Preform for plastics material bottles or wide-necked vessels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

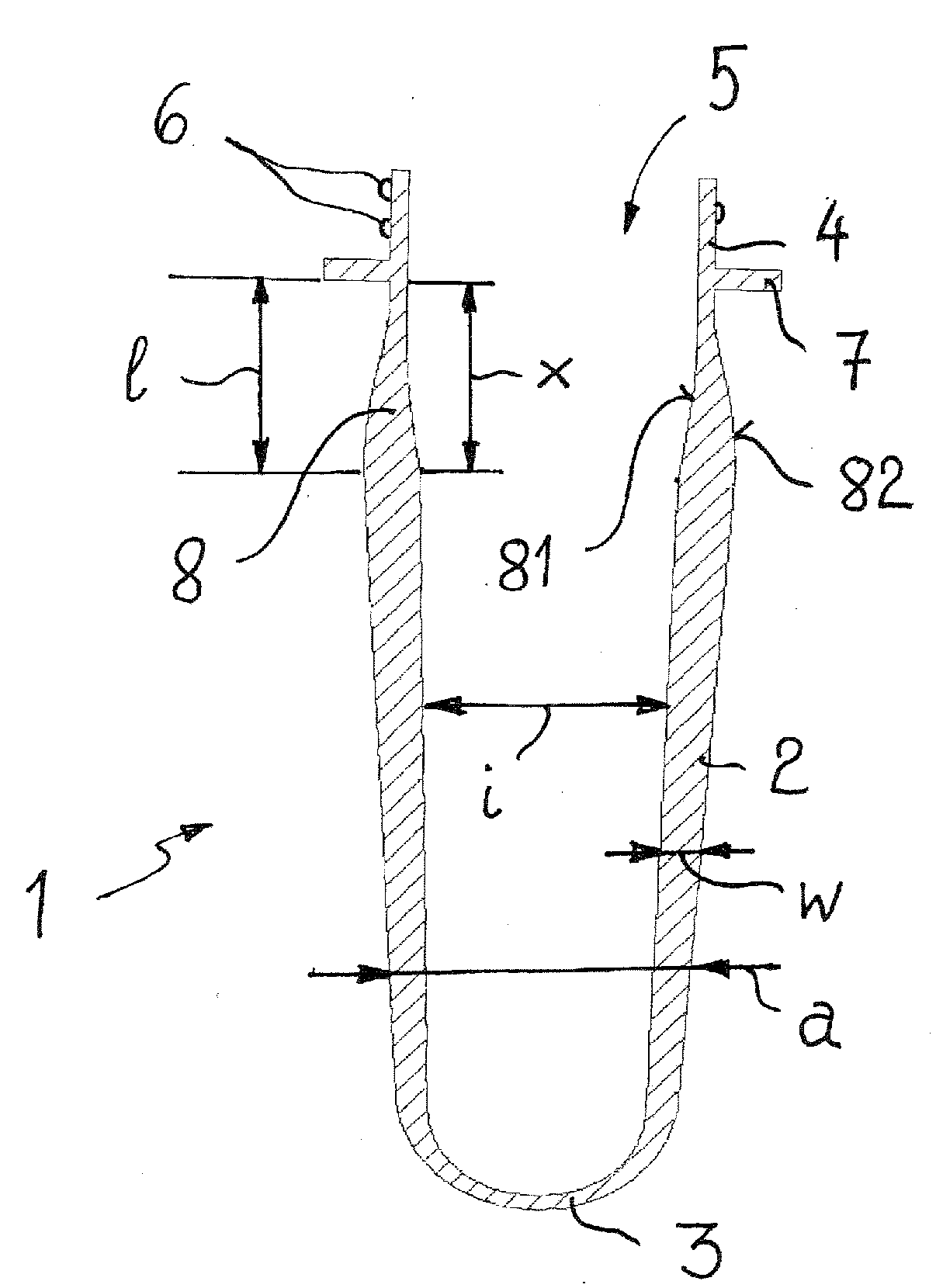

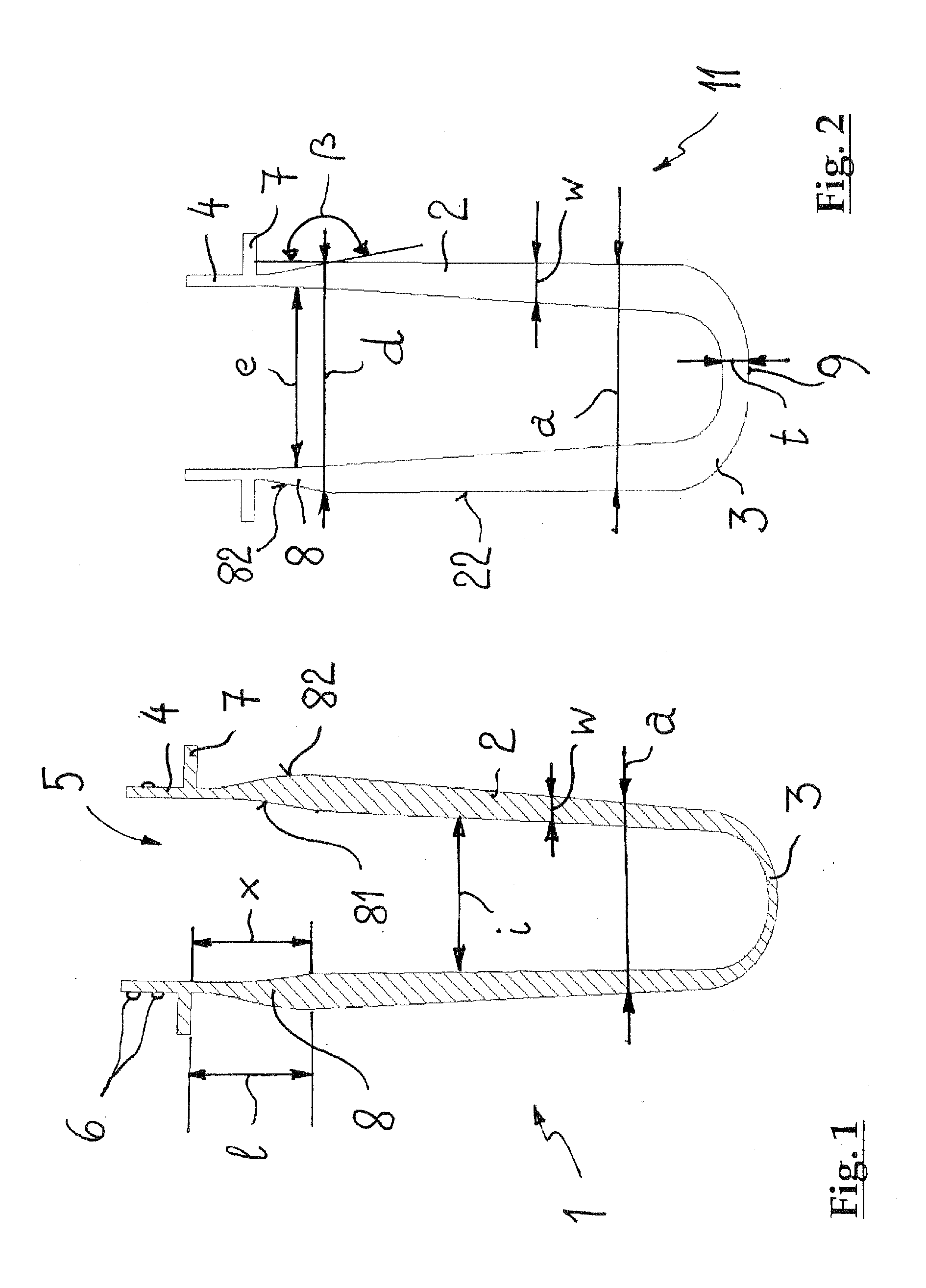

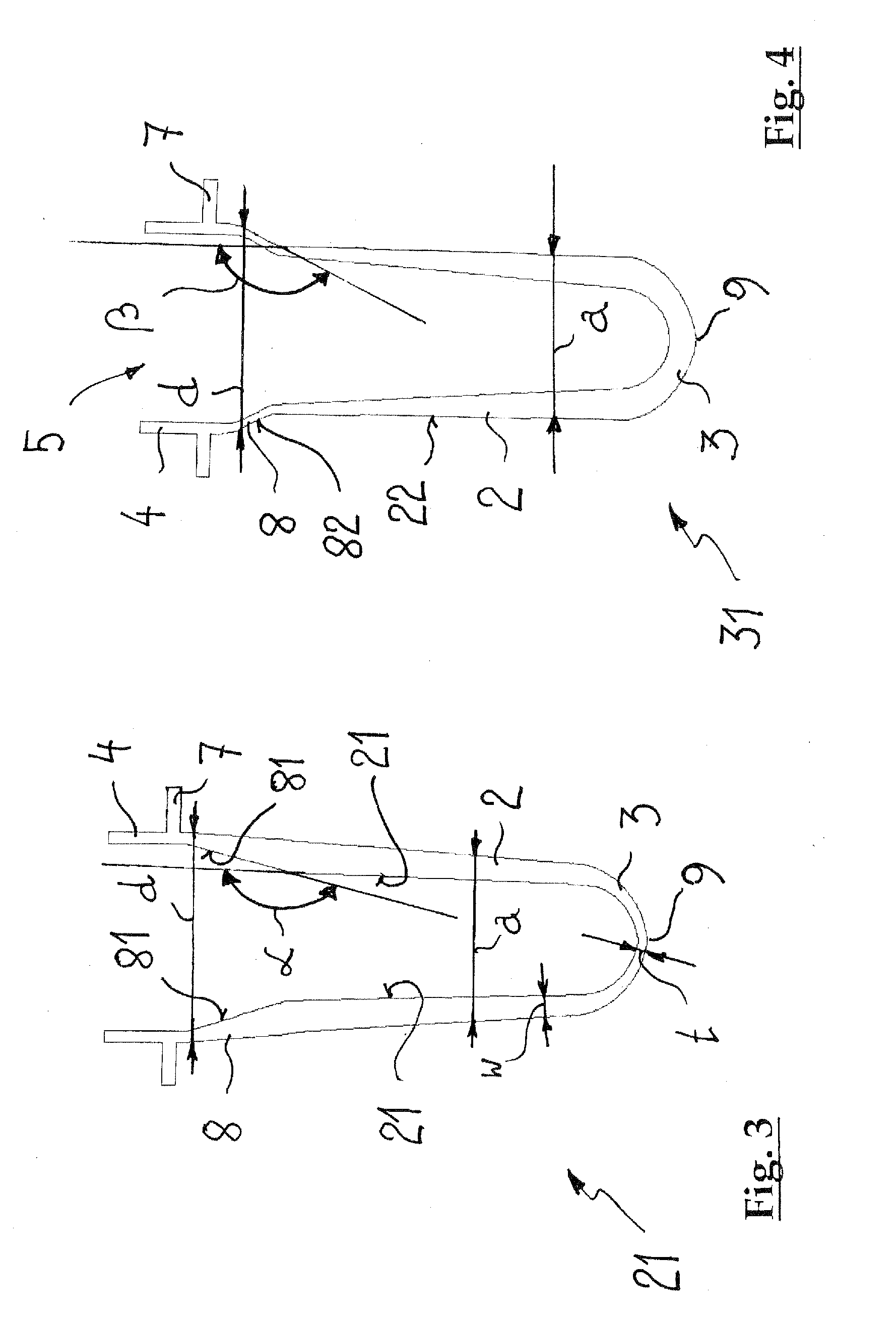

[0027]The preform illustrated in FIG. 1 is denoted in its entirety by reference numeral 1. It has a rigid, substantially elongate, frustoconically embodied body portion 2, one longitudinal end of which is closed by a dome-shaped end portion 3. The other longitudinal end of the body 2 is adjoined in the first place by what is known as a preform collar 8 which forms the transition of the body portion 2 to a neck portion 4 comprising a pouring opening 5. The neck portion 4 conventionally already displays the subsequent shape of the neck of the inflated plastics material bottle or a wide-necked vessel. Threaded portions 6 or the like are formed on the outside of the neck portion 4 for securing a closure part. The preform 1 is manufactured for example in an injection moulding method. Alternative manufacturing methods are for example extrusion or, with appropriate raw materials, spray foaming.

[0028]The preform collar 8 is separated from the neck portion 4 by an annularly encircling transp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com