High-performance alloy steel solid-phase additive forming device and process based on induction heating compensation

A technology of additive forming and induction heating, which is applied in the direction of additive processing, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of frictional heat generation, high melting point of high-performance alloy steel, and large deformation resistance, etc., to achieve The effect of breaking through the bottleneck of overall high-performance forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The technical problem to be solved in this embodiment is: high-melting-point metal materials such as high-performance alloy steel, it is difficult to reach the required temperature in the process of solid-phase additive manufacturing. Based on this, this embodiment provides a high-performance alloy steel solid-phase additive forming device and process based on induction heating compensation. The method is to use the induction heating principle to realize rapid heating and softening of high-performance alloy steel and other metal materials, and combine The violent and large plastic deformation characteristics of friction stir are aimed at realizing the near-forged microstructure and performance of metal material parts such as high-performance alloy steel in solid-phase additive manufacturing, breaking through the overall high-performance manufacturing of high-performance alloy steel complex parts. technical bottleneck.

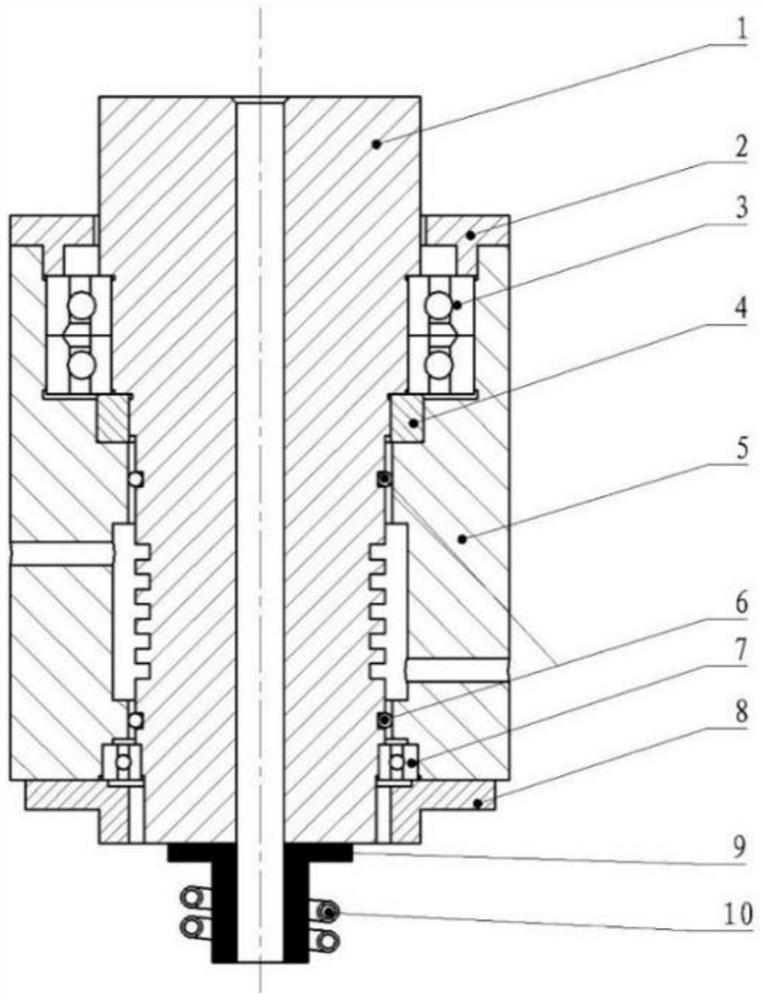

[0033]This embodiment is achieved through the foll...

Embodiment 2

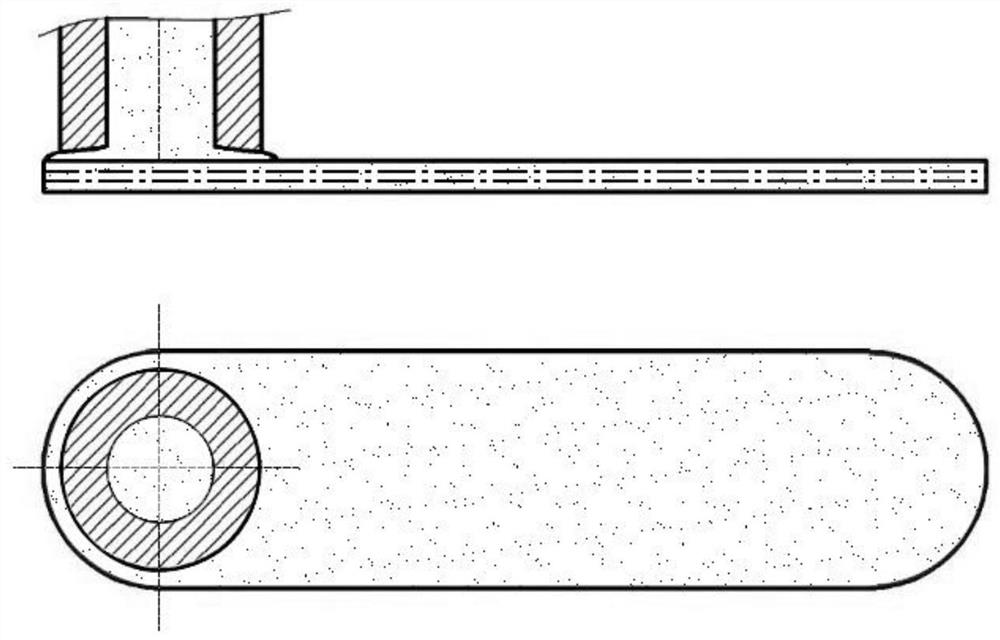

[0043] This embodiment provides a high-performance alloy steel solid-phase additive forming process, using the solid-phase additive forming device based on induction heating compensation in Embodiment 1, such as image 3 As shown, the following process steps are implemented:

[0044] ① Select 30CrMnSiA high-performance alloy steel powder with a particle size of about 150 μm as the additive raw material;

[0045] ② The lower end surface of the additive forming tool head 9 is in contact with the forming substrate to form a closed cavity, and the 30CrMnSiA high-performance alloy steel powder raw material is sent from the feeding channel to the additive forming tool head 9 under the action of the feeding pressure, and is placed in the additive forming tool head. 9 forms a high pressure inside; adjust the feeding pressure so that the internal pressure of the additive forming tool head 9 is not lower than 30MPa;

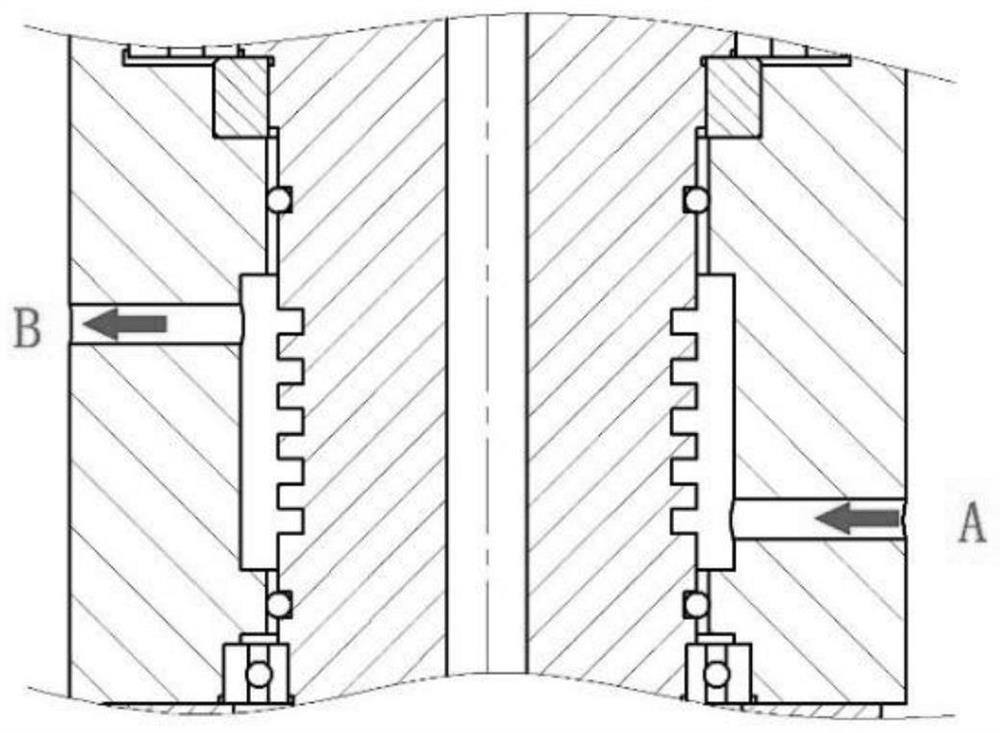

[0046] ③ The cooling fluid inlet A and outlet B are connected with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com