Manufacturing method of silicon carbide carrying disc for plasma etching and silicon carbide carrying disc

A manufacturing method and technology of silicon carbide, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high processing cost, long processing time, and poor understanding, so as to shorten processing time, improve processing efficiency, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

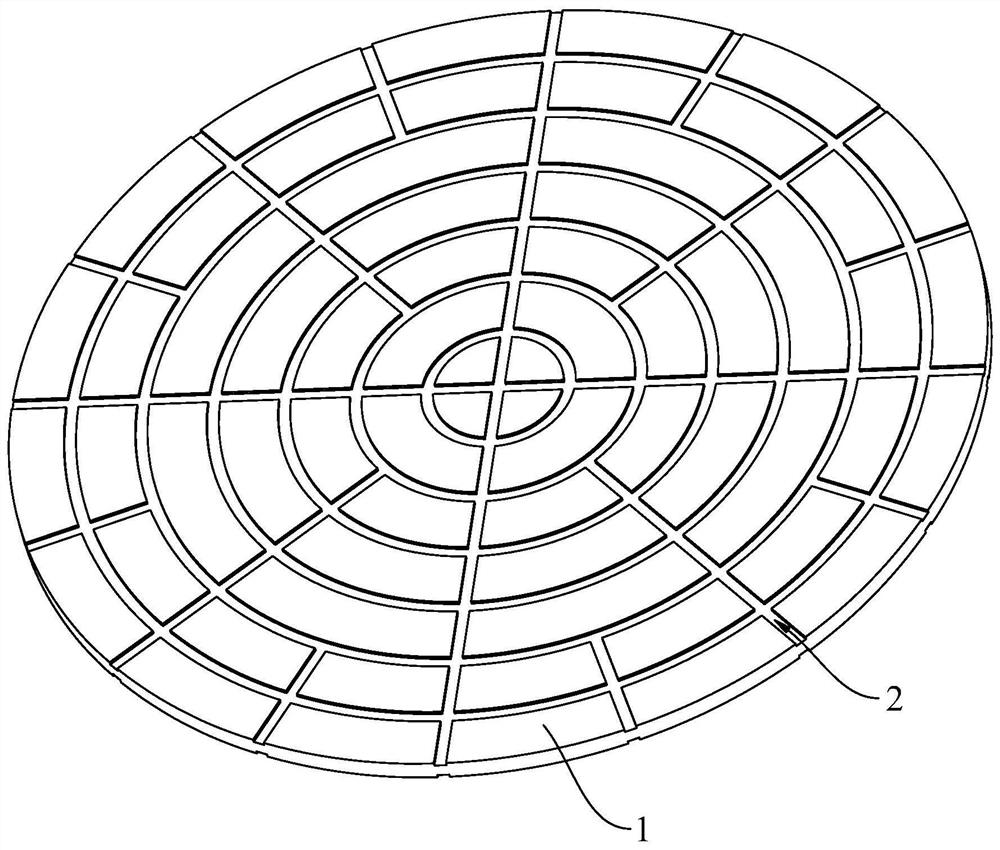

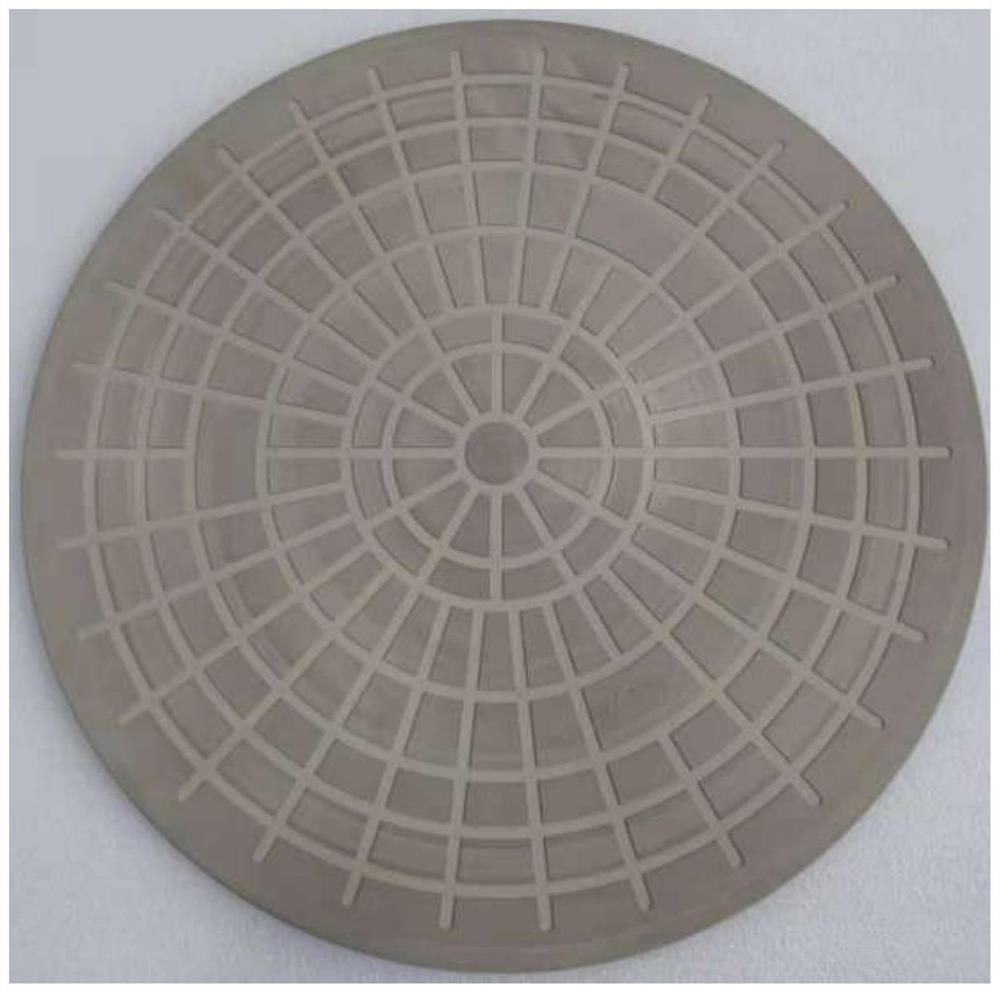

[0046] The parameters of the prepared silicon carbide carrier plate: diameter 380 mm, total thickness 4.4 mm, back groove depth 0.15 mm, back groove width 5 mm, front groove depth 1.2 mm, front groove diameter 101 mm.

[0047] The manufacturing method is as follows:

[0048] (1) Blank molding: Silicon carbide granulated powder in solid phase sintering system is used to form silicon carbide blanks that meet the size requirements through dry pressing and then isostatic pressing or direct isostatic pressing.

[0049] (2) Blank processing: According to the finished size of the plasma-etched carrier plate and the high-temperature sintering shrinkage rate, a certain sintering allowance is reserved for the outer circle, total thickness, and groove depth on the front and back sides, and the formed silicon carbide blank is processed in a machining center . After this step, the diameter of the silicon carbide blank is 464.8 mm, the total thickness is 5.8 mm, the depth of the back groov...

Embodiment 2

[0053] The parameters of the prepared silicon carbide carrier plate: diameter 380 mm, total thickness 4.4 mm, back groove depth 0.2 mm, back groove width 5 mm, front groove depth 1.2 mm, front groove diameter 102 mm.

[0054] The manufacturing method is as follows:

[0055] (1) Blank molding: Silicon carbide granulated powder in solid phase sintering system is used to form silicon carbide blanks that meet the size requirements through dry pressing and then isostatic pressing or direct isostatic pressing.

[0056] (2) Blank processing: According to the finished size of the plasma-etched carrier plate and the high-temperature sintering shrinkage rate, a certain sintering allowance is reserved for the outer circle, total thickness, and groove depth on the front and back sides, and the formed silicon carbide blank is processed in a machining center . After this step, the silicon carbide blank has a diameter of 463.8 mm, a total thickness of 5.8 mm, a reverse groove depth of 0.45 ...

Embodiment 3

[0060] The parameters of the prepared silicon carbide carrier plate: diameter 380 mm, total thickness 3.2 mm, reverse groove depth 0.15 mm, reverse groove width 5 mm, front groove depth 1 mm, front groove width 100.5 mm in diameter.

[0061] The manufacturing method is as follows:

[0062] (1) Blank molding: Silicon carbide granulated powder in solid phase sintering system is used to form silicon carbide blanks that meet the size requirements through dry pressing and then isostatic pressing or direct isostatic pressing.

[0063] (2) Blank processing: According to the finished size of the plasma-etched carrier plate and the high-temperature sintering shrinkage rate, a certain sintering allowance is reserved for the outer circle, total thickness, and groove depth on the front and back sides, and the formed silicon carbide blank is processed in a machining center . After this step, the silicon carbide blank has a diameter of 463.8 mm, a total thickness of 4.4 mm, a reverse groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com