Cavity clad layer of magnetism-based or aluminum-based filter and preparation method thereof

A technology of filters and magnesium substrates, applied in the field of magnetron sputtering, can solve the problems of easy oxidation and discoloration of the silver plating layer, and achieve the effects of improving anti-oxidation and discoloration, reducing costs, and being easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Based on the aluminum substrate and the front plate of the inner cavity of the magnesium substrate filter, the specific implementation steps are as follows:

[0038] 1) Pretreatment

[0039] Use 0.6Mpa pressure and 1200 mesh (11μm) corundum sand to clean the passivation layer on the surface of the filter, then clean it in absolute ethanol, and dry it with compressed air.

[0040] 2) deposition process

[0041] The deposition system is the UDP-850 magnetron sputtering system produced by the British Teer company. The size of the target is 725mm×175mm×10mm. The A, B, C and D targets are respectively equipped with Cr, Cu, Al and Ag targets. Vacuum up to 3.0×10 -5 torr (4×10 -3 Pa), the product is deposited, and the process parameters are as follows:

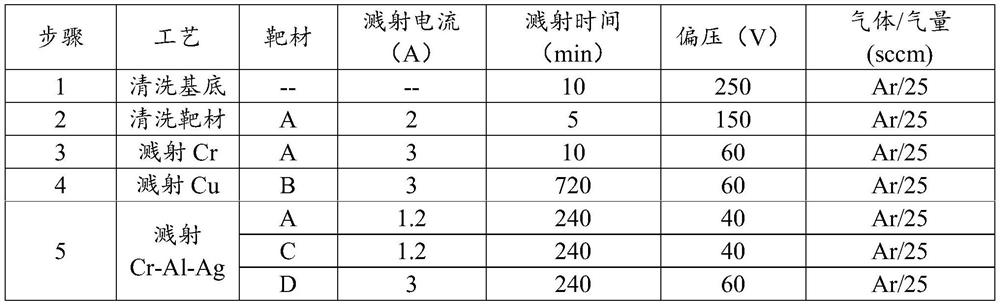

[0042] Table 1 Process parameters of magnetron sputtering on the front plate of the aluminum matrix filter cavity

[0043]

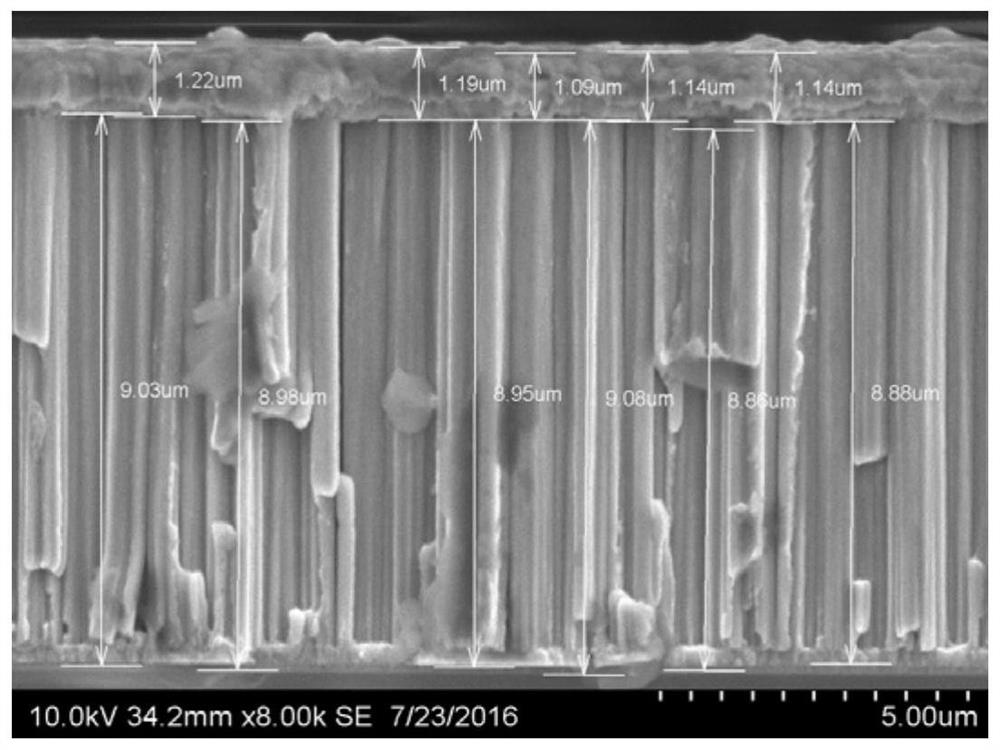

[0044]Utilize the scanning electron microscope to test the Cu bottom layer thickness and the ...

Embodiment 2

[0046] Based on the aluminum matrix filter, the specific implementation steps are as follows:

[0047] 1) Pretreatment

[0048] First carry out industrial alkali cleaning, pickling and deionized water ultrasonication on the filter product, then use 0.6Mpa pressure, 1200 mesh (11μm) corundum sand to clean the surface passivation layer, then clean it in absolute ethanol, and then use compressed air blow dry.

[0049] 2) deposition process

[0050] The deposition system uses the UDP-850 magnetron sputtering system produced by the British Teer company. The size of the target is 725mm×175mm×10mm. The A, B, C and D targets are respectively equipped with Cr, Cu, Al and Ag targets. Vacuum up to 3.0×10 -5 torr (4×10 -3 Pa), the product is deposited, and the process parameters are as follows:

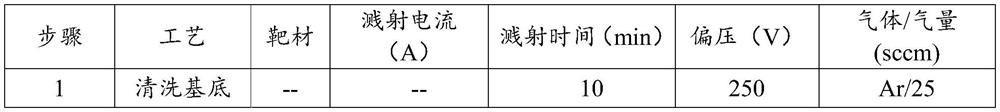

[0051] Table 2 Aluminum substrate filter magnetron sputtering process parameters

[0052]

[0053]

[0054] 3) According to the energy spectrum test and analysis, the molar ratio of C...

Embodiment 3

[0056] Based on the magnesium matrix filter, the specific implementation steps are as follows:

[0057] 1) Pretreatment

[0058] First carry out industrial alkali cleaning, pickling and deionized water ultrasonication on the filter product, then use 0.6Mpa pressure, 1200 mesh (11μm) corundum sand to clean the surface passivation layer, then clean it in absolute ethanol, and then use compressed air blow dry.

[0059] 2) deposition process

[0060] The deposition system uses the UDP-850 magnetron sputtering system produced by the British Teer company. The size of the target is 725mm×175mm×10mm. The A, B, C and D targets are respectively equipped with Cr, Cu, Al and Ag targets. Vacuum up to 3.0×10 -5 torr (4×10 -3 Pa), the product is deposited, and the process parameters are as follows:

[0061] Table 3 Magnetron sputtering process parameters of magnesium substrate filter

[0062]

[0063]

[0064] 3) According to the energy spectrum test and analysis, the molar ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com