Composition and grinding wheel made of composition

A composition and grinding wheel technology, applied in the field of the composition and the produced grinding wheel, can solve the problems of long downtime for changing the grinding wheel, poor wear resistance of the grinding wheel, and high failure rate of the machine tool, so as to improve the service life, ensure continuous operation, improve the cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

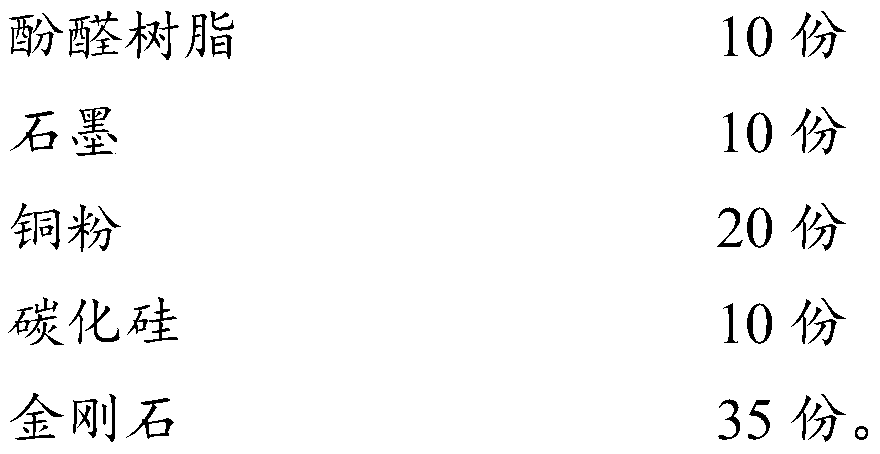

[0030] Components of the grinding wheel:

[0031]

[0032] The preparation method of emery wheel, comprises the steps:

[0033] Step 1: mixing the composition or the components of the abrasive layer for 40 minutes to prepare a mixed material;

[0034] Step 2: Take the mixed material prepared in step 1 and place it in the mold cavity, and press it at 180°C for 20 minutes to prepare the grinding wheel abrasive ring;

[0035] Step 3: take the aluminum base body of the grinding wheel and fix it with the grinding wheel abrasive ring prepared in step 2, reduce the diameter of the grinding wheel to 125mm, process according to size and shape, and pack.

Embodiment 2

[0037] Components of the grinding wheel:

[0038]

[0039] The preparation method of emery wheel, comprises the steps:

[0040] Step 1: mixing the composition or the components of the abrasive layer for 40 minutes to prepare a mixed material;

[0041] Step 2: Take the mixed material prepared in Step 1 and place it in the mold cavity, and press it at 170°C for 50 minutes to prepare the grinding wheel abrasive ring;

[0042] Step 3: take the aluminum base body of the grinding wheel and fix it with the grinding wheel abrasive ring prepared in step 2, reduce the diameter of the grinding wheel to 125mm, process according to size and shape, and pack.

Embodiment 3

[0044] Components of the grinding wheel:

[0045]

[0046] The preparation method of emery wheel, comprises the steps:

[0047] Step 1: mixing the composition or the components of the abrasive layer for 40 minutes to prepare a mixed material;

[0048] Step 2: Take the mixed material prepared in Step 1 and place it in the mold cavity, and press it at 175°C for 35 minutes to prepare the grinding wheel abrasive ring;

[0049] Step 3: take the aluminum base body of the grinding wheel and fix it with the grinding wheel abrasive ring prepared in step 2, reduce the diameter of the grinding wheel to 125mm, process according to size and shape, and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com