Method for preparing metal-base lubricating film by low temperature ion plating

A lubricating film and metal-based technology, which is applied in the field of ion plating to prepare metal-based lubricating films, can solve the problems that the properties of lubricating films cannot meet the requirements, and achieve the effect of high bonding force and good lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

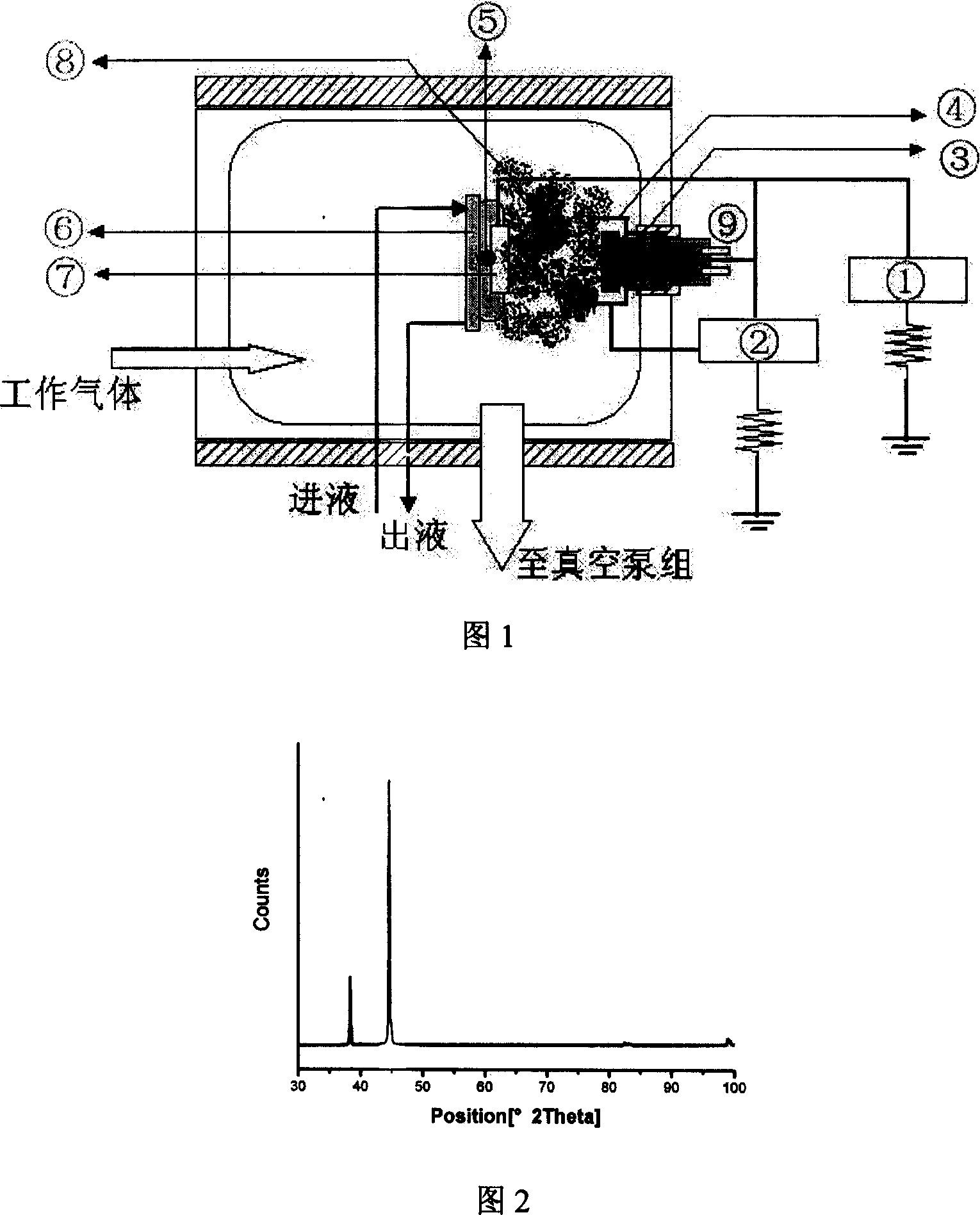

Embodiment 1

[0027] The metal Ag target (purity ≥ 99.9wt%) is processed into a cylinder with a diameter of 80mm and a height of 40mm, and installed on the target port of the ion coating machine; a 9Cr18 steel substrate with a diameter of 30mm and a thickness of 5mm is installed on the sample fixture. The target distance is 100 mm, and the angle between the normal of the substrate surface and the normal of the target surface is 15°. Install a platinum resistance Pt100 on the bonding surface of the substrate and the fixture, and communicate with the temperature detection host computer to detect the deposition temperature of the substrate. Turn on the vacuum pump group, the background vacuum reaches 5.9×10 -3 Above Pa. Introduce Ar gas to maintain the partial pressure of Ar gas at 1.8Pa-2.0Pa. Turn on the DC bias power supply, apply -1500V DC bias to the sample, Ar + Ion bombardment for 10 min. Liquid nitrogen was passed into the sample holder, and the temperature of the substrate was mon...

Embodiment 2

[0029] The target is replaced with a Cu target, and its installation and pretreatment process are the same as in Example 1. When the substrate temperature reaches -147°C, reduce the partial pressure of Ar gas to 8.0×10 -1 Pa, adjust the DC bias voltage to -200V, energize the target, adjust the target voltage to 20V, target current to 70A, start to deposit the film, and the deposition time is 6min. After the coating substrate returned to room temperature naturally, the coating substrate was taken out, and the results showed that the low-temperature ion-plated Cu film crystallized well. Electron microscope observation shows that the thin film has a compact structure and no obvious defects.

Embodiment 3

[0031] The target is replaced with an AgCu alloy target, and a single crystal silicon wafer is used as a substrate, and the installation and pretreatment process are the same as those in Example 1. When the substrate temperature reaches -85°C, reduce the partial pressure of Ar gas to 8.0×10 -1 Pa, adjust the DC bias voltage to 0V, energize the target, adjust the target voltage to 20V, target current to 80A, start to deposit the film, and the deposition time is 5min. Take it out after the coating substrate naturally returns to room temperature. The results showed that a good AgCu film was obtained on the single crystal silicon substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com