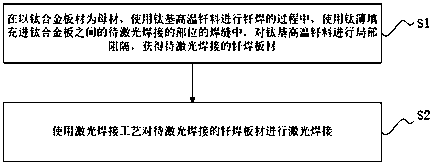

Laser welding method for titanium alloy sandwiched brazed plates

A laser welding and titanium alloy technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of poor fatigue performance of the overall structure, affecting the integrity of the overall structure, etc., to achieve laser welding process optimization, weld seam Well-organized, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

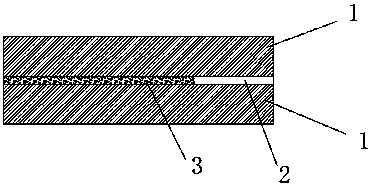

[0042] In the first step, 1.0mm thick TC4 titanium alloy plate 1 is used as the upper and lower skin brazing base materials, and titanium-based high-temperature solder 3 is selected as the connecting solder between the double-layer plates, preferably Ti-15Cu-25Ni . Cut the TC1 titanium alloy strip 2 with a thickness of 0.05mm into a long strip with a width of 5mm, and set it at the welding seam position, such as image 3 shown. After the setting is completed, it is heated in a vacuum furnace to melt the solder, and the upper and lower layers of base metal are connected together to form a double-layer brazing sheet.

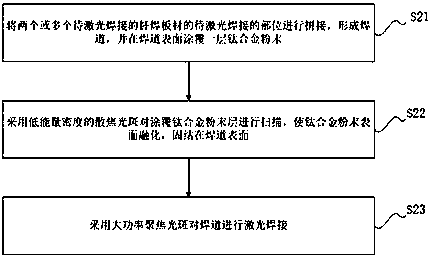

[0043] In the second step, after two or more double-layer brazing sheets are formed, when they are spliced into a whole by laser welding, firstly, a layer of titanium alloy powder 5 with a composition of TC4 is coated on the surface of the welding bead, and the powder composition is TC4 titanium alloy powder, BaF 2 , NaF 2 Mix according to the mass ratio of ...

Embodiment 2

[0045] In the first step, 1.0mm thick TC4 titanium alloy plate 1 is used as the upper and lower skin brazing base materials, and titanium-based high-temperature solder 3 is selected as the connecting solder between the double-layer plates, preferably Ti-15Cu-25Ni . Cut the TC1 titanium alloy strip 2 with a thickness of 0.05mm into a long strip with a width of 5mm, and set it at the welding seam position, such as image 3 shown. After the setting is completed, it is heated in a vacuum furnace to melt the solder, and the upper and lower layers of base metal are connected together to form a double-layer brazing sheet.

[0046] In the second step, after two or more double-layer brazing sheets are formed, when they are spliced into a whole by laser welding, firstly, a layer of titanium alloy powder 5 with a composition of TC4 is coated on the surface of the welding bead, and the powder composition is TC4 titanium alloy powder, BaF 2 , NaF 2 Mix according to the mass ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com