30 min. Under stirring, slowly add 100kg of sodium tripolyphosphate and 150kg of sodium bicarbonate until all are dissolved, then add 600kg of potassium bicarbonate, stir and dissolve for 10-15min; add 1200kg of urea, stir to dissolve. This solution is mixed solution A, and its final temperature is 5°C.

[0070] In a 150L mixing kettle, under low-speed stirring, slowly add 36kg cocamidopropyl betaine, 30kg alkyl polyglycoside, 18kg fluorocarbon surfactant F1157N, 21kg ethylene glycol butyl ether, and 12kg formaldehyde. For mixed solution B.

[0071] The carbon dioxide pressure reducing valve is energized and preheated for 3 to 5 minutes. Open the valve of the carbon dioxide cylinder and adjust the pressure reducing valve to slowly inflate until the back pressure of the storage tank is 1.0MPa; ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com