Laser-electric resistance seam welding in-phase compound welding method of frame-covering structure

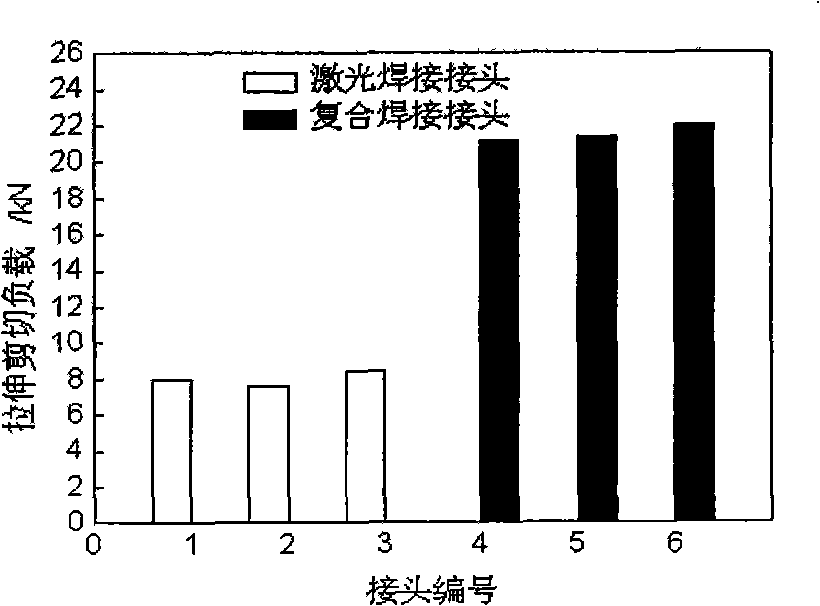

A skeleton structure, resistance seam welding technology, applied in laser welding equipment, roller electrode welding, welding equipment, etc., can solve the problems of narrow weld seam and low shear strength of weld seam, improve weld seam structure, improve static load and fatigue resistance, and improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

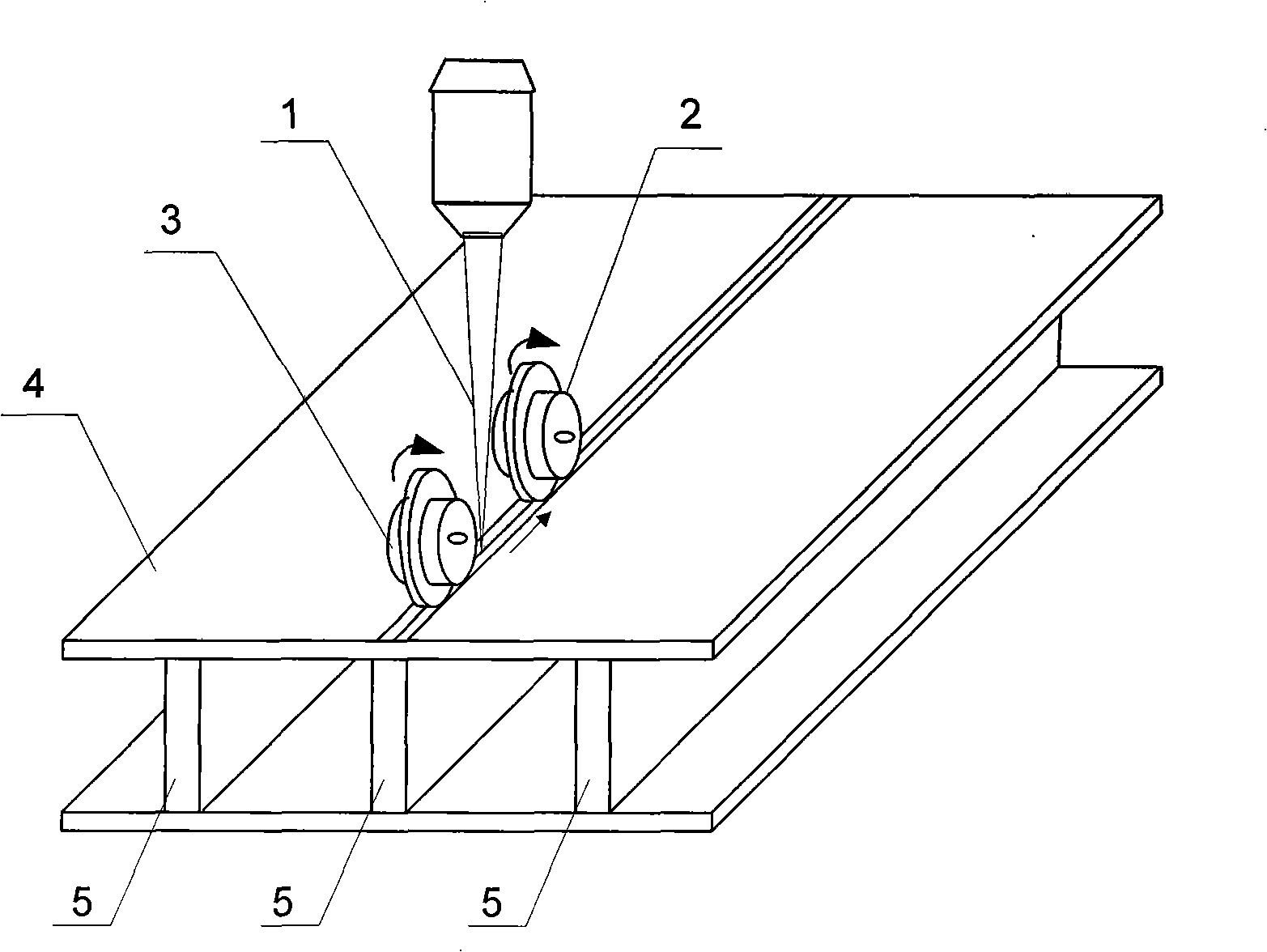

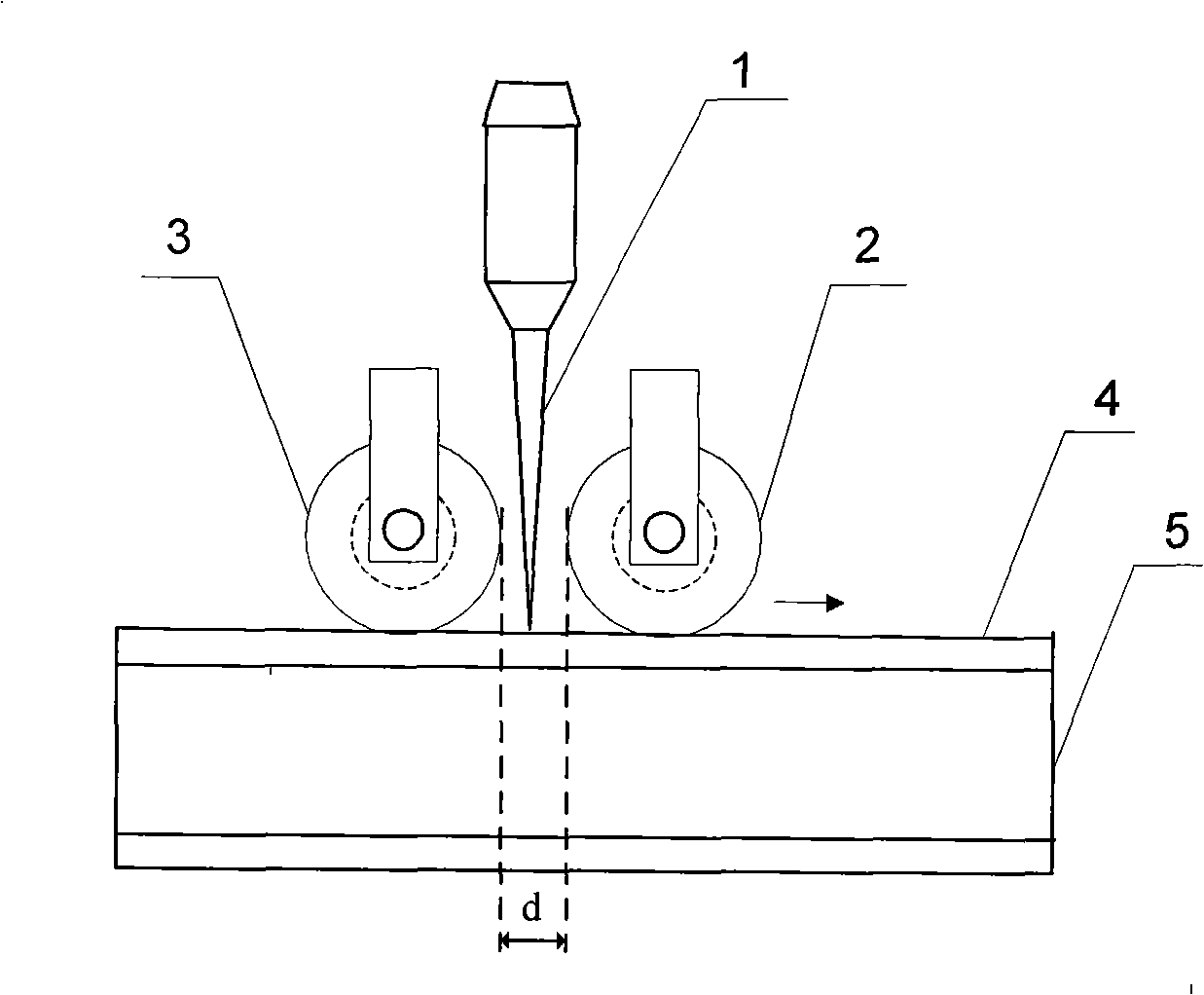

[0014] Specific implementation mode one: the following combination figure 1 , figure 2 , Figure 6-Figure 9 This embodiment is described. In this embodiment, laser welding and resistance seam welding are used for synchronous composite welding of the workpiece to be welded with a skin skeleton structure; The weld seam formed at the contact between the skin 4 and the skeleton 5 is arranged front and back on the upper top face of the skin 4, and while moving forward, presses the skin 4 to the skeleton 5 below it, during the welding process , the laser beam 1 is always located in the middle of the first roller electrode 2 and the second roller electrode 3 .

[0015] During welding, the skin 4 and the skeleton 5 are closely attached by the synchronous pressurization of the first roller electrode 2 and the second roller electrode 3, and the forward movement of the workbench fixing the skin 4 and the skeleton 5 can further Drive the rotation of the first roller electrode 2 and th...

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the type of laser beam 1 is CO 2 Gas laser beam, YAG solid-state laser beam, semiconductor laser beam or fiber laser beam, and others are the same as the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the resistance seam welding current is direct current, alternating current or pulse current, and the others are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com