Device and method for controlling welding deformation of girth of thin-walled cylinder through thermal field regulation and control

A thin-walled cylinder, circular seam welding technology, applied in welding equipment, laser welding equipment, manufacturing tools, etc., can solve the magnitude of residual stress reduction after welding. Fundamentally reduce the structural residual stress after welding, welding structural deformation and other problems, to achieve the effect of easy post-weld deformation control, small welding deformation trend, and small heat affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

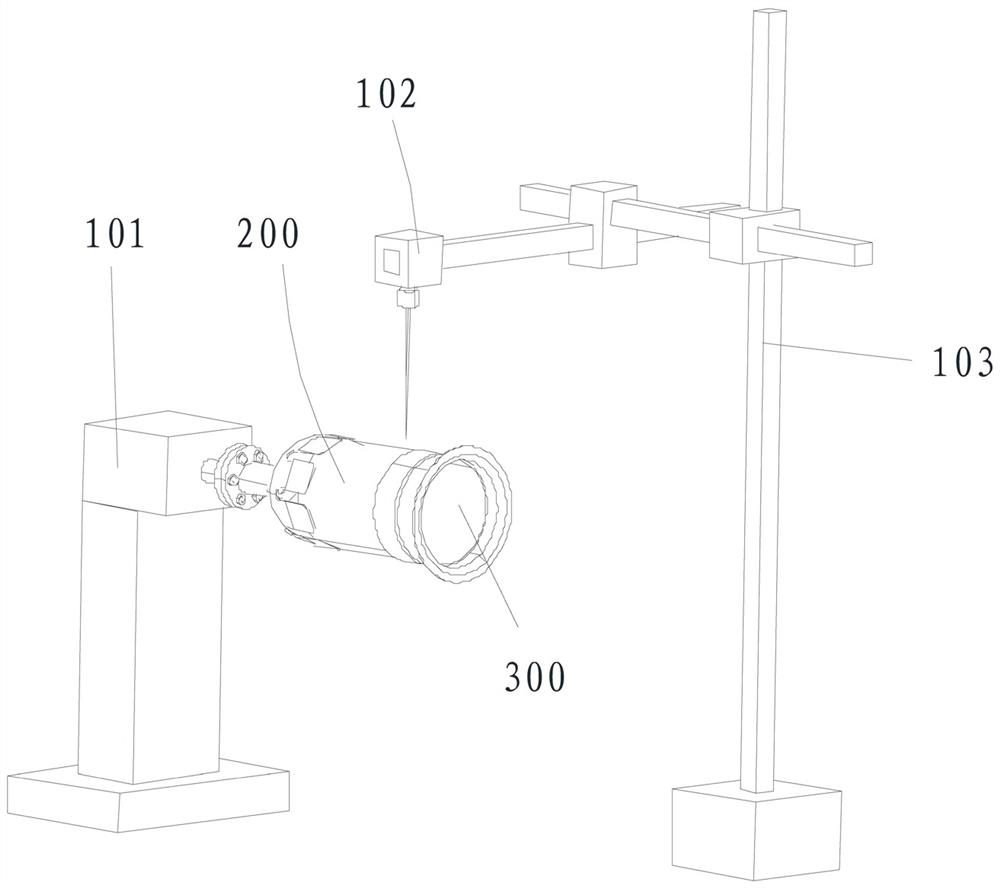

[0156] In this embodiment, a device 300 for regulating and controlling the welding deformation of thin-walled cylindrical girth seam is provided, such as Figure 8 to Figure 10 shown, including:

[0157] A support part 301, the support part 301 is circular, and the outer diameter of the support part 301 matches the inner diameter of the inner cylinder of the thin-walled cylinder 200 to be welded; the inner side of the support part 301 is provided with several parallel annular rings Grooves 302, each groove 302 contains a resistance wire 303, and an annular laser absorption groove 304 is arranged on the outer side of the support part 301 along the circumferential direction, for absorbing the laser beam during the circumferential seam welding of the thin-walled cylinder 200;

[0158] Two annular lock sleeves 305 are respectively inserted into the inner side of the support portion 301 from both end surfaces of the support portion 301, cooperate with the inner surface of the suppo...

Embodiment 2

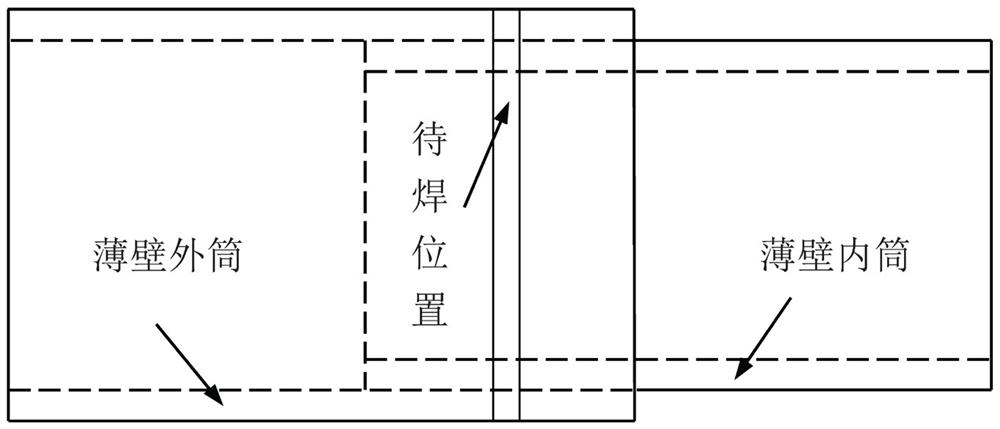

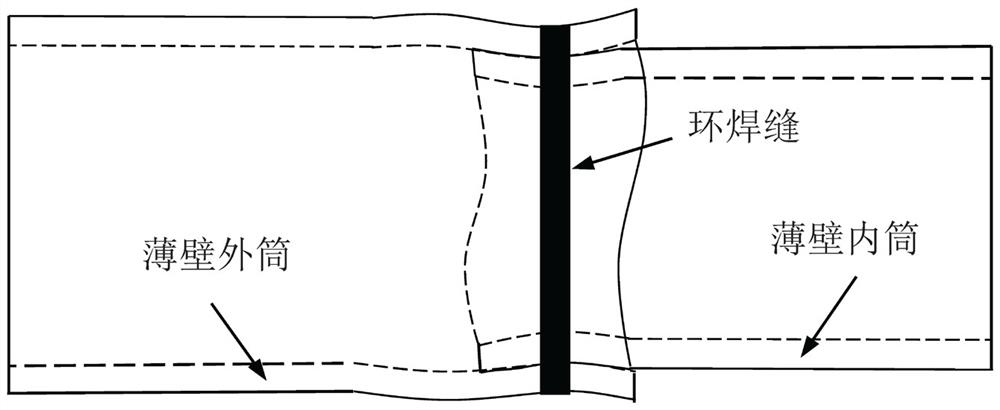

[0164] This embodiment provides a method for regulating and controlling the welding deformation of a thin-walled cylindrical girth seam by thermal field regulation, and it is necessary to provide the device described in Embodiment 1, including:

[0165] Before welding, a device 300 is placed on the inner wall of the thin-walled cylinder 200 to be welded, and after the resistance wire 303 embedded in the device 300 is energized, the support part 301 and the annular locking sleeve 305 absorb the resistance wire 303 The transferred heat simultaneously generates outward and inward expansion, and the expanded device 300 deforms the structure of the thin-walled cylinder 200 in the circumferential direction, thereby forming a certain amount of pre-circular tensile stress inside the cylinder structure before welding As welding auxiliary stress, the pre-circular tensile stress is coupled and superposed with the dynamic stress during welding, so that the welding residual stress of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com