Open three-jaw self-centering rotary device

A rotary device and self-centering technology, applied in auxiliary devices, applications, auxiliary welding equipment, etc., can solve the problems of low machining accuracy, complex structure and high cost, and achieve the effect of reducing the overall length and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

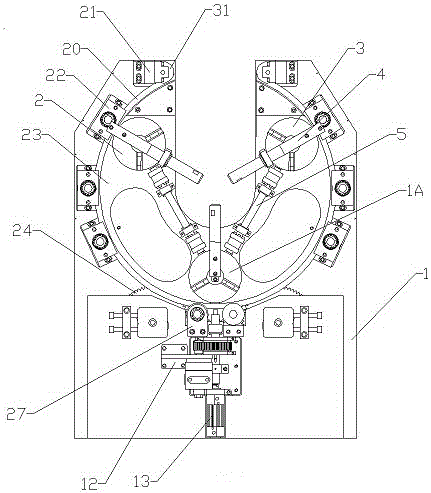

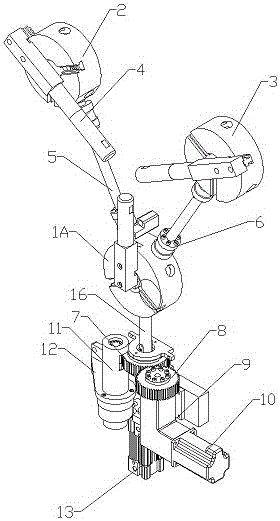

[0042] Examples such as figure 1 , figure 2 As shown, an open-type three-jaw self-centering revolving device includes a self-centering chuck part and a self-centering revolving part assembled together. The self-centering chuck part is used to clamp the workpiece and the self-centering revolving part Drive the workpiece for rotation processing.

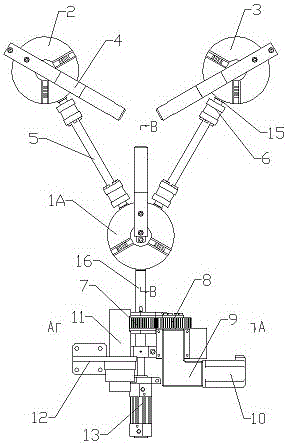

[0043] Such as image 3 As shown, the self-centering chuck part is composed of three centering chucks arranged in a triangle, and the three centering chucks are driven by the same power and synchronously linked to realize the self-centering function of the open self-centering chuck part.

[0044] The three centering chucks include a main chuck 1A, a sub-chuck 2, and a sub-chuck 3 evenly distributed on the same plane at 120 degrees; each chuck is provided with a clamping rod 4.

[0045] The clamping rod 4 and the claw 17 are connected by threads, and changing the clamping rod 4 of different lengths can realize the clamping of a wide range of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com