Hydraulic drive, particularly of a digger, particularly for a rotation system

The technology of a driving device and a slewing device is applied in the field of hydraulic drive devices especially for excavators, especially for slewing devices, and can solve problems such as waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

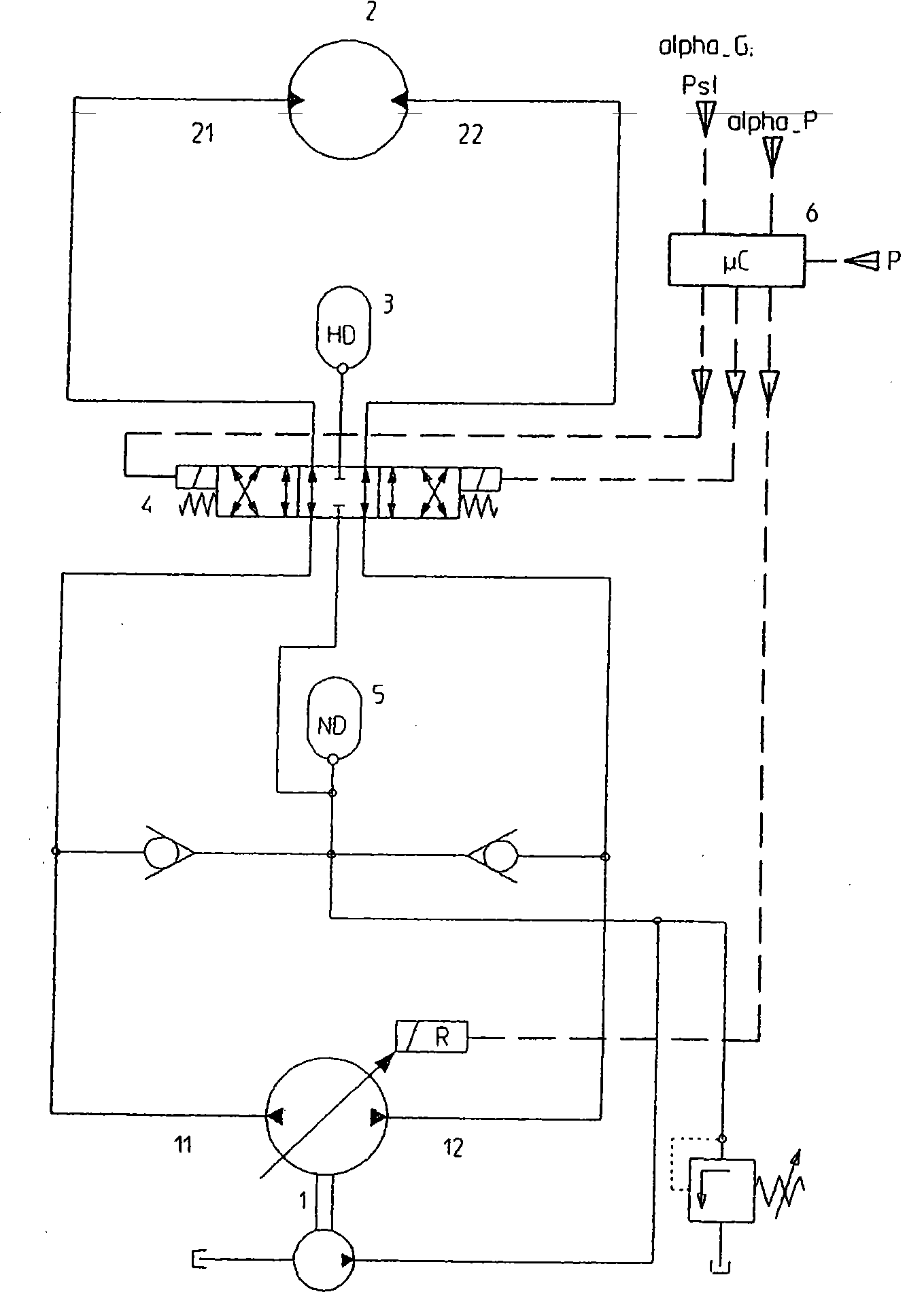

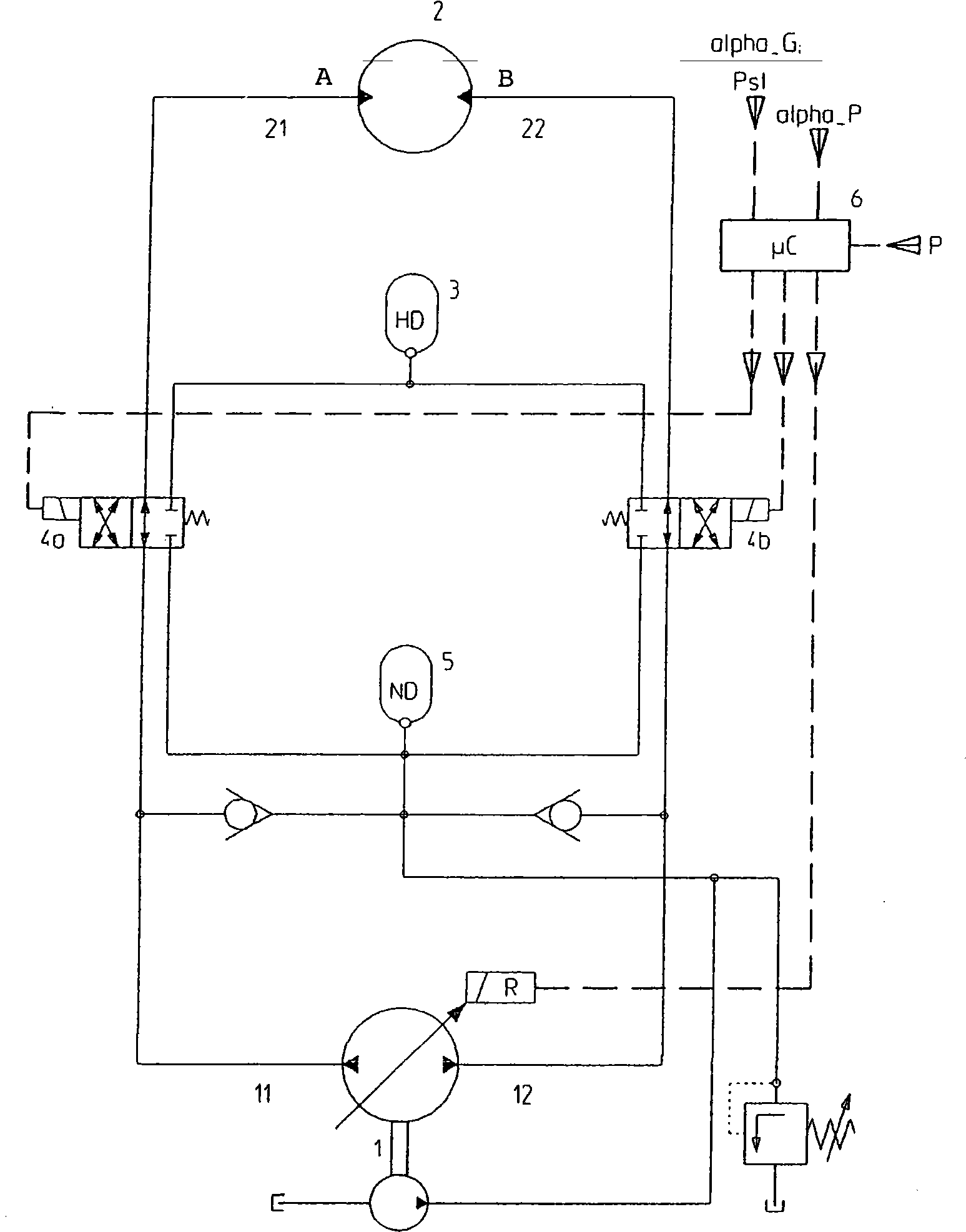

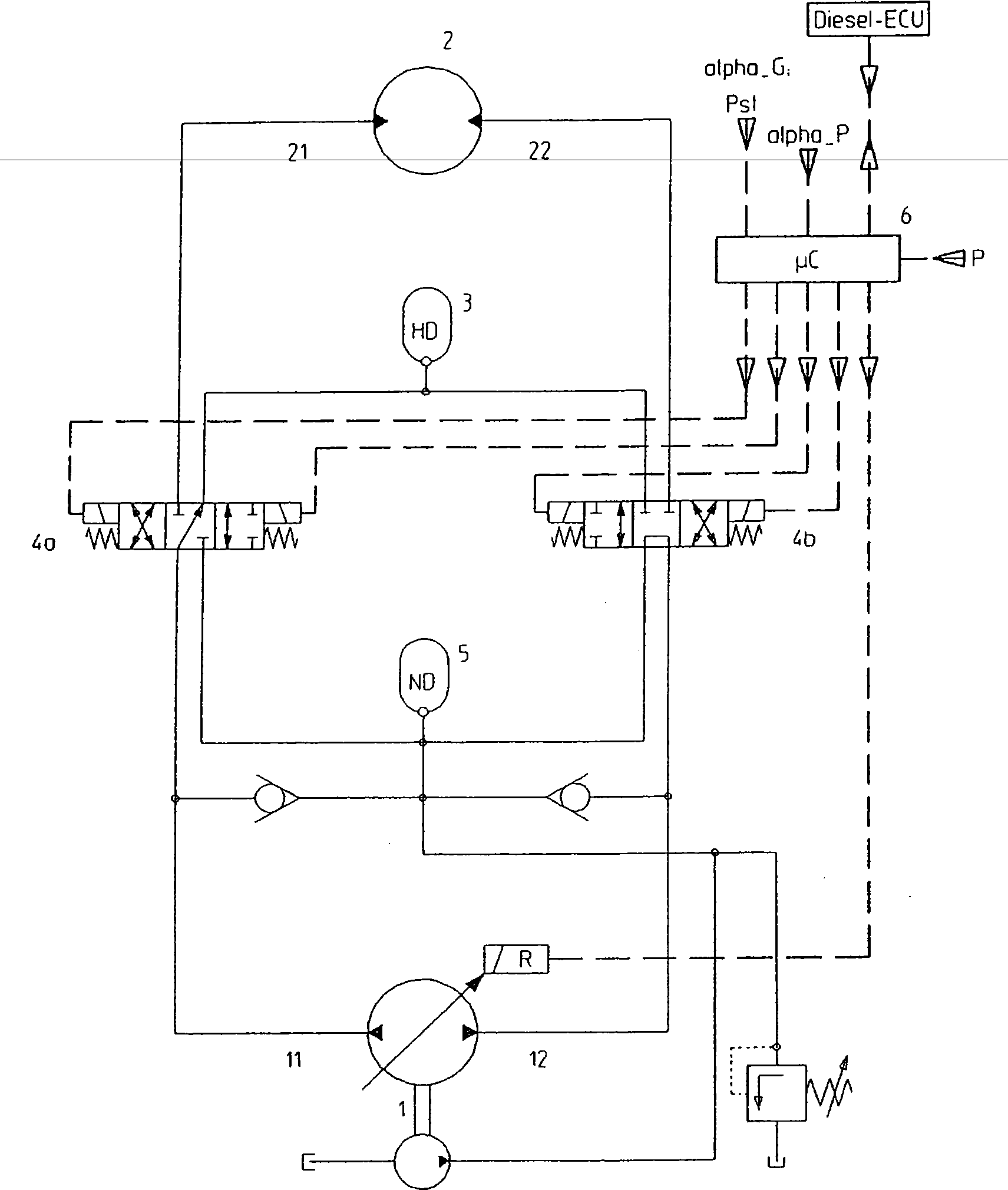

[0052] figure 1 The table shows a first embodiment of the hydraulic drive device according to the invention, in this embodiment, during the braking phase of the slewing device, in the first energy storage mode according to the invention, the energy from the braking can be stored in the high pressure In the accumulator 3, and when the slewing device is accelerated again, this energy can be given back to the drive device in the first recuperation mode, so that the diesel engine can be dimensioned correspondingly smaller.

[0053] The hydraulic drive according to the invention in the first embodiment now comprises a pump 1 and a motor 2 , here a variable axial piston pump and a constant displacement hydraulic motor, each of which has two delivery directions. The high-pressure accumulator 3 can communicate with the left side 11 of the pump 1 at the right side of the valve 4 through the valve 4 (here, a 6 / 3 valve, a three-position six-way valve), and communicate with the pump at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com