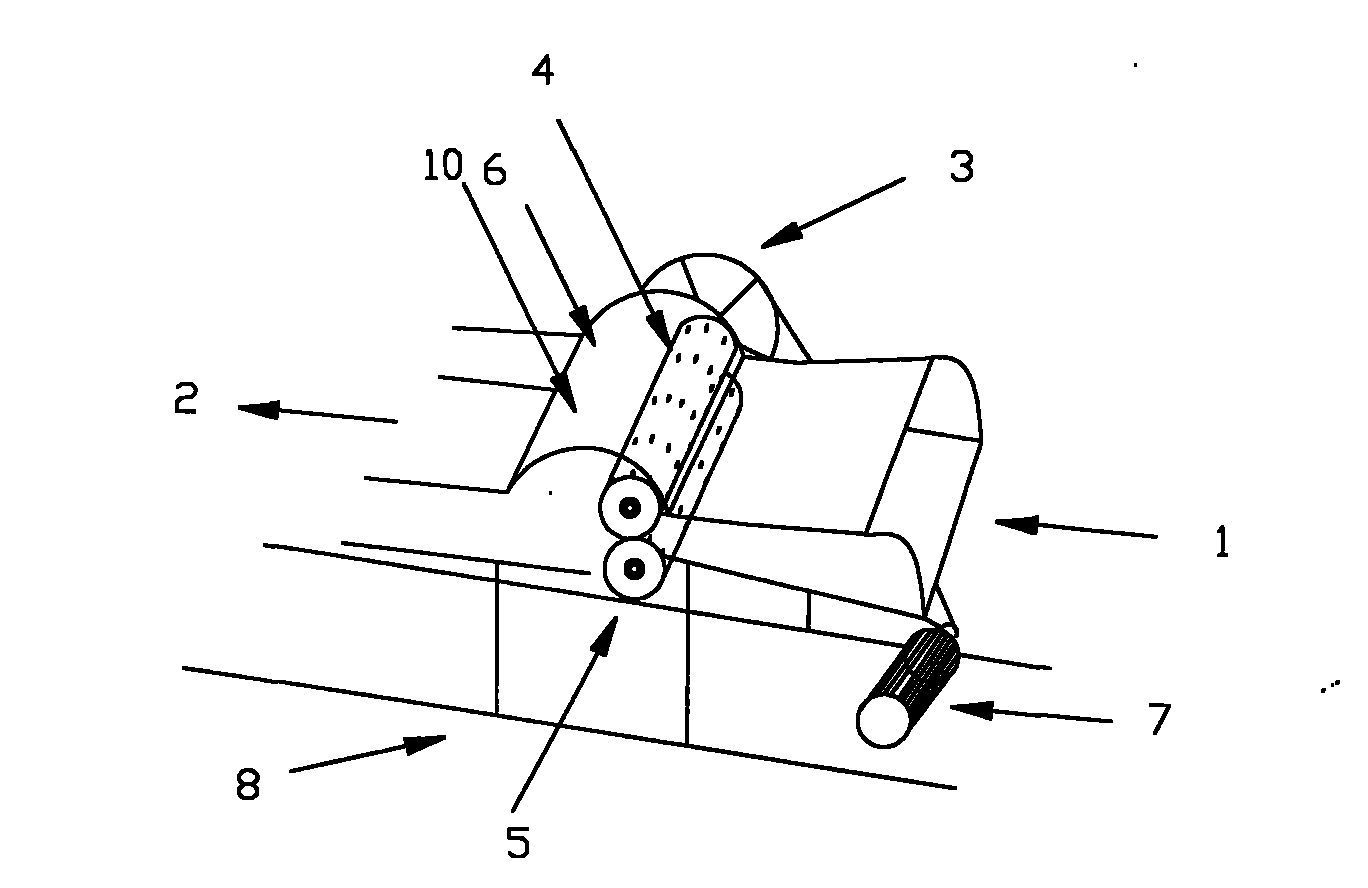

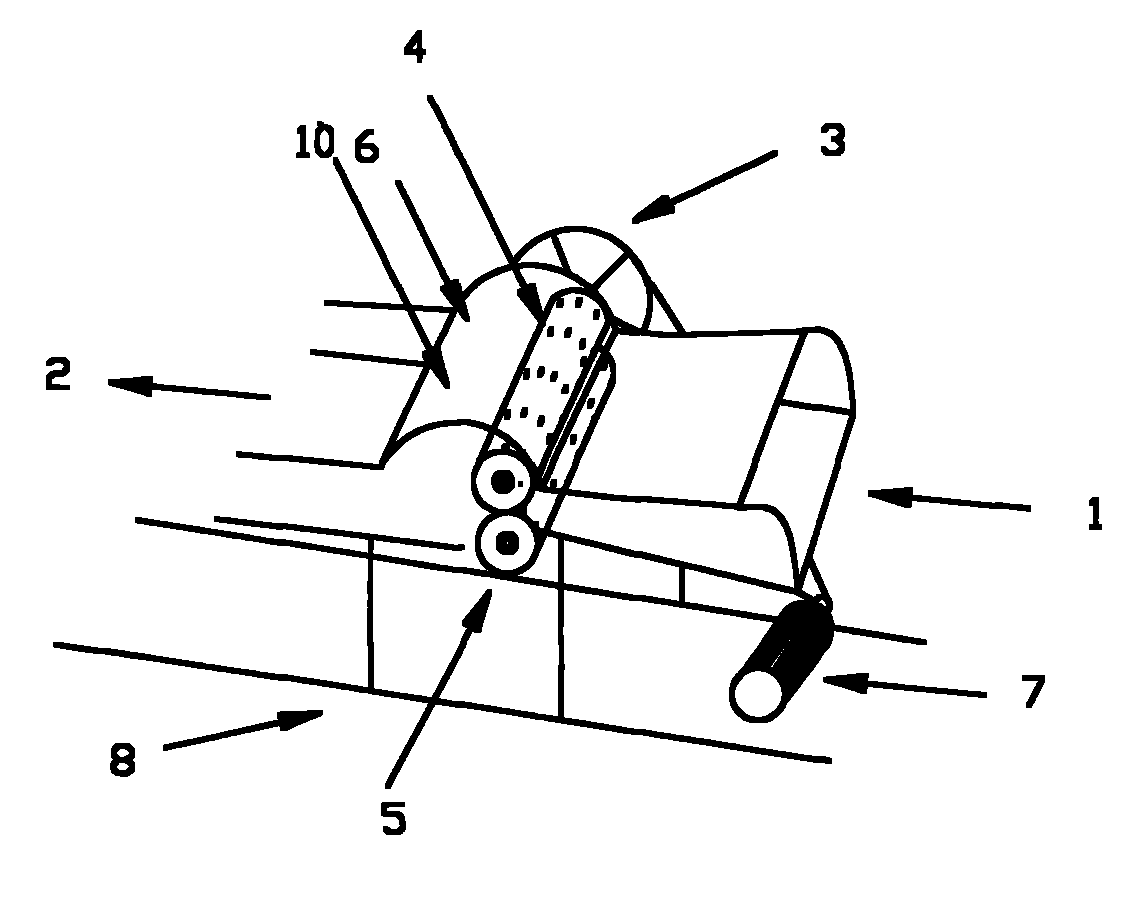

In-situ composting method and device of crop straws

A crop straw and composting technology, applied in the field of agricultural environmental protection research, can solve the difficult problems of vegetable straw, pathogenic bacteria killing and ammonia nitrogen volatilization loss, and achieve the effect of shortening the decomposing time, reducing nitrogen loss and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

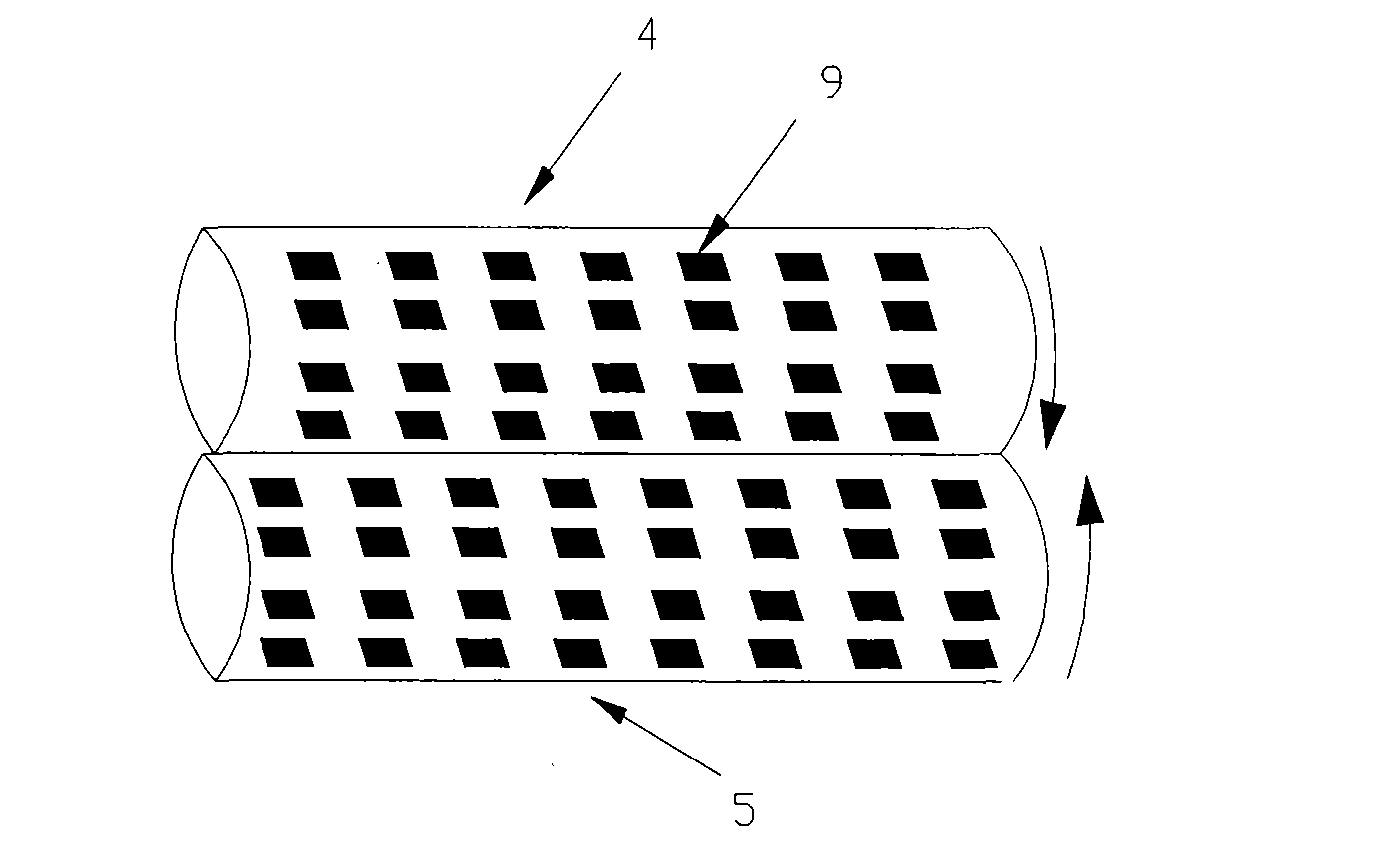

Method used

Image

Examples

Embodiment 1

[0036] A solar greenhouse with an area of about 600m 2 After the eggplants are harvested, collect the eggplant stalks and some non-commercial eggplants to one side of the solar greenhouse, let them cool for a day, so that the leaves of the plants are wilted, and grind them with the above-mentioned improved grinder. After grinding, the length of the straws is about 2- 10 cm, at this time, the water content is about 65%, and the fresh weight is about 3 tons. Add superphosphate, 5% magnesium sulfate and 0.1% straw decomposing bacteria agent (Nanjing Ningliang Bio Produced by Engineering Co., Ltd., Ningliang brand TPM decay accelerator), weighing 52.5, 52.5, and 1.0 kg respectively, mixed with straw, stacked into strips with a width of about 1.5 meters, a height of about 1.5 meters, and a length of about 4 meters. Cover the composted straw with grass covering the greenhouse to prevent the moisture from dispersing too quickly. On the second day of composting, the temperature rose...

Embodiment 2

[0038] A paddy field with an area of about 1200m 2 After the rice machine is harvested, the rice stalks are collected at one end of the paddy field, pulverized by the above-mentioned improved pulverizer, and rubbed with a straw kneading machine (the straw kneading machine SFSC720 produced by Jiangsu Zhengchang Group Co., Ltd.), The water content of the kneaded straw is about 55%, and the fresh weight is about 800 kg. Add urea according to 4% of the weight of the straw, and it is about 14.4 kg. The stacks with a length of about 2 meters are covered with plastic film. The temperature rises to 50°C on the second day after stacking. After that, the temperature has been maintained at about 65°C. After 10 days of stacking, the straw has basically softened and turned black. At the same time, scatter the composted rot evenly in the field, and basically turn the straw into the soil after rotary tillage with a rotary tiller, and sow wheat after the land preparation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com