Automatic cable stripping and separating device and stripping and separating method

A technology for separating devices and cables, applied in cable installation devices, cable installation, equipment for dismantling/armored cables, etc., can solve the problems of cable stripping, inability to collect, unfavorable recycling and secondary utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0030] Wherein, the accompanying drawings are only for illustrative purposes, showing only schematic diagrams, rather than physical drawings, and should not be construed as limitations on this patent; in order to better illustrate the embodiments of the present invention, some parts of the accompanying drawings will be omitted, Enlarged or reduced, does not represent actual product size.

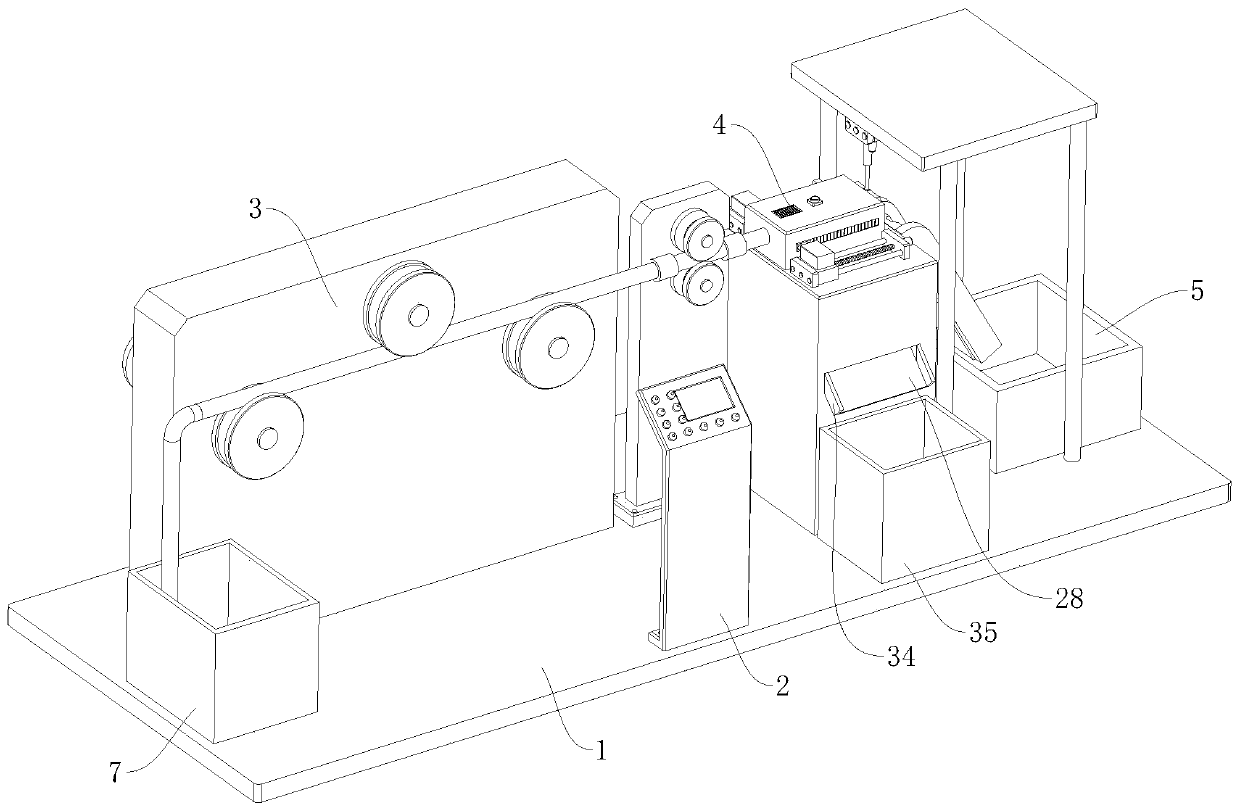

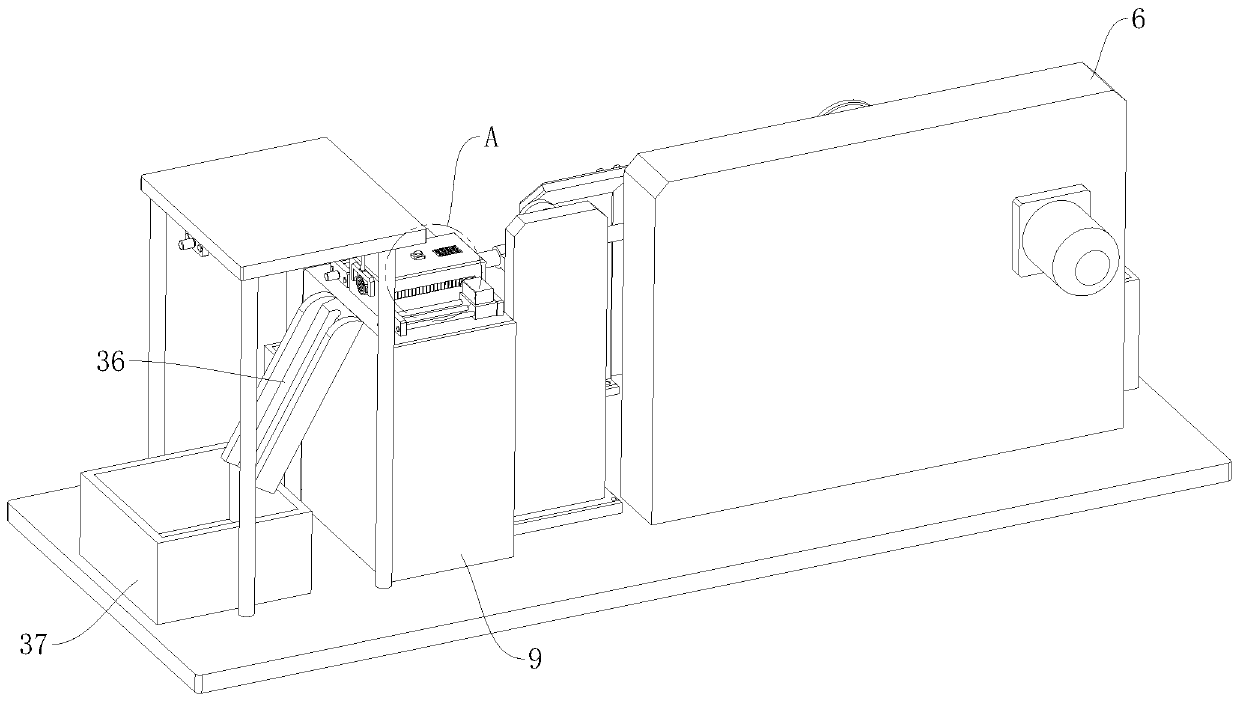

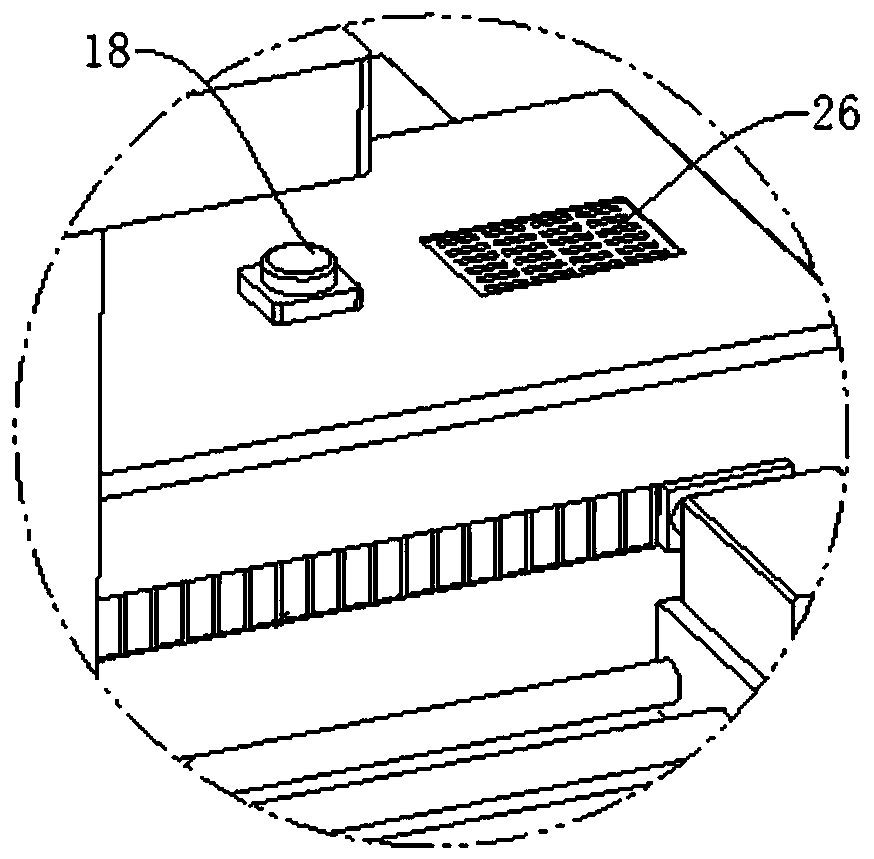

[0031] refer to Figure 1 to Figure 8 The shown automatic cable peeling and separating device includes a base 1 , a controller 2 , a continuous feeding mechanism 3 , a peeling mechanism 4 and a feeding mechanism 5 , and the controller 2 is fixed on the top of the base 1 .

[0032] The base 1 can usually be selected from a high-strength steel plate to firmly form a support and be fixed on a level ground.

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com