Non-flash forging process for middle flanges of transmission shafts

A technology of flange-free flying and transmission shaft, which is applied in the direction of manufacturing tools, engine components, metal processing equipment, etc., can solve the problems of waste of raw materials, need for trimming process, and existence of forging flash, so as to reduce production costs and reduce processing Cost, reduce the effect of forging difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The flash-free forging process for the intermediate flange of the transmission shaft of the present invention comprises the following steps:

[0028] (1) Blanking: Use a fully automatic sawing machine or shearing machine to cut 45# steel into billets of specified size;

[0029] (2) Medium frequency induction heating: the heating temperature of the billet is controlled between 1100° and 1200°, and the temperature control is based on the infrared thermometer;

[0030] (3) Upsetting: remove the scale on the surface of the billet;

[0031] (4) Final forging: place the upset blank in the forging mold, strike the mold and master the striking force;

[0032] (5) Punching: Punch out the middle skin part of the final forging.

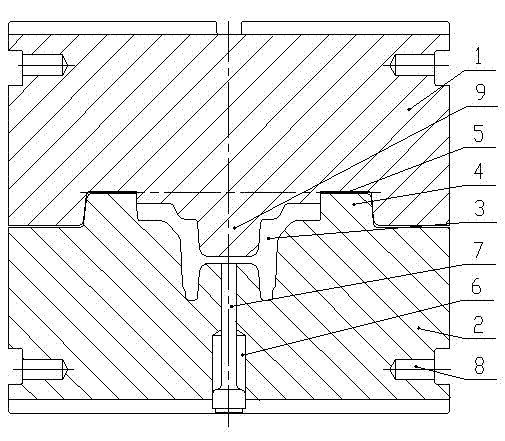

[0033] Such as figure 1 As shown, the forging mold includes an upper module 1 and a lower module 2, the lower module 2 is provided with a mold cavity 3, the top of the lower module 2 is provided with a boss 4, and the bottom of the upper module 1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com