Inter-sheet dead area optimization process based uniform-spraying manufacturing method for complex curved surface

A technology of complex curved surfaces and manufacturing methods, applied in the direction of spraying devices, etc., can solve the problems of reducing production efficiency, spending a lot of manpower and material resources, and stopping production of spraying robots, and achieves the effects of optimizing spraying, enhancing spraying quality, and improving spraying uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

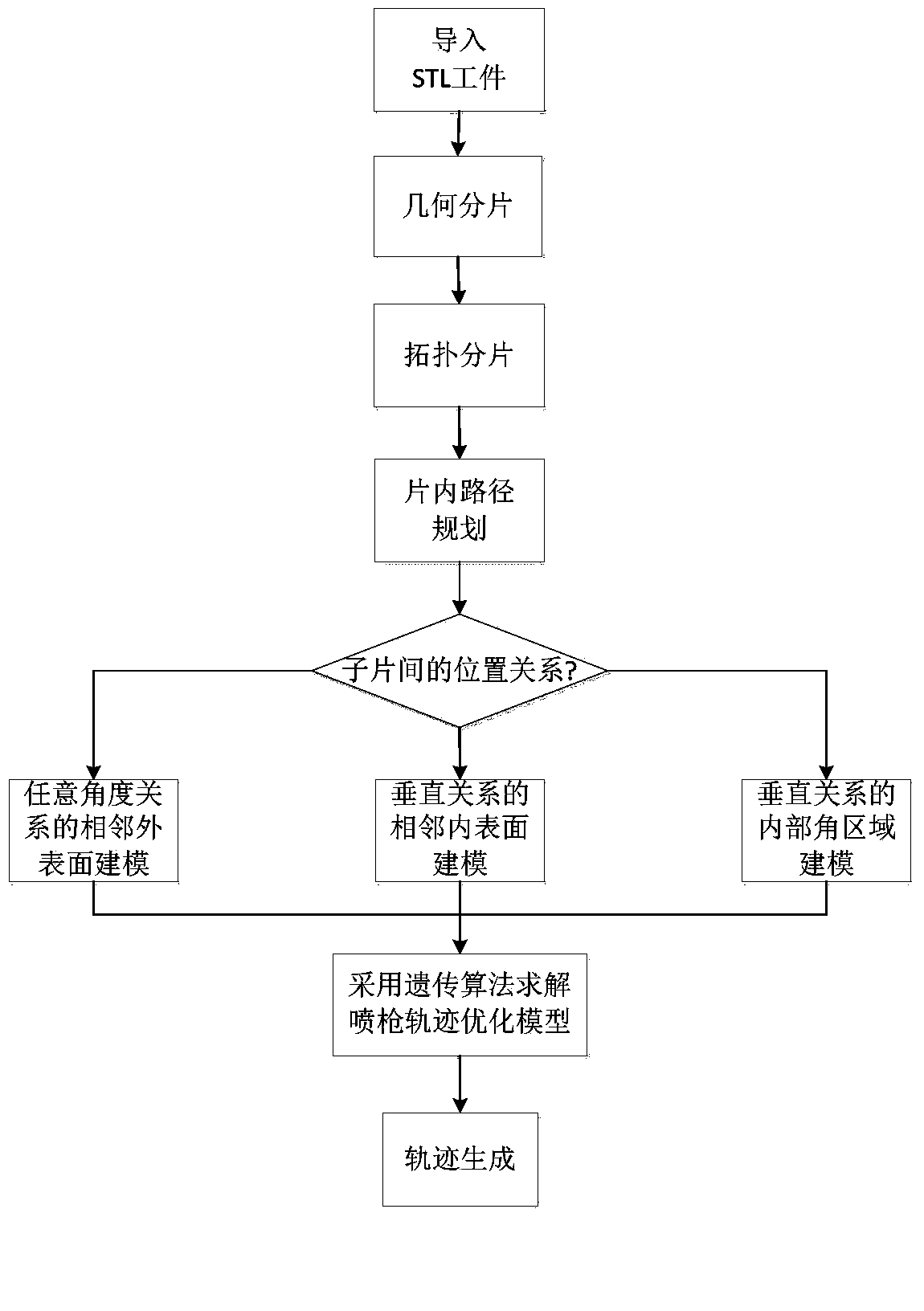

[0023] figure 1 The invention proposes a complex curved surface uniform spraying manufacturing method based on the optimization process of the blind area between sheets. As shown in the figure, the following steps are included:

[0024] 1. Import of workpieces and slice processing of complex surfaces

[0025] 1) Workpiece STL model import:

[0026] The import of the workpiece model is mainly to select the workpiece model file from the workpiece model library and judge whether the format of the file is STL format. If so, the file is directly read and displayed in the left tree of the development software of the present invention, otherwise it is converted into a file in STL format, and then the workpiece model is imported.

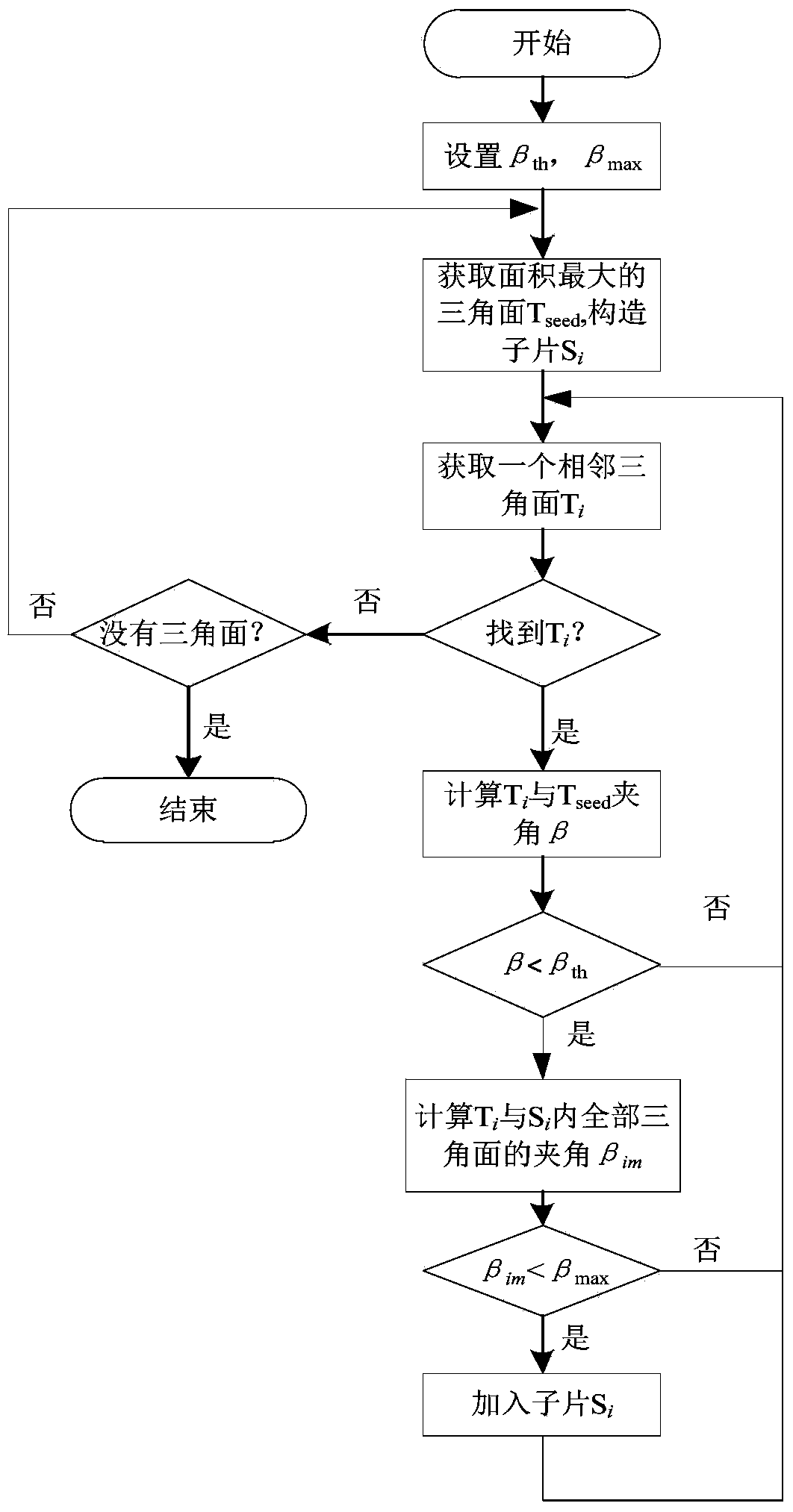

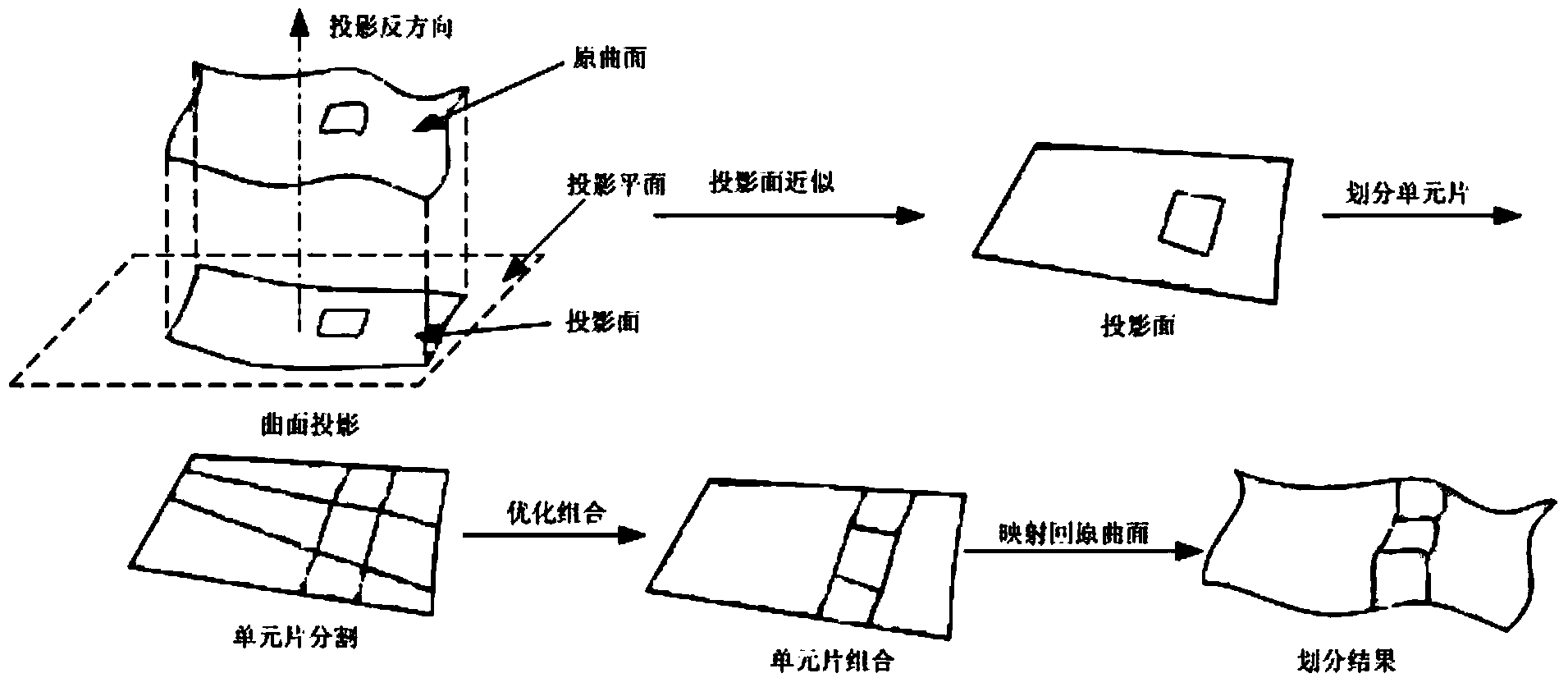

[0027] 2) Geometric sharding:

[0028] According to the imported STL workpiece model, the sprayed surface is approxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com